Documente Academic

Documente Profesional

Documente Cultură

4AG Tune

Încărcat de

Mohd HattaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

4AG Tune

Încărcat de

Mohd HattaDrepturi de autor:

Formate disponibile

Hey all wrote this up about 4 months ago in word, never got around to finishing it as I lost my Rolla and

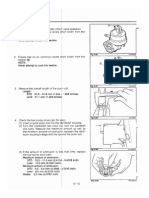

interest for now So I may as well post up what I had typed up even though it is not really finished Might be of help to N.A 4age fans Matts Modified N.A 4AGE Page For modifications to the GEN 1, 2 & 3 4AGE 16v ( TVIS Bigports and the Smallport ) First some basic back ground info for better understanding: What is Camshaft duration & lift? Camshaft lift is measured from the top of the base circle to the tip of the lobe. In this case, the lift is 7.1mm. This lift is generated over 116 degrees of cam-lobe duration. Since the cam spins at half crankshaft speed, you double the duration to come up with an advertised duration of 232 degrees. If you have a 7.1mm lift cam this douse not mean your valves open up 7.1mm they actually open up less due to the Valve clearance that you set with the Shims. Standard clearance is 0.15 to 0.25mm for the intake & 0.20 to 0.30mm for the exhaust So if theyre set to 0.15mm your valve will open 6.95mm

The above drawing I based measurements on a standard Smallport cam shaft. The Bigport camshaft is 240 duration & 7.56mm lift Aftermarket performance camshafts are designed to open the valves more and for a longer period. When you build performance N.A engines you normally need to run a much higher RPM to make more power then the standard engine would make. Performance Camshafts are designed to keep making the power at those higher rpms you need to run, though the downside of this is you loose your bottom end power. So the bigger profile of the camshaft the higher the RPM range you make peak power at and the less bottom end you will have. Also the engine must be made to idle at a faster rpm. The bigger the cam the faster it must idle depending on the tune. It would also determine how street able the engine would end up being. Advancing and retarding Cam shafts what does it do? To advance and retard your engines cam timing you would need to buy a set of adjustable cam gears, you could skip a tooth on the cam gears but this would be too much and affect the

performance of the engine. The Crankshaft does 720 degrees for 1 complete cycle, In that time the camshaft has done 360degrees The 4age has an 18tooth crank gear to spin the 36tooth camshaft gears at engine speed. So 1 tooth on the cam gear is 10 degrees for the camshaft on the 4age 16v engine Advancing your camshafts will move the standard power curve of the engine which would give you a low to midrange power To do this you must rotate the cam gears in a clockwise direction. Retarding the cams will do the opposite, give you more mid to top end power To do this you must rotate the cam gears in an anti-clockwise direction. Usually when buying performance cam shafts they come with a cam card that tells you at what degree the camshafts need to be dialed into. Dialing in cams is when you place a degree wheel on the crank shaft and two dial indicators on the shims/lifters. One for intake side and the other for exhaust side. This is so you can set the cams to exactly the right degree to start opening or closing the valves. It is also a good idea for a third dial indicator down the spark plug hole if you can, so it can sit on the piston to check TDC and the degree wheel has not moved when your rotating the crank. This is the cam card that came with my 270duration & 7.9mm lift cams They are designed as a midrange camshaft and improved the torque of the engine much more then it gave power as the peek rpm they are designed for is near standard.

After installing these cams the engine became very responsive and peaked much faster then a standard 4age. The power Curve in result was much more aggressive. The only downside is I lost power under 4000rpm, and it idled very lumpy at 900rpm. Engine Balancing: Engine balancing is when we make the rotating and reciprocating mass the same weight so the engine spins more free and smooth, For an example an unbalanced engine is like running as fast as you can with a brick stuck to one foot. I wont go into it too much as it is not something that can really be done at home, Though if you are thinking about building a performance engine I would seriously recommend it getting done buy a professional. 3 angle valve seats! 3 angle valve seats in the 4age or any modern engine for that matter you will find is standard

from factory. The reason for this is so the air can flow past the seating aria more freely (More air into combustion chamber) then it would with just a 45 degree seat common on much older engines. There are 5 angle seat cutters, so you can have 5 angle seats witch would be better again. Facing valves! Normally valve faces are ground to 45 degrees to match the seating aria to seal the ports off from the combustion chamber when valves are closed. To improve the flow of the valves you can have a back cut ground above the face of about 20 degrees or so. Not sure how much difference this modification will make as I did not do it on my engine as my ports and valves where pretty much stock. This pic I drew may help understanding.

Piston, Con Rod & Crank shaft terms:

Compression Ratios: Compression ratio is the volume of a combustion chamber and cylinder, when the piston is at BDC and the volume when the piston is at TDC. The higher the compression ratio, the more mechanical energy an engine can squeeze from its air-fuel mixture. High ratios place increased oxygen and fuel molecules into a reduced space allowing for increased power at the moment of ignition. This link is a quick calculator to work out your compression ratio. http://www.csgnetwor...m/compcalc.html

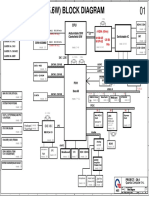

Engine Power Calculator HP = C.I. / 150.8 x RPM / 5252 x C.R x (14.7 + boost) x V.E. C.I = Cubic Inch RPM = The rpm in which it makes its max power C.R = Compression ratio V.E = Volumetric efficiency V.E is a percentage so when you put it in the math formula if it is 99% you would put .99 if it is 102% you would put in 1.02 EG: Workings for a Smallport 4AGE 16v 98/150.8x7200/5252x10.3x14.7x.99 = 133.5hp Standard 4A-GE 16v Bigport VE = 1.02 Standard 4A-GE 16v Smallport VE = .99 Also bit of useful info, there is about 19.4kw Loss through a C52 gearbox and final drive in 3rd gear

Building a 4AGE 16v N.A engine There are many different things you can do to a 4AGE 16v engine to make them perform better then standard. You may have cold air induction or a nice set of extractors installed for a little extra power (2-3kw maybe?), the real difference to be made is buy pulling the engine down and machining and replacing parts for performance items. The first thing you could try is installing some small profile camshafts. They say that the biggest camshaft the standard ECU can take is around a 264 duration cam, when I installed a set of midrange 270s the stock ECU could barely keep the engine running. So a piggy back computer had to be fitted to sort it out. Any bigger then a 270 duration cam and it would defiantly need to go to a complete aftermarket ECU. As the cams I installed had an advertised power range of 3000rpm to 6500rpm they did not make much more power then the standard engine as the peek power was around the same RPM. What the cams did do to it is give it a bag full of torque. To make a bit more power with that size cam you could give it more compression. The late model 4ages run around a 10.3:1 compression ratio. To achieve more compression you could get the cylinder head face machined down to decrease combustion chamber CC. The standard 4AGE 16v combustion chamber CC is 3839cc. Machining it down to a 36cc combustion chamber on a standard 4AGE 16v will leave you with a CR of around 10.8:1 , and an increased power over a standard 133.4hp 4age of

6hp (4.47kw) in theory. So the only real way to improve the power is bigger cams. If your after more top end power I would recommend something around 290duration & 9mm lift as this cam would make power around 8000 8500 rpm. Though it would be a very good idea to install some aftermarket Valve springs that can take the 9mm lift without the spring coil binding. It would also have to be a stiffer spring so that it can take the rpms and close the valve in time before it reopens. This is a TRD copy valve spring that I used in my 4age on the left and the original 4age 16v valve spring on the right, as you can see the TRD copy valve spring will coil bind much later then the original one would and it is also a stiffer spring.

Using a lift as high as 9mm or over can turn into a disaster as the cam lobe can flick the shims out of the valve buckets, 9mm lift cams are boarder line so if I had a cam that size I would install some shim under buckets, This can be very expensive for what they are. But apparently the Shim under buckets from a Toyota 1SZ-FE 1.0 liter 4 cylinder engine use a bucket that's compatible with the 4age 16v. More info on this: http://www.club4ag.com/faq%20and%20tech_pa...r%20Tuning.html With camshafts that size you would also defiantly need to run a higher compression of around 11:1 or better 11.5:1 though milling the head down heaps might not be a good idea as the valve to piston clearance will be much less due to the bigger lift and lower sitting head, So it is a good idea to use some aftermarket forged pistons with +dome to give the compression you need. They are also normally stronger pistons designed to take the extra HP & RPM. Arias Pistons make a 4age 16v piston with a +Dome CC of 7.5cc and are listed that with stock head and gaskets it will give a 10.7:1 compression ratio. Though they are only made to suit bore size of 81.5mm (standard size is 81mm) so the engine block will have to be pulled down and bored out to that oversize. To bump it up a bit more you could use a TRD head gasket 0.5mm thick, this should give you around an 11.3:1 CR. If you are willing to go that far it would be a good idea to replace your old worn out & most likely stretched rod bolts with some ARP ones. They are much stronger and can take more abuse from revs, though the big ends must be closed and honed back to size when you install new rod bolts. Also if you are going to be revving the engine up to or over 8500rpm it would be good to have the bottom end balanced as the forged pistons will most likely be a different weight then the standard cast pistons and throw out the balance.

The Standard rods should take 9000rpm maximum with some ARP bolts so if your not going to rev the engine past that the standard rods should be fine as long as you have some ARP in them, As you can see the Smallport 7 rib block rods (20mm pin, 42mm big-end) are very strong and are the same rods used in the 4AGZE supercharged engine.

Though if the rpm concerns you, you can have the sides lynished to remove any stress points and then have the rods shotpeened as well. If you really wanted to have a strong engine you could install a ARP head bolt stud kit and an ARP main cap (crankshaft main bearing cap) stud kit , Though with the main cap kit you should have it tunnel bored with the new studs fitted to ensure 100% alignment just like the rod bolts. Anything past 9000rpm you will defiantly need Aftermarket Forged rods. There is also aftermarket 215mm Aluminium and Chrome Moly flywheels that weigh around 3.6kg available for the 4AGE but street driven engines with aggressive cams you may prefer the Lightweight Chrome-Moly flywheel because the lower weight of the Lightweight Aluminium may hamper idle at lower rpm running. In my opinion if your going to go to the expense of getting forged pistons and rods you may as well build a 7AGE using the 1762cc 7AFE bottom end and get the Forged rods and pistons to suit that engine. If you bore that block out to an 81.5mm bore it becomes a 1782cc engine. You will have to use the 4AGE 16v crank timing gear and a longer timing belt as the 7A block is taller to take the extra stroke of 85.5mm, Porsche 924/944 belt has been rumored to fit. You will also need a custom exhaust manifold so it can have clearance under the sump if the engine is in a FWD car. The 7A also does not have oil squirters (piston coolers) like the Smallport 4age 16v (100kw engine) douse. The 7A uses a 6 bolt fly wheel apposed to the 8 bolt 4age flywheel, The 7A 6 bolt can be made stronger using 3 solid steel dowel pins and some ARP replacement bolts. One advantage with the 7A engine is due to the extra capacity you will not need to rev the engine out so much to make the same power as a 4AGE making power @ 9000rpm. So you could probably get away with using some standard cast pistons and use a 82mm over size to increase the capacity to 1803cc and save $$ on forged pistons, I would still recommend replacing the rods with forged items as the standard 7A rods have a very narrow neck, they also use a 18mm press fit pin and would most likely brake after constantly seeing 8500rpm every day. This is a standard 7A rod Vs a Forged item with a 20mm floating pin little end to suit the later 4AGE pitons. The big end is machined to suit the standard 7A crank size.

As you can see the 7 rib 4AGE block (painted orange) and the 7AFE block (bare) are nearly the same, just the 7A is taller to accommodate longer stroke, so you will need to use the 6bolt 7A crank. Both blocks are a standard 81mm bore.

If you are going to be running over a 11:1 compression ratio it is a good idea to not have any sharp points removed in the combustion chamber that will cause pre ignition due to hot spots. As you can see in the pic below on the standard 4age (left) you can see an example of a hot spot. The pic on the left is an engine that would be running high compression and has had the spots taken away.

Resized to 91% (was 1055 x 408) - Click image to enlarge

While youre playing around with that you may as well clean the ports up of any sand casting marks left from when the head was cast. You can also open up under the valve a little bit but dont go 2 crazy as you will loose power, its best just to keep to cleaning the ports out and putting nice round edges on things that have sharp turns. If youre planning to run up to a 272 you will fined the Smallport head with light port work is all that is needed. With 288s I would start playing with throttle bodies. A 290 cam or bigger it would probably be best to run a Bigport head and ported intake manifold with over size throttle body or run a Quad throttle body set up.

\\\\ More to come //// EDIT *** added some stuff about heads ^^^^

S-ar putea să vă placă și

- R33 GTSt Tuning Stages 1 & 2 GuideDocument4 paginiR33 GTSt Tuning Stages 1 & 2 GuideLijah AzrinÎncă nu există evaluări

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesDe la EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesEvaluare: 5 din 5 stele5/5 (1)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe la EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualÎncă nu există evaluări

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe la EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualEvaluare: 2.5 din 5 stele2.5/5 (2)

- Vacuum From Toyota Corolla 4aDocument6 paginiVacuum From Toyota Corolla 4azulÎncă nu există evaluări

- AE86 Levin-TruenoDocument1 paginăAE86 Levin-TruenoToshiba PortegeÎncă nu există evaluări

- Zspeedracing Master Catalogue 2008Document13 paginiZspeedracing Master Catalogue 2008api-3863246100% (1)

- How To Guide - Changing Spark Plugs On A RB25DETDocument4 paginiHow To Guide - Changing Spark Plugs On A RB25DETseastate100% (1)

- How To Guide - Fitting Brembo Brakes On A StageaDocument4 paginiHow To Guide - Fitting Brembo Brakes On A StageaseastateÎncă nu există evaluări

- Building A 5SG EngineDocument5 paginiBuilding A 5SG Enginedhendriadi69Încă nu există evaluări

- Design of The SR20Document11 paginiDesign of The SR20hugostvÎncă nu există evaluări

- ECU Diagnostic Codes For 4A EnginesDocument3 paginiECU Diagnostic Codes For 4A EnginesMie Starr YusofÎncă nu există evaluări

- Honda OBD I Vehicles (1985 - 1995) Supported by Actron's Honda/Nissan/Toyota Code Scanner CP9025Document8 paginiHonda OBD I Vehicles (1985 - 1995) Supported by Actron's Honda/Nissan/Toyota Code Scanner CP9025izalirunk100% (1)

- Engine BWA - 2.0 FSI Timing Belt Installation - Not OEMDocument22 paginiEngine BWA - 2.0 FSI Timing Belt Installation - Not OEMJonathan AmirmadhiÎncă nu există evaluări

- 1kzte EngineDocument2 pagini1kzte EngineCarlos CavalcantiÎncă nu există evaluări

- Ford E350 Super Duty SWAT Vehicle SITEDocument1 paginăFord E350 Super Duty SWAT Vehicle SITEdefensetechsÎncă nu există evaluări

- RPO Codes and DescriptionsDocument412 paginiRPO Codes and DescriptionsJhovany LMÎncă nu există evaluări

- Cam Shaft Removal and InstallationDocument9 paginiCam Shaft Removal and InstallationAlexander Dominguez0% (1)

- Rear Light Removal & Earthing FixDocument6 paginiRear Light Removal & Earthing FixKároly Dávid NyulasiÎncă nu există evaluări

- G1880GEDocument3.728 paginiG1880GETc Mrt Çap TmlÎncă nu există evaluări

- Mazda RX 8 Series II Workshop Manual (Preview)Document6 paginiMazda RX 8 Series II Workshop Manual (Preview)Amip FolkÎncă nu există evaluări

- Abandoned 1992 Toyota AE101 Turbo Project Car for Sale with 3SGTE Engine ModsDocument1 paginăAbandoned 1992 Toyota AE101 Turbo Project Car for Sale with 3SGTE Engine ModsjaiusopÎncă nu există evaluări

- Loads of B20 Information - EK9Document14 paginiLoads of B20 Information - EK9k24hybridÎncă nu există evaluări

- Wiper Washer SystemDocument7 paginiWiper Washer SystemToua YajÎncă nu există evaluări

- Toyota CamryDocument2 paginiToyota CamryJon WestÎncă nu există evaluări

- Adjustable Fuel Pressure RegulatorDocument5 paginiAdjustable Fuel Pressure RegulatorAchintya MehrotraÎncă nu există evaluări

- Greddy Turbo Kit For Mazda RX-8Document18 paginiGreddy Turbo Kit For Mazda RX-8Varvados Karazhan100% (1)

- Rb30 Dohc: R32 & R33 Skyline Specific Last Update - This Guide Has Originated From The Following HUGE Thread On SAUDocument10 paginiRb30 Dohc: R32 & R33 Skyline Specific Last Update - This Guide Has Originated From The Following HUGE Thread On SAUChris Mi-e Dor RomâniaÎncă nu există evaluări

- Fto TuningDocument6 paginiFto TuningghettoglamourdjÎncă nu există evaluări

- Harrop Lc200-1ur InstallDocument22 paginiHarrop Lc200-1ur InstallArtur ElectroMecânicoÎncă nu există evaluări

- Nisssan Motorsports Competition PartsDocument108 paginiNisssan Motorsports Competition Partsletranquangha100% (1)

- Nissan Skyline RB Engine Oil Control ModsDocument1 paginăNissan Skyline RB Engine Oil Control Modsbyrnesvictim100% (1)

- HondaCR VDocument38 paginiHondaCR VClaudio Borquez SuszkoÎncă nu există evaluări

- The Cosworth YB SeriesDocument6 paginiThe Cosworth YB SeriesJameel Khan67% (3)

- Suzuki DT6 Parts Catalog 1984-1985Document30 paginiSuzuki DT6 Parts Catalog 1984-1985OsPetersonÎncă nu există evaluări

- Complete Mini Moto Guide PDFDocument23 paginiComplete Mini Moto Guide PDFdodgydonkey100% (1)

- Microsquirt Hardware 3.3Document152 paginiMicrosquirt Hardware 3.3Amin Rolando Barraza LauraÎncă nu există evaluări

- Acura TSX 2004 Multiplex Integrated Control SystemDocument55 paginiAcura TSX 2004 Multiplex Integrated Control Systemjorge antonio guillenÎncă nu există evaluări

- MG100 Series Owners Manual5. Clean Channel VOLUME control1715. Overdrive Channel VOLUME controlDocument6 paginiMG100 Series Owners Manual5. Clean Channel VOLUME control1715. Overdrive Channel VOLUME controlALÎncă nu există evaluări

- HKS EVC 6 ManualDocument52 paginiHKS EVC 6 Manualkai_isman67% (3)

- Instruction Manual: E84111-K00060-00 Published Feb.2008 Ver.3-1.01Document36 paginiInstruction Manual: E84111-K00060-00 Published Feb.2008 Ver.3-1.01Kluzu Formaggio100% (1)

- Apexi Installation Instruction Manual: S-AFC 2Document64 paginiApexi Installation Instruction Manual: S-AFC 2THMotorsports.netÎncă nu există evaluări

- Hondata S300 Wideband Setup Guide: Wiring InformationDocument2 paginiHondata S300 Wideband Setup Guide: Wiring InformationSimson Anson100% (1)

- Yamaha Raptor 80 Owners ManualDocument145 paginiYamaha Raptor 80 Owners ManualAaron MasonÎncă nu există evaluări

- Typhoon 50 PartsDocument68 paginiTyphoon 50 PartsPetrovics AttilaÎncă nu există evaluări

- 4 Throttles' Vacuum From Toyota Corolla Levin AE101 4A-GE 20vDocument6 pagini4 Throttles' Vacuum From Toyota Corolla Levin AE101 4A-GE 20vTobyÎncă nu există evaluări

- Lubrication System Overview for Toyota 4A-FE EngineDocument31 paginiLubrication System Overview for Toyota 4A-FE EnginedwcdiscoÎncă nu există evaluări

- Honda Accord Tourer 7th Gen Facelift AccessoriesDocument16 paginiHonda Accord Tourer 7th Gen Facelift AccessoriesAOCUKÎncă nu există evaluări

- Sony XAV-63 - ManualDocument64 paginiSony XAV-63 - ManualVinay Patel100% (1)

- 07 - Chassis ElectricalDocument52 pagini07 - Chassis ElectricalEdgardo Rivas100% (1)

- Apexi VAFC (Vtec Controller) Info!Document6 paginiApexi VAFC (Vtec Controller) Info!bso10% (1)

- 24L FourDocument28 pagini24L FourIqbal NugrohoÎncă nu există evaluări

- 04-06 TSX Exterior LightsDocument48 pagini04-06 TSX Exterior LightsNes MzzÎncă nu există evaluări

- H22a WiringDocument1 paginăH22a Wiringcullen114100% (1)

- Rebuild Yamaha Vision Motorcycle TCI Electronic Ignition ModuleDocument11 paginiRebuild Yamaha Vision Motorcycle TCI Electronic Ignition Modulexplod11Încă nu există evaluări

- Dodge 5.7 Service InformationDocument243 paginiDodge 5.7 Service InformationNay Linn Htet100% (1)

- SEMIKRON Brochure Power Electronics For Motor DrivesDocument20 paginiSEMIKRON Brochure Power Electronics For Motor Driveschristian limaÎncă nu există evaluări

- DC-DC Converters - Jaycar Tech NotesDocument5 paginiDC-DC Converters - Jaycar Tech Noteskimbalsummers801Încă nu există evaluări

- Transas TC - Patch - Readme Patch InstallationDocument16 paginiTransas TC - Patch - Readme Patch InstallationPrinceBabuÎncă nu există evaluări

- CIK Tokyo 26Document1 paginăCIK Tokyo 26Mohd HattaÎncă nu există evaluări

- Setting Up ETAS INCA For ECM DevicesDocument5 paginiSetting Up ETAS INCA For ECM DevicesMohd HattaÎncă nu există evaluări

- IC Engine Lab Manual 1Document30 paginiIC Engine Lab Manual 1Dipti Mittal100% (1)

- Airpax - Catalog Stepper MotorsDocument80 paginiAirpax - Catalog Stepper MotorsMark LaurenceÎncă nu există evaluări

- Series 4SQ Stepper Motors 1.8°: Not Available For Sale in EuropeDocument1 paginăSeries 4SQ Stepper Motors 1.8°: Not Available For Sale in EuropeMohd HattaÎncă nu există evaluări

- Basic InstrumentionDocument30 paginiBasic InstrumentionMohd HattaÎncă nu există evaluări

- ISO Calculation Procedure 1Document49 paginiISO Calculation Procedure 1Mohd HattaÎncă nu există evaluări

- Die Cast MetalDocument68 paginiDie Cast MetalMohd HattaÎncă nu există evaluări

- ETAS Webinar ECU BasicsDocument30 paginiETAS Webinar ECU BasicswlidhaaaÎncă nu există evaluări

- Double CCDocument13 paginiDouble CCAllison GallowayÎncă nu există evaluări

- Sec 9Document7 paginiSec 9Mohd HattaÎncă nu există evaluări

- 4AG TuneDocument9 pagini4AG TuneMohd Hatta100% (1)

- IC Engine Lab Manual 1Document30 paginiIC Engine Lab Manual 1Dipti Mittal100% (1)

- Sec5 4 3Document7 paginiSec5 4 3Mohd HattaÎncă nu există evaluări

- Daftar NOSS Version 25 Jun 2014Document255 paginiDaftar NOSS Version 25 Jun 2014Ahmad ImranÎncă nu există evaluări

- IC Engine Lab Manual 1Document30 paginiIC Engine Lab Manual 1Dipti Mittal100% (1)

- Sec5 4 5Document4 paginiSec5 4 5Mohd HattaÎncă nu există evaluări

- Sec10 1Document9 paginiSec10 1Mohd HattaÎncă nu există evaluări

- Sec 8Document7 paginiSec 8Mohd HattaÎncă nu există evaluări

- Sec10 2Document9 paginiSec10 2Mohd HattaÎncă nu există evaluări

- Sec 7Document9 paginiSec 7Mohd HattaÎncă nu există evaluări

- Sec5 4 4Document7 paginiSec5 4 4Mohd HattaÎncă nu există evaluări

- Sec6 2Document9 paginiSec6 2Mohd HattaÎncă nu există evaluări

- Sec5 4 1Document7 paginiSec5 4 1Mohd HattaÎncă nu există evaluări

- Sec6 1Document9 paginiSec6 1Mohd HattaÎncă nu există evaluări

- Sec5 3 3Document6 paginiSec5 3 3Jennifer Amutha DavidÎncă nu există evaluări

- Sec5 4 2Document7 paginiSec5 4 2Mohd HattaÎncă nu există evaluări

- Sec5 3 2Document6 paginiSec5 3 2Mohd HattaÎncă nu există evaluări

- Pre Flight Checklist DJI APA 10 2019.01Document3 paginiPre Flight Checklist DJI APA 10 2019.01Thomas EnglishÎncă nu există evaluări

- Introduction To Econometrics, 5 Edition: Chapter 4: Nonlinear Models and Transformations of VariablesDocument10 paginiIntroduction To Econometrics, 5 Edition: Chapter 4: Nonlinear Models and Transformations of VariablesRamarcha KumarÎncă nu există evaluări

- Sijilat - Kingdom of BahrainDocument1 paginăSijilat - Kingdom of BahrainSunil SharmaÎncă nu există evaluări

- Ozone Generators Comparison ChartDocument1 paginăOzone Generators Comparison Chartqualiman1Încă nu există evaluări

- FortiMail Cloud Gateway PDFDocument4 paginiFortiMail Cloud Gateway PDFunivocalÎncă nu există evaluări

- Improve Sewerage System in Madurai CityDocument36 paginiImprove Sewerage System in Madurai CityKumar Malleswar VujjiÎncă nu există evaluări

- Resume 24Document4 paginiResume 24Bhaktish ArwankarÎncă nu există evaluări

- OmniMeter Universal Smart Meter User Manual EKM MeteringDocument2 paginiOmniMeter Universal Smart Meter User Manual EKM MeteringChris CalderónÎncă nu există evaluări

- India's Growing Smartphone Market Dominated by Chinese BrandsDocument3 paginiIndia's Growing Smartphone Market Dominated by Chinese BrandsAnshika YadavÎncă nu există evaluări

- Baltimore County Inspector General's Report On Councilman Julian Jones' EmailsDocument35 paginiBaltimore County Inspector General's Report On Councilman Julian Jones' EmailsFern MarieÎncă nu există evaluări

- Ws c3508g XL en DatasheetDocument6 paginiWs c3508g XL en DatasheetRobison Meirelles juniorÎncă nu există evaluări

- Seisan TutorialDocument34 paginiSeisan TutorialhenryÎncă nu există evaluări

- HMT - Machine Tools DivisionDocument14 paginiHMT - Machine Tools DivisionDanish MansoorÎncă nu există evaluări

- Dashboard Java Inheritance, Polymorphism, Abstract Class, Interface Pre-QuizDocument6 paginiDashboard Java Inheritance, Polymorphism, Abstract Class, Interface Pre-QuizNikita Ichale67% (3)

- One Shot Face Recognition: Mid Term Presentation Presented By, Amitrajit Chattopadhyay, 3 Year Ug, Iisc 1.04.2020Document10 paginiOne Shot Face Recognition: Mid Term Presentation Presented By, Amitrajit Chattopadhyay, 3 Year Ug, Iisc 1.04.2020amitrajit chattopadhyayÎncă nu există evaluări

- Marketing Cloud Email Specialist Exam NotesDocument16 paginiMarketing Cloud Email Specialist Exam NotesSAIÎncă nu există evaluări

- Online Blood Donation Management SystemDocument50 paginiOnline Blood Donation Management SystemBabalsure RaghuanthÎncă nu există evaluări

- Quanta QL4Document44 paginiQuanta QL4Robson ZimmermannÎncă nu există evaluări

- Seminar TopicsDocument11 paginiSeminar Topicsrameshchowdary113Încă nu există evaluări

- Industrial Control Electronics by Michael JacobDocument606 paginiIndustrial Control Electronics by Michael JacobNarasimha Sai Sangapu88% (8)

- Allgon System Ab: Electrical Specifications Electrical SpecificationsDocument1 paginăAllgon System Ab: Electrical Specifications Electrical SpecificationsРоманКочневÎncă nu există evaluări

- 00250600BCST49051 Cdfe02 38Document38 pagini00250600BCST49051 Cdfe02 38Mohammed HijaziÎncă nu există evaluări

- Corporate CardsDocument184 paginiCorporate CardsSanthosh GKÎncă nu există evaluări

- Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument12 paginiSaudi Arabian Oil Company (Saudi Aramco) General Instruction ManualJoypee MacasamponÎncă nu există evaluări

- MAE3456 - MEC3456 LAB 01: Due: 11:59PM (Sharp), Friday 12 March 2021 (End of Week 2)Document6 paginiMAE3456 - MEC3456 LAB 01: Due: 11:59PM (Sharp), Friday 12 March 2021 (End of Week 2)kainÎncă nu există evaluări

- SG MP 2022 Salary ReportDocument97 paginiSG MP 2022 Salary ReportDfffÎncă nu există evaluări

- Revised ResumeDocument2 paginiRevised Resumebcrowde1Încă nu există evaluări

- Educational Technology: Meaning and NatureDocument275 paginiEducational Technology: Meaning and NatureammanapparaÎncă nu există evaluări

- Yu 2017Document10 paginiYu 2017Ehsan AbarghooeiÎncă nu există evaluări

- Vip Club Proposal: VIP Group Dar-Es-Salaam, TanzaniaDocument10 paginiVip Club Proposal: VIP Group Dar-Es-Salaam, TanzaniaOMG DISCOUNT CARDSÎncă nu există evaluări