Documente Academic

Documente Profesional

Documente Cultură

A Solar Cell

Încărcat de

Praba Karan DDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A Solar Cell

Încărcat de

Praba Karan DDrepturi de autor:

Formate disponibile

A solar cell (also called photovoltaic cell or photoelectric cell) is a solid state electrical device that converts the

energy of light directly into electricity by the photovoltaic effect. Assemblies of cells used to make solar modules which are used to capture energy from sunlight, are known as solar panels. The energy generated from these solar modules, referred to as solar power, is an example of solar energy.

Working Principle Photovoltaics is the field of technology and research related to the practical application of photovoltaic cells in producing electricity from light, though it is often used specifically to refer to the generation of electricity from sunlight. Cells are described as photovoltaic cells when the light source is not necessarily sunlight. These are used for detecting light or other electromagnetic radiation near the visible range, for example infrared detectors, or measurement of light intensity.

The solar cell works in three steps: 1. Photons in sunlight hit the solar panel and are absorbed by semiconducting materials, such as silicon. 2. Electrons (negatively charged) are knocked loose from their atoms, allowing them to flow through the material to produce electricity. Due to the special composition of solar cells, the electrons are only allowed to move in a single direction. 3. An array of solar cells converts solar energy into a usable amount of direct current (DC) electricity.

Solar Cell construction

Silicon-based PV semiconductor solar cells have been used to demonstrate the most practical and reliable application of the photovoltaic effect. A simple, rugged semiconductor junction can be produced from single-crystal silicon. Low resistance contacts are added to tap the electrical energy produced when the cell is exposed to sunlight. Approximately a DC voltage of 0.45 volts is generated across each cell regardless of the dimensions for this particular cell architecture. The DC current and thus the power available are strictly dependent on the cell area exposed to the sun and the absorption capability of the silicon wafer, which is located between the two contacts, as illustrated in Figure. It is important to mention that the higher the absorption capability of the semiconductor material, the higher the PV voltage will be across the cell terminals. Higher voltage is possible by connecting the cells in series, while higher output power is possible by connecting the cells in parallel. Solar cells can be installed on glass-filled polyester substrate. The net cell output is the product of solar intensity (I = 100 mW/cm2) and the conversion efficiency of the device, which is typically now about 16 percent for a silicon cell. A solar module may contain several cells connected in series and parallel

Types of solar cells

The four general types of silicon photovoltaic cells are:

1. 2. 3. 4.

Single-crystal silicon. Polycrystal silicon (also known as multicrystal silicon). Ribbon silicon. Amorphous silicon (abbreviated as "aSi," also known as thin film silicon).

Single-crystal silicon cell Most photovoltaic cells are single-crystal types. To make them, silicon is purified, melted, and crystallized into ingots. The ingots are sliced into thin wafers to make individual cells. The cells have a uniform color, usually blue or black. The majority of PV cells produced today use crystalline silicon (c-Si) as it is a light absorbing semiconductor. The c-Si technology was originally developed for the semiconductor industry to produce PV cells for integrated circuits and microchips. These PV cells have energy conversion efficiencies between 11 percent and 16 percent. The energy conversion efficiency of a solar cell is the percentage of incident sunlight converted into electricity. While the efficiency of c-Si is high, it absorbs light poorly and requires many layers to perform efficiently in solar applications. Polycrystal silicon cell Polycrystalline silicon, also called polysilicon, is a material consisting of small silicon crystals.This is relatively a fast and low cost process to manufacture thick crystalline cells. Instead of drawing single crystals using seeds, the molten silicon is cast into ingots. In the process, it forms multiple crystals. The conversion efficiency is lower, but the cost is much lower, giving a net reduction in cost per watt of power. Amorphous silicon or thin film silicon cell They are known as thin-film because they are deposited in very thin layers on stainless steel, glass or a flexible substrate. The thickness of the film is less than 1 micron. Like c-Si, thin-film PV cells are combined into modules and laminated to protect them from the elements. They are less expensive than c-Si cells, but their demonstrated energy conversion efficiency is only around 8%. The advantage of thin-film technology is that it can be applied over large areas, providing more opportunity to generate electricity in cloudy conditions.

Ribbon silicon cell Ribbon-type photovoltaic cells are made by growing a ribbon from the molten silicon instead of an ingot. These cells operate the same as single and polycrystal cells. The anti-reflective coating used on most ribbon silicon cells gives them a prismatic rainbow appearance

Advantages of the photovoltaic power

No fuel requirements Modular design High Reliability of PV modules Easy to maintain - Operation and routine maintenance requirements are simple. Long life - With no moving parts and all delicate surfaces protected, modules can be expected to provide power for 15 years or more. 6. National economic benefits - Reliance on imported fuels such as coal and oil is reduced. 7. Environmentally benign - There is no pollution through the use of a PV system - nor is there any heat or noise generated which could cause local discomfort. PV systems bring great improvements in the domestic environment when they replace other forms of lighting kerosene lamps, for example.

1. 2. 3. 4. 5.

Solar cell Applications Rural electrification

1. 2. 3. 4. 5.

lighting and power supplies for remote building (mosques, churches, temples etc farms, schools, mountain refuge huts) - low wattage fluorescent lighting is recommended power supplies for remote villages street lighting individual house systems mini grids

Water pumping and treatment systems

1. 2. 3. 4. 5. 6.

pumping for drinking water pumping for irrigation dewatering and drainage ice production saltwater desalination systems water purification

Health care systems

1. 2. 3. 4. 5. 6.

lighting in rural clinics UHF transceivers between health centres vaccine refrigeration ice pack freezing for vaccine carriers sterilises blood storage refrigerators

Communications

1. 2. 3. 4. 5. 6.

radio repeaters remote TV and radio receivers remote weather measuring mobile radios rural telephone kiosks data acquisition and transmission (for example, river levels and seismographs)

Transport aids

1. 2. 3. 4. 5.

road sign lighting railway crossings and signals hazard and warning lights navigation buoys road markers

Security systems

1. 2. 3.

security lighting remote alarm system electric fences

Miscellaneous

1. 2. 3. 4. 5. 6. 7. 8.

ventilation systems calculators pumping and automated feeding systems on fish farms solar water heater circulation pumps boat/ship power vehicle battery trickle chargers earthquake monitoring systems emergency power for disaster relief

S-ar putea să vă placă și

- Photovoltaic EnergyDocument6 paginiPhotovoltaic EnergyKento FujimoriÎncă nu există evaluări

- Modeling and Control of DC-DC Boost Converter Using K-Factor Control For MPPT of Solar PV SystemDocument6 paginiModeling and Control of DC-DC Boost Converter Using K-Factor Control For MPPT of Solar PV SystemHoang ManhÎncă nu există evaluări

- NTY311KL r11 I01Document262 paginiNTY311KL r11 I01kokobookÎncă nu există evaluări

- Development of Solar CellsDocument15 paginiDevelopment of Solar CellsPrithvi HarveÎncă nu există evaluări

- D7 Solar Panel DevicesDocument12 paginiD7 Solar Panel Devicesarunguptha_gs100% (1)

- Solar Panel - WikipediaDocument77 paginiSolar Panel - WikipediaAnilÎncă nu există evaluări

- Abstract of Solar CellDocument7 paginiAbstract of Solar CellnuraleeeÎncă nu există evaluări

- Solar CellDocument11 paginiSolar Cellapi-3808445100% (2)

- Solar Cell DefinitionDocument26 paginiSolar Cell Definitionrajani kanthÎncă nu există evaluări

- Generation of Solar Cells.Document35 paginiGeneration of Solar Cells.Prabath Madusanka100% (1)

- Solar Cells: by Aman Shah and Nyla VaidyaDocument14 paginiSolar Cells: by Aman Shah and Nyla VaidyaNyla VaidyaÎncă nu există evaluări

- I-V Characteristic of A Solar CellDocument4 paginiI-V Characteristic of A Solar Cellzubair100% (1)

- Solar Cell PresentationDocument26 paginiSolar Cell Presentationraj1090Încă nu există evaluări

- Cis Cigs Solar Cells3102Document26 paginiCis Cigs Solar Cells3102malika_83Încă nu există evaluări

- Solar Energy - FinalDocument5 paginiSolar Energy - FinalRandomÎncă nu există evaluări

- Applications For Solar EnergyDocument2 paginiApplications For Solar EnergyHammadiÎncă nu există evaluări

- Me411 PhotovoltaicsDocument20 paginiMe411 PhotovoltaicskudanyamuÎncă nu există evaluări

- Electrostatic VoltmeterDocument11 paginiElectrostatic Voltmeterگيدوڙو ماڇيÎncă nu există evaluări

- Solar Cells: By: Omar Ahmed Syed To: Assıst .Prof. Dr. Ayşe DuldaDocument40 paginiSolar Cells: By: Omar Ahmed Syed To: Assıst .Prof. Dr. Ayşe DuldaMr. K.S. Raghul Asst Prof MECHÎncă nu există evaluări

- Infrared Plastic Solar CellDocument28 paginiInfrared Plastic Solar CellChandra PrakashÎncă nu există evaluări

- LED LIGHTING Research Report AbstractDocument14 paginiLED LIGHTING Research Report AbstractAkachi Okoro0% (1)

- A Presentation ON: Submitted By:-Renu MeenaDocument10 paginiA Presentation ON: Submitted By:-Renu MeenaDinesh MeenaÎncă nu există evaluări

- Dye Sensitized Solar Cell: Presented By: S.Shashank ChettyDocument26 paginiDye Sensitized Solar Cell: Presented By: S.Shashank Chettyabebaw matebuÎncă nu există evaluări

- Design and Proposal of Solar Photovoltaic Power Plant For Medium Scale IndustryDocument12 paginiDesign and Proposal of Solar Photovoltaic Power Plant For Medium Scale Industrykartik kapoorÎncă nu există evaluări

- A Microcontroller Based Solar Panel Tracking SystemDocument10 paginiA Microcontroller Based Solar Panel Tracking Systemvershakhemka7193100% (1)

- Mass. It Is Approximately Equal To: Fig.1: Air Mass. Fig.2: Effect of AMDocument6 paginiMass. It Is Approximately Equal To: Fig.1: Air Mass. Fig.2: Effect of AMSajjad HossainÎncă nu există evaluări

- Infra Red Plastic Solar CellDocument25 paginiInfra Red Plastic Solar CellRaghavendra Raghav100% (7)

- Versatile Power SupplyDocument23 paginiVersatile Power SupplyPrashant BijweÎncă nu există evaluări

- Electric Double-Layer Capacitor - Wikipedia, The Free EncyclopediaDocument15 paginiElectric Double-Layer Capacitor - Wikipedia, The Free Encyclopediad_richard_dÎncă nu există evaluări

- Better Ways of Using Solar Energy: Indian Institute of Technology HyderabadDocument9 paginiBetter Ways of Using Solar Energy: Indian Institute of Technology HyderabadimnishitÎncă nu există evaluări

- Lab Report - Part A: Kanvasree Vuyyuru (C2084903)Document8 paginiLab Report - Part A: Kanvasree Vuyyuru (C2084903)suryaÎncă nu există evaluări

- Casting Manufacturing Processes Fundamentals of Metal Casting Metals For CastingDocument47 paginiCasting Manufacturing Processes Fundamentals of Metal Casting Metals For CastingarobaidiÎncă nu există evaluări

- Solar CellsDocument91 paginiSolar CellscmeliovÎncă nu există evaluări

- Seminar On Solar Mobile Charger: Submitted To: Submitted byDocument16 paginiSeminar On Solar Mobile Charger: Submitted To: Submitted byAkhila GottemukkulaÎncă nu există evaluări

- Solar Energy Technologies Unit 2 LightingDocument111 paginiSolar Energy Technologies Unit 2 LightingTharun RagavÎncă nu există evaluări

- Dye Sensitized Solar CellDocument54 paginiDye Sensitized Solar Cellcharu agrawalÎncă nu există evaluări

- Solar Energy: The Ultimate Renewable Resource: Bhim KafleDocument57 paginiSolar Energy: The Ultimate Renewable Resource: Bhim KafleAadeem NyaichyaiÎncă nu există evaluări

- First Page of AssignmentDocument8 paginiFirst Page of Assignmentmatougabouzmila0% (1)

- Batteries & Fuel Cells-1Document33 paginiBatteries & Fuel Cells-1Abdo MohdyÎncă nu există evaluări

- SolarDocument13 paginiSolarVinay Maisuriya0% (1)

- Thin-Film Solar CellDocument72 paginiThin-Film Solar CellPraveen KumarÎncă nu există evaluări

- Plastic Solar Cell Technology: by Muhammed Raslan S5 EL Rollno 37Document12 paginiPlastic Solar Cell Technology: by Muhammed Raslan S5 EL Rollno 37N OÎncă nu există evaluări

- Presentation On Solar EnergyDocument16 paginiPresentation On Solar EnergyDeep MandloiÎncă nu există evaluări

- Types of Solar CellsDocument7 paginiTypes of Solar CellsDouglas OngomÎncă nu există evaluări

- Suspension Insulator StringDocument8 paginiSuspension Insulator Stringneo83% (6)

- Refining of Lead and Nickel PDFDocument7 paginiRefining of Lead and Nickel PDFgtdomboÎncă nu există evaluări

- Electrochemistry - UNIT 2Document38 paginiElectrochemistry - UNIT 2shrijÎncă nu există evaluări

- Unit V Emerging Solar Cell TechnologiesDocument16 paginiUnit V Emerging Solar Cell TechnologiesArchana Diwakar RanjishÎncă nu există evaluări

- Solar EnergyDocument30 paginiSolar EnergyJatin Sharma cse 20Încă nu există evaluări

- .Tech Seminar 1ga15ee018Document22 pagini.Tech Seminar 1ga15ee018Himalaya SinghÎncă nu există evaluări

- Solar Energy Projects ListDocument8 paginiSolar Energy Projects ListSanjana Singh100% (1)

- Report On Solar PV TechnologiesDocument16 paginiReport On Solar PV Technologiessagar paneliyaÎncă nu există evaluări

- A Project On Solar EnergyDocument21 paginiA Project On Solar EnergyVishal KarmakarÎncă nu există evaluări

- Solar Thermal Energy Part 1Document19 paginiSolar Thermal Energy Part 1Tushar SanwareyÎncă nu există evaluări

- A Photovoltaic Panel Model in Matlab SimulinkDocument6 paginiA Photovoltaic Panel Model in Matlab SimulinkAnonymous kxFNcpÎncă nu există evaluări

- Platic Solar CellDocument17 paginiPlatic Solar CellSachin UkkaliÎncă nu există evaluări

- Solar Irrigation SystemDocument18 paginiSolar Irrigation SystemHarishwar ReddyÎncă nu există evaluări

- Structural Steel Properties and TestingDocument11 paginiStructural Steel Properties and TestingRushikesh ChevaleÎncă nu există evaluări

- 4.0 Separators: Typical Profile of Microporous Polyethylene Automotive Battery SeparatorDocument10 pagini4.0 Separators: Typical Profile of Microporous Polyethylene Automotive Battery SeparatorpurushothamkrÎncă nu există evaluări

- Need For Solar CellsDocument36 paginiNeed For Solar CellssahitÎncă nu există evaluări

- Solar Photovoltaic SystemDocument60 paginiSolar Photovoltaic SystemUmeshÎncă nu există evaluări

- V Belt Drive ProblemsDocument1 paginăV Belt Drive ProblemsPraba Karan DÎncă nu există evaluări

- Revised Update For DRM TransmittersMW 26082016Document2 paginiRevised Update For DRM TransmittersMW 26082016Praba Karan DÎncă nu există evaluări

- DOME Internal Test 1 Question PaperDocument1 paginăDOME Internal Test 1 Question PaperPraba Karan DÎncă nu există evaluări

- Ugly Choke BalunDocument8 paginiUgly Choke BalunPraba Karan DÎncă nu există evaluări

- Model Question PapersDocument4 paginiModel Question PapersPraba Karan D67% (3)

- Slim Jim Antenna 2mDocument1 paginăSlim Jim Antenna 2mPraba Karan DÎncă nu există evaluări

- 3D Choke RingDocument6 pagini3D Choke RingPraba Karan DÎncă nu există evaluări

- Ground Plane 1111111111Document1 paginăGround Plane 1111111111Praba Karan DÎncă nu există evaluări

- Finger Print: Image SpecificationDocument1 paginăFinger Print: Image SpecificationPraba Karan DÎncă nu există evaluări

- HistoryDocument6 paginiHistoryPraba Karan DÎncă nu există evaluări

- Trends and Future Outlook For Thermal Power Plants: Hiroshi NishigakiDocument4 paginiTrends and Future Outlook For Thermal Power Plants: Hiroshi NishigakiPraba Karan DÎncă nu există evaluări

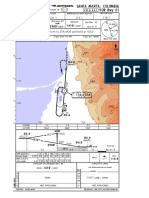

- Santa Marta, Colombia SKSM/SMR VOR Rwy 01: 13-1 119.1 118.7 VOR Cat A, B & C Simon Bolivar Intl 125.0 127.7Document1 paginăSanta Marta, Colombia SKSM/SMR VOR Rwy 01: 13-1 119.1 118.7 VOR Cat A, B & C Simon Bolivar Intl 125.0 127.7Guillermo Serrano KelcyÎncă nu există evaluări

- Filters With LabViewDocument14 paginiFilters With LabViewNataly MedinaÎncă nu există evaluări

- Implementation of Modified P&o-Mppt AlgorithmDocument8 paginiImplementation of Modified P&o-Mppt AlgorithmVaralakshmi SeerapuÎncă nu există evaluări

- Configuring BIOS Settings (Roma)Document2 paginiConfiguring BIOS Settings (Roma)Christian LaranoÎncă nu există evaluări

- Lecture Logical EffortDocument111 paginiLecture Logical EffortYagami LightÎncă nu există evaluări

- Digital Communications - Viva Voce QuestionsDocument3 paginiDigital Communications - Viva Voce QuestionsAllanki Sanyasi Rao100% (1)

- 207.OTN 260SCX2 and 130SCX10 Cards V1 04 11feb16Document24 pagini207.OTN 260SCX2 and 130SCX10 Cards V1 04 11feb16Ronald N Meza C100% (1)

- O W N e R S M A N UDocument6 paginiO W N e R S M A N Uapi-25885158100% (2)

- SECTION 15180 BMS and Automatic ControlsDocument32 paginiSECTION 15180 BMS and Automatic ControlskdpmansiÎncă nu există evaluări

- Canems Injection Manual PDFDocument66 paginiCanems Injection Manual PDFPeter McCrackenÎncă nu există evaluări

- Altistart 48 ManualDocument84 paginiAltistart 48 ManualSohaib Khalid100% (1)

- RDG RDF Room Thermostats A6V10254838 HQ enDocument32 paginiRDG RDF Room Thermostats A6V10254838 HQ endimlou1Încă nu există evaluări

- Ic21 Sect 10 Pilot DevicesDocument222 paginiIc21 Sect 10 Pilot DevicesFawzi AlzubairyÎncă nu există evaluări

- Catalogo Edibon 2018Document96 paginiCatalogo Edibon 2018fgrojasgÎncă nu există evaluări

- SpaceTrack 4000 CaprockDocument2 paginiSpaceTrack 4000 CaprockVanessa ChingÎncă nu există evaluări

- Direct On Line (DOL) Motor StarterDocument8 paginiDirect On Line (DOL) Motor Startermaruf048100% (1)

- Divided by The PermittivityDocument1 paginăDivided by The PermittivityVasanth Kumar NainalaÎncă nu există evaluări

- Chang-Joon LeeDocument1 paginăChang-Joon LeeCJ LeeÎncă nu există evaluări

- CH 2 - Electrostatic Potential - MCQDocument2 paginiCH 2 - Electrostatic Potential - MCQDeepali MalhotraÎncă nu există evaluări

- CDR Questionnaire Form: of The Project I.E. How The Objectives of The Project Was Accomplished in Brief.)Document3 paginiCDR Questionnaire Form: of The Project I.E. How The Objectives of The Project Was Accomplished in Brief.)Uttam AcharyaÎncă nu există evaluări

- Ee3015 PDFDocument1 paginăEe3015 PDFRovick TarifeÎncă nu există evaluări

- Product Catalogue 2015Document203 paginiProduct Catalogue 2015Burghelea Ovidiu-GabrielÎncă nu există evaluări

- 55:041 Electronic Circuits: Sections of Chapter 3 &4Document97 pagini55:041 Electronic Circuits: Sections of Chapter 3 &4Daniel GarzonÎncă nu există evaluări

- HCPL-7800A: Isolation AmplifierDocument9 paginiHCPL-7800A: Isolation AmplifierkarkonÎncă nu există evaluări

- 6204 Parts Lists PDFDocument51 pagini6204 Parts Lists PDFMirzaÎncă nu există evaluări

- CA2031 CableAccess 600ACrossRefDocument2 paginiCA2031 CableAccess 600ACrossRefLuis GalánÎncă nu există evaluări

- DSE 4510 Dse4520 Operator ManualDocument64 paginiDSE 4510 Dse4520 Operator ManualPedro100% (5)

- Ignition Systems For Gasoline EnginesDocument27 paginiIgnition Systems For Gasoline Enginesanon_53273932Încă nu există evaluări

- Experiment-3 30KV Insulation TesterDocument4 paginiExperiment-3 30KV Insulation TesterAbhinav SinhaÎncă nu există evaluări