Documente Academic

Documente Profesional

Documente Cultură

1375 04 0879 p4

Încărcat de

rkadiraj7011Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1375 04 0879 p4

Încărcat de

rkadiraj7011Drepturi de autor:

Formate disponibile

Chinese Chemical Letters Vol. 16, No. 10, pp 1375-1378, 2005 http://www.imm.ac.cn/journal/ccl.

html

1375

Energy Storage Properties of Phase Change Materials Prepared from PEG/CPP

Ya Nan ZANG1,2, En Yong DING1

1

Key Laboratory of Cellulose and Lignocellulosics Chemistry, Guangzhou Institute of Chemistry, Chinese Academy of Sciences, Guangzhou 510650 2 Graduate School of the Chinese Academy of Sciences, Beijing 100039

Abstract: New kinds of solid-solid phase change materials have been prepared in our laboratory. In these materials, the rigid polymer chlorinated polypropylene is taken as skeletons and the flexible polymer polyethylene glycol 6000 and polyethylene glycol 10000 are taken as functional chains. Results show that chlorinated polypropylene grafted by polyethylene glycol 10000 has greater enthalpy than chlorinated polypropylene grafted by polyethylene glycol 6000. Keywords: Polyethylene glycol, chlorinated polypropylene, phase change materials.

Latent heat storage is one of the most efficient ways of storing thermal energy. Unlike the sensible heat storage method, the latent heat storage method provides much higher storage density, with a smaller temperature difference between storing and releasing heat. Phase change materials (PCMs) can be used for energy storage and temperature control1,2. Among them, the solid-solid phase change materials are focus of attention 3, 4. They can be applied in many fields such as solar energy utilization, waste heat recovery, electric appliances with thermostatic regulators and so on5. In our laboratory, new kinds of solid-solid phase change materials with netted structure had been prepared. In these materials, chlorinated polypropylene (CPP) was taken as skeletons. Chlorinated polypropylene is chemical stable and mechanical sturdy. Polyethylene glycol (PEG) with average molecular weight 6000 and 10000 were taken as functional branch chains. The results show that the chlorinated polypropylene grafted by polyethylene glycol 10000 has greater enthalpy than chlorinated polypropylene grafted by polyethylene glycol 6000. Experimental All reactions were carried out according to the following procedure6. Water was separated as toluene azeotrope from the solution of polyethylene glycol 6000 (18 g, [OH] 0.006 mol) in 80 mL of toluene. Sodium (0.138 g, [Na]0.006 mol) was added to this solution. The metalation of hydroxyl group in polyethylene glycol 6000 was carried out

E-mail: Dingey@gic.ac.cn

1376

Ya Nan ZANG et al.

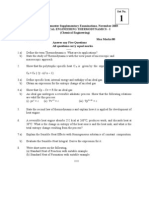

under reflux with stirring for 20 h under nitrogen at 115 . The reaction solution became dark brown. This reaction mixture was used in the next procedure. In a 250 mL four-necked round bottled flask, the solution of chlorinated polypropylene (0.82 g, [Cl]0.006 mol) in 40 mL toluene was added. The dark-brown solution of sodium alkoxide derivative of polyethylene glycol 6000 was added dropwise, and the reaction mixture was stirring vigorously at 85 in an oil bath under nitrogen for the prescribed time. Then toluene of the solution was removed. The resulted polymer was washed by distilled water and then dried in vacuum at room temperature. Chlorinated polypropylene grafted by polyethylene glycol 10000 reacted like chlorinated polypropylene grafted by polyethylene glycol 6000. Results and Discussion Figure 1 shows the framework vibration FT-IR spectra for chlorinated polypropylene grafted by polyethylene glycol 6000 (a), chlorinated polypropylene grafted by polyethylene glycol 10000 (b), and chlorinated polypropylene (c). It can be seen that the absorption bands due to COC stretching vibration of the ether group are detected at about 1100cm-1 in both PEG6000/CPP and PEG10000/CPP phase change materials. The thermal behaviors of PEG6000/CPP and PEG10000/CPP phase change materials were measured by DSC at the heating and the cooling rate of 5/min in nitrogen atmosphere. From Figure 2, the enthalpy of chlorinated polypropylene grafted by polyethylene glycol 6000 is 67.5 J/g. From Figure 3, the enthalpy of chlorinated polypropylene grafted by polyethylene glycol 10000 is 142.5 J/g. The results showed that chlorinated polypropylene grafted by polyethylene glycol 10000 has greater enthalpy than chlorinated polypropylene grafted by polyethylene glycol 6000. One of the causes

Figure 1 FTIR spectra and partial enlarged FTIR spectra

Transmittance %

4000

3000 2000 Wavenumber(cm-1)

1000

1200

1000 800 Wavenumber(cm-1)

(a) chlorinated polypropylene grafted by polyethylene glycol 6000, (b) chlorinated polypropylene grafted by polyethylene glycol 10000, (c) chlorinated polypropylene

Energy Storage Properties of Phase Change Materials

1377

Figure 2 The DSC curve of chlorinated polypropylene grafted by polyethylene glycol 6000

Figure 3 The DSC curve of chlorinated polypropylene grafted by polyethylene glycol 10000

is that the crystallinity reaches the maximum when the molecular weight is 10,000, i.e. the number of segments (CH2CH2O) is about 2277. If the number of segments was less than 227, the crystallization of the whole number of segments could decline, so the enthalpy decreased. If the number of the segments was more than 227, the chain was too long, it would tangle together, and impede to form well-defined crystal. Therefore, above two factors work together and lead to crystallinity and the enthalpy reach the maximum when the molecular weight is 10000. So that chlorinated polypropylene grafted by polyethylene glycol 10000 has greater enthalpy. In conclusion, by chemical methods, the new kinds of phase changed materials were prepared by chemical methods. The results showed that the chlorinated polypropylene grafted by polyethylene glycol 10000 has greater enthalpy than the chlorinated polypropylene grafted by polyethylene glycol 6000.

1378

Ya Nan ZANG et al.

References

1. 2. 3. 4. 5. 6. 7. S. L. Harlan, ACS Symp. Ser., 1991, 457, 248. R. E. Frye, U. S. P5066411, 1991. T. Kondo, M. Tanaka, Y. Tamiguichi, et al., J. P06108043, 1994. M. A. Hamdan, F. A. Elwerr, Solar Energy, 1996, 56 (2), 183. Y. Jiang, E. Y. Ding, G. K. Li, Guangzhou Chemistry, 1999, 3, 48. Z. Y. Xie, M. Li, X. F. Chen, et al., J. Appl. Polym. Sci., 1996, 61, 495. Y. Jiang, E. Y. Ding, G. K. Li, Polymer, 2002, 43 (1), 117.

Received 6 December, 2004

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Projection of PlanesDocument36 paginiProjection of Planesrkadiraj7011Încă nu există evaluări

- 1878set 1Document2 pagini1878set 1rkadiraj7011Încă nu există evaluări

- Chapter 2-Thermodynamics 1Document12 paginiChapter 2-Thermodynamics 1rkadiraj7011Încă nu există evaluări

- Epfl TH4805Document176 paginiEpfl TH4805rkadiraj7011Încă nu există evaluări

- ENMA490 Final Presentation Sp06Document31 paginiENMA490 Final Presentation Sp06rkadiraj7011Încă nu există evaluări

- Filmetrics - Advanced Thin Film MeasurementDocument12 paginiFilmetrics - Advanced Thin Film Measurementrkadiraj7011Încă nu există evaluări

- Labs-Engineering Drawing Lab 2Document7 paginiLabs-Engineering Drawing Lab 2rkadiraj7011Încă nu există evaluări

- Engineering CurvesDocument4 paginiEngineering Curvesrkadiraj7011Încă nu există evaluări

- Jawaharlal Nehru Technological University Hyderabad: Kukatpally, Hyderabad - 500 085, Andhra Pradesh (India)Document2 paginiJawaharlal Nehru Technological University Hyderabad: Kukatpally, Hyderabad - 500 085, Andhra Pradesh (India)rkadiraj7011Încă nu există evaluări

- Intersection of SolidsDocument6 paginiIntersection of Solidsrkadiraj7011Încă nu există evaluări

- Engineering Thermodynamics Lecture Notes (Draft) : Wayne HackerDocument24 paginiEngineering Thermodynamics Lecture Notes (Draft) : Wayne Hackerrkadiraj7011Încă nu există evaluări

- Dmm1 Lesson PlanDocument65 paginiDmm1 Lesson Planrkadiraj7011100% (1)

- A Review On Phase Change Energy Storage - Materials and ApplicationsDocument19 paginiA Review On Phase Change Energy Storage - Materials and Applicationsrkadiraj7011Încă nu există evaluări

- Entry Level RecruitmentDocument4 paginiEntry Level Recruitmentrkadiraj7011Încă nu există evaluări

- 6th Class State Syllabus Scholarship Test PaperDocument9 pagini6th Class State Syllabus Scholarship Test PaperChandra Sekhar69% (45)

- Em Lab-II ManualDocument45 paginiEm Lab-II Manualrkadiraj701150% (4)

- Genetic Algorithms: and Other Approaches For Similar ApplicationsDocument83 paginiGenetic Algorithms: and Other Approaches For Similar Applicationsveerapandian29Încă nu există evaluări

- Mental Arithmetic Level I Model Paper IDocument10 paginiMental Arithmetic Level I Model Paper Irkadiraj7011Încă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- UiPath Automation and AI Trends 2024Document16 paginiUiPath Automation and AI Trends 2024myschool.appliÎncă nu există evaluări

- Ruwac Master Catalog - Email PDFDocument32 paginiRuwac Master Catalog - Email PDFMiguel Alfonso Ruiz MendezÎncă nu există evaluări

- XL3 N 250 LegrandDocument12 paginiXL3 N 250 LegrandxdjqjfrxhiivnpÎncă nu există evaluări

- Tutorial Chap 3Document2 paginiTutorial Chap 3Yaacub Azhari SafariÎncă nu există evaluări

- Em1 (Michael Braungart, William McDonough) Cradle To C (BookFi) PDFDocument202 paginiEm1 (Michael Braungart, William McDonough) Cradle To C (BookFi) PDFstefpravlibitÎncă nu există evaluări

- 737 Incident ReportDocument61 pagini737 Incident ReportAbdul Qadeer Khan100% (1)

- Design of Air IDocument5 paginiDesign of Air IInvedeÎncă nu există evaluări

- International Institute of Management & Technical Studies: Subject Name: Fluid Mechanics - II (GPME2002)Document3 paginiInternational Institute of Management & Technical Studies: Subject Name: Fluid Mechanics - II (GPME2002)hussain lunawadiÎncă nu există evaluări

- 3D Simulation of The Vertical Axis Wind TurbinesDocument4 pagini3D Simulation of The Vertical Axis Wind TurbinesMostafa RashedÎncă nu există evaluări

- An1914 PDFDocument56 paginiAn1914 PDFUpama Das100% (1)

- CV Pedro Neira Eng Peru 03-01-2012-ScribdDocument3 paginiCV Pedro Neira Eng Peru 03-01-2012-ScribdPedro Neira FerrandÎncă nu există evaluări

- ClutchDocument4 paginiClutchtisha revillaÎncă nu există evaluări

- Rick Wakeman - The Cycle of Life (Piano Keyboard)Document19 paginiRick Wakeman - The Cycle of Life (Piano Keyboard)deusdetcoppen100% (1)

- Question Bank of DRCBMDocument11 paginiQuestion Bank of DRCBMrishinathnehruÎncă nu există evaluări

- Comment Faire Un Plan de Dissertation en SesDocument8 paginiComment Faire Un Plan de Dissertation en SesWriteMyPhilosophyPaperMilwaukee100% (1)

- 6head Syrup Filling Line Automatic PDFDocument18 pagini6head Syrup Filling Line Automatic PDFSrinivas0% (1)

- Malaysian Armed Forces Order of Battle Signals PDFDocument2 paginiMalaysian Armed Forces Order of Battle Signals PDFcatracho84Încă nu există evaluări

- NR 220802 Chemical Engineering Thermodynamics IDocument5 paginiNR 220802 Chemical Engineering Thermodynamics ISrinivasa Rao GÎncă nu există evaluări

- 2 CB Amplifier PDFDocument12 pagini2 CB Amplifier PDFDioselle CastilloÎncă nu există evaluări

- Welcome To Errum Marketing Private Limited: Our MissionDocument4 paginiWelcome To Errum Marketing Private Limited: Our MissionGurpreet KaurÎncă nu există evaluări

- HP Alphaserver Es45Document38 paginiHP Alphaserver Es45Tsure11Încă nu există evaluări

- Alteva Mitel 5312 QuikRefGuideDocument2 paginiAlteva Mitel 5312 QuikRefGuideWalter MejiaÎncă nu există evaluări

- Social Studies Content Enhancement Routines Implementation ReviewDocument1 paginăSocial Studies Content Enhancement Routines Implementation Reviewapi-215901090Încă nu există evaluări

- Ovum Trends Customer Engagement 5191349Document20 paginiOvum Trends Customer Engagement 5191349MiguelÎncă nu există evaluări

- 6370 mp-2100.pdf&isFromRegistration 1Document4 pagini6370 mp-2100.pdf&isFromRegistration 1Xuân TrườngÎncă nu există evaluări

- SKGY ProfileDocument37 paginiSKGY ProfileYogendra SharmaÎncă nu există evaluări

- Basic Framework For Submission of Performance-Based SolutionsDocument85 paginiBasic Framework For Submission of Performance-Based Solutionshareeshrp_87515719350% (2)

- Fhwa Hop 06 006 PDFDocument369 paginiFhwa Hop 06 006 PDFashwini thakurÎncă nu există evaluări

- Vectrino Profiler Brochure PDFDocument4 paginiVectrino Profiler Brochure PDFtracto15Încă nu există evaluări

- PM 2 000354 en 01Document32 paginiPM 2 000354 en 01younesÎncă nu există evaluări