Documente Academic

Documente Profesional

Documente Cultură

BRC Food6 - Checklist

Încărcat de

Ledo HoussienDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

BRC Food6 - Checklist

Încărcat de

Ledo HoussienDrepturi de autor:

Formate disponibile

BRC Food 6

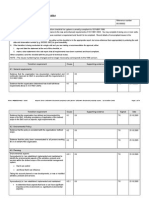

P=Procedure Senior Management Review

Clause

Issue Senior Management

Requirement

Evidence

1.1 1.1.1 1.1.2 1.1.3 1.1.4 1.1.5

Policy, signed and communicated Objectives Senior management review Managmeent meeting program Provision of resources

x x x x

Policy Objectives and attainment plan Review meeting minutes Monthly meeting minutes

1.1.6 1.1.7 1.1.8 1.1.9

Industry updates Copy of the standard Maintain certification Attendance at opening and closing audit meetings

Conferences, memberships, technical journals, email updates Copy of the standard or receipt

1.1.10 Organizational structure and authority

Root cause analysis of past nonconformances

Review of nonconformances, root cause analysis, verification

1.2

Example evidence

Training required

Risk Assessment required

Documentation required

1.2.1 1.2.2 2 2.1 2.1.1 Prerequisite programs HACCP HACCP team

Organizational chart and absence coverage Job descriptions and work instructions

x x

Organizational chart, deputies, list of responsibilities Job descriptions and work instructions

HACCP team, training

Team list and training records

2.2 2.2.1

Prerequisite programs Product description Scope of HACCP plan, products and process descriptions Source of product / process description Intended use Description of intended use, specific risk target groups, potenital misuse of product Flow diagram Diagrams illustrating process flow and layout schematic Verification of flow diagram Flow diagrams verified and challenged annually x x x x

2.3 2.3.1 2.3.2 2.4

2.4.1 2.5 2.5.1

2.6 2.6.1

2.7 2.7.1 2.7.2 2.7.3

Listing of hazards Listing of potential hazards Definition of hazards hazard control measures CCP determination Using decision tree, identify which control points are CCP's CCP limits Limits for each CCP defined

x x x x

2.8 2.8.1 2.9 2.9.1

decision tree

x

validation studies showing that control measures and limits will effectiveyly control hazards in all forseeable circumstances

2.9.2 2.10 CCP monitoring

Validation of CCP's

2.10.1

Procedures for monitoring CCP limits, and corrective actions in case of limits being exceeded

P

Recording and verification procedures (verification to include verifying records as well as actions)

2.10.2

Recording of monitoring

2.11

Corrective action

2.11.1 2.12 2.12.1 HACCP documentation and record keeping Verification

Procedures to follow in the event of limits being exceded as well as failure of control measures

Activities to ensure the HACCP plan is effective

2.13 2.13.1 2.14

Records created and maintained to verify HACCP is actively in place HACCP review Review of both implementation and effetiveness of the HACCP plan verified annually or in the event of significant changes Food safety and quality management systems Food safety and quality manuals All policies and procedures are documented. Fully implemented and available where needed Policies, procedures and work instructions are formatted as to be understandable to staff

2.14.1

3 3.1 3.1.1 3.1.2

3.1.3

3.2

Document control Mechanism for controlling document versions, change log and update procedure Records

reasons for alteration of records is documented on record list of controlled documents, change log, change procedure

3.2.1 3.3

3.3.1 3.3.2 3.4 3.4.1 3.4.2 Internal audit

Records are understandble, record alteration procedure Record retention procedure

P P

Internal audits cover all requirements of the Standard Internal auditors appropriately trained Internal audit reports show evidence of conformance, and closure of nonconformance Internal inspections covering site conditions and hygiene x

Internal audit report audit technique training for internal auditors

3.4.3 3.4.4

x x

internal audit report

inspection reports

3.5 3.5.1 3.5.1.1 3.5.1.2 3.5.1.3

Supplier approval and monitoring Raw materials and packaging Listing of all ingredients and packaging, and associated risks Supplier approval procedure, and ongoing monitoring procedure Exception procedure in case of nonapproved supplies being used x P P

grouped or individual listing of all materials

3.5.2

Acceptance monitoring

reveiving inspections, pre-use testing, additional document requirements Proof of acceptance

3.5.2.1 3.5.2.2 Service supplier management

Procedure on how incoming materials are assessed for acceptance Records of acceptance

P x

3.5.3 3.5.3.1

Procedure for approval and monitoring of service suppliers Service contracts adressing specifications or expectations outsourced processing management Brand owner is aware of outsourced processing Monitoring of contracted processing

P

contracts and specifications for service suppliers

3.5.3.2

3.5.4 3.5.4.1 3.5.4.2

x x

docmented in contract with brand owner verification of certification or audit reports contracts of specification and expectation in place

3.5.4.3

Managing of contracted processing

3.5.4.4 3.6 3.6.1 Specifications

Monitoring of contract processing results

results and analysis of process outcome

Specifications in place for all raw materials and packaging

specifications

3.6.2 3.6.3 3.6.4 3.6.5

Activities and instructions on the process floor equate to product and customer specifications Specifications in place for all finished products Specifications are agreed with or available to customers Specifications are reviewed when required, minimum every 3 years

specifications

3.7 3.7.1

Corrective action Documented procedure for corrective actions Control of nonconforming product Hold program, including dispensation program Traceability Identification of all materials within site to allow traceability Mass balace and traceability test Rework is included in traceability program Complaint handling Complaint program, resolved through trained staff Complaint data analyzed for trends and used for improivements x x

ongoing trend analysis for complaint data

3.8 3.8.1 3.9 3.9.1 3.9.2 3.9.3

test results

3.10 3.10.1 3.10.2

3.11

Incident management Incident management procedures based on potential large scale interruptions Recall and product withdrawal procedure Procedures tested annually Notification of CB in the event of recall Site Standards External standards Protecting site from external contaminants and impacts Site exterior maintained in good order Building exterior maintained in good condition Security Security risk assessment and mitigation completed, reviewed annually Controlled access and employee security training Registered with appropriate government agencies, where required Layout, flow and segregation

site map, appropriate zone designations

3.11.1 3.11.2 3.11.3 3.11.4 4 4.1 4.1.1 4.1.2 4.1.3 4.2

P P

CB on recall contact list

4.2.1 4.2.2

x x

4.2.3

Proof of registration

4.3

4.3.1

Site map designating product risk zones

4.3.2 4.3.3 4.3.4 4.3.5 4.3.6 4.3.7 4.3.8 4.4 4.4.1 4.4.2 Building

Site map identifying activites Visitors and contractors managed on site Contamination control in low risk areas High care areas provide appropriate practices High risk areas segregated, and use appropriate practices Sufficient space to work effecitvely hygenically Temporary structures do not add risk

site map sign in and awareness activities

4.4.3

4.4.4

Walls constructed and maintained to appropriate standard Floors constructed and maintained to appropriate standard Drains constructed and maintained to appropriate standard. Drainage does not impact product integrity If HC /HR, then msut have a drain plan showing drains, flow direction, back flow prevention or other risks. Ceilings and overheads construted and maintained to appropriate standard Suspended ceilings (building voids) on inspection program Ventilation to outside is pest proof. Windows protected from breakage where they pose a risk Doors constructed and maintained to appropriate standard. Doors do not allow pest ingress. Lighting is suitable and sufficient

Drain plan / drawing

4.4.5 4.4.6 4.4.7 4.4.8

Void inspection record

4.4.9 4.4.10

4.4.11 4.4.12 4.4.13 4.5 4.5.1 4.5.2 4.5.3 Utilities

Light bulbs protected from breakage Adequate ventilation and extraction HR areas using filtered air.

Water is potable, plant tested for relevant contaminants. Water distribution plan Restrictions if non-potable water is used. Steam, compressed air, gasses, do not pose contamination risks. Compressed air with direct product contact is filtered. Equipment Equipment designed, constructed and installed to be effectively cleaned and maintained. Equipment with direct food contact made of suitable materials. Maintenance Preventative maintenance program is effective Equipment inspection program where not covered by PM program Temporary repairs controlled Product protected during maintenance activities. Post maintenance line clearance procedure used.

R x

Plant sample test results. plan showing all taps, outlets and storage. If used, reference to legislation. HACCP process flow diagram showing use of utilities, verify protection.

4.5.4 4.6

4.6.1 4.6.2 4.7 4.7.1 4.7.2 4.7.3

Approvals of suitability or conformance

PM program

Inspection program Work orders tied to temporary repairs

4.7.4

4.7.5 4.7.6 4.8 4.8.1 4.8.2 4.8.3 Staff facilities

Approved chemicals / materials used in maintenance. Shop and engineering rooms maintained

Approvals for materials based on use

Adequate changing facilities for employees and visitors Personal storage for employees. Separate storage for clean uniforms provided. In HC areas: - segragated changerooms, changing instructions, footwear dedicated to high care area only, distinctive clothing, handwashing during changing, handwash and sanitize on entry In HR areas: - changing instructions, dedicated footwear, footwear barrier system, disctinctive clothing, handwashing during changing, hand wash and sanitize on entry Handwashing to include: - suitable temperature, liquid soap, single use drying, hands free taps, signage Washrooms: - segragated, handwashing with signange Smoking and waste managed to protect product Employee food stored in clean hygienic state. No food in production or storage areas. Cafetria operations suitably controlled to prevent contamination and employee illness

4.8.4

4.8.5

4.8.6 4.8.7 4.8.8

4.8.9

4.8.10

cafeteria training, inspections

4.9 4.9.1

Chemical and physical contamination control Chemical controls Approved purchase, specifications, suitability proof, avoidance of scented products, appropriate labeling, segregated and secure storage, use by trained personnel protect product from chemical taint Metal control Sharps and knife control procedures Protection from staples, paper clips, and other closures Glass and brittle material control Excluded or protected List of items, location and condition. Periodic check program, procedures for cleaning and replacing as needed. Glass breakage procedure: - quarantine, cleaning, inspection and authorization, clothing change, training and recording Products packed in glass Segragated storage of empty containers Breakage control: - removal of product, cleaning, designated cleaning materials, lidded waste containers, post breakage inspection, restart authorization p

sharps policy

4.9.1.1 4.9.1.2 4.9.2 4.9.2.1 4.9.2.2 4.9.3 4.9.3.1

4.9.3.2

4.9.3.3 4.9.3.4 4.9.3.4.1

4.9.3.4.2

4.9.3.4.3 4.9.4 4.9.4.1

records of breakage Wood Restricted use, monitoring of condition Foreign body detection and removal equipment Foreign body detection and removal equipment Risk assessment to assess need choice and installation based on industry best practice System testing frequency risk based Investigation and trend analysis of findings Filters and sieves Investigation and trend analysis of findings inspected and checks recorded Metal detectors and x-ray Risk assessment to assess need. Justification for absence choice and installation based on industry best practice Reject or stop and alarm system Operating and testing procedures. x x

4.10

4.10.1 4.10.1.1 4.10.1.2 4.10.1.3 4.10.1.4 4.10.2 4.10.2.1 4.10.2.2 4.10.3 4.10.3.1 4.10.3.2 4.10.3.3 4.10.3.4

findings report / investigations /trend analysis

4.10.3.5 4.10.3.6 4.10.4 4.10.4.1 4.10.5 4.10.5.1 4.10.6 4.10.6.1 4.10.6.2

checks to include: - labelled test pieces, ferrous stainless and non-ferrous, detect and reject tested, memory / reset tests, use of sample test packs Test failure procedure Magnets Magnet specification, inspection, cleaning and testing Optical sorting Operating and testing procedures. Container cleaning cleaning and protection of containers based on best practice Cleaning effectiveness tests. Housekeeping and hygiene SSOP's Defined expectations for cleaning Time and resources for effective cleaning Cleaning verification Dedicated, distinctive cleaning equipment properly managed CIP Systems monitored and maintained Appropriate desgin and installation, system change log maintained Monitored system conditions, effectiveness testing Waste Licences of waste contractors, including those for recycling x

p p

p p

4.11 4.11.1 4.11.2 4.11.3 4.11.4 4.11.5 4.11.6 4.11.6.1 4.11.6.2 4.11.6.3 4.12 4.12.1

x P

schematic

contracts / licences

4.12.2 4.12.3

Food waste and animal feed streams segragated External waste collection identified and maintained Unsafe or trademarked materials appropriately denatured and destroyed Pest control Competent persons perform risk assessment and manage pest control If company managed pest control, effective competency and systems in place x

contract, training or licencing licencing, training records, chemical controls licence, record of destruction

4.12.4 4.13 4.13.1

4.13.2

4.13.3 4.13.4 4.13.5 4.13.6 4.13.7 4.13.8 4.13.9

Adequate pest control documentation and records Outdoor baits secured in place, no rodenticides indoors Bug lights appropriately locted and functional Approprate actions in the event of infestation Inspection records and follow up of recommendations Additional effectiveness survey, typically quarterly Trend analysis of inspections and catch records minimum annually

site map, product specifications, pest control reports

pest inspection records

effectiveness report

trend analysis

4.14

Storage facilities Procedures adequate to ensure product integrity during storage are in place, understood and followed

4.14.1

4.14.2

Where temperature control is required, it is sufficient and monitored Where controlled atmosphere is required, it is maintained and records maintained Stock rotation systems are effectively in place during storage Shipping and transportation Product integrity is maintained during loading Traceability is maintained during shipping Pre-load inspections performed and recorded Where temperature control is required, it is documented Unloading equipment maintained and clean Transport procedures to ensure product integrity, including security and breakdown Sub-contracted transportation meets all requirements of section 4.15 Product control Design and development Guidelines and restrictions on R&D introducing new hazards HACCP review completed prior to product introduction to operations P

temperature monitoring

4.14.3 4.14.5

4.15 4.15.1 4.15.2 4.15.3 4.15.4 4.15.5

shipping records indicate lots

inspection records temperature monitoring records

4.15.6 4.15.7 5 5.1 5.1.1 5.1.2

P

contract, load sign off documents

R&D review policy

5.1.3 5.1.4

Product trials where needed to validate process Shelf life trails or data completed Label design satisfies requirements and regulations of country of sale Lable claims have validated evidence Allergen management Risk assessment as to potential for raw materials to be contaminated with allergens List showing all allergens on site Risk assessment to identify vectors of allergen contamination Documented allergen segregation procedures in place and effective If rework of allergen containing materials is carried out, appropriate controls in place If contamination connot be effectively controlled, appropriate consumer lable warnings in place Validation of allergen free label claims Allergen cleaning procedures validated and verified. Allergen cleaning equipment segragated and identified All persons entering the site shall have allergen awareness training x

supplier certification or questionaires what and where allergens are found target market label regulations and approval process

5.1.5 5.1.6

5.2

5.2.1 5.2.2 5.2.3 5.2.4

x x x P

5.2.5

5.2.6 5.2.7

validation studies

5.2.8 5.2.9

cleaning validation studiues visitor and contractor training

5.2.10 Provenance and assured status

Effective packaging changeover system

5.3 5.3.1

Where provenance is required, raw material verification in place Records of material provenance maintained. Mass balance every 6 months Process flow specific to assured status products documented and appropriate controls to maintain in place

certificates for raw materials

5.3.2

mass balance results

5.3.3

flow diagram specific to assured status product

5.4

Product packaging Documented evidence of suitability based on intended use for all packaging Storage conditions suitable to maintain packaging integrity. Obsolete packaging suitably controlled Product contact liners for work in process and ingredients purchased by the company appropriately colored Inspection and testing Product inspection and testing Product testing program based on risk

proof of material compatability

5.4.1

5.4.2

5.4.3

5.5

5.5.1 5.5.1.1

5.5.1.2 5.5.1.3 5.5.2 5.5.2.1 5.5.2.2 Lab testing

Results reviewed, analyzed, and where needed, acted upon Ongoing shelf life studies in place

trend analysis

Pathogen testing fully segragated Laboratory controls in place to prevent contamination Critical lab testing performed by accredted laborotory, or in accordance to accredtation guidelines Good lab practices in place Product release Where required, positive release procedures fully implemented Process controls Control of operations Process specifications and work instructions available and suitable Process monitoring in place to esnure production meets specifications If process controls are automated, suitable tested failure alert system is in place Process validation frequency basd on risk Procedures to evaluate product in the event of process deviation Product changeover procedure x P P

changeover pre-op inspections process validation matrrix

5.5.2.3 5.5.2.4 5.6 5.6.1 6 6.1 6.1.1

x x

lab accreditation

6.1.2

6.1.3 6.1.4 6.1.5 6.1.6

6.1.7

Product packaging verification

packaging verification checks

6.2 6.2.1 6.2.2 6.3

Quantity control Weight control programs meet regulatory requirements Weight control programs meet customer specifications Calibration Equipment to be calibrated is: documented, identified, scheduled, protected Calibration frequency based on risk and procedures based on standard Reference calibration equipment traceable to Standard Procedures to follow in the event of equipment found out of calibration and product potentially at risk Personnel Training Pre-employment training for staff, temps and contractors Training relevant to CCP`s Assessment and delivery plan for staff training Records of training Staff competency and training effectiveness assessments x x

job / training matrix regulation for country of destination

6.3.1 6.3.2 6.3.3

calbration methods and matrix calbration certificate of standards

6.3.4 7 7.1 7.1.1 7.1.2 7.1.3 7.1.4 7.1.5

7.2

Personal hygiene

jewelry policy

7.2.1 7.2.2

Policies for jewelry, nail care and personal hygiene Hand cleaning on entry to production areas Cuts protected, bandages appropriately colored, meteal detectable. If metal detectors are present, bandages are tested for detection Personal medicine policy and procedure x

7.2.3 7.2.4 7.2.5

x P

test results

7.3

Medical screening Procedure for employees to notify site of sickness or sympton if relevant Notification to visitors of health and sickness risk and procedures Procedure for site to follow if employees or visitors indicate they may be suffering from a relevant disease Protective clothing Protctive clothing policy, including wearing outside of the work environment Protective clothing is suitable to protect the product Work wear laundered by service contractor or in house. Self laundry only for enclosed or low risk zones

7.3.1 7.3.2

P P

7.3.3

7.4

7.4.1 7.4.2

7.4.3

7.4.4 7.4.5 7.4.6

Laundry for HC / HR areas includes: laundry procedures, commercial sterilization, segragation, protection of clean work wear Gloves suitable for purpose, preferably colored. Non-launderable articles maintained clean and sanitary.

A=Assess Assess during facility E=Evidence tour I=Interview

A A A

A A High care / high risk

Clause

Event

Expectation

Evidence

Outcome Issues identified, action plans in place, resources allocated, targets defined, verification of results

1.1.3

Senior management review

Meeting to ensure food safety and quality measures are in place and appropriate action plans managed Meeting minutes

1.1.4

Management meetings

Program of meetings to track objectives, issues and ongoing operational results Ensure flow diagrams used within the HACCP plan and other areas are up to date and accurate

Meeting minutes Singed and dated flow diagrams, or other evidance of their verification

Periodic review of objectives and operational performance, a means of steering the operation to ensure overall goals are met and maintained. Data analysis for senior management review. Flow diagrams support control activities, reported in internal audit

2.6.1

Verification of HACCP flow diagrams

2.14.1

HACCP review

Comprehensive review of the HACCP plan, to ensure it is effectively in place and adequately manages risk within the operation Review notes All clauses and requirements of the stadnard are audited to ensure effective compliance

HACCP plan accurately reflects the process. Reported to senior management review

3.4.1

Internal audit

Documented evidence showing conformance to the standard. Reproted to senior Internal audit report management review Site conditions and activities meet expectations. Reported to monthly management meetings

3.4.4

Internal inspections

Environmental and hygiene programs and results audited and inspected

Inspection report

3.6.5

Specifications

Specifications are periodically reviewed to ensure accuracy to current operations

Specification review Site ensures program or dated specifications are up to specifications date.

3.9.2

3.11.3 4.2.1

Mass balance of finished goods, raw materials and Traceability test packaging tested Recall procedure is validated and tested to ensure operational readiness and Recall test effectiveness Security risk Operation security risks assessment assessed

Test results

Full traceability achieved within 4 hours

Test report Security risk assessment report

Opportunity for process improvements Opportunity for improvements

Minimum frequency

Annual

Monthly

Annual, or in the event of changes

Annual, or in the event of changes

Annual, or more frequent based on risk

Monthly

Every 3 years or more as required

Annual

Annual Annual

S-ar putea să vă placă și

- BRC Issue 8 UpdateDocument37 paginiBRC Issue 8 Updatelaurentiu29100% (1)

- BRC Gap AnalysisDocument11 paginiBRC Gap AnalysisChiekoi PasaoaÎncă nu există evaluări

- Procurment in Emergency SituationsDocument2 paginiProcurment in Emergency Situationspalani velanÎncă nu există evaluări

- How To Set Up Sampling Zone For An Environmental Monitoring ProgramDocument46 paginiHow To Set Up Sampling Zone For An Environmental Monitoring ProgramAsep R100% (1)

- CCP and OprpDocument5 paginiCCP and OprpGorack ShirsathÎncă nu există evaluări

- Haccp ManualDocument51 paginiHaccp ManualJack Mata100% (2)

- Taccp Presentation PDFDocument36 paginiTaccp Presentation PDFAnous Alami100% (1)

- Ingredient Supplier Assessment QuestionnaireDocument24 paginiIngredient Supplier Assessment QuestionnaireVladimir JankovÎncă nu există evaluări

- BSI Allergen Risk Assessment (1) .NHDXSZDocument7 paginiBSI Allergen Risk Assessment (1) .NHDXSZRosinanteÎncă nu există evaluări

- SOP Allergen ControlDocument3 paginiSOP Allergen ControlyolasusantoÎncă nu există evaluări

- Summary of BRC Global Food Safety Standard Issue 6 Changes Landscape 110111 PDFDocument28 paginiSummary of BRC Global Food Safety Standard Issue 6 Changes Landscape 110111 PDFEileen OngÎncă nu există evaluări

- BRC WorkbookDocument32 paginiBRC WorkbookSâu Mập ÚÎncă nu există evaluări

- Fsms Iso 22000Document93 paginiFsms Iso 22000sajid waqasÎncă nu există evaluări

- BRC Risk AssessmentDocument54 paginiBRC Risk AssessmentGaganpreet100% (5)

- HACCP Example - KraftDocument83 paginiHACCP Example - KraftRichard Ingram100% (2)

- Iso 22000 Checklist Fsms f6.4-22 (FSMS)Document14 paginiIso 22000 Checklist Fsms f6.4-22 (FSMS)BRIGHT DZAHÎncă nu există evaluări

- GG039 GlobalG.A.P. Food Defense Risk Assessment SampleDocument11 paginiGG039 GlobalG.A.P. Food Defense Risk Assessment SampleBhuvanesh Waran100% (2)

- G65 BRC Checklist (1aug10)Document15 paginiG65 BRC Checklist (1aug10)almasofia3Încă nu există evaluări

- OPRP 4 Management of Cleaning ValidationDocument1 paginăOPRP 4 Management of Cleaning ValidationJuan Pablo Azcuña C.Încă nu există evaluări

- AIB HACCP Checklist2007Document9 paginiAIB HACCP Checklist2007m125esteban2003Încă nu există evaluări

- Environmental Monitoring ProgramDocument4 paginiEnvironmental Monitoring ProgramJoyster AvilaÎncă nu există evaluări

- Audit Report Template FSSC-22000 - 2018Document21 paginiAudit Report Template FSSC-22000 - 2018Tanzila Siddiqui100% (1)

- 1 Developing A Food Safety PlanDocument8 pagini1 Developing A Food Safety PlanJulius MuhimboÎncă nu există evaluări

- Methodology For Determination of Hazard Controls CCP S and OPRP SDocument4 paginiMethodology For Determination of Hazard Controls CCP S and OPRP SRosinanteÎncă nu există evaluări

- FSSC 22000 FSMS Implementation Package V5.1 BrochureDocument44 paginiFSSC 22000 FSMS Implementation Package V5.1 BrochureSutha Tamil Nambe100% (1)

- BRC Implementation Workbook SampleDocument24 paginiBRC Implementation Workbook SampleErki KippastoÎncă nu există evaluări

- FSSC 22000 V5.1 Training Matrix 2021 TOOLDocument5 paginiFSSC 22000 V5.1 Training Matrix 2021 TOOLdiana ungureanuÎncă nu există evaluări

- Comparison of TS ISO 22002-1 & PAS 223Document4 paginiComparison of TS ISO 22002-1 & PAS 223AnilZapateÎncă nu există evaluări

- Tesco PIU Guidelines On The Audit Process For Sites Supplying TescoDocument7 paginiTesco PIU Guidelines On The Audit Process For Sites Supplying TescoGourav TailorÎncă nu există evaluări

- 14 Rapporto Audit BRC Addendum 8 Emiss Gennaio 16 L 1 607Document27 pagini14 Rapporto Audit BRC Addendum 8 Emiss Gennaio 16 L 1 607Phuong NguyenÎncă nu există evaluări

- FSSC Training ReportDocument6 paginiFSSC Training ReportGilbert AgudoÎncă nu există evaluări

- Food Traceability Template for Production and Dispatch RecordsDocument4 paginiFood Traceability Template for Production and Dispatch RecordsCharles J KunjumonÎncă nu există evaluări

- Example HACCP StudyDocument10 paginiExample HACCP StudyAdnan MeghaniÎncă nu există evaluări

- FSSC V5 2019Document30 paginiFSSC V5 2019danuÎncă nu există evaluări

- BRC Global Standard For Food Safety Issue 7 Voluntary Module 11 Meat Supply Chain Free PDFDocument15 paginiBRC Global Standard For Food Safety Issue 7 Voluntary Module 11 Meat Supply Chain Free PDFMiguel Ernesto Lacayo ChávezÎncă nu există evaluări

- Protocol For Validation of FSMS - FinalVersionDocument25 paginiProtocol For Validation of FSMS - FinalVersionChel Zalamea Domingo100% (1)

- Product withdrawal procedureDocument5 paginiProduct withdrawal procedureGorack ShirsathÎncă nu există evaluări

- FSMA - GMP ChecklistDocument10 paginiFSMA - GMP Checklistaji sulaimanÎncă nu există evaluări

- Allergen ControlDocument2 paginiAllergen ControlPoulami De100% (1)

- The Changes in ISO 22000-2018 and The Implications For FSSC 22000Document29 paginiThe Changes in ISO 22000-2018 and The Implications For FSSC 22000jo100% (1)

- F048 - Understanding High Care and High Risk 3 21 9 12 FinalDocument19 paginiF048 - Understanding High Care and High Risk 3 21 9 12 Finalshakeyken0% (1)

- New Guideline Document From FSSC 22000 in July 2023Document20 paginiNew Guideline Document From FSSC 22000 in July 2023ahmedÎncă nu există evaluări

- sfc2017 Environmental MonitoringDocument74 paginisfc2017 Environmental MonitoringLuis Gutiérrez100% (2)

- IFS Food Defense Implementation Guidelines Jan 2012 EnglishDocument16 paginiIFS Food Defense Implementation Guidelines Jan 2012 Englishnmmartinsa100% (1)

- FSMS Compliance ChecklistDocument18 paginiFSMS Compliance ChecklistJose III LlanetaÎncă nu există evaluări

- How To Establish An FSSC 22000 ProgramDocument16 paginiHow To Establish An FSSC 22000 ProgramfaisalÎncă nu există evaluări

- Critical Elements For EMPDocument54 paginiCritical Elements For EMPGaganpreet KaurÎncă nu există evaluări

- Procedure Manual: Function: Haccp Support Programs Title: Allergen ManagementDocument3 paginiProcedure Manual: Function: Haccp Support Programs Title: Allergen Managementajan76100% (1)

- VACCP - Food Fraud PreventionDocument28 paginiVACCP - Food Fraud Preventionnichecon1100% (4)

- Managing Pest Control Under 40 CharactersDocument2 paginiManaging Pest Control Under 40 CharactersAnggerÎncă nu există evaluări

- VACCP and TACCP food safety plansDocument4 paginiVACCP and TACCP food safety planscarlaÎncă nu există evaluări

- Ha CCP Document Record FormsDocument23 paginiHa CCP Document Record FormsFlorence Reid100% (1)

- 2) AUA Training - ISO 22000Document45 pagini2) AUA Training - ISO 22000adhavanannathuraiÎncă nu există evaluări

- IFS Food Defense GuidelinesDocument16 paginiIFS Food Defense GuidelinesCarlos Rosete100% (2)

- The Food Safety Enhancement Program Approach To A Preventive Control Plan - Canadian Food Inspection AgencyDocument39 paginiThe Food Safety Enhancement Program Approach To A Preventive Control Plan - Canadian Food Inspection AgencyAndreiÎncă nu există evaluări

- EMP Environmental Monitoring ProgramDocument10 paginiEMP Environmental Monitoring Programkiagus artaÎncă nu există evaluări

- ISO 22000 - Documentation Requirement SummaryDocument10 paginiISO 22000 - Documentation Requirement SummaryminhajurrehmanÎncă nu există evaluări

- BRC FOOD ISSUE 8 - Understanding The Requirements PDFDocument13 paginiBRC FOOD ISSUE 8 - Understanding The Requirements PDFCarlos Rosete100% (1)

- Validating Preventive Food Safety and Quality Controls: An Organizational Approach to System Design and ImplementationDe la EverandValidating Preventive Food Safety and Quality Controls: An Organizational Approach to System Design and ImplementationEvaluare: 5 din 5 stele5/5 (1)

- FSMA and Food Safety Systems: Understanding and Implementing the RulesDe la EverandFSMA and Food Safety Systems: Understanding and Implementing the RulesÎncă nu există evaluări

- 2016 ContractorSafetyMeetingDocument176 pagini2016 ContractorSafetyMeetingLedo HoussienÎncă nu există evaluări

- Element 4.0 - The (Swot) MatrixDocument46 paginiElement 4.0 - The (Swot) MatrixLedo HoussienÎncă nu există evaluări

- For Produced HerbsDocument1 paginăFor Produced HerbsLedo HoussienÎncă nu există evaluări

- Management System Certification Audit Summary ReportDocument8 paginiManagement System Certification Audit Summary ReportLedo HoussienÎncă nu există evaluări

- M3097 - 2 SSMDocument13 paginiM3097 - 2 SSMLedo HoussienÎncă nu există evaluări

- Effective Occupational Safety and Health Management System: Integration of OHSAS 18001, ILO-OSH 2001, and Or-OshaDocument18 paginiEffective Occupational Safety and Health Management System: Integration of OHSAS 18001, ILO-OSH 2001, and Or-Oshaazniwani83Încă nu există evaluări

- 4.0 Context of The Organization: © 2014 Cavendish Scott, IncDocument9 pagini4.0 Context of The Organization: © 2014 Cavendish Scott, IncLedo HoussienÎncă nu există evaluări

- Planning Integrated Management System Audit To Ensure Conformance, Consistency and Continual ImprovementDocument13 paginiPlanning Integrated Management System Audit To Ensure Conformance, Consistency and Continual ImprovementIOSRjournalÎncă nu există evaluări

- 1-Importance of A ShmsDocument43 pagini1-Importance of A Shmsmskumar_554Încă nu există evaluări

- BV Quality Certification Transition Policy FOR ISO 9001:2015 AND ISO 14001:2015. (TP/01)Document2 paginiBV Quality Certification Transition Policy FOR ISO 9001:2015 AND ISO 14001:2015. (TP/01)Ledo HoussienÎncă nu există evaluări

- Verifying The Effectiveness of Corrective ActionDocument46 paginiVerifying The Effectiveness of Corrective ActionLedo Houssien100% (4)

- ISO 9001 Client Transition ChecklistDocument11 paginiISO 9001 Client Transition Checklisttimisite247Încă nu există evaluări

- Checklist According To DIN EN ISO 14065:2013 For Greenhouse Gas Validation and Verification BodiesDocument16 paginiChecklist According To DIN EN ISO 14065:2013 For Greenhouse Gas Validation and Verification BodiesLedo Houssien0% (1)

- OHSAS18001Document67 paginiOHSAS18001Anand Dubey100% (1)

- 021 BSCI Initial Audit ReportDocument12 pagini021 BSCI Initial Audit ReportLedo HoussienÎncă nu există evaluări

- 2 Page QMS ManualDocument3 pagini2 Page QMS ManualLedo HoussienÎncă nu există evaluări

- Module 5 LKLJKDocument12 paginiModule 5 LKLJKLedo HoussienÎncă nu există evaluări

- 7.0 Service RealizationDocument35 pagini7.0 Service RealizationLedo HoussienÎncă nu există evaluări

- ISO 17021-1 2015gg Documentation KitDocument9 paginiISO 17021-1 2015gg Documentation KitLedo HoussienÎncă nu există evaluări

- Int Management Review PDFDocument2 paginiInt Management Review PDFLedo HoussienÎncă nu există evaluări

- Update On ISO 9000 and OHSAS 18001, SII, 2005-05, C CorrieDocument58 paginiUpdate On ISO 9000 and OHSAS 18001, SII, 2005-05, C CorrieSunnyfrombiotechÎncă nu există evaluări

- IMS ProceduresdsffdsaDocument4 paginiIMS ProceduresdsffdsaLedo HoussienÎncă nu există evaluări

- 2 Page QMS ManualDocument3 pagini2 Page QMS ManualLedo HoussienÎncă nu există evaluări

- bms.0630 r0 Management of Change PDFDocument3 paginibms.0630 r0 Management of Change PDFLedo HoussienÎncă nu există evaluări

- Burj Al Arab HseDocument2 paginiBurj Al Arab HseLedo HoussienÎncă nu există evaluări

- Audit Report Form Stage 2Document11 paginiAudit Report Form Stage 2muthuswamy77Încă nu există evaluări

- ISO 14001 Transition ChecklistDocument9 paginiISO 14001 Transition ChecklistLedo HoussienÎncă nu există evaluări

- Enviroemntal Oil and Gas Project Management PDFDocument76 paginiEnviroemntal Oil and Gas Project Management PDFOrtiz CatalinaÎncă nu există evaluări

- Correlation & Regression Analysis GuideDocument40 paginiCorrelation & Regression Analysis Guidejames smithÎncă nu există evaluări

- Introduction To Data Analysis Handbook - PartIIDocument23 paginiIntroduction To Data Analysis Handbook - PartIIIp GhosTÎncă nu există evaluări

- Everest Group Talent Availability For Auto Engineering ServicesDocument39 paginiEverest Group Talent Availability For Auto Engineering ServicesVivek SengarÎncă nu există evaluări

- Havells AR 2017-18 PDFDocument139 paginiHavells AR 2017-18 PDFMAHENDRA GUPTA100% (1)

- Data-Driven Business Models TaxonomyDocument16 paginiData-Driven Business Models TaxonomyMery Citra SondariÎncă nu există evaluări

- Adolescents' Health Literacy, Health Protective Measures, and Health-Related Quality of Life During The Covid-19 PandemicDocument13 paginiAdolescents' Health Literacy, Health Protective Measures, and Health-Related Quality of Life During The Covid-19 PandemicGusti RamadhanÎncă nu există evaluări

- MFDM™ AI - The Renaissance - QUIZ - Atualizado - RespDocument10 paginiMFDM™ AI - The Renaissance - QUIZ - Atualizado - RespIgorJales67% (49)

- 2359-Article Text-7873-1-10-20230314Document8 pagini2359-Article Text-7873-1-10-20230314Hợp ĐứcÎncă nu există evaluări

- Research Methods Module 1Document11 paginiResearch Methods Module 1Uday GowdaÎncă nu există evaluări

- Simple Linear Regression Model Ordinary Least Square (OLS) MethodDocument18 paginiSimple Linear Regression Model Ordinary Least Square (OLS) MethodhelloÎncă nu există evaluări

- CI Project Guidebook v1.0Document137 paginiCI Project Guidebook v1.0Joyce CarreonÎncă nu există evaluări

- Completely Randomized DesignDocument5 paginiCompletely Randomized DesignQuinn's Yat100% (3)

- Running Head: Lived Experiences of Teenage Single Mothers Pursuing Higher EducationDocument14 paginiRunning Head: Lived Experiences of Teenage Single Mothers Pursuing Higher EducationMavel DesamparadoÎncă nu există evaluări

- Faculty of Computer & Mathematical Sciences Time Series Analysis and Forecasting (Sta570) Assessment 3 Forecasting The Market Stock Price of PadiniDocument21 paginiFaculty of Computer & Mathematical Sciences Time Series Analysis and Forecasting (Sta570) Assessment 3 Forecasting The Market Stock Price of PadiniesshadieqÎncă nu există evaluări

- Icles' Motilal Jhunjhunwala College, Vashi IT& CS DepartmentDocument41 paginiIcles' Motilal Jhunjhunwala College, Vashi IT& CS DepartmentBharat PoojaryÎncă nu există evaluări

- Margareta Nordin, Gunnar B. J. Andersson, M. H. Pope - Musculoskeletal Disorders in The Workplace - Principles and Practice, 2nd Edition (2006)Document403 paginiMargareta Nordin, Gunnar B. J. Andersson, M. H. Pope - Musculoskeletal Disorders in The Workplace - Principles and Practice, 2nd Edition (2006)Kings AndrewÎncă nu există evaluări

- SB3203 Research Method & Data AnalysisDocument2 paginiSB3203 Research Method & Data AnalysisHenriettah NakisoziÎncă nu există evaluări

- Evaluation of Relative Importance of Environmental Issues Associated With A Residential Estate in Hong KongDocument13 paginiEvaluation of Relative Importance of Environmental Issues Associated With A Residential Estate in Hong KongMohammed Younus AL-BjariÎncă nu există evaluări

- Semester 5: WN Question PapersDocument1 paginăSemester 5: WN Question PapersRahul ThoratÎncă nu există evaluări

- 2021 01 Slides l4 MLDocument253 pagini2021 01 Slides l4 MLsajjad BalochÎncă nu există evaluări

- Exploring Marketing Research: Exploratory Research and Qualitative AnalysisDocument30 paginiExploring Marketing Research: Exploratory Research and Qualitative Analysisadil sheikhÎncă nu există evaluări

- Implementasi Data Mining Clustering Tingkat Kepuasan Konsumen Terhadap Pelayanan Go-JekDocument7 paginiImplementasi Data Mining Clustering Tingkat Kepuasan Konsumen Terhadap Pelayanan Go-JekM Yanualdi FajriÎncă nu există evaluări

- DWDM Unit-5Document52 paginiDWDM Unit-5Arun kumar SomaÎncă nu există evaluări

- Impact of CRM Practices On Organization Performance With Spe-Cial Reference To Selected Pharmaceutical Companies in Rajasthan RegionDocument24 paginiImpact of CRM Practices On Organization Performance With Spe-Cial Reference To Selected Pharmaceutical Companies in Rajasthan RegionArnab DasÎncă nu există evaluări

- Regression: Variables Entered/RemovedDocument2 paginiRegression: Variables Entered/RemovedAryanÎncă nu există evaluări

- Uses and Gratifications Theory and Digital Media Use - The Test of Emotional FactorsDocument10 paginiUses and Gratifications Theory and Digital Media Use - The Test of Emotional FactorsGlobal Research and Development ServicesÎncă nu există evaluări

- Design Manual for Small Scale Irrigation SchemesDocument93 paginiDesign Manual for Small Scale Irrigation SchemesRajendra K Karki100% (1)

- Social Determinants of Health and Adolescent Pregnancy: An Analysis From The National Longitudinal Study of Adolescent To Adult HealthDocument8 paginiSocial Determinants of Health and Adolescent Pregnancy: An Analysis From The National Longitudinal Study of Adolescent To Adult HealthLegawati P2KS Prov KaltengÎncă nu există evaluări

- Impact of AIS on Organizational EffectivenessDocument39 paginiImpact of AIS on Organizational EffectivenessKyle Baladad50% (2)

- Benefits of A Multipurpose Furniture To The Selected Senior High School Students of EacDocument68 paginiBenefits of A Multipurpose Furniture To The Selected Senior High School Students of EacEarl TamayoÎncă nu există evaluări