Documente Academic

Documente Profesional

Documente Cultură

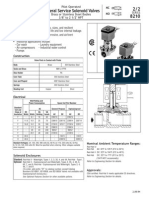

Pipe Fitting 79026 08 - 09

Încărcat de

martinvandoornDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pipe Fitting 79026 08 - 09

Încărcat de

martinvandoornDrepturi de autor:

Formate disponibile

Precision Pipe Fittings

Index

CNPClose Nipple NPHex Nipple RNPHex Reducing Nipple LNPHex Long Nipple APAdapter RAPReducing Adapter RBPReducing Bushing CGPHex Coupling RCGPReducing Coupling CPPCap PPPlug FLPFemale Elbow SLPStreet Elbow RSLPReducing Street Elbow MLPMale Elbow FTPFemale Tee STPStreet Tee FTBMMale Branch Tee MTPMale Tee CSPCross Safety Instructions 3 3 3 3 4 4 4 5 5 5 5 6 6 6 6 7 7 7 7 8 8

precision pipe fittings

18 to 1 sizes 316 stainless steel, brass, and exotic materials NPT threads

HOKE Incorporated 405 Centura Court PO Box 4866 (29305) Spartanburg, SC 29303 Phone (864) 574-7966 Fax (864) 587-5608 www.hoke.com sales@hoke.com

Hoke Precision Instrument Pipe Fittings

Hoke Precision Instrument Pipe Fittings are manufactured with high quality NPT tapered threads in a wide variety of configurations to provide broad application capabilities.

precision pipe fittings

Threads

Threads utilized on Hoke Precision Instrument Pipe fittings are National Pipe Taper (NPT) which exceed the requirements of ANSI B1.20.1.

Materials

Hoke Precision Pipe Fittings are available as standard in Brass and 316 Stainless Steel. Hoke pipe fittings can also be supplied in other materials including, Monel, Hastelloy C, Inconel and Titanium and in special shapes. Specifications for standard materials are: 316 Stainless Steel Forgings 316 Stainless Steel Bar Stock Brass Forgings, Alloy 377 Brass Bar Stock, Alloy 353 Brass Bar Stock, Alloy 360 ASTM A-182 ASTM A-479 QQ-B-626 ASTM B-453 QQ-B-626

Pressure Ratings

Pressure ratings for temperatures up to 100 F are identified for each individual pipe fitting in the dimensional data charts.

Temperature*

Temperatures noted below apply to basic fitting capabilities. In all cases consideration must also be given to the type of thread sealant used. For example, Teflon tape has a maximum temperature rating of 450 F. 316 stainless steel: 325 F to +1200 F (198 C to +648 C) Brass: 325 F to +400 F (198 C to +204 C)

Heat Traceability

Hokes 316 Stainless Steel Precision Instrument Pipe Fittings are heat code traceable. To obtain certified material test reports (CMTRS) for these components, place separate orders for such items and specify CMTRS required.

* Prolonged exposure to temperature over 800 F is not recommended.

HOKE Incorporated 405 Centura Court PO Box 4866 (29305) Spartanburg, SC 29303 Phone (864) 574-7966 Fax (864) 587-5608 www.hoke.com sales@hoke.com

Precision Instrument Pipe Fittings

Hoke Pipe Fitting Part Numbering

The part numbering system for Hoke Precision Instrument Pipe Fittings is completely descriptive and easily understood. Example:

PIPE SIZE IN SIXTEENTHS OF AN INCH 4 NPT PIPE SIZE (IF DIFFERENT) IN SIXTEENTHS OF AN INCH 2 18 NPT MATERIAL BRASS BR 316 SS 316 EXAMPLE: 4RAP2316 316 316 Stainless Steel

PIPE FITTING TYPE RAP Reducing Adapter

Assembly Instructions

To ensure a leak-tight seal, the use of a pipe thread sealant is recommended. One commonly utilized technique is Teflon Tape. The chart below provides information regarding the recommended tape width and the approximate number of threads which should be wrapped

NOMINAL PIPE SIZE 18 38 1

RECOMMENDED TAPE WIDTH 18

EFFECTIVE THREAD LENGTH (EXTERNAL) L* 38 38 916 1116

APPROX. # OF THREADS 7 713 7 7 723 8

* ISA Handbook of Control Valves. Note: Dimensions are in inches. The Pipe Thread Sealants may have lower temperature capabilities than the basic fitting. Example: For a NPT, L = 38 Approximate number of threads which should be wrapped = 713

HOKE

Precision Instrument Pipe Fittings

CNP Close Nipple (male NPT both ends)

PIPE SIZE ORDER BY PART NUMBER 4CNP [ ] 6CNP [ ] 8CNP [ ] 12CNP [ ] MALE 38 A 118 118 1 1 DIMENSIONS E (MIN. OPENING) 932 38 2764 58 WORKING PRESSURE (PSIG) BRASS 5700 5500 5400 4600 316SS 9900 9000 8900 8300

NP Hex Nipple (male NPT both ends)

PIPE SIZE ORDER BY PART NUMBER 1NP [ ] 2NP [ ] 4NP [ ] 6NP [ ] 8NP [ ] 12NP [ ] 18NP [ ] MALE 116 18 38 1 A 11364 1732 11932 158 2 2 2 DIMENSIONS E MIN 18 316 932 38 1532 58 78 F HEX 516 716 916 1116 78 1116 138 WORKING PRESSURE (PSIG) BRASS 7100 7100 5700 5500 5400 4600 3400 316SS 12,300 12,300 9900 9000 8900 8300 5900

RNP Hex Reducing Nipple (male NPT to reduced male NPT)

ORDER BY PART NUMBER 2RNP1 [ ] 4RNP2 [ ] 6RNP4 [ ] 8RNP4 [ ] 8RNP6 [ ] 12RNP6 [ ] 12RNP8 [ ] 16RNP8 [ ] 16RNP12 [ ] PIPE SIZE MALE 18 38 1 1 REDUCED MALE 116 18 38 38 A 1316 1932 1 11116 11116 12332 12932 2932 2932 DIMENSIONS E MIN 332 316 932 932 38 38 716 716 58 F HEX 716 916 1116 78 78 1116 1116 138 138 WORKING PRESSURE (PSIG) BRASS 7100 7100 5700 5700 5500 5500 6200 6200 4600 316SS 12,300 12,300 9900 9900 9000 9000 10,100 10,100 8300

LNP Hex Long Nipple (male NPT both ends)

PIPE SIZE ORDER BY PART NUMBER 2LNP [ ]/200 2LNP [ ]/250 4LNP [ ]/200 4LNP [ ]/250 4LNP [ ]/300 4LNP [ ]/400 6LNP [ ]/200 6LNP [ ]/250 6LNP [ ]/400 8LNP [ ]/300 12LNP [ ]/300 16LNP [ ]/300 16LNP [ ]/400 MALE 18 18 38 38 38 1 1 A 2 2 2 2 3 4 2 2 4 3 3 3 4 DIMENSIONS E MIN 316 316 932 932 932 932 1116 1116 1116 78 1116 138 138 F HEX 716 716 916 916 916 916 1116 1116 1116 78 1116 138 138 WORKING PRESSURE (PSIG) BRASS 7100 7100 5700 5700 5700 5700 5500 5500 5500 5400 4600 3400 3400 316SS 12,300 12,300 9900 9900 9900 9900 9000 9000 9000 8900 8300 5900 5900

Dimensions for reference only. Subject to change.

HOKE

Precision Instrument Pipe Fittings

AP Adapter (female NPT same size male NPT)

PIPE SIZE ORDER BY PART NUMBER 2AP [ ] 4AP [ ] MALE 18 38 A 1 138 1916 12932 13132 DIMENSIONS E MIN 316 932 38 1532 2132 F HEX 916 78 1116 1 WORKING PRESSURE (PSIG) BRASS 4200 4200 3400 2700 2100 316SS 7300 7300 5500 4900 3700

F-Hex E

6AP [ ] 8AP [ ] 12AP [ ]

RAP Reducing Adapter (female NPT to reduced male NPT)

ORDER BY PART NUMBER

F-Hex E

PIPE SIZE FEMALE 38 38 1 1 MALE 18 18 38 38 A 1 1516 1 1 1 11316 11316 2 2 2

DIMENSIONS E MIN 316 316 932 932 38 932 38 1532 1532 58 F HEX 78 78 1116 1116 1 1 1 158 158

WORKING PRESSURE (PSIG) BRASS 4200 3400 3400 2700 2700 2100 2100 2100 2500 2500 316SS 7300 5500 5500 4900 4900 3700 3700 3700 4300 4300

4RAP2 [ ] 6RAP2 [ ] 6RAP4 [ ] 8RAP4 [ ] 8RAP6 [ ] 12RAP4 [ ]

12RAP6 [ ] 12RAP8 [ ] 16RAP8 [ ] 16RAP12 [ ]

RBP Reducing Bushing (male NPT to reduced female NPT)

F-Hex

ORDER BY PART NUMBER 2RBP1 [ ] 4RBP2 [ ] PIPE SIZE MALE 18 38 38 1 1 FEMALE 116 18 18 38 38 A 1 1 118 118 1532 1532 1732 1916 1916 1916 1 DIMENSIONS E MIN 316 932 1132 38 716 716 716 3764 58 2332 78 F HEX 716 916 78 78 1116 1116 1116 138 138 WORKING PRESSURE (PSIG) BRASS 7000 4200 6600 4200 5700 2900 7300 5200 4000 5600 3200 316SS 12,200 7300 11,400 7300 9300 4800 13,100 9400 7300 9500 5400

6RBP2 [ ] 6RBP4 [ ] 8RBP4 [ ]

8RBP6 [ ] 12RBP4 [ ] 12RBP6 [ ] 12RBP8 [ ] 16RBP8 [ ] 16RBP12 [ ]

HOKE

Dimensions for reference only. Subject to change.

Precision Instrument Pipe Fittings

CGP Hex Coupling (female NPT both ends)

PIPE SIZE ORDER BY PART NUMBER 2CGP [ ] 4CGP [ ] 6CGP [ ] 8CGP [ ] 12CGP [ ] 16CGP [ ] FEMALE 18 38 1 A 1316 118 1 1 1916 2 DIMENSIONS E MIN 1132 716 3764 2332 5964 1164 F HEX 916 78 1116 1 158 WORKING PRESSURE (PSIG) BRASS 4200 4200 3400 2700 2100 2500 316SS 7300 7300 5500 4900 3700 4300

RCGP Reducing Coupling (female NPT to reduced female NPT)

ORDER BY PART NUMBER 4RCGP2 [ ] 6RCGP4 [ ] 8RCGP4 [ ] 8RCGP6 [ ] 12RCGP4 [ ] 12RCGP6 [ ] 12RCGP8 [ ] 16RCGP8 [ ] 16RCGP12 [ ] PIPE SIZE FEMALE 38 1 1 MALE 18 38 38 A 1 138 1 1 12332 2116 2116 2316 2 DIMENSIONS E MIN 1132 716 716 3764 716 3764 2332 2332 5964 F HEX 78 1116 1116 1 1 1 158 158 WORKING PRESSURE (PSIG) BRASS 4200 3400 2700 2700 2100 2100 2100 2500 2500 316SS 7300 5500 4900 4900 3700 3700 3700 4300 4200

CPP Cap (female NPT)

PIPE SIZE ORDER BY PART NUMBER 2CPP [ ] 4CPP [ ] 6CPP [ ] 8CPP [ ] 12CPP [ ] 16CPP [ ] FEMALE 18 38 1 DIMENSIONS A 1116 78 1132 1 1716 158 F HEX 916 78 1116 1 158 WORKING PRESSURE (PSIG) BRASS 4200 4200 3400 2700 2100 2500 316SS 7300 7300 5500 4900 3700 4300

PP Plug (male NPT)

PIPE SIZE ORDER BY PART NUMBER 1PP [ ] 2PP [ ] 4PP [ ] 6PP [ ] 8PP [ ] 12PP [ ] 16PP [ ] MALE 116 18 38 1 DIMENSIONS A 4764 1516 1 1 1516 11116 F HEX 516 716 916 1116 78 1116 138 Dimensions for reference only. Subject to change.

HOKE

Precision Instrument Pipe Fittings

FLP Female Elbow (female NPT both ends)

ORDER BY PART NUMBER 2FLP [ ] 4FLP [ ] 6FLP [ ] 8FLP [ ] 12FLP [ ] PIPE SIZE FEMALE 18 38 L 2732 1 118 1 DIMENSIONS E MIN 1132 716 3764 2332 5964 W 1116 1316 1 1 WORKING PRESSURE (PSIG) BRASS 3600 2900 2300 2200 2200 316SS 5600 4600 3700 3500 3400

SLP Street Elbow (female to male NPT)

ORDER BY PART NUMBER 1SLP [ ] 2SLP [ ]

L W-Wrench Flat

PIPE SIZE FEMALE 116 18 38 L 2732 1 118 1716

DIMENSIONS S 2332 2532 118 1 11132 1 E MIN 18 316 932 38 1532 58 W 716 1116 1316 1 1

WORKING PRESSURE (PSIG) BRASS 5000 3600 2900 2300 2200 2200 316SS 7900 5600 4600 3700 3500 3400

4SLP [ ] 6SLP [ ] 8SLP [ ] 12SLP [ ]

S

RSLP Reducing Street Elbow (female NPT reduced male NPT)

PIPE SIZE ORDER BY PART NUMBER 6RSLP4 [ ] 8RSLP4 [ ] 8RSLP6 [ ] FEMALE 38 REDUCED FEMALE 38 L 1 1 1 DIMENSIONS S 118 118 1532 E MIN 932 932 1332 W 1316 1 1 WORKING PRESSURE (PSIG) BRASS 2300 2200 3600 316SS 3700 3500 5600

MLP Male Elbow (male NPT both ends)

PIPE SIZE ORDER BY PART NUMBER 2MLP [ ] 4MLP [ ] 6MLP [ ] 8MLP [ ] 12MLP [ ] MALE 18 38 S 2332 6164 1 1316 1 DIMENSIONS E MIN 316 932 38 1532 58 W 716 1116 1116 1 1 WORKING PRESSURE (PSIG) BRASS 6200 5000 4800 4700 4400 316SS 9700 7800 7500 7400 6900

HOKE

Dimensions for reference only. Subject to change.

Precision Instrument Pipe Fittings

FTP Female Tee (female NPT all ports)

PIPE SIZE ORDER BY PART NUMBER 2FTP [ ] 4FTP [ ] 6FTP [ ] 8FTP [ ] 12FTP [ ] FEMALE 18 38 A 1 11116 2 2 278 L 2732 1 118 1716 DIMENSIONS E MIN 1132 716 3764 2332 5964 W 1116 1316 1 158 WORKING PRESSURE (PSIG) BRASS 3600 2900 2300 2200 4200 316SS 5600 4600 3700 3500 7900

STP Street Tee (female by male run/female branch)

ORDER BY PART NUMBER 2STP [ ] 4STP [ ] 6STP [ ] 8STP [ ] 12STP [ ] DIMENSIONS PIPE SIZE 18 38 A 11732 12732 218 21532 3764 L 2732 1 118 1716 S 2532 1 118 11132 158 E MIN 316 932 38 1532 58 W 1116 1316 1 158 WORKING PRESSURE (PSIG) BRASS 3600 2800 2300 2200 3800 316SS 5600 4500 3700 3500 7200

FTBM Male Branch Tee (female run/male branch)

ORDER BY PART NUMBER 2FT/BM2 [ ] 4FT/BM4 [ ] 6FT/BM6 [ ] 8FT/BM8 [ ] DIMENSIONS PIPE SIZE 18 38 A 11116 11116 2 2 L 2732 2732 1 118 S 2732 1 118 11132 E MIN 316 932 38 1532 W 1116 1116 1316 1 WORKING PRESSURE (PSIG) BRASS 6200 2900 2300 2200 316SS 9700 4600 3700 3500

MTP Male Tee (male NPT all ports)

PIPE SIZE ORDER BY PART NUMBER 2MTP [ ] 4MTP [ ] 6MTP [ ] 8MTP [ ] 12MTP [ ] MALE 18 38 A 1 2 2 21732 3 DIMENSIONS S 1 1 11764 1 E MIN 316 932 38 1532 58 W 716 1116 1116 1 1 WORKING PRESSURE (PSIG) BRASS 6200 5000 4800 4700 4400 316SS 9700 7800 7500 7400 6900

Dimensions for reference only. Subject to change.

HOKE

Precision Instrument Pipe Fittings

CSP Cross

PIPE SIZE ORDER BY PART NUMBER 2CSP [ ] 4CSP [ ] 6CSP [ ] 8CSP [ ] FEMALE 18 38 A 11116 11116 2 2 DIMENSIONS L 2732 2732 1 118 E MIN 1132 716 3764 2332 W 1116 1116 1 1 WORKING PRESSURE (PSIG) BRASS 6900 2800 4600 2200 316SS 10,800 4500 7200 3500

Safety Instructions

1. Do not tighten or loosen any part of a fitting or valve when the system is pressurized. Make sure the system is not pressurized when tightening or loosening a fitting or valve connection. 2. Do not loosen Hoke Gyrolok nut or any product component in order to relieve or bleed down system pressure. 3. Do not exceed pressure-temperature specifications stated in the appropriate catalog. 4. When the application involves use of a toxic or hazardous fluid, exercise extra caution during operation and maintenance. 5. Before assembling new, unused Hoke Gyrolok tube fitting ends, loosen the Hoke Gyrolok nut before inserting the tube to allow full insertion of the tube to the base of the body bore. 6. Always use tubing that is compatible with the fitting or valve material. Tubing appropriate for use with Hoke products is described in Hokes Tubing Data Charts. For example, use 316 Stainless Steel fittings with 316 Stainless Steel tubing. 7. Always leave a length of straight tube between the tube bend and the fitting. A tube bent too close to the fitting connection may be a source of leakage. 8. During assembly of the Hoke Gyrolok tube end, always hold the fitting or valve body with one wrench while separately wrench tightening the Hoke Gyrolok nut. Follow the same precaution when disassembling. 9. Always use a Hoke tube insert (basic part number T1) when assembling a Hoke Gyrolok fitting to soft, pliable plastic tubing. 10. Always use proper thread lubricants or sealants on tapered pipe threads. Note that thread sealants may have lower temperature ratings than the basic fitting. 11. NPT threads should be torqued in accordance with an industry standard, such as Underwriters Laboratory UL842. Note that previously assembled threads may require additional tightening. 12. When installing an NPT ended valve, hold the valve body near the connection with one wrench, while separately wrench tightening the mating pipe. Turn the pipe, not the valve. Follow the same precaution when disconnecting. 13. Do not hold the valve handle when tightening an end connection. 14. Do not use excessive force to open or close a Ball Valve, e.g., Do not use a handle extension. 15. On initial installation, valves may require an adjustment of the packing nut due to storage variations, systems parameters, and cold flow properties of TFE.

FOR YOUR SAFETY: It is solely the responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation, and maintenance of these products. Material compatibility, product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or property damage. 8 HOKE

Dimensions for reference only. Subject to change.

Tech

DOPAK

g Sa m pl in

A

S

SAM

PLING

,

IN

TEX

C.

RIA, TEX

Hoke GO Regulator Tomco CIRCOR Tech

405 Centura Court PO Box 4866 (29305) Spartanburg, SC 29303 Tel (864) 574-7966 Fax (864) 587-5608 www.circortechnologies.com

Hoke Controls / Panels Plus

2054 Francis St. Ontario, CA 91761 Tel (909) 923-3770 Fax (909) 923-2550 www.circor-panelsplus.com

Texas Sampling, Inc

3706 Rio Grande Victoria, Texas 77901 Tel (361) 575-8087 Fax (361) 575-8157 www.texassampling.com

CIRCOR Instrumentation

Technologies

Central Europe Leeuwenhoekweg 24 2661 CZ Bergschenhoek The Netherlands Tel +31 10 4206011 Fax +31 10 4566774 www.circortechnologies.com

Dopak Inc.

9572 Kempwood Houston, Texas 77080 Tel (713) 460-8311 Fax (713) 460-8578 www.dopak.com

Circle Seal Controls

2301 Wardlow Circle Corona, CA 92880 Tel (951) 270-6200 Fax (951) 270-6201 www.circlesealcontrols.com

Hoke GmbH

Weitzesweg 11 Postfach 1541 D-61118 Bad Vilbel-Dortelweil Germany Tel +49 6101 82 56 0 Fax +49 6101 82 56 40 www.hoke.de

CIRCOR Instrumentation Technologies

CIRCOR Instrumentation Technologies (CIT) is a product group of CIRCOR International (NYSE: CIR), specializing in uid process control solutions with orice sizes typically up to 1. Our main product lines include ball, needle, packless, diaphragm, solenoid, and metering valves, pressure regulators, quick couplers, Gyrolok compression tube ttings, and fully integrated sampling systems.

CIT markets primarily to the petrochemical, rening, power generation, food and beverage, semiconductor, and pharmaceutical industries, and to OEMs. CIT separates itself from the competition by offering highly engineered components manufactured to exacting standards and a variety of custom options.

79026 08/09 APS158

S

A

VI

TO

S-ar putea să vă placă și

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- Precision Pipe Fittings: IndexDocument10 paginiPrecision Pipe Fittings: IndexniginpÎncă nu există evaluări

- Hoke Pipe Fittings With AbbreviationsDocument10 paginiHoke Pipe Fittings With AbbreviationsAmet koko TaroÎncă nu există evaluări

- Grundfos Submersible JOCKEYDocument18 paginiGrundfos Submersible JOCKEYdanilolabreÎncă nu există evaluări

- Fragola Performance CatalogDocument64 paginiFragola Performance CatalogChad MarÎncă nu există evaluări

- BTC Gate ValvesDocument26 paginiBTC Gate ValvesCamilo Sanchez VanegasÎncă nu există evaluări

- SELENOIDE-Valv Solen 8210Document6 paginiSELENOIDE-Valv Solen 8210MARACO46Încă nu există evaluări

- Grundfos PumpsDocument44 paginiGrundfos Pumpsbellis1037100% (2)

- Seko Motor Drive 2012Document12 paginiSeko Motor Drive 2012tooedÎncă nu există evaluări

- Каталог адаптеров ParkerDocument26 paginiКаталог адаптеров ParkergeomashsnabÎncă nu există evaluări

- General Service Solenoid Valves: NC NODocument6 paginiGeneral Service Solenoid Valves: NC NOAngel Azathoth GoetzÎncă nu există evaluări

- 3SV SubmittalDocument2 pagini3SV SubmittalBilly Isea DenaroÎncă nu există evaluări

- 10K Series Pipe FittingsDocument11 pagini10K Series Pipe FittingsNilesh MistryÎncă nu există evaluări

- Series 405NRSRW Specification SheetDocument2 paginiSeries 405NRSRW Specification SheetWattsÎncă nu există evaluări

- Válvula de Bola de Tres Vías VZBADocument3 paginiVálvula de Bola de Tres Vías VZBAJohnny Diaz VargasÎncă nu există evaluări

- MasterSeries 880V Specification SheetDocument4 paginiMasterSeries 880V Specification SheetFEBCOÎncă nu există evaluări

- Refco ToolsDocument28 paginiRefco ToolsTinosÎncă nu există evaluări

- MasterSeries 860 Specification SheetDocument2 paginiMasterSeries 860 Specification SheetFEBCOÎncă nu există evaluări

- D 520 1378 601 - R - 0001Document10 paginiD 520 1378 601 - R - 0001Riju MathewÎncă nu există evaluări

- Isometric Piping 1 To 74Document127 paginiIsometric Piping 1 To 74Priyanathan Thayalan100% (2)

- Principle of Operation: Target Inline FlowmeterDocument7 paginiPrinciple of Operation: Target Inline Flowmeterابزار دقیقÎncă nu există evaluări

- Hawe Rapid RangeDocument16 paginiHawe Rapid RangecinbrekÎncă nu există evaluări

- S H/ HP: Eries P PDocument59 paginiS H/ HP: Eries P Pvinodkhare2007Încă nu există evaluări

- Series U5B Specification SheetDocument2 paginiSeries U5B Specification SheetWattsÎncă nu există evaluări

- Tabela Completa Especificacao de TubulacaoDocument251 paginiTabela Completa Especificacao de TubulacaoAlessandre OliveiraÎncă nu există evaluări

- RegulatorDocument6 paginiRegulatorFlorin GoiaÎncă nu există evaluări

- Full Lift Spring Loaded Open PDFDocument4 paginiFull Lift Spring Loaded Open PDFVenkatespatange RaoÎncă nu există evaluări

- 8475PZ7Document8 pagini8475PZ7caballero_tigreÎncă nu există evaluări

- Masoneilan Equipment DataDocument3 paginiMasoneilan Equipment DataalvimranÎncă nu există evaluări

- VZPR enDocument14 paginiVZPR enoanzarÎncă nu există evaluări

- Grundfos L SP PG 001 Sec5 6 8 10 Inch 7 09Document40 paginiGrundfos L SP PG 001 Sec5 6 8 10 Inch 7 09perssan_88Încă nu există evaluări

- Zap DataSheet RevDDocument2 paginiZap DataSheet RevDnmihai73Încă nu există evaluări

- Schedule of Loads: Arch. Hervy G. Catilogo, UapDocument1 paginăSchedule of Loads: Arch. Hervy G. Catilogo, UapEmmanuel Linguaje Managbanag IIÎncă nu există evaluări

- RPL Staubli D100eDocument0 paginiRPL Staubli D100ejuanverengeurÎncă nu există evaluări

- Lolli: Screw-Lock Ball Coolant Nozzle With Integral Copper Tube For CNC LathesDocument1 paginăLolli: Screw-Lock Ball Coolant Nozzle With Integral Copper Tube For CNC LathesAllison V. MoffettÎncă nu există evaluări

- rc33026 D12-UscDocument7 paginirc33026 D12-Usceww08Încă nu există evaluări

- Fuel Oil PumpDocument8 paginiFuel Oil PumprezashahalamÎncă nu există evaluări

- Inter M Pt-9107sDocument16 paginiInter M Pt-9107sspeedyeduÎncă nu există evaluări

- Pipe Fitter Hand Book-1 PDFDocument1 paginăPipe Fitter Hand Book-1 PDFpanduranganraghuramaÎncă nu există evaluări

- 7200 Series: Acrylic TubeDocument2 pagini7200 Series: Acrylic Tubeatnkpr_vn9368Încă nu există evaluări

- 0304Document14 pagini0304Hair Samayoa BrionesÎncă nu există evaluări

- Zupcaste Pumpe 2pfDocument13 paginiZupcaste Pumpe 2pfmilokisrÎncă nu există evaluări

- A P19-23Document5 paginiA P19-23Madeshwaran KuppusamyÎncă nu există evaluări

- Needle ValvesDocument18 paginiNeedle ValvesPablo RodriguezÎncă nu există evaluări

- Series SS07F Specification SheetDocument2 paginiSeries SS07F Specification SheetWattsÎncă nu există evaluări

- AirdromeDocument137 paginiAirdromejcÎncă nu există evaluări

- PH WR WattsRadiant Catalog FullLine 03 RadiantPEXAL-En-20100519Document6 paginiPH WR WattsRadiant Catalog FullLine 03 RadiantPEXAL-En-20100519sas999333Încă nu există evaluări

- Process Industry Practices PipingDocument5 paginiProcess Industry Practices PipingAmreusit SaschimbnumeleÎncă nu există evaluări

- Pipe Fittings: 1/16 To 1 In. Sizes 316 Stainless Steel, Brass, and Carbon Steel NPT, ISO/BSP, and SAE ThreadsDocument16 paginiPipe Fittings: 1/16 To 1 In. Sizes 316 Stainless Steel, Brass, and Carbon Steel NPT, ISO/BSP, and SAE ThreadsMehmet YılmazÎncă nu există evaluări

- Series TDV Specification SheetDocument2 paginiSeries TDV Specification SheetWattsÎncă nu există evaluări

- 01SD1B02Document5 pagini01SD1B02raobabar21Încă nu există evaluări

- 8475-3A Gardner Denver PZ-7 5000PSIDocument8 pagini8475-3A Gardner Denver PZ-7 5000PSIAmauri CortesÎncă nu există evaluări

- Goulds Pumps Jet Pump Repair PartsDocument12 paginiGoulds Pumps Jet Pump Repair PartsMarissa Bryce50% (2)

- Line ProportionerDocument2 paginiLine ProportionerpsycopaulÎncă nu există evaluări

- 3-40 Hydraulic HosesDocument38 pagini3-40 Hydraulic HosesherberthhpÎncă nu există evaluări

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1De la EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Evaluare: 3.5 din 5 stele3.5/5 (3)

- Hoke Condensed Product Catalog 09.2012Document22 paginiHoke Condensed Product Catalog 09.2012martinvandoornÎncă nu există evaluări

- Datasheet Diaphragm Seal Threaded Type200 201 PDFDocument4 paginiDatasheet Diaphragm Seal Threaded Type200 201 PDFmartinvandoornÎncă nu există evaluări

- Hoke Needle ValvesDocument38 paginiHoke Needle ValvesmartinvandoornÎncă nu există evaluări

- Gyrolok CatalogDocument58 paginiGyrolok CatalogmartinvandoornÎncă nu există evaluări

- 1900series 2007-04 LoDocument2 pagini1900series 2007-04 LomartinvandoornÎncă nu există evaluări

- GyrolokFlangesDocument8 paginiGyrolokFlangesmartinvandoornÎncă nu există evaluări

- Formed-Cylinders 2007-04 LoDocument14 paginiFormed-Cylinders 2007-04 LomartinvandoornÎncă nu există evaluări

- Gyrolok Complete 79002 1206 ENGDocument59 paginiGyrolok Complete 79002 1206 ENGmartinvandoornÎncă nu există evaluări

- Formed-Cylinders 2009-10 LoDocument14 paginiFormed-Cylinders 2009-10 LomartinvandoornÎncă nu există evaluări

- A Report On External Analysis of Construction in NepalDocument13 paginiA Report On External Analysis of Construction in Nepalsubash upretiÎncă nu există evaluări

- 5100 NSL (User's Guide) PDFDocument40 pagini5100 NSL (User's Guide) PDFJEREMEE MICHAEL TYLERÎncă nu există evaluări

- Biology: Higher Tier Paper 1HDocument28 paginiBiology: Higher Tier Paper 1HkaruneshnÎncă nu există evaluări

- Safe and Gentle Ventilation For Little Patients Easy - Light - SmartDocument4 paginiSafe and Gentle Ventilation For Little Patients Easy - Light - SmartSteven BrownÎncă nu există evaluări

- REE0913ra LegazpiDocument6 paginiREE0913ra LegazpiScoopBoyÎncă nu există evaluări

- Pictionary Unit 12 - IGMSDocument4 paginiPictionary Unit 12 - IGMSNadia Jimenez HernandezÎncă nu există evaluări

- Papr114 SpectralDocument4 paginiPapr114 Spectrallilivaca28Încă nu există evaluări

- 017 - Chapter 3 - L13Document6 pagini017 - Chapter 3 - L13nanduslns07Încă nu există evaluări

- Genmega G2500Document103 paginiGenmega G2500tchindaforentÎncă nu există evaluări

- R0221120 - Salsabilla Cindy Pratama - Daily ActivityDocument15 paginiR0221120 - Salsabilla Cindy Pratama - Daily Activitysalsabilla cindy pratamaÎncă nu există evaluări

- Internship ReportDocument50 paginiInternship ReportSachinÎncă nu există evaluări

- 49728393Document17 pagini49728393MarcoÎncă nu există evaluări

- Role of BisoprololDocument43 paginiRole of BisoprololFidel Martua Marpaung67% (3)

- What Makes A Cup of NESCAFÉ So Special? The Best Coffee Beans andDocument4 paginiWhat Makes A Cup of NESCAFÉ So Special? The Best Coffee Beans andYenny YanyanÎncă nu există evaluări

- Aerial MV Covered Networks: Worth A New Look?: 2. Medium Voltage Overhead Insulated/ Covered LinesDocument1 paginăAerial MV Covered Networks: Worth A New Look?: 2. Medium Voltage Overhead Insulated/ Covered LinesAnonymous 1AAjd0Încă nu există evaluări

- MantrasDocument45 paginiMantrasharibhakta100% (1)

- 1.8 CarderoDocument29 pagini1.8 CarderoRodrigo Flores MdzÎncă nu există evaluări

- STPM Mathematics T Past Year Question P1 P2 P3Document19 paginiSTPM Mathematics T Past Year Question P1 P2 P3Sou Voyage0% (3)

- Zbus and Symmetrical Fault AnalysisDocument20 paginiZbus and Symmetrical Fault Analysishj203800Încă nu există evaluări

- Rangtong Shentong ViewDocument19 paginiRangtong Shentong Viewlongjim31100% (1)

- DM HSD GU35 URAS2 Technical Guidelines For Usage of Rope Access System V2.1Document20 paginiDM HSD GU35 URAS2 Technical Guidelines For Usage of Rope Access System V2.1Natalie BlackmoreÎncă nu există evaluări

- Rule 8. Fire Safety Enforcers Chapter 1. Qualifications of Fire Safety Enforcers Division 1. Minimum RequirementsDocument13 paginiRule 8. Fire Safety Enforcers Chapter 1. Qualifications of Fire Safety Enforcers Division 1. Minimum Requirementspatitay036817Încă nu există evaluări

- Sandvik DD210Document4 paginiSandvik DD210Lener Elvin Lopez LavadoÎncă nu există evaluări

- Ultrafast Lasers Technology and Applications (Optical Science and CRC 1st Ed., 2002) (ISBN 0824708415), Martin E. Fermann, Almantas Galvanauskas Gregg SuchaDocument797 paginiUltrafast Lasers Technology and Applications (Optical Science and CRC 1st Ed., 2002) (ISBN 0824708415), Martin E. Fermann, Almantas Galvanauskas Gregg SuchaRokas DanilevičiusÎncă nu există evaluări

- Bravo Petroleum ProfileDocument8 paginiBravo Petroleum ProfileJacob Thom ZiwahwaÎncă nu există evaluări

- Harmonization of HR Policies - RoughDocument119 paginiHarmonization of HR Policies - RoughFrancis SoiÎncă nu există evaluări

- Assignment Oumh2103 English For Science Technical PurposesDocument12 paginiAssignment Oumh2103 English For Science Technical PurposesKhairul AnuarÎncă nu există evaluări

- Catalyst PreparationDocument15 paginiCatalyst PreparationVISHAL SHARMAÎncă nu există evaluări

- Maximizing Bass Reflex System Performance Through Optimization ofDocument32 paginiMaximizing Bass Reflex System Performance Through Optimization ofGilberto MontaniÎncă nu există evaluări

- 2020 Sustainabilty Report - ENDocument29 pagini2020 Sustainabilty Report - ENGeraldÎncă nu există evaluări