Documente Academic

Documente Profesional

Documente Cultură

Turbines

Încărcat de

msvgiwiDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Turbines

Încărcat de

msvgiwiDrepturi de autor:

Formate disponibile

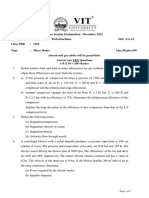

TURBINES

A turbine converts energy in the form of falling water into rotating shaft power. The selection of the best turbine for any particular hydro site depends on the site characteristics, the dominant ones being the head and flow available. Selection also depends on the desired running speed of the generator or other device loading the turbine. Other considerations such as whether the turbine is expected to produce power under part-flow conditions, also play an important role in the selection. All turbines have a power-speed characteristic. They will tend to run most efficiently at a particular speed, head and flow combination. A turbine design speed is largely determined by the head under which it operates. can be classified as high head, medium head or low head machines. Turbines are also divided by their principle way of operating and can be either impulse or reaction turbines. High head medium head cross-flow multi-jet Pelton Turgo reaction turbines Francis propeller Kaplan low head

impulse turbines

Pelton Turgo

cross-flow

Groups of impulse and reaction turbines The rotating element (called `runner') of a reaction turbine is fully immersed in water and is enclosed in a pressure casing. The runner blades are profiled so that pressure differences across them impose lift forces, like those on aircraft wings, which cause the runner to rotate. In contrast, an impulse turbine runner operates in air, driven by a jet (or jets) of water. Here the water remains at atmospheric pressure before and after making contact with the runner blades. In this case a nozzle converts the pressurised low velocity water into a high speed jet. The runner blades deflect the jet so as to maximise the change of momentum of the water and thus maximising the force on the blades. Impulse turbines are usually cheaper then reaction turbines because there is no need for a specialist pressure casing, nor for carefully engineered clearances. However, they are only suitable for relatively high heads. Impulse turbines Impulse turbines are generally more suitable for micro-hydro applications compared with reaction turbines because they have the following advantages: greater tolerance of sand and other particles in the water, better access to working parts, no pressure seals around the shaft, easier to fabricate and maintain, better part-flow efficiency. The major disadvantage of impulse turbines is that they are mostly unsuitable for low-head sites because of their low specific speeds. The crossflow, Turgo and multi-jet Pelton are suitable at medium heads.

A Pelton turbine consists of a set of specially shaped buckets mounted on a periphery of a circular disc. It is turned by jets of water which are discharged from one or more nozzles and strike the buckets. The buckets are split into two halves so that the central area does not act as a dead spot incapable of deflecting water away from the oncoming jet. The cutaway on the lower lip allows the following bucket to move further before cutting off the jet propelling the bucket ahead of it and also permits a smoother entrance of the bucket into the jet. (see diagrams below) The Pelton bucket is designed to deflect the jet through 165 degrees (not 180 degrees) which is the maximum angle possible without the return jet interfering with the following bucket for the oncoming jet.

Runner of a Pelton turbine

source: http://www.hydrowest.com/runners1.htm

bucket shape source: http://europa.eu.int/en/comm/dg17/hydro/layman2.pdf In large scale hydro installation Pelton turbines are normally only considered for heads above 150 m, but for micro-hydro applications Pelton turbines can be used effectively at heads down to about 20 m. Pelton turbines are not used at lower heads because their rotational speeds become very slow and the runner required is very large and unwieldy. If runner size and low speed do not pose a problem for a particular installation, then a Pelton turbine can be used efficiently with fairly low heads. If a higher running speed and smaller runner are required then there are two further options: - increasing the number of jets. Having two or more jets enables a smaller runner to be used for a given flow and increases the rotational speed. The required power can still be attained and the part-flow efficiency is especially good because the wheel can be run on a reduced number of jets with each jet in use still receiving the optimum flow. - twin runners. Two runners can be placed on the same shaft either side by side or on opposite sides of the generator. This configuration is unusual and would only be used if the number of jets per runner had already been maximised, but it allow the use of smaller diameter and hence faster rotating runners.

Reaction turbines

The reaction turbines considered here are the Francis turbine and the propeller turbine. A special case of the propeller turbine is the Kaplan. In all these cases, specific speed is high, i.e. reaction turbines rotate faster than impulse turbines given the same head and flow conditions. This has the very important consequences in that a reaction turbine can often be coupled directly to an alternator without requiring a speed-increasing drive system. Some manufacturers make combined turbine-generator sets of this sort. Significant cost savings are made in eliminating the drive and the maintenance of the hydro unit is very much simpler. The Francis turbine is suitable for medium heads, while the propeller is more suitable for low heads. On the whole, reaction turbines require more sophisticated fabrication than impulse turbines because they involve the use of larger and more intricately profiled blades together with carefully profiled casings. Francis turbines can either be volute-cased or open-flume machines. The spiral casing is tapered to distribute water uniformly around the entire perimeter of the runner and the guide vanes feed the water into the runner at the correct angle. The runner blades are profiled in a complex manner and direct the water so that it exits axially from the centre of the runner. In doing so, the water imparts most of its pressure energy to the runner before leaving the turbine via a draft tube. The Francis turbine is generally fitted with adjustable guide vanes. These regulate the water flow as it enters the runner and are usually linked to a governing system which matches flow to turbine loading in the same way as a spear valve or deflector plate in a Pelton turbine. When the flow is reduced the efficiency of the turbine falls away.

Francis turbine (source: adapted from http://lingolex.com/bilc/engine.html & http://starfire.ne.uiuc.edu/~ne201/1996/schoenau/wheel~1.html) Propeller turbine The basic propeller turbine consists of a propeller, similar to a ship's propeller, fitted inside a continuation of the penstock tube. The turbine shaft passes out of the tube at the point where the tube changes direction. The propeller usually has three to six blades, three in the case of very low head units and the water flow is regulated by static blades or swivel gates ("wicket gates") just upstream of the propeller. This kind of propeller turbine is known as a fixed blade axial flow turbine because the pitch angle of the rotor blades cannot be changed. The part-flow efficiency of fixed-blade propeller turbines tend to be very poor. Kaplan

Large scale hydro sites make use of more sophisticated versions of the propeller turbines. Varying the pitch of the propeller blades together with wicket gate adjustment, enables reasonable efficiency to be maintained under part flow conditions. Such turbines are known as variable pitch or Kaplan turbines. Centrifugal pumps can be used as turbines by passing water through them in reverse. Research is currently being done to enable the performance of pumps as turbines to be predicated more accurately. Home page for Main Menu

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- HydroDocument9 paginiHydromsvgiwiÎncă nu există evaluări

- BIS Standards On WeldingDocument5 paginiBIS Standards On Weldingkislay.shahiÎncă nu există evaluări

- Brinell Hardness TestDocument8 paginiBrinell Hardness Testinnocentsoul100% (7)

- Lab 2hardness EngDocument25 paginiLab 2hardness EngmsvgiwiÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- FlowCheck User ManualDocument88 paginiFlowCheck User ManualNicole WilliamsÎncă nu există evaluări

- European Aviation Safety Agency: Easa Type-Certificate Data SheetDocument8 paginiEuropean Aviation Safety Agency: Easa Type-Certificate Data SheetAlberto CisnerosÎncă nu există evaluări

- Syarif Ishak Alkadri: PLTMH, Cross-Flow Turbine, Runner, Nozzle, EfficiencyDocument17 paginiSyarif Ishak Alkadri: PLTMH, Cross-Flow Turbine, Runner, Nozzle, EfficiencyDian DedeÎncă nu există evaluări

- Binder 1Document18 paginiBinder 1tj82npdh9cÎncă nu există evaluări

- Dynamic Analysis and Balancing of An 1150 MW Turbine-Generator SystemDocument10 paginiDynamic Analysis and Balancing of An 1150 MW Turbine-Generator SystemThanhluan NguyenÎncă nu există evaluări

- Generator Rotor Removal PDFDocument8 paginiGenerator Rotor Removal PDFMohamed Omar100% (1)

- Estudio de Turbina Pelton CFDDocument108 paginiEstudio de Turbina Pelton CFDOscar Choque JaqquehuaÎncă nu există evaluări

- ESPSS BrochureDocument2 paginiESPSS Brochurejakub_gramolÎncă nu există evaluări

- FSX-414 Datasheet, FSX-414 Chemical, FSX-414 Heat Treatment PDFDocument2 paginiFSX-414 Datasheet, FSX-414 Chemical, FSX-414 Heat Treatment PDFJ. BangjakÎncă nu există evaluări

- Fluid InstabilityDocument12 paginiFluid InstabilityJarot PrakosoÎncă nu există evaluări

- 210479820563440B840B297C6C79B23CDocument3 pagini210479820563440B840B297C6C79B23CyashvantÎncă nu există evaluări

- Implement Model of Variable Pitch Wind Turbine - SimulinkDocument4 paginiImplement Model of Variable Pitch Wind Turbine - SimulinkJie LIUÎncă nu există evaluări

- Digital Twins Enhance LNG Plant PerformanceDocument6 paginiDigital Twins Enhance LNG Plant Performancekhaled_behery9934Încă nu există evaluări

- MatlabDocument47 paginiMatlabalkadyasÎncă nu există evaluări

- Introduction To ANSYS CFX Workshop 04 AxDocument32 paginiIntroduction To ANSYS CFX Workshop 04 AxLam Trinh NguyenÎncă nu există evaluări

- 09SS003 Duke Doosan Buck CTCC - Final Electrical Tests - Rev.2Document8 pagini09SS003 Duke Doosan Buck CTCC - Final Electrical Tests - Rev.2SteveÎncă nu există evaluări

- Fluid Mechanics-II Lab Manual: University College of Engineering and TechnologyDocument27 paginiFluid Mechanics-II Lab Manual: University College of Engineering and Technologyzia malikÎncă nu există evaluări

- Wind Energy Term PaperDocument5 paginiWind Energy Term Paperea6qsxqd100% (1)

- Pv-Wind Hybrid PowerDocument49 paginiPv-Wind Hybrid PowerHAIMANOT100% (1)

- Notes-Fluid Flow MachineryDocument48 paginiNotes-Fluid Flow MachineryIanÎncă nu există evaluări

- Survey of Implanting Wind Mill in Vellore TAMIL NADUDocument11 paginiSurvey of Implanting Wind Mill in Vellore TAMIL NADUKB Praveen KumarÎncă nu există evaluări

- The Making of An Expert EngineerDocument591 paginiThe Making of An Expert Engineernathanielsamson100% (8)

- 2GTG - Know How Training 14 March 2013 - Participants 2pg - 2Document72 pagini2GTG - Know How Training 14 March 2013 - Participants 2pg - 2Annisa AnugraÎncă nu există evaluări

- Ejercicos Van WylenDocument11 paginiEjercicos Van WylenJorgeJiménezÎncă nu există evaluări

- Wind Tesla TurbineDocument9 paginiWind Tesla TurbineRonan RojasÎncă nu există evaluări

- Rashid Kolaghassi Physics IaDocument14 paginiRashid Kolaghassi Physics Iaapi-590770395Încă nu există evaluări

- FPE - Class Tutorials - 29072018 - 053044PM PDFDocument12 paginiFPE - Class Tutorials - 29072018 - 053044PM PDFDKÎncă nu există evaluări

- Thermal Power PlantDocument26 paginiThermal Power PlantratrideviinhostelÎncă nu există evaluări

- Steam Turbine Maintenance Manual-1Document244 paginiSteam Turbine Maintenance Manual-1Trie Wahyudi100% (4)