Documente Academic

Documente Profesional

Documente Cultură

53

Încărcat de

hoathuytiencbhDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

53

Încărcat de

hoathuytiencbhDrepturi de autor:

Formate disponibile

Macromol. Biosci.

2001, 1, 2529

25

Full Paper: Poly (l-lactide) (PLLA)-degrading enzyme was produced in a liquid culture of Amycolatopsis sp. (strain 41). In comparison with polyester substrates, silk powder from silkworm cocoons was the most effective in inducing enzyme production within 5 d. Application to DEAE and Superdex 75 columns resulted in a major protein with molecular weight estimated to be 42 kDa from size exclusion chromatography or 40 kDa from SDSPAGE analysis. Optimum pH and temperature are 6.0 and 3745 8C, respectively. Besides PLLA, the enzyme degrades casein, silk powder and Suc-(Ala)3-pNA at an even lower level than Proteinase-K, but not Suc-(Gly)3pNA, poly (e-caprolactone) and poly (b-hydroxybutyrate).

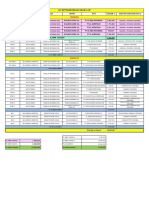

Profiles of A280, protein concentration and PLLA-degrading activity in the second DEAE application.

Poly (l-lactide)-Degrading Enzyme Produced by Amycolatopsis sp.

Hardaning Pranamuda,1 Akio Tsuchii,2 Yutaka Tokiwa* 2

1 2

Agency for the Assessment and Application of Technology, Jakarta 10340, Indonesia National Institute of Bioscience and Human Technology, Tsukuba, Ibaraki 305-8566, Japan Fax: +81-298-56-4898; E-mail: ytokiwa@nibh.go.jp

Introduction

A significant increase is observed in the need for new macromolecular material with a low burden on the environment, so called biodegradable polymers. The Japan Biodegradable Plastic Society estimated the production of biodegradable polymers to be 10% of total plastic production in the years following 2010, compared to 0.01% in 1996. One of the most likely candidates is poly (l-lactide) (PLLA) which can be produced from renewable resources through lactic acid fermentation. In spite of the great expectations placed on PLLA, information on its biodegradation is less than that on poly (hydroxyalkanoate) (PHA) and poly (e-caprolactone) (PCL). Hence, it is important to gather information regarding possibly adverse effects that might occur with the widespread use of PLLA in the near future. Some reports have been published concerning microbial degradation of PLLA.[1 6] We confirmed that the distribution of PLLA-degrading microorganisms is limited in the natural environment when compared with microorganisms that are able to degrade other polyesters, such as PCL and poly (b-hydroxybutyrate) (PHB).[1 3] An Amycolatopsis sp. strain HT-32 was successfully isolated and used to demonstrate PLLA-film degradation.[1] Further

Macromol. Biosci. 2001, 1, No. 1

isolation of PLLA-degrading microorganisms led to the isolation of four actinomycetes and four bacteria; one actinomycete was identified as Amycolatopsis sp. (strain 41) on the basis of morphological observation and analysis of 16s RNA (H. Jikuya, pers. commun.). Ikura et al. reported the isolation of PLLA-degrading actinomycete which was taxonomically similar to the Amycolatopsis strain.[4] Microbial degradation of silk fibroin was studied using Amycolatopsis sp.[5] Interestingly, it was found that the strain was able to degrade PLLA. Moreover, our report showed that out of 25 reference strains belonging to genus Amycolatopsis, 15 were able to form clear zones on an agar plate emulsified with PLLA.[6] Amycolatopsis might play an important role in the natural biodegradation of PLLA. On the other hand, Williams firstly demonstrated the enzymatic degradation of PLLA with Proteinase-K, Bromelain and Pronase.[7, 8] Among these enzymes, Proteinase-K is so effective that it has often been used for evaluating the degradability of PLLA and copolymers.[7, 9] Proteinase-K is a serine protease produced by Tritirachium album, a fungus that grows on native keratin as its sole carbohydrate and nitrogen source.[10] Our literature study confirmed that until now there is no report dealing

1616-5187/2001/01010025$17.50+.50/0

i WILEY-VCH Verlag GmbH, D-69451 Weinheim 2001

26

H. Pranamuda, A. Tsuchii, Y. Tokiwa

with enzyme production by a PLLA-degrading microbial strain.[10] Here, we employed our isolate strain, Amycolatopsis sp. (strain 41), to produce a PLLA-degrading enzyme. Purification was performed and some characteristics of the purified enzyme were investigated.

Superdex 75 HiLoadi 16/60 column. The column was run using a 0.05 m phosphate buffer (pH 7.5) with 0.1 m NaCl solution. The chromatographic columns were controlled with an Aktai Prime system (Pharmacia Amersham Biotech) and were operated at room temperature. Assay of PLLA-Degrading Activity

Experimental Part

Materials A PLLA pellet LACTY #1012 was obtained from Shimadzu Co. (Japan) with a number average molecular weight (Mn) of 1.4 6 105. PLLA powder for an enzyme assay was prepared as follows: A 5% (wt/vol) chloroform solution was dripped into 1 l of methanol to obtain a fibrous precipitate. The fiber was filtered and air-dried for one day, followed by drying under vacuum for one night. The fiber was then ground in a metal mortar under liquid N2, then dried and sieved through 250 lm mesh before use. Silk powder extracted from silkworm cocoons was purchased from Tosco Co. (Japan) and washed with hot water for 8 h 4 times under vigorous stirring to remove the watersoluble part, i. e., sericin. Amino acid analysis showed that the powder was composed of glycine 44.6 (mol-%); alanine, 29.5 and serine, 11.7. Other polyesters, such as poly(e-caprolactone) TONE 767 (PCL; Mn = 1.8 6 104) and (PHB) powders were obtained from Union Carbide Co. (USA) and Mitsubishi Gas Chemical Co. (Japan), respectively. Culture of Amycolatopsis sp. (Strain 41) Amycolatopsis sp. (strain 41) was grown and stored on an agar slant containing ISP no. 2 medium. Clear-zone forming ability was examined by streaking the strain on PLLA, PCL, PHB and silk agar plates prepared as previously reported.[6] The plates were incubated at 30 8C for 14 d and the formation of the clear zone was observed. Liquid cultures were carried out in a 500-ml Erlenmeyer flask containing 100 ml of basal medium with 10 mg of yeast extract and 100 mg of either emulsified-polyester or silk substrate. One-loopful of spores from the slant was inoculated and pre-cultured at 30 8C, 180 rpm for 5 d. 10 ml of the broth were transferred to a new medium and cultured under the same condition for enzyme production. Enzyme Purification The culture broth was collected by centrifugation at 10 000 rpm for 15 min and filtration through Milipore filter (pore size, 0.45 lm). A 0.02-m Tris/HCl buffer (pH 9.0) was used for anion exchange chromatography with a DEAE HiPrepi 16/10 column. The broth was dialyzed before application to the column. After elution with 500 ml of 0.04 m NaCl solution, the active protein was collected, dialyzed and prepared for a second application to the same column. 500 ml of 0.02 m NaCl solution was used to elute the active protein. The major active fraction was concentrated using a collodion bag in a cold room under vacuum. Purification was continued with size-exclusion chromatography using a

PLLA-degrading activity was measured in a reaction mixture composed of 5 mg of PLLA powder, 2.0 ml of 0.1 m phosphate buffer (pH 7.0), 0.05 ml of 0.5% (wt/vol) octyl glucopyranoside and 0.5 ml of enzyme solution. The mixture was shaken at 100 times/min at 37 8C for 12 h. l-Lactic acid formed during the reaction was enzymatically analyzed with an l-lactic acid analysis kit (Roche Diagnostic Co.). One unit (U) of PLLA-degrading activity was defined as the amount of enzyme required to produce 1 lmol of L-lactic acid in 1 min. Activity on Different Substrates Total-organic-carbon (TOC) was used to examine the activity of solubilization of solid substrates, such as PLLA, PCL, PHB and silk powder. To satisfy the minimum volume required for TOC measurements, the reaction mixture was twice as large as that above, i. e., 10 mg substrate, 4.0 ml of 0.1 m phosphate buffer (pH 7.0), 0.1 ml of 0.5% (wt/vol) octyl glucopyranoside, and 1 ml of enzyme solution. In the substrate and enzyme controls, the enzyme and the substrate were omitted from the mixture, respectively. After reaction by shaking at 100 times/min, at 37 8C for 12 h, the watersoluble TOC was measured with a TOC 5000A Analyzer (Shimadzu Co., Japan). The TOC value of the sample was obtained after substraction from both controls. Proteolytic activity was measured with casein as a substrate.[11] Peptide p-nitroanilides, i. e., Suc-(Ala)3-pNA and Suc(Gly)3-pNA were tested using a mixture of 0.2 ml of enzyme solution and 2.0 ml of 5 mm substrate solution. The mixture was incubated at 30 8C and the liberation of p-nitroaniline (pNA) was spectrophotometrically monitored at 410 nm for 10 min. Proteinase-K (Sigma Co.) was used to compare activity towards the above substrates. A 0.005% (wt/vol) enzyme solution was prepared in 0.1 m phosphate buffer (pH 7.0). Other Analyses Protein concentration was measured using the Lowry method with bovine serum albumine (BSA) as the standard. The molecular weight of the purified PLLA-degrading enzyme was determined both by size-exclusion chromatography with a Superdex 75 HiLoadi 16/60 column using the standard proteins, i. e., blue dextran, BSA, ovalbumin, chymotrypsinogen and ribonuclease (Amersham Pharmacia Biotech) and by SDS-PAGE using standard low-molecularweight markers (Amersham Pharmacia Biotech). Optimum pH was evaluated using buffers at pH 410 for PLLA-degrading activity determination at 37 8C. The following 0.05 m buffers were used: citrate buffer (pH 46), phosphate buffer (pH 68), Tris/HCl (pH 79), glycine/NaOH

Poly (L-lactide)-Degrading Enzyme Produced by Amycolatopsis sp.

27

(pH 910). Optimum temperature was determined by performing the enzyme reaction at different temperatures from 30 to 60 8C at pH 7.0 (0.1 m phosphate buffer).

Table 1. Properties of broths after culture of Amycolatopis sp. (strain 41) using emulsified polyesters and silk powder. Culture substrate pH TOC of the broth lg N ml1 324 18 62 55 14 Solubilization of PLLA powdera) lg TOC N h1 N ml1 broth 8 nsb) 13 258 nsb)

Results and Discussion

Enzyme Production by Amycolatopsis sp. (Strain 41) Using Polyesters and Silk Substrates

Observation of the formation of clear zones on polyester and silk plates revealed that Amycolatopsis sp. (strain 41) formed clear zones with high clarity on PLLA, PHB and silk plates but with low clarity on PCL plates, suggesting a wide substrate-degrading specificity of the strain. Table 1 shows the properties of the broths obtained after 5 d of liquid culture. It was observed that, in comparison with the control, the pH of the broths were the same or lower in cultures with polyester substrates. In particular, the PLLA broth showed a very low pH and high TOC, owing to the accumulation of acidic PLLA-degradation products which cannot be assimilated by the strain. Conversely, the silk broth showed a higher pH than the control because of the formation of amino compounds from silk degradation. The ability of the broths to degrade PLLA was measured as TOC that represents the water-soluble PLLA-degradation products such as L-lactic acid and oligolactide. Using this measure, the silk broth produced an extremely high TOC concentration during the enzyme reaction as shown in the Table 1. It indicates that silk powder is the most effective in inducing the production of PLLA-degrading enzyme. So, in further experiments, silk powder was used as the substrate for enzyme production. Strydom et al. reported that silk fibroin contains a large amount of l-alanine and glycine within amino acid sequence: (Gly-Ala)2-Gly-Ser-Gly-(Ala)2-Gly-[Ser-GlyPLLA PCL PHB Silk Control (no substance)

a)

6.1 7.2 6.5 7.9 6.8

b)

Measurement of the activity as was described in the Experimental Part. ns: Not a significant amount of TOC.

(Ala-Gly)n]8, where n is usually 2.[12] A similarity is observed in chemical structure between l-alanine and llactic acid. Hence, it is thought that the strain might recognize silk fibroin as a PLLA analogue, hence secreted the enzyme.

Purification of the PLLA-Degrading Enzyme

After dialysis against 0.02 m Tris/HCl buffer (pH 9.0), the broth was applied to a DEAE column. Elution with 500 ml of a 0.04-m NaCl solution resulted in two peaks with PLLA-degrading activity, which appeared very close together. The peaks (defined as fraction A) were pooled and dialyzed. A second application to the column gave at least 3 peaks (A-1, A-2 and A-3) by elution with 500 ml of 0.02 m NaCl solution, as shown in Figure 1. We confirmed that the protein elution was not complete with the above gradient. However, among the eluted peaks, A-1

Figure 1. Profiles of A280, protein concentration and PLLA-degrading activity in the second DEAE application.

28

H. Pranamuda, A. Tsuchii, Y. Tokiwa

Table 2. Summary of PLLA-degrading enzyme purification from Amycolatopis sp. (strain 41). Total protein mg Dialyzed broth First DEAE eluate (Fraction A) Second DEAE eluate (Fraction A-1) Superdex 75 (Fraction A-1-a)

a)

Table 3. Comparison of substrate specificity between the purified enzyme and Proteinase-K.

Substrate Unit of specific activity Purified enzymea) 0.08 2.5 0 0 0.07 0.12 0 Proteinase-Kb) 3.40 0.62 0 0 0.21 1.0 0

Specific Total activity activity Unita) 17.1 16.3 1.9 0.5 2.0 3.0 2.7 5.0

Yield % 100 95 11

8.5 5.4 0.7 0.1

Casein PLLA powder PCL powder PHB powder Silk powder Suc-(Ala)3-pNA Suc-(Gly)3-pNA

3

a)

dA280 min1 mg1 protein mg TOC N h1 mg1 protein mg TOC N h1 mg1 protein mg TOC N h1 mg1 protein mg TOC N h1 mg1 protein mmol pNA N min1 mg1 protein mmol pNA N min1 mg1 protein

One unit is defined as the amount of enzyme which formed 1 lmol of L-lactic acid in 1 min.

b)

Purified enzyme solution with a protein concentration of 83.5 lg N ml1. A 0.005% (wt/vol) Proteinase-K enzyme solution of protein concentration 63.5 lg N ml1.

ascertained using SDS-PAGE analysis, as shown in Figure 2. A single band of protein was obtained with a molecular weight of about 40 kDa, suggesting that the preparation yields a homogeneous product.

Characteristics of the Purified Enzyme

Table 3 presents a comparison of the substrate specificity of the purified enzyme (A-1-a) and that of Proteinase-K. The enzyme shows lower proteolytic activity against casein, but higher degrading activity against PLLA than Proteinase-K. The purified enzyme does not degrade PCL and PHB substrates as well as Proteinase-K. It suggests that the purified enzyme is different from a lipase and PHB-depolymerase, which are commonly known to be able to degrade PCL and PHB, respectively. The purified enzyme is still able to degrade silk powder, even at a low level. In the case of peptide p-nitroanilide substrates, the purified enzyme degraded Suc-(Ala)3-pNA, a typical substrate for Proteinase-K and elastase, but not Suc-(Gly)3pNA.[10, 13] It is considered that the ability of the purified enzyme and Proteinase-K to degrade silk fibroin was originated from their ability to cleave the Ala-Ala rather than Gly-Gly bond. Investigation on the optimum pH and temperature resulted that the enzyme showed highest activity at pH 6.0 and temperature 3745 8C. However, the activity remained 85% at pH 9.0. This is the first report dealing with the purification of a PLLA-degrading enzyme produced by a PLLA-degrading microorganism. The enzyme will be very useful for evaluating the degradability of plastic polymers containing PLLA.

Figure 2.

SDS-PAGE analysis of active fraction A-1-a.

was considered the major component with a high protein concentration and PLLA-degrading activity. Therefore, we used only fraction A-1 for further purification. It was pooled and concentrated using a collodion bag under vacuum. After dialysis against 0.05 m phosphate buffer (pH 7.5), purification using Superdex 75 column was performed and resulted in a major active protein (fraction A1-a). Table 2 summarizes the results of purification. The PLLA-degrading enzyme was purified 2.5-fold with a recovery of 3% and a specific activity of 5.0 U N mg protein1. The low activity and protein recoveries might be due to the failure to elute the adsorbed protein at the second DEAE application and to the loss of active protein in the collodion bag during the concentration process. The molecular weight of fraction A-1-a (Mr) was found to be 42 kDa by size exclusion chromatography on a Superdex 75 column. The homogeneity of the purified enzyme was

Received: November 13, 2000

Poly (L-lactide)-Degrading Enzyme Produced by Amycolatopsis sp.

29

[1] H. Pranamuda, Y. Tokiwa, H. Tanaka, Appl. Environ. Microbiol. 1997, 63, 1637. [2] M. L. Tansengco, Y. Tokiwa, Chem. Lett. 1998, 1043. [3] T. Suyama, Y. Tokiwa, P. Quinchanpagdee, T. Kanagawa, Y. Kamagata, Appl. Environ. Microbiol. 1998, 64, 5008. [4] Y. Ikura, T. Kudo, J. Gen. Appl. Microbiol. 1999, 45, 247. [5] Y. Tokiwa, M. Konno, H. Nishida, Chem. Lett. 1999, 353. [6] H. Pranamuda, Y. Tokiwa, Biotechnol. Lett. 1999, 21, 901. [7] D. F. Williams, Eng. Med. 1981, 10, 5. [8] D. F. Williams, J. Mater. Sci. 1982, 17, 1233.

[9] M. S. Reeve, S. P. McCarthy, R. A. Gross, Macromolecules 1994, 27, 825. [10] W. Ebeling, N. Hennrich, M. Klockow, H. Metz, H. D. Orth, H. Lang, Eur. J. Biochem. 1974, 47, 91. [11] W. Rick, in: Method of Enzymatic Analysis, volume 2, H. U. Bergmeyer, Ed., Verlag C. W. 1974, pp. 10071009. [12] D. J. Strydom, T. Haylett, R. H. Stead, Biochem. Biophys. Res. Commun. 1977, 79, 932. [13] E. G. Del Mar, C. Largman, J. W. Brodrick, M. Fassett, M. C. Geokas, Biochem. 1980, 19, 468.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Mind Map: Amino Acid MetabolismDocument1 paginăMind Map: Amino Acid MetabolismAbbey Ayala100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- From Volcanic Origins of Chemoautotrophic Life To Bacteria, Archaea and EukaryaDocument22 paginiFrom Volcanic Origins of Chemoautotrophic Life To Bacteria, Archaea and Eukaryaapi-3713202Încă nu există evaluări

- Glycine Methionine Balance RevisitedDocument3 paginiGlycine Methionine Balance RevisitedPetra JobovaÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- 1 - Amisoft ECS 22W, Prodew 500, Ajidew Nl-50 2019-09-24 09 - 24 - 07Document77 pagini1 - Amisoft ECS 22W, Prodew 500, Ajidew Nl-50 2019-09-24 09 - 24 - 07Trần NhỏÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Polymers and Amino Acids Part 3 - Amino Acids and ProteinsDocument13 paginiPolymers and Amino Acids Part 3 - Amino Acids and ProteinsMichael Angelo FilomenoÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- At The End of The Topic, Students Should Be Able To:: Tutorial 19: Amino AcidsDocument5 paginiAt The End of The Topic, Students Should Be Able To:: Tutorial 19: Amino AcidsizabelÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Mechanism of Enzyme ActionDocument10 paginiMechanism of Enzyme Actionsd2808Încă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Enthalpy of Protonation of GlycineDocument6 paginiEnthalpy of Protonation of GlycineNur Wana100% (1)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- 2004 Nasional BelarusDocument14 pagini2004 Nasional BelarusFeni Utari BasyarÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Biochem Protein Module 3.1Document23 paginiBiochem Protein Module 3.1Jemina Rafanan RacadioÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Chem162 SpectSeries Report 111314Document4 paginiChem162 SpectSeries Report 111314charwill12340% (4)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- 06.11.22 - SR - STAR CO-SC (MODEL-A&B) - Jee - Adv - 2018 - P1 - PTA-7 - KEY & SOLDocument12 pagini06.11.22 - SR - STAR CO-SC (MODEL-A&B) - Jee - Adv - 2018 - P1 - PTA-7 - KEY & SOLOrganic PrasadÎncă nu există evaluări

- German Problems 2004Document127 paginiGerman Problems 2004akenoÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Indian Association of Chemistry Teachers: National Standard Examination in Chemistry 2008-2009Document7 paginiIndian Association of Chemistry Teachers: National Standard Examination in Chemistry 2008-2009Anmol AroraÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Shower Shampoo With OlivoilDocument1 paginăShower Shampoo With OlivoildairaslkfosdkjflskdjÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- 58 CitaDocument6 pagini58 CitaKaren Alejandra López CastañosÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Conversion of Amino Acids To Specialized ProductsDocument15 paginiConversion of Amino Acids To Specialized ProductsmrbrendonÎncă nu există evaluări

- Midterm Exam Review Presentation With Answers PDFDocument22 paginiMidterm Exam Review Presentation With Answers PDFProf. AndreaÎncă nu există evaluări

- Metabolism of Amino AcidsDocument91 paginiMetabolism of Amino AcidsAditya NayakÎncă nu există evaluări

- Effects of Foliar Application of Glycine and Glutamin On BasilDocument9 paginiEffects of Foliar Application of Glycine and Glutamin On BasilMohammad Kazem souriÎncă nu există evaluări

- DNA and DestinyDocument26 paginiDNA and DestinyGN100% (1)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Effect of PH On Non-Enzymatic Browning Reaction DuringDocument8 paginiEffect of PH On Non-Enzymatic Browning Reaction DuringYazwar KotoÎncă nu există evaluări

- Zinc Glycine ComplexDocument2 paginiZinc Glycine ComplexSaba AmirÎncă nu există evaluări

- Project Report On Amino Acid From Protein Source, Plant Growth PromoterDocument7 paginiProject Report On Amino Acid From Protein Source, Plant Growth PromoterEIRI Board of Consultants and PublishersÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- GlycineDocument17 paginiGlycineRahul IyerÎncă nu există evaluări

- BIOMOLECULESDocument54 paginiBIOMOLECULESTanmayÎncă nu există evaluări

- Ts-2 Production of 5-Aminolevulinic Acid by Propionibacterium Acidipropionici Tistr442Document4 paginiTs-2 Production of 5-Aminolevulinic Acid by Propionibacterium Acidipropionici Tistr442Giang Huy DiệmÎncă nu există evaluări

- 7.840,000 Total Asbm Cigading: MV Bottiglieri Franco Vela B/L ListDocument1 pagină7.840,000 Total Asbm Cigading: MV Bottiglieri Franco Vela B/L ListTaufan RangkutiÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Characteristic of Latex & Attention in Development of Latex ReagentsDocument26 paginiCharacteristic of Latex & Attention in Development of Latex Reagentsdooq poobÎncă nu există evaluări

- Iron DeterminationDocument4 paginiIron Determinationancuta.lupaescuÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)