Documente Academic

Documente Profesional

Documente Cultură

NPR (Nippon Piston Ring) Piston Rings

Încărcat de

joralbbargarDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

NPR (Nippon Piston Ring) Piston Rings

Încărcat de

joralbbargarDrepturi de autor:

Formate disponibile

NPR (Nippon Piston Ring) Piston Rings.

1. The most important functions of NPR Piston Rings.

NPRs most important principles of Piston Rings are: a. Function (Reliability). b. Reduced Weight. c. Low Friction. d. Low Production Cost. Functions of each 1st, 2nd, and Oil Control Rings (please see below figures):

Print Introduction

1) Gas seal: The seal must perform during both the compression stroke and expansion stroke to provide maximum performance. This is the best achieved with the proper amount of lubricant oil film on the piston ring cylinder contact point and complete contact of the bottom of the piston ring against the piston groove. Therefore, the proper seal improves performance and decreases oil consumption. 2) Oil Control: The function of the oil control ring is to assure the proper amount of lubricant film. By providing the correct lubricant film for all piston ring contact points on the cylinder, this will prevent scuffing and excessive wear. However, an excessive amount of lubricant film will force too much oil into the combustion chamber resulting in soot in the exhaust. 3) Heat Conduction: The function of heat conduction is to allow heat to escape from the piston head to cylinder wall and then to cooling water and/or cooling fins. If the heat is not allowed to decrease, oil temperature will increased. This results in reduced oil viscosity and increased oil consumption. 4) Bearing: Pistons have reciprocation motion in both expansion and compression strokes. Because of this the piston exerts a higher pressure against one side of the cylinder wall during the expansion stroke. The piston ring assures a proper clearance between the piston and the cylinder wall while maintaining complete contact around the entire circumference of the cylinder wall. This prevents both gas blow by and piston scoring.

2. The quality advantages of NPR Steel Rings.

Print Introduction

NPRs unrivaled Piston Rings and Pistons will satisfy the needs of todays higher performance engine. All Piston Rings and Pistons listed in this catalog are the results of our hard bench engine tests taking into consideration material composition and surface treatment design. These tests on actual engines were conducted with the cooperation of the automobile manufacturer to assure a proper match to your engines specifications.

Material Steel vs. Cast Iron vs. Ductile Iron.

Todays modern engines have higher operating temperatures, higher compression, higher stress and higher restrictions on emissions. These conditions have put greater demands on piston rings. Steel rings outperform their cast iron predecessors in reduced oil consumtiopn, reduced blow by, reduced wear, reduced breakage, and reduced friction.

Oil consumption

Steel piston rings allow for a reduction in the radial wall thickness. This (thinner) and lighter design seals more completely against the ring groove. Also, the steel ring with greater strength, reduced width conforms better to less than perfect cylinder bores. These two advantages reduce oil consumption by move than 30%.

Durability of Steel

The inherent strength of high alloy steel dramatically reduces the chance of ring breakage. Late model engines have reduced their ring thickness from 2.0 to 1.2 and 1.0 mm. Steel also provides for longer service life because ring wear is reduced by over 60% Steel Piston Rings Advantages: Higher tensile strength. Higher yield strength. Greater fatigue life. Greater hardness. Lower ring mass. Better stress resistance. Reduced rings side wear. Reduced grooves pound out. Longer service life. Better conformability. Superior oil economy. Superior blow-by control. Lower friction.

Benefits:

Surface Treatment

NPRs surface treatment is also very high quality, and the result of our technology. The chart below shows surface treatment comparison.

ii

3. Piston Ring Name of Parts Free (Unstressed) Ring

1. 2. 3. 4. 5. 6. 7. 8. 9. Ring face or Periphery. Total free gap (m). T: Radial wall thickness (ai). Butt ends. Inside Surface. Back of the ring. B: Ring width (h1) Side Face. Peripheral edges.

Print Introduction

Closed Gap

10. Closed gap (S1). 11. Cylinder Bore (H). Nominal ring diameter (d1). Symbols in ( ) are as given in : ISO6621/1 SAE J1588 JIS B 8032

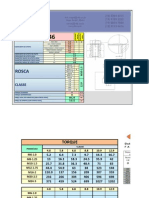

Recommended Closed Ring Gap NPR generally manufacturers its rings to meet the JIS (Japanese Industrial Standard) B8032-6-1998. It is import to recognize that some end gaps for individual engines may vary from this standard because of the original engine manufacturers requirements. The table appearing below is for reference only. All sizes are in millimeters. Recomendacion De Cierre Del Espacio Final Del Anillo (End Gap) NPR generalmente fabrica sus anillos para piston siempre siguiendo las normas del FIS (El estandar industrial Japones) B8032-6-1998. Es importante reconocer que en algunos motores, el espacio final del anillo puede variar del JIS a causa de los requerimientos del fabricante. La tabla que aparece debajo es de referencia solamente. Todas las medidas son en milimetros. Cylinder Bore Size 40.00 ~ 59.00 60.00 ~ 74.00 75.00 ~ 89.00 90.00 ~ 109.00 110.00 ~ 120.00 Compression Ring Gap 0.15 ~ 0.35 0.20 ~ 0.40 0.25 ~ 0.50 0.30 ~ 0.55 0.35 ~ 0.60 2pc. Oil Ring Gap 0.15 ~ 0.35 0.20 ~ 0.40 0.25 ~ 0.50 0.30 ~ 0.50 0.35 ~ 0.60 3pc. Oil Ring Gap 0.20 ~ 0.95 0.25 ~ 1.00 0.30 ~ 1.05 0.35 ~ 1.10

iii

4. Explanation of NPR Ring set Code.

Print Introduction

1) Type of Set. S: Eleven digits code started with S represents a complete set of piston rings for an engine model S assigned by Make and Model codes. For instance, TOYOTA 22RE (4 cylinder) has been assigned as T10103. In this case, SWT10103ZZ-2 represents four sets of each 1st, 2nd, and oil rings. Eleven digits code started with Y represents only one cylinder set of piston ring. In case of TOYOTA 22RE, YWT10103ZZ-2 represents one set of 1st, 2nd, and oil rings. NPR has both engine set (S-) and cylinder set (Y-) code in the same Make, Model and Application for some makes (HONDA / ISUZU / SUZUKI / YAMAHA etc.).

Y: Note:

Note 2: Since a cylinder set code (Y-) represents a piston ring set for only one cylinder, an engine requires a cylinder set multiplied by the number of cylinders of the engine. 2) Series Marks

US Application

Most of Piston Rings for Gas Engine : Mt.777 or 777. Most of Piston Rings for Diesel Engine : Mt.555 or 555.

Export Piston Rings

There are varieties of Piston Ring Series. Please see above.

Important Note!

From time to time the surface treatment specifications may be changed. Contact NPR, if you have questions on individual engine applications.

iv

Explanation of Series # There are various combinations of piston rings to make the set suitable to the engine. Using a ring set containing three rings per cylinder, we explain our basic Series #s as under:

Print Introduction

Mt. : Top and bottom sides of the ring are Chrome Plated. X : Plate expander is coupled with oil control ring.

Important Note!

Diesel Ring 555 Series: Because Diesel Cylinders may have different inside Cylinder wall surfaces, NPR ring surface treatments on Top and Oil Control Ring will change: Ring Type 555 Mt.555 Mt.555F Surface Treatment Chrome on outside contact surface. Chrome on Top, Bottom and Outside contact surface. There may be Chrome on the inside surface depending on individual application. Chrome on Top and Bottom surfaces, but no Chrome on outside contact surfaces. Typically used in Chromard Liner applications.

From time to time the surface treatment specifications may be changed. Contact NPR, if you have questions on individual engine applications.

3) Make US Application Code D10 F20 H30 I10 L02 M30 M31 N30 N31 S20 T10 T20 Export Code D10 F20 H20 H30 I10 K04 L02 M30 M31 N30 N31 S20 T10 T20

Print Introduction

Make DAIHATSU SUBARU ACURA, HONDA ISUZU, (GM, CHEVROLET, GEO) DAEWOO, HYUNDAI, KIA, MAZDA MITSUBISHI, (CHRYSLER, DODGE, EAGLE, PLYMOUTH, HYUNDAI) MAZDA, MITSUBISHI INFINITI, NISSAN, (FORD MERCURY) NISSAN DIESEL SUZUKI, (GM, CHEVROLET, GEO) LEXUS, TOYOTA, (GM, CHEVROLET, GEO) MAZDA (FORD, MERCURY) Make DAIHATSU SUBARU HINO HONDA ISUZU KOMATSU DAEWOO, HYUNDAI, KIA, MAZDA MITSUBISHI HYUNDAI, MITSUBISHI NISSAN NISSAN DIESEL SUZUKI TOYOTA KIA, MAZDA

NOTE:

EXPLANATION OF MAKES IN PARENTHESIS ( ) When engines are out-sourced, you may find some set codes which have a make code assigned for an engine manufacturer other than the vehicle manufacturer (For example: SWM31047 is used for Chrysler engine).

4) Model A three digit number is uniquely assigned by an engine model connected with a make code. 5) Serial Code for Application Assigned by engineer. 6) Oversize Code 0: Standard. No Color 1: Oversize (0.25mm). White 2: Oversize (0.50mm). Blue 3: Oversize (0.75mm). Black 4: Oversize (1.00mm). Yellow 5: Oversize (1.25mm). Orange 6: Oversize (1.50mm). Green * Indication is only for Nifflex type expander rings. * * Please note that there may be some exceptions for this color code depending on the original manufacturers requirement. *

vi

Installation Instruction of Oil Rings.

(Instalacion del Anillo de Control de Aceite) 1. Series 777 Oil Rings. (Anillo de Aceite Serie 777)

Fit the spacer expander into the ring groove, and ensure that the ends are butting as shown in the illustration. Acomodar el espaciador dentro de la ranura y asegurarse que las orillas se lleguen a juntar, sin encimarse. Como se muestra en la ilustracion donde las orillas del espaciador se juntan. Hold with thumb the spacer expander with its ends completely butting. Install the upper side rail with its gap approximately 45 Degree left of Spacer Expander end. Con el dedo pulgar sostener el espaciador donde se juntan ambas orillas. Installar primero la lamina o riel superior con una distancia de una pulgada o 45 grados a la izquierda donde se juntaron las orillas del espaciador. Install the lower side rail with its gap approximately 45 Degree right of the expander ends. Posteriormente de la misma manera a como se menciono anteriormente se instala la lamina o riel inferior con una distancia de una pulgada o 45 grados hacia la derecha de donde se juntaron las orillas del espaciador. If you have followed these instructions, this ring will Be installed as illustrated on the right. Make sure each gap is located as illustration to the right demonstrates. Si usted ha seguido estas instrucciones como la ilustracion que aparece de lado derecho. Tiene que asegurarse que los huecos (Gap) sean colocados como se muestra en el dibujo.

Print Introduction

vii

Installation Instruction of Oil Rings.

(Instalacion del Anillo de Control de Aceite.)

Print Introduction

2. Series 777 Oil Rings for Subaru EA Engine. (Serie 777 Anillo de Control de Aceite para Subaru Tipo de Maquina EA.)

In EA Engine pistons, there is a knock pin in the oil ring groove. Install the spacer expander around the whole piston perimeter, placing its ends approximately 180 Degree from the knock pin. Los pistones del motor EA tienen un pasador en el Surco del anillo aceitador. Instale el expansor Espaciador alrededor del perimetro total del piston, Ubicando sus extremos a unos 180 Grado de dicho pasador.

One of the two side rails has one of its ends slightly bent. Hook the bent part into the spacer expander, at a point located approximately 45 Degree left of the piston head UP mark, then install the rail around the whole piston perimeter (see figure). Uno de los dos rieles laterales tiene uno de sus extremos ligeramente doblado. Enganche esta parte doblada en el expansor espaciador, en un punto ubicado a unos 45 Grado a la izquierda de la marca UP grabada en la cabeza del piston, e instale el riel alrededor del perimetro total del pison (ver figura).

Install the lower side rail with its gap approximately 45 Degree right of the piston head UP mark. Instale el riel lateral inferior con su hueco ubicado a unos 45 Grado a la derecha de la marca UP grabada en la cabeza del piston.

viii

Installation Instruction of Oil Rings.

(Instrucciones para Instalar el Anillo De Control de Aceite.) 3. Series 555 Oil Rings. (Anillo de Aceite Serie 555)

First, disconnect the joint of coil expander. Primero, desconectar el alambrillo en forma de espiral del espaciador.

Print Introduction

Next, encircle the 1st oil ring groove with coil expander and joint the ends of coil expander again. Despues, instale el alambrillo en forma de espiral dentro de la ranura del piston en la ranura correspondiente y cerrar el circulo.

Last, install the ring outside of coil expander. (Please use Piston Ring Installation Tool). Finalmente, instalar el espaciador por fuera del alambrillo en forma de espiral.

The end of the ring must be placed on the opposite side of the joint of the coil expander. Las orillas del anillo deben de ser colocadas del lado opuesto a la union del alambrillo en forma de espiral.

ix

Installation Instruction of Compression Rings. Print Introduction

N or Number is facing upward when installed on the piston. Siempre hay que asegurarse que al instalar el anillo de compresion para la primera ranura del piston, este debera notarse que la N y el numero1 deberan estos estar siempre hacia arriba dentro la primera ranura del piston.

Use Piston Ring tool to expand the end gap. Then install 2nd and Top ring to Piston Ring Groove. Siempre es recomendable usar herramienta especial, como Ensanchadores del Anillo de Piston. Para el segundo anillo de compresion se usa el mismo procedimiento del primer anillo de compresion, pero en este hay que notar que el numero 2 y la letra N, deberan estar siempre hacia arriba dentro de la segunda ranura del piston.

Do not install compression rings like rail rings. Nunca hay que instalar los anillos de compression de la misma manera que se instalan los anillos de control de aceite (rieles o laminas).

RING SPECIFICATIONS AND DEFINITION GUIDE

Cross-section Configuration / Configuration Code

P CR1 BF CR1-BF T1 B1-T1 IB BF-IB CR1-BF-IB T1-IB IC T1-IC T1-RC B1-TUC B-UC TUC UC TUH ES-TUC

K2 BF-K2 CR1-BF-K2 T1-K2 BF-K3 BF-K1 CR1-BF-K1 T1-K1 BF-K1-IC T1-K1-IC

Material Code: Material Name CR : NPR CAST IRON HB : NIPPALOY (Spheroidal graphite Cast Iron) SR : STEEL Code: Surface Treatment Fe : Phosphated Cr : Chromium plated on sliding surface 2Cr: Both side faces chromium plated 4Cr: All surfaces Chromium plated GN : Nitrided PVD: PVD Coated JF : UNIFRON coated

C1, BC1, BC2, BC3, BC14, BC-16 E-C1, E-C2, E-BC1, E-BC3, E-BC16 NIFFLEX-S NIFFLEX-H

Above figures show basic cross-section configuration but not in detail

B mm : Ring Width T mm : Ring Rdial Wall Thickness

Print Material Code

S-ar putea să vă placă și

- NPR 2013noacatalogforprintoutDocument596 paginiNPR 2013noacatalogforprintoutSelvaraji MuthuÎncă nu există evaluări

- 2012 Noa Catalog For PC ScreenDocument0 pagini2012 Noa Catalog For PC ScreenJuan Manuel Gomez HernandezÎncă nu există evaluări

- NPR American Piston PDFDocument296 paginiNPR American Piston PDFFernando Bautista100% (1)

- 4032 Installation Tips: Piston To Cylinder Wall ClearanceDocument2 pagini4032 Installation Tips: Piston To Cylinder Wall ClearanceMihneaStefanÎncă nu există evaluări

- Catalogo Engimax Motores IsuzuDocument38 paginiCatalogo Engimax Motores IsuzuAlexis SanchezÎncă nu există evaluări

- Piston Instrc4032Document2 paginiPiston Instrc4032RickracerÎncă nu există evaluări

- Needle en b173-217Document45 paginiNeedle en b173-217charles_boyle_3Încă nu există evaluări

- JE Piston Terminology and FeaturesDocument4 paginiJE Piston Terminology and FeaturesCarlos García Hernández100% (1)

- Calculo de Torque X Forca AxialDocument4 paginiCalculo de Torque X Forca Axialmajonas77Încă nu există evaluări

- Worm Gear Sets enDocument30 paginiWorm Gear Sets enDimas Dwi HÎncă nu există evaluări

- Komatsu Liner KitDocument34 paginiKomatsu Liner KitMANCHING MOKÎncă nu există evaluări

- KZ1000 KZ1100Document370 paginiKZ1000 KZ1100motomech100% (12)

- ENGIMAX Komatsu Liner KitDocument24 paginiENGIMAX Komatsu Liner KitahmedalgaloÎncă nu există evaluări

- Mitsubishi Fuso Liner KitDocument45 paginiMitsubishi Fuso Liner Kitchristopher Huaman SanchezÎncă nu există evaluări

- Funcion de Los Anillos de PistonDocument21 paginiFuncion de Los Anillos de PistonDiego OrozcoÎncă nu există evaluări

- Isuzu NKR 4jb1Document62 paginiIsuzu NKR 4jb1Jakes Schmidt79% (14)

- HY07-1110UK 2H Inch Series Tie Rod 210 Bar Hydraulic CylindersDocument42 paginiHY07-1110UK 2H Inch Series Tie Rod 210 Bar Hydraulic CylindersYashwanth ReddyÎncă nu există evaluări

- HOS Frame and Running Gear Data Standard Frame and Running Gear AssembliesDocument8 paginiHOS Frame and Running Gear Data Standard Frame and Running Gear AssembliesJose Luis RattiaÎncă nu există evaluări

- Fig. 1 Comparison of BS IV & BS VI Emission ElementsDocument27 paginiFig. 1 Comparison of BS IV & BS VI Emission Elementsp1dnd_628915447Încă nu există evaluări

- Kawasaki ZX9R 98-99Document307 paginiKawasaki ZX9R 98-99motomech100% (3)

- MC Series MNDocument33 paginiMC Series MNnvkjayanthÎncă nu există evaluări

- Maximizing Bearing PerformanceDocument12 paginiMaximizing Bearing PerformanceJurun_Bidanshi100% (1)

- Group 3 - RDocument196 paginiGroup 3 - RJusto Paniagua Champa67% (3)

- Pinto+Doc Med+ResDocument20 paginiPinto+Doc Med+ResSirRD80% (5)

- Yamaha XTZ 750 ST Service ManualDocument425 paginiYamaha XTZ 750 ST Service ManualAmigosek80% (5)

- CP Carrillo HardwareDocument23 paginiCP Carrillo HardwarePaul ZiddyÎncă nu există evaluări

- GT2000 TurbineplansDocument27 paginiGT2000 TurbineplansSzabolcs Szalai100% (1)

- Piston Ring Assembly Tips 4strk - Ringinstall2!24!05Document2 paginiPiston Ring Assembly Tips 4strk - Ringinstall2!24!05michaelmangaaÎncă nu există evaluări

- International Navistar Works KitDocument7 paginiInternational Navistar Works Kithuskerchamps100% (1)

- Engine Rotary Motor MazdaDocument32 paginiEngine Rotary Motor Mazdastripy101100% (1)

- EngineRotary EditedDocument32 paginiEngineRotary EditedNamit GuptaÎncă nu există evaluări

- KLR 685cc Kit-InstructionsDocument4 paginiKLR 685cc Kit-InstructionsNoel LabuschagneÎncă nu există evaluări

- Automotive Piston RingDocument68 paginiAutomotive Piston RingARVINDA KUMARÎncă nu există evaluări

- 7.0 Reference: 7.1 Engine Room LayoutDocument3 pagini7.0 Reference: 7.1 Engine Room LayoutCarlos MenaÎncă nu există evaluări

- T JZX90 / JZX100 N O H: Oyota EW Wners AndbookDocument12 paginiT JZX90 / JZX100 N O H: Oyota EW Wners AndbookZom ByeÎncă nu există evaluări

- Generator Bearing ServiceDocument10 paginiGenerator Bearing ServiceMustafa A.W100% (1)

- Crankshaft Grinding GuidelinesDocument2 paginiCrankshaft Grinding Guidelinesиван ТрояновÎncă nu există evaluări

- Helical Gearbox InstallationDocument8 paginiHelical Gearbox InstallationKUNALJAYÎncă nu există evaluări

- S SE EC CT Tiio ON N 1 1: Section 1Document14 paginiS SE EC CT Tiio ON N 1 1: Section 1Miguel Hernandez Barbosa100% (1)

- Internal Gears: KHK Products Are Available From Maryland MetricsDocument6 paginiInternal Gears: KHK Products Are Available From Maryland MetricsbtfreekÎncă nu există evaluări

- 2015 TAG USA Stock Moto CR125 Karting RegulationsDocument7 pagini2015 TAG USA Stock Moto CR125 Karting RegulationsJames McMahonÎncă nu există evaluări

- Pinto+doc Med+res PDFDocument20 paginiPinto+doc Med+res PDFfarish100% (1)

- MEO Class 2 Orals Function 6 Q & ADocument7 paginiMEO Class 2 Orals Function 6 Q & Aneeraj118550% (2)

- Connecting Rod PDFDocument9 paginiConnecting Rod PDFvictoverÎncă nu există evaluări

- Z 50 ADocument65 paginiZ 50 AHans SiezenisÎncă nu există evaluări

- Service Bulletin RN-6.1: Technical Information To All Owners / Operators of Sulzer RN and RN..M Engines 25.02.2000Document20 paginiService Bulletin RN-6.1: Technical Information To All Owners / Operators of Sulzer RN and RN..M Engines 25.02.2000zbkt07100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsDe la EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsEvaluare: 4 din 5 stele4/5 (1)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe la EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualÎncă nu există evaluări

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe la EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualEvaluare: 2.5 din 5 stele2.5/5 (2)

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)De la EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Încă nu există evaluări

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- High-Performance GM LS-Series Cylinder Head GuideDe la EverandHigh-Performance GM LS-Series Cylinder Head GuideEvaluare: 4.5 din 5 stele4.5/5 (2)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallDe la EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallEvaluare: 4 din 5 stele4/5 (8)

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeDe la EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeÎncă nu există evaluări

- #3584 Architecural ProductsDocument25 pagini#3584 Architecural Productspeter cooperÎncă nu există evaluări

- ZEXEL NozzlesDocument24 paginiZEXEL NozzlesAten Haris100% (1)

- Eicher EngineDocument4 paginiEicher EnginePranay JoshiÎncă nu există evaluări

- C1250C 50 HZ PDFDocument4 paginiC1250C 50 HZ PDFBắc NhậtÎncă nu există evaluări

- Manual de Servicio Toyota 2NR-FE PDFDocument73 paginiManual de Servicio Toyota 2NR-FE PDFNelson Caño Basalo83% (6)

- Preparation 2zr-Fbe Engine Mechanical SST PDFDocument3 paginiPreparation 2zr-Fbe Engine Mechanical SST PDFAlbert BriceñoÎncă nu există evaluări

- Spesifikasi Compressor Hatlapa L140Document2 paginiSpesifikasi Compressor Hatlapa L140hanafiajaÎncă nu există evaluări

- Basic Mechanical Engineering 2Nd Edition Pravin Kumar Full ChapterDocument67 paginiBasic Mechanical Engineering 2Nd Edition Pravin Kumar Full Chapterjefferson.kleckner559100% (8)

- Camshaft PDFDocument6 paginiCamshaft PDFjoaobargasÎncă nu există evaluări

- Yfz 350t Yamaha DespieceDocument68 paginiYfz 350t Yamaha DespieceRafael EquihuaÎncă nu există evaluări

- 1100 Series VistaDocument64 pagini1100 Series VistaJesus Neto100% (5)

- The New Renault Dci 1.6l Diesel EngineDocument27 paginiThe New Renault Dci 1.6l Diesel EngineBorja Navas Sanchez100% (2)

- Workshop Manual Deutz VolvoDocument28 paginiWorkshop Manual Deutz VolvoMarcelo Daniel Gonzalez LLanosÎncă nu există evaluări

- 2004 Ski Doo Racing HandbookDocument274 pagini2004 Ski Doo Racing HandbookMDA1980Încă nu există evaluări

- ReviewerDocument30 paginiReviewerAriel Mark PilotinÎncă nu există evaluări

- Caso Siilar dt13 Epa07Document5 paginiCaso Siilar dt13 Epa07angel cob ekÎncă nu există evaluări

- Tom Os: Workshop ManualDocument45 paginiTom Os: Workshop ManualMarkoÎncă nu există evaluări

- UniKL MIAT Piston 2 Mid Block TestDocument6 paginiUniKL MIAT Piston 2 Mid Block Testmellon3duwenÎncă nu există evaluări

- Common Rail Fuel InjectionDocument13 paginiCommon Rail Fuel InjectionAnoj pahathkumburaÎncă nu există evaluări

- SUZUKI DF200 225 250 Service InfoDocument8 paginiSUZUKI DF200 225 250 Service InfoCandido IsazaÎncă nu există evaluări

- Diesel Engine Fuel Injectors: A Highway & Heavy Parts EbookDocument37 paginiDiesel Engine Fuel Injectors: A Highway & Heavy Parts Ebookscania100% (1)

- 3406B TruckDocument4 pagini3406B Truckvictor franco gallegosÎncă nu există evaluări

- Altronics A1 BLLTN 08-1990 PDFDocument2 paginiAltronics A1 BLLTN 08-1990 PDFSMcÎncă nu există evaluări

- ID Analisis Penggunaan Koil Racing TerhadapDocument11 paginiID Analisis Penggunaan Koil Racing TerhadapJalalludinÎncă nu există evaluări

- BE0520B100004DDocument2 paginiBE0520B100004DLUKASÎncă nu există evaluări

- Fuchs Titan Passenger Car Web Jan 2015Document10 paginiFuchs Titan Passenger Car Web Jan 2015api-295271471Încă nu există evaluări

- CHED Memo 37, Series 2007Document35 paginiCHED Memo 37, Series 2007Guimo Pantuhan50% (2)

- Trattorino 2867071185 E1Document36 paginiTrattorino 2867071185 E1lorant hathaziÎncă nu există evaluări

- ATPL - AGK WEB 07 Janu 19Document96 paginiATPL - AGK WEB 07 Janu 19Tanvir HasanÎncă nu există evaluări

- Genima ED4W-YD90-Serie-Spareparts-CatalogDocument33 paginiGenima ED4W-YD90-Serie-Spareparts-Catalogcupid75Încă nu există evaluări