Documente Academic

Documente Profesional

Documente Cultură

(RMD™) MIG Welding Process

Încărcat de

Pradip GoswamiDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

(RMD™) MIG Welding Process

Încărcat de

Pradip GoswamiDrepturi de autor:

Formate disponibile

Miller - New Regulated Metal Depositio...

Order Literature Contact Us Site Search

Miller Electric

Products Where To Buy Service Resources Industries & Interests About Us Our Company Follow Us Miller History Trade Shows News Releases Employment Site Help Multiprocess Fume Extraction Multioperator Induction Heating Submerged Arc Generators Advanced Mfg. Sys.Plasma Cutters Spot Welders Consumables Service Parts SmartSelector

MIG (GMAW) TIG (GTAW) Stick (SMAW) Engine-Driven Wire Feeders

Helmets & Welding ProtectionWorkstations Accessories Guns & Torches Industrial System Builder New Products Register Your Product Welding & Cutting Safety Improving Your Skills Video Library Discussion Forums Email Newsletters Follow Us Manufacturing Fabrication Construction Service Trucks Industry News Blog Email Newsletters Help Me Choose

Company Store Special Offers Owner's Manual & Parts List Articles (Tech, How-To, Success) Business Tools Industry News Blog Resources for Sale Fun Stuff Racing, Customizing, Restoring Welding Projects Farm & Ranch Welding Instructors Discussion Forums

Page 1 of 5

Miller - New Regulated Metal Depositio...

7/3/2011

Miller - New Regulated Metal Depositio...

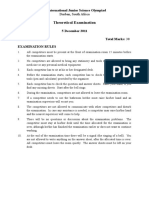

Articles & Stories Home Resources Article Search Technical/Informational ShareThis

New Regulated Metal Deposition (RMD) MIG Welding Process Improves Stainless Steel Pipe Fabrication

Executive Summary Millers new Regulated Metal Deposition (RMD) MIG welding process (modified short-circuit MIG) improves welding quality and productivity on stainless steel pipe. The RMD process is easy to learn and addresses the welder shorter by providing an easier process that gets more work done faster and at a higher quality.

Precisely-controlled metal transfer provides uniform droplet deposition, making it easier for the welder to control the puddle. Easily bridges gaps up to 3/16-in. and creates more consistent root reinforcement on the inside of the pipe. Shielding gas comes out of the gun relatively undisturbed, pushing through the root opening and preventing sugaring on the back side of the weld. This allows certain 300 series stainless steels to be welded without a backing gas, which can improve productivity by as much as 400 percent. RMD maintains a consistent arc length regardless of stick-out. The amount of the root pass metal deposited will be sufficient to supply the heat input requirements of the first Pulsed MIG or flux-cored fill pass, possible eliminating the need for a TIG hot pass. Same wire and shielding gas can be used for the fill and cap passes using a next generation Pulsed MIG process called Pro-Pulse, which improves travel speeds and deposition rates while lowering heat input.

WELDING SMARTER ON STAINLESS

New GMAW Technology for Root Pass Welding Boosts Productivity and Quality, Addresses Welder Shortage For stainless steel pipe fabricators, the good news is that the oil refining and petrochemical sector is experiencing 20 to 30 percent more activity per year than in the recent past (according to Cambridge Energy Research Associates, www.cera.com, an adviser to energy companies). Ethanol and bio-fuel plant construction, which requires large amounts of stainless pipe, is also driving up demand. In the U.S., ethanol consumption is currently 7.6 billion gallons per year and forecast to rise to 13.3 billion gallons by the end of 2008 (according to the Renewable Fuels Association, www.ethanolrfa.org, an industry trade group). The Energy Independence and Security Act, signed by President Bush in 2007, expands the Renewable Fuels Standard by requiring the use of 36 billion gallons of renewable fuel annually by 2022. Of particular note, the legislation specifically states that 21 billion gallons of that goal must come from advanced biofuels, including celluosic ethanol. The bad news? Finding qualified welders is already difficult, and its only getting worse. To meet demand, stainless pipe fabrication shops already work hard. Now they have an opportunity to work smarter by substituting a modified short circuit GMAW processes, called Regulated Metal Deposition (RMD), for the traditional GMAW and GTAW processes for the root pass. Changing the Game Pipe fabricators are particularly skeptical about short circuit GMAW, and with good reason. With traditional GMAW, the short circuits occur at erratic intervals and with varying intensity. As a result, the weld puddle experiences a great deal of agitation. To prevent cold lap, or lack of fusion, the operator must work to control and manipulate the weld puddle. High-speed video demonstrates how the short circuit explosion causes the weld puddle to splash up and freeze on the sidewall of the pipe, which is how cold lap occurs. It also leads to spatter and extensive clean-up time. Because it takes a great deal of skill to produce code-quality root welds with traditional short circuit GMAW, many fabricators shun the process, and many end users do not include it in their list of approved procedures. Fortunately, technology advances are changing the game. With RMD technology, the welding system anticipates and controls the short circuit, then reduces available welding current to create a consistent metal transfer. Precisely controlled metal transfer provides uniform droplet deposition, making it easier for the welder to control the puddle. High-speed video proves that stable short circuits create only small ripples in the weld puddle, which in turn allow consistent tie-in to the sidewall. With a stable and more controllable weld puddle, apprentice operators can quickly and easily learn to create uniform, high-quality welds. The RMD process also provides several other benefits. First, the smooth metal transfer compensates for a high-low misalignment between pipe sections. It easily bridges gaps of up to 3/16 in. Second, smooth metal transfer creates more consistent root reinforcement on the inside of the pipe. Third, the shielding gas coming out of the gun remains relatively undisturbed by the controlled transfer. As a result, enough shielding gas gets pushed through the root opening to prevent sugaring (oxidation) on the backside of the weld. Some fabricators have qualified procedures to weld some of the 300 series stainless steels without a backing gas, improving productivity by up to 400 percent (large diameter pipes take a long time to purge, and the gas is costly). Fourth, the RMD process maintains a consistent arc length regardless of electrode stick-out. It compensates for operators that have problems holding a constant stick-out, and it enables a better view of the weld puddle. Note that as apprentice operators weld from the 4- to 6-oclock position, they tend to increase their wire stick-out. With older technology, a long stick-out skews welding parameters and often leads to quality issues. Fifth, RMD creates a root pass weld with a 1/8- to 1/4-in. throat. In many instances, the amount of root pass metal deposited will be sufficient to support the heat input requirements of the first pulsed GMAW or FCAW fill pass. Fabricators can eliminate the GTAW hot pass, saving about $15 on a 12-in., schedule 40 pipe.

Page 2 of 5

Miller - New Regulated Metal Depositio...

7/3/2011

Miller - New Regulated Metal Depositio...

The RMD process deposits more metal than other processes. It can eliminate the need for a hot pass, saving approximately $15 per joint (based on a schedule 40, 12-in. diameter pipe). The increased root pass thickness results are not material dependent. This photo was taken using carbon steel; similar results will occur with stainless. Finally, the same wire and shielding gas can be used for the fill and cap passes using a next-generation pulsed GMAW process called Pro-Pulse. This process improves performance and operator acceptance compared to traditional pulsed welding, and it improves both travel speeds and deposition rates while lowering overall heat input. Establishing Good Technique As with any welding process, success with the RMD process requires establishing and maintaining good preparation and welding techniques. The following guidelines, which are extremely easy to follow, lead to proven success and increased productivity for welding stainless steel pipe. Start with pipe joint sections that have the standard 37.5-degree bevels, for a total included angle of 75 degrees. The lands can range from a knife edge to 3/32 in. Use a minimum 1/8-in. root opening to ensure proper root reinforcement on the welds backside. An easy way to space the gap is with a filler metal rod that matches the desired gap size. Tack the pipe with the RMD process, making tacks (in this order) at the 12-, 6-, 3- and 9-oclock positions. Remove the filler metal spacer after making the first tack, then check the gap with a tool designed for that purpose. Tacks on smaller diameter pipe can be 1/4- to 1/2-in. long. Tacks on larger pipe may be 1 in. or longer. Note that tack welds will shrink during cooling, causing the gap to close up. In areas with less than a 1/8-in. gap, grind the joint using a 3/32-in. cutting wheel to open the root. Finish preparing the pass by grinding each tack weld to a feather edge to ensure that the root pass consumes the tack weld. Welding in the 1G Rolled Position Benefits of the RMD process include:

RMD, a new modified short circuit transfer technology, will help fabricators of stainless steel pipe address two of their largest issues: finding qualified welders and increasing productivity to meet customer demand.

Start the arc in the center of a tack around the 1:30- to 2-oclock position. Hold the gun perpendicular to the pipe with a 5- to 10-degree drag angle. Use a 3/8- to 5/8-in. electrode stick-out. In some cases, this may require a recessed contact tip to help maintain correct stick-out. Establish the weld puddle and position the electrode in the center of the weld puddle as the pipe rolls away from the operator (essentially, the operator is dragging the weld puddle). Watch the puddle closely to ensure that it ties into the sidewalls. Normally, do not use a weave technique. However, if the gap is greater than 3/16 in., the operator may need to weave the electrode slightly across the gap and up the sidewall to bridge it. When the electrode is properly positioned in the weld puddle, the RMD process creates a muted buzzing sound that is much softer than the crackling bacon sound of traditional short circuit GMAW. Although the RMD process appears colder than typical GMAW, the weld puddle fuses into the sidewall and penetrates the joint due to the calm metal transfer and stable arc. The face of a good root weld appears flat (neither concave or convex) and, as noted, it is thicker than a traditional GMAW root With traditional GMAW, operators position the arc on the leading edge of the puddle. Do not do this with RMD, as the arc will stutter and create spatter and greater penetration on the inside of the pipe (note that an optimum root has about a 1/16-in. reinforcement). If travel speeds become too slow and the electrode becomes positioned too far back in the puddle, the arc becomes unstable (listen for a sound more like traditional GMAW. Also, the weld face will be convex. If this happens, grind out the high spots to prevent areas of lack of fusion on the next pass). If the joint is misaligned, continue to concentrate the arc in the center of the joint. Do not favor the high side of the joint; the new technology will automatically compensate. Let the arc do the work! Welding in the 5G Fixed Position Begin welding in the 12-oclock position. As with the 1G position, start the arc in the center of a tack weld using a 5- to 10 -degree drag angle and a 3/8- to 5/8-in. stick-out.

An apprentice welder can become proficient with the process in less than two days; an experienced welder can become proficient in less than two hours Welding travel speeds of 6 to 12 inches per minute (vs. 3 to 8 ipm for SMAW and 3 to 5 ipm for GTAW, both in the fixed position) Potential to eliminate the hot pass Potential to eliminate backing gas for some of the 300 series stainless steel grades Superior quality welds Reduced rework costs (which can add up to $500 to fix a serious flaw) Exceptional tolerance for high-low misalignment between pipe sections Minimal clean-up (no slag to chip, little or no spatter) Same wire and shielding gas for subsequent passes with a pulsed GMAW process, reducing downtime associated with process changeover

At the start of the weld, keep the arc in the center of the puddle, but move the electrode back and forth across the gap using a half moon motion (with the face of the moon pointing down). At about the 1-oclock position, gravity starts to push the puddle down the joint. Once gravity takes over, stop weaving and concentrate on directing the electrode into the center of the weld puddle. At about the 5-oclock position, use a slight side-to-side motion until reaching 6 oclock, ending the bead on the feathered tack weld. The side-to-side motion flattens the weld bead and minimizes grinding. If the weld does not end on a tack weld (e.g., the operator breaks the arc for whatever reason), this may lead to a pinhole at the end of the weld. Grind out the end of the weld before resuming. After completing the root pass, also grind out starts, stops and high points before making the first fill pass (remember that the root pass with the modified process can eliminate the hot pass). Five Critical Things

Page 3 of 5

Miller - New Regulated Metal Depositio...

7/3/2011

Miller - New Regulated Metal Depositio...

The techniques for welding carbon steel pipe are the same as those described here for welding stainless; however, to qualify procedures for welding 300 series stainless steel pipe without backing gas, fabricators must do the following: 1. Ensure a minimum 1/8-in. gap around the entire circumference of the joint. This gap allows the shielding gas to flow through to protect the backside of the joint from oxidation. 2. Clean the pipe both inside and out to remove any contaminates or unwanted substances. Use a wire brush to clean at least 1 in. back from the edge of the joint. 3. Use only a stainless steel wire with a high silicon content, such as a 316LSi or 308LSi . Higher silicon content helps the puddle wet out and acts as a deoxidizer. 4. For optimum performance, use a Tri-H gas thats 90 percent helium, 7.5 percent argon and 2.5 percent CO2. Alternatively, use 98 percent argon and 2 percent CO2. 5. For best results, use a tapered nozzle for the root pass because it localizes the gas coverage. Tapered nozzles with built-in gas diffusers provide exceptional coverage. Note that using the RMD process without a backing gas does produce a small amount of oxide scale on the backside of the weld, which usually flakes off as the weld cools. While within the standards for oil and petrochemical applications, it does not meet the high purity standard found in the pharmaceutical, semi-conductor or food industries. Pipe fabricators have long memories. Chances are, most have tried, and many have rejected, the other GMAW procedures for root pass welding. However, GMAW technology advances in recent years now provide dramatically better results. It sounds clich, but you actually have to experience the new modified short circuit transfer to believe how easily an operator can learn it and how easily it creates a quality root bead. Hopefully, the 100- to 400-percent productivity improvements will be enough of an incentive for stainless pipe fabricators to re-examine the GMAW process.

Technical/Informational Products PIPEPRO 304 PIPEWORX Welding Categories MIG Regulated Metal Deposition (RMD) Welding Applications Stainless Steel Welding Fabrication Pipe Fabrication Key Business Issues Improving Weld Quality Operator Efficiency/Welder Shortage Increasing Productivity Related Articles New MIG Technology Makes Welde... Marine Repair Facility Complet... Phoenix Mechanical Contractor ... New GMAW Options Offer Increas... Pulsed MIG Welders from Miller... View All

Page 4 of 5 Miller - New Regulated Metal Depositio... 7/3/2011

The RMD process creates a root bead that matches the quality of a GTAW root bead. Unlike GTAW, which requires a high learning curve, the new GMAW process enables an apprentice operator to make production-quality welds after two days of training.

Miller - New Regulated Metal Depositio...

Article Search

Select one or all topics to refine your search.

Search By Topic:

Welding Category Welding Application Key Business Issues Keyword Search

Search

View All Articles RSS Let the latest articles come to you! Subscribe to the Articles RSS Feed What is RSS?

Enter Your Email Go

Follow Us:

Social Media Terms of Use Home | Products | Where to Buy | Service | Resources | Industry & Interests | About Us Partner Login | International | Site Help | Privacy Policy | Terms of Use 2011 Miller Electric Mfg Co. All Rights Reserved.

Page 5 of 5

Miller - New Regulated Metal Depositio...

7/3/2011

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Rigaku Nex QCDocument12 paginiRigaku Nex QCLuis ReyesÎncă nu există evaluări

- Alkaline Earth MetalDocument33 paginiAlkaline Earth MetalSup FansÎncă nu există evaluări

- Mineral-rich Bilimbi fruit analysisDocument3 paginiMineral-rich Bilimbi fruit analysisveronica francisÎncă nu există evaluări

- Chloroplast, PPTDocument21 paginiChloroplast, PPTSuchitra Sk88% (8)

- Water WastewaterDocument20 paginiWater WastewaterterryjoseeÎncă nu există evaluări

- WHMIS Handbook PDFDocument22 paginiWHMIS Handbook PDFNÎncă nu există evaluări

- Application News: Infrared Spectra of Polyvinyl ChlorideDocument2 paginiApplication News: Infrared Spectra of Polyvinyl ChlorideRudiyansah RudiyansahÎncă nu există evaluări

- PK - FKK.PPM - Manual Makmal Che565: Chemical Engineering Laboratory IiiDocument21 paginiPK - FKK.PPM - Manual Makmal Che565: Chemical Engineering Laboratory Iiibedirtupak92% (12)

- Lesson 2 Dna Structure and Dna ExtractionDocument8 paginiLesson 2 Dna Structure and Dna ExtractionGreatel Elijah TorregosaÎncă nu există evaluări

- Atomic Structure Part 6Document38 paginiAtomic Structure Part 6xenaÎncă nu există evaluări

- PIP PCECV001 Guidelines For Application of Control ValvesDocument39 paginiPIP PCECV001 Guidelines For Application of Control ValvesAndresÎncă nu există evaluări

- U15 S1-2 HW KeysDocument6 paginiU15 S1-2 HW KeysRohith GudatiÎncă nu există evaluări

- How Does A Refrigerator WorkDocument5 paginiHow Does A Refrigerator WorkAlfis0% (1)

- Unit 1 - Construction Materials - WWW - Rgpvnotes.inDocument21 paginiUnit 1 - Construction Materials - WWW - Rgpvnotes.inmadhavi likharÎncă nu există evaluări

- Atracurium BesylateDocument4 paginiAtracurium BesylateStill DollÎncă nu există evaluări

- Biopolymers - Sustainability For The Automotive Value-Added ChainDocument4 paginiBiopolymers - Sustainability For The Automotive Value-Added ChainDiana LondoñoÎncă nu există evaluări

- RAC (ME 802) by Prof. Sangeev S. TomarDocument9 paginiRAC (ME 802) by Prof. Sangeev S. Tomarapi-19832143Încă nu există evaluări

- Qcs 2010 'Part 8.04 Pipeline InstallationDocument29 paginiQcs 2010 'Part 8.04 Pipeline InstallationRotsapNayrb100% (2)

- Method Statement FOR Waste Polymer Slurry Disposal: PT Bauer Pratama IndonesiaDocument4 paginiMethod Statement FOR Waste Polymer Slurry Disposal: PT Bauer Pratama IndonesiaFendi Rang TigorÎncă nu există evaluări

- Is 2986Document9 paginiIs 2986sreenathaÎncă nu există evaluări

- The Changing World of OleochemicalsDocument9 paginiThe Changing World of OleochemicalsMarta Szymańska100% (1)

- LCGC Europe 2001Document4 paginiLCGC Europe 2001Jhonattan BaezÎncă nu există evaluări

- Omeprazole: by Jennica Mae V. CuicoDocument7 paginiOmeprazole: by Jennica Mae V. Cuicoジェンニカ メイÎncă nu există evaluări

- 1 s2.0 S2352179118302382 MainDocument5 pagini1 s2.0 S2352179118302382 MainIrfan IsdhiantoÎncă nu există evaluări

- Determination of Moisture ContentDocument21 paginiDetermination of Moisture ContentasadaltafgillÎncă nu există evaluări

- Trouble Shooting EngineDocument34 paginiTrouble Shooting EngineDesta Andri MuryonoÎncă nu există evaluări

- 12 Biology Notes Ch06 Molecular Basis of InheritanceDocument14 pagini12 Biology Notes Ch06 Molecular Basis of Inheritancehimanshu kumarÎncă nu există evaluări

- Group 4 Lab Exercise on Vapor-Liquid EquilibriumDocument21 paginiGroup 4 Lab Exercise on Vapor-Liquid EquilibriumEUNICE JOI SARCONÎncă nu există evaluări

- Photos of Defects Found in RadiographyDocument14 paginiPhotos of Defects Found in RadiographyKavipriyan KaviÎncă nu există evaluări

- MCQ IjsoDocument20 paginiMCQ IjsommhabgÎncă nu există evaluări