Documente Academic

Documente Profesional

Documente Cultură

Exhaust Dyeing With Reactive Dyes

Încărcat de

ahsannazirDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Exhaust Dyeing With Reactive Dyes

Încărcat de

ahsannazirDrepturi de autor:

Formate disponibile

4/20/2012

Exhaust Dyeing with Reactive Dyes

Dr. Tanveer Hussain Dean Faculty of Engineering & Technology National Textile University Faisalabad.

4/20/2012 Dr. Tanveer Hussain 1

Variables in Reactive Dyeing

Dye variables System/process variables

4/20/2012

Dr. Tanveer Hussain

4/20/2012

Dye variables in Reactive Dyeing

Dye chemistry Substantivity Reactivity Diffusion coefficient Solubility

4/20/2012

Dr. Tanveer Hussain

Reactive Dye Chemistry

Chromophore

Affects colour gamut, light fastness, chlorine/ bleach fastness, solubility, affinity, and diffusion Azo dyes are dischargeable. Disazo dyes have the disadvantage of being much more sensitive to reduction and many of them are difficult to wash-off. Anthraquinone dyes exhibit relatively low substantivity and are easier to wash-off. Most of them possess excellent fastness to light and to creaseresistant finishes, but they are not dischargeable. Phthalocyanine dyes diffuse slowly and are difficult to wash-off

4/20/2012 Dr. Tanveer Hussain 4

4/20/2012

Reactive Dye Chemistry

Reactive Group

Affects

affinity efficiency of reaction with the fibre, dyefibre bond stability,

Determines

Sat requirement Alkali requirement Temperature requirement

4/20/2012

Dr. Tanveer Hussain

Reactive Dye Chemistry

S-triazine dyes

Do not have good wet fastness properties in acidic media Due to their high substantivity, have poor wash-off properties. Monochlorotriazines have good fastness to light, perspiration and chlorine. The fluorotriazine groups form linkages with cellulose that are stable to alkaline media

4/20/2012 Dr. Tanveer Hussain 6

4/20/2012

Reactive Dye Chemistry

Reactive dyes of dichloroquinoxaline, monochlorotriazine and monofluorotriazine types show a tendency for lower resistance to peroxide washing and dyefibre bond stability A lower sensitivity to changes in dyeing conditions (particularly temperature) is the most important characteristic feature of the monochlorotriazine-vinyl sulphone heterobifunctional dyes

4/20/2012 Dr. Tanveer Hussain 7

Reactive Dye Chemistry

Vinyl sulphone reactive system

have poor alkaline fastness. chemical bond between the vinyl sulphone and the cellulosic fibre is very stable to acid hydrolysis. The substantivity of hydrolysed byproducts of vinyl sulphone is low, so washing off is easy

The turquoise reactive dye shows an optimum dyeing temperature that is generally about 20 C higher than that of other dyes with the same reactive group

4/20/2012 Dr. Tanveer Hussain 8

4/20/2012

Dye Substantivity

Substantivity is more dependent on the chromophore as compared to the reactive system. A higher dye substantivity may result in:

4/20/2012

a lower dye solubility a higher primary exhaustion a higher reaction rate for a given reactivity less diffusion, migration and levelness a higher risk of unlevel dyeing, more difficult removal of unfixed dye

Dr. Tanveer Hussain 9

4/20/2012

Dr. Tanveer Hussain

10

4/20/2012

Dye Substantivity

An increase in the dye substantivity may be affected by:

higher concentration of electrolyte, lower temperature, higher pH (up to 11) lower liquor to goods ratio

4/20/2012

Dr. Tanveer Hussain

11

Half dyeing time

4/20/2012

Dr. Tanveer Hussain

12

4/20/2012

Dye Reactivity

4/20/2012

Dr. Tanveer Hussain

13

Dye Reactivity

A high dye reactivity entails a lower dyeing time and a lower efficiency of fixation. Reactivity of a dye can be modified by altering the pH or temperature, or both.

4/20/2012

Dr. Tanveer Hussain

14

4/20/2012

Diffusion Coefficient

Dyes with higher diffusion-coefficients usually result in better levelling and more rapid dyeing. Diffusion is hindered by the dye that has reacted with the fibre and the absorption of active dye is restrained by the presence of hydrolysed dye. Different types of dyes have different diffusion characteristics. For example, the order of decreasing diffusion is: unmetallised dyes, 1:1 metal-complex dyes, 1:2 metal complex dyes; phthalocyanine dyes. An increase in the diffusion is affected by:

increasing temperature, decreasing electrolyte concentration, adding urea in the bath using dyes of low substantivity.

4/20/2012

Dr. Tanveer Hussain

15

Dye Solubility

Dyes of better solubility can diffuse easily and rapidly into the fibres, resulting in better migration and levelling. An increase in dye solubility may be affected by:

increasing the temperature, adding urea decreasing the use of electrolytes.

4/20/2012

Dr. Tanveer Hussain

16

4/20/2012

System Variables in Reactive Dyeing

Temperature pH Electrolyte Liquor ratio Surfactants & other auxiliaries

4/20/2012

Dr. Tanveer Hussain

17

Effect of Temperature

A higher temperature in dyeing with reactive dyes results in:

a higher rate of dyeing lower colour yield better dye penetration rapid diffusion better leveling a higher risk of dye hydrolysis lower substantivity

4/20/2012 Dr. Tanveer Hussain 18

4/20/2012

Effect of pH

pH influences primarily the concentration of the cellusate sites on the fibre. Raising the pH value by 1 unit corresponds to a temperature rise of 20 C. The dyeing rate is best improved by raising the dyeing temperature once a pH of 1112 is reached. Further increase in pH will reduce the reaction rate as well as the efficiency of fixation

4/20/2012 Dr. Tanveer Hussain 19

Type of Alkali

Different types of alkalis, such as caustic soda, soda ash, sodium silicate or a combination of these alkalis, are used in order to attain the required dyeing pH. The choice of alkali usually depends upon the dye used, the dyeing method as well as other economic and technical factors

4/20/2012

Dr. Tanveer Hussain

20

10

4/20/2012

Effect of Electrolyte

The addition of electrolyte results in:

increase in the rate and extent of exhaustion, increase in dye aggregation decrease in diffusion.

The electrolyte efficiency increases in the order: KCl < Na2SO4 < NaCl There may be impurities present in the salt to be used, such as calcium sulphate, magnesium sulphate, iron, copper and alkalinity, that can be a source of many dyeing problems

4/20/2012 Dr. Tanveer Hussain 21

Effect of Liquor Ratio

At lower liquor ratios, there is:

Higher exhaustion, and Higher colour strength

4/20/2012

Dr. Tanveer Hussain

22

11

4/20/2012

Effect of surfactants & auxiliaries

Some anionics may enhance colour yield Some non-ionics may decrease exhaustion and colour yield Some non-ionics may slow down dye hydrolysis Triethanolamine (TEA) is known to enhance colour strength by enhancing the swellability and accessibility of the cellulose structure

4/20/2012 Dr. Tanveer Hussain 23

Reactive Dye Exhaustion

Primary exhaustion

Occurs before addition of alkali

Secondary exhaustion

Occurs after addition of alkali

Rate of exhaustion can be increased by selecting dyes of high substantivity, increasing the temperature and increasing the electrolyte concentration. Degree of exhaustion can be increased by selecting dyes of high substantivity, lowering a bit the equilibrium temperature and increasing the electrolyte concentration and dyeing time.

4/20/2012 Dr. Tanveer Hussain 24

12

4/20/2012

Reactive Dye Migration

The intrinsic properties of a reactive dye that affect migration are:

substantivity, molecular structure, physical chemistry and stereochemistry.

The higher the dye substantivity, the lower is the migration. The external factors that affect migration are:

concentration of the dye, temperature, time, liquor ratio, liquor circulation the form of the textile material

4/20/2012

Dr. Tanveer Hussain

25

Reactive Dye Levelness

Levelness of dyeing may be inhibited by:

4/20/2012

high substantivity, lower dye migration too much salt in the dyebath too high rate of exhaustion too high concentration of alkali a rapid shift of dyebath pH, too high rate of fixation too high rate of rise of temperature poor liquor agitation.

Dr. Tanveer Hussain 26

13

4/20/2012

Approaches to Obtain Level Dyeing

Controlled absorption can be obtained by salt dosing, alkali dosing, and/or controlling the rate of heating.

4/20/2012 Dr. Tanveer Hussain 27

Obtaining Level Dyeing in Light Shades

During the primary exhaustion, the dye is free to migrate. During the secondary exhaustion stage, dye migration is poor. For light dyeing shades (less than 1 % o.w.f.) the degree of primary exhaustion is over 80% and the degree of secondary exhaustion is very small. Therefore control of the primary exhaustion stage is very important if level dyeing is to be obtained. The rate of primary exhaustion is dependent on the amount of electrolyte used. Dosing or split addition of salt is recommended to obtain level dyeing.

4/20/2012

Dr. Tanveer Hussain

28

14

4/20/2012

Obtaining Level Dyeing in Medium & Dark Shades

For medium shades, both primary and secondary exhaustion steps are important for obtaining level dyeing. Both controlled salt and alkali addition are important in this case. In the case of deep shades, the all-in salt addition may be possible, but during the secondary exhaustion, alkali dosing is important

4/20/2012 Dr. Tanveer Hussain 29

Obtaining level dyeing in general

Dyes with high substantivity, low secondary exhaustion, and low MI (Migration Index) values require controlled addition of electrolyte after the addition of the dye. In contrast, dyes with low substantivity, high secondary exhaustion, and medium to high migration index values require precise control of liquor ratio, concentration of electrolyte, and addition profile of the fixation alkali

4/20/2012 Dr. Tanveer Hussain 30

15

4/20/2012

Ways to Enhance Dye Fixation & Colour Yield

Use of fixation accelerators Use of shorter liquor ratio Dyeing at low temperature (with decreasing temperature the substantivity for fibre increases, causing increased exhaustion) Modification of chromophore and reactive group Use of dyes with high substantivity and high reactivity Treating cellulosic fibres with swelling agents Modification in appearance techniques Changing the morphology of fibre by chemical modification.

4/20/2012 Dr. Tanveer Hussain 31

Approaches for Uniform Rise in Rate of Fixation

Controlling the temperature of the dyeing process suitably (possible for hot dyeing dyes only); Adding alkali in stages (it is virtually impossible, however, to prevent a sharp rise in fixation rate whenever alkali is added); Starting with a weaker alkali such as soda ash, and following this with a stronger alkali, but only after a higher degree of fixation has been achieved; Progressive metering of alkali (such as the Remazol automet process);

4/20/2012

Dr. Tanveer Hussain

32

16

4/20/2012

Exhaust dyeing method example 1

4/20/2012

Dr. Tanveer Hussain

33

Exhaust dyeing method example 2

4/20/2012

Dr. Tanveer Hussain

34

17

4/20/2012

Washing-off of Hydrolyzed Dye

Phases

dilution of dye and chemicals (salt, alkali) in solution and on the surface of the cellulose; diffusion of the deeply-penetrated, unfixed, hydrolysed dye to the fibre surface; and dilution and removal of the diffused-out dye

4/20/2012

Dr. Tanveer Hussain

35

Washing-off of Hydrolyzed Dye

Goods are rinsed cold twice to remove electrolyte & alkali then rinsed hot to desorb some hydrolysed dye from the fibre, prior to a soaping process at or near the boil. A subsequent cold rinse completes the task of removing un-reacted and hydrolysed dye

4/20/2012

Dr. Tanveer Hussain

36

18

4/20/2012

Washing-off Factors

Dye substantivity Diffusion behaviour Liquor ratio Washing temperature Electrolyte concentration pH Presence of calcium and magnesium ions in the boiling soap/hardness of water Amount of unfixed dye Washing time Number of washing cycles/washing baths/Filling and draining Washing auxiliary employed Mechanical action

4/20/2012

Dr. Tanveer Hussain

37

Dye-fiber Bond Stability

Dyes that react by a nuceophilic displacement mechanism show good stability to alkali and, to different degrees, less stability to acid. Dyes that react by nucleophilic addition give dye fibre bonds with good stability to acid, but are less stable to alkali. The triazinecellulose bond is generally resistant to oxidative breakdown in the presence of perborate, whereas this is a serious defect of some of the pyrimidine based systems

4/20/2012 Dr. Tanveer Hussain 38

19

4/20/2012

Fastness of Reactive Dyes

Factors

The chromophoric group, the stability of the dyefibre bond the completeness of the removal of the unfixed dye.

To maximise wet fastness, particularly in deep shades, it is advisable to apply cationic aftertreatments.

4/20/2012 Dr. Tanveer Hussain 39

Sustainable Reactive Dyeing

Shorter/more robust dyeing procedures Reduced water consumption Reduced energy consumption Reduced effluent discharge Improved ecological image

4/20/2012

Dr. Tanveer Hussain

40

20

4/20/2012

4/20/2012

Dr. Tanveer Hussain

41

4/20/2012

Dr. Tanveer Hussain

42

21

4/20/2012

4/20/2012

Dr. Tanveer Hussain

43

4/20/2012

Dr. Tanveer Hussain

44

22

4/20/2012

4/20/2012

Dr. Tanveer Hussain

45

4/20/2012

Dr. Tanveer Hussain

46

23

4/20/2012

4/20/2012

Dr. Tanveer Hussain

47

4/20/2012

Dr. Tanveer Hussain

48

24

4/20/2012

4/20/2012

Dr. Tanveer Hussain

49

4/20/2012

Dr. Tanveer Hussain

50

25

4/20/2012

BASF has developed a new polymer which combines with a reactive dye hydrolysate to eliminate its substantivity for the substrate in the presence of salt.

4/20/2012

Dr. Tanveer Hussain

51

26

S-ar putea să vă placă și

- Reactive DyesDocument24 paginiReactive DyesrehanabbaciÎncă nu există evaluări

- Problems Solving in Dyeing of Cotton Textile Material With Reactive DyesDocument7 paginiProblems Solving in Dyeing of Cotton Textile Material With Reactive DyesMohammed Atiqul Hoque ChowdhuryÎncă nu există evaluări

- Direct Dyes What Is Direct Dye?Document3 paginiDirect Dyes What Is Direct Dye?MD. Tofazzal HossainÎncă nu există evaluări

- Session 12-14 Dyes - Application TypesDocument56 paginiSession 12-14 Dyes - Application TypesShagun SinhaÎncă nu există evaluări

- Key Factors To Be Considered For Reactive Dyeing Right First TimeDocument12 paginiKey Factors To Be Considered For Reactive Dyeing Right First TimeLasitha Nawarathna50% (2)

- Direct Dyes Lecture: Introduction, Properties, MechanismDocument27 paginiDirect Dyes Lecture: Introduction, Properties, MechanismrehanabbaciÎncă nu există evaluări

- Application of Vat Dyes Home Textile DyeingDocument10 paginiApplication of Vat Dyes Home Textile DyeingHrishikesh DhawadshikarÎncă nu există evaluări

- Exhaust Dyeing Polyester with Disperse DyesDocument16 paginiExhaust Dyeing Polyester with Disperse DyesBurak EmekliogluÎncă nu există evaluări

- Disperse DyeDocument44 paginiDisperse DyeRatul HasanÎncă nu există evaluări

- Right First Time Dyeing: RFT PrinciplesDocument8 paginiRight First Time Dyeing: RFT PrinciplesAnu MehtaÎncă nu există evaluări

- A Novel Method of Dyeing Nylon With Cold Brand Reactive Dyes and Assessment of Its Fastness Properties 2165 8064.S2 002 PDFDocument3 paginiA Novel Method of Dyeing Nylon With Cold Brand Reactive Dyes and Assessment of Its Fastness Properties 2165 8064.S2 002 PDFNabarupa BoseÎncă nu există evaluări

- Bifunctional Reactive Dyes: High Fixation Rates and Fastness PropertiesDocument3 paginiBifunctional Reactive Dyes: High Fixation Rates and Fastness PropertiesSaif RahmanÎncă nu există evaluări

- Salt Alkali Free ReactiveDocument6 paginiSalt Alkali Free ReactiveSaif Rahman100% (1)

- Contineous Dyeing of Reactive DyesDocument9 paginiContineous Dyeing of Reactive DyesMohammed Atiqul Hoque ChowdhuryÎncă nu există evaluări

- Standardization of Recipe For DyeingDocument7 paginiStandardization of Recipe For DyeingfreakishroseÎncă nu există evaluări

- Cationization of FabricDocument7 paginiCationization of Fabricraheem umer100% (1)

- Dyeing of Polyester/Cellulose BlendsDocument17 paginiDyeing of Polyester/Cellulose Blendsnagpal_aakashÎncă nu există evaluări

- Classification of Dyes: Natural, Synthetic, and by ChromophoreDocument12 paginiClassification of Dyes: Natural, Synthetic, and by ChromophoreSabeeh Ul HassanÎncă nu există evaluări

- Vat DyeDocument13 paginiVat DyeTanmoy AntuÎncă nu există evaluări

- Definition of Pad-Batch DyeingDocument4 paginiDefinition of Pad-Batch DyeingJuan CubasÎncă nu există evaluări

- Intro, Classification & Functions of Auxiliaries .PPTX Lecture 123Document16 paginiIntro, Classification & Functions of Auxiliaries .PPTX Lecture 123nida0% (1)

- One-bath Dyeing Guide for Blended FabricsDocument4 paginiOne-bath Dyeing Guide for Blended FabricsNguyễn Huy CườngÎncă nu există evaluări

- Colour and Textile Chemistry-A Lucky Career Choice: Aatcc Review April 2009Document32 paginiColour and Textile Chemistry-A Lucky Career Choice: Aatcc Review April 2009Neva BernadetteÎncă nu există evaluări

- Advantage of Reactive DyesDocument3 paginiAdvantage of Reactive Dyeschi005Încă nu există evaluări

- Cationic DyesDocument3 paginiCationic Dyesmayree_gÎncă nu există evaluări

- Disperse or Polyster DyesDocument12 paginiDisperse or Polyster DyesMohammed Atiqul Hoque ChowdhuryÎncă nu există evaluări

- FactSheet Dyeing Finishing DyStar IngeoColorationPack PDFDocument53 paginiFactSheet Dyeing Finishing DyStar IngeoColorationPack PDFJose Iniesta PerezÎncă nu există evaluări

- Presentation On: Dyeing of Cotton With Reactive Dye: Prepared By: Tanvir Ahammed RanaDocument30 paginiPresentation On: Dyeing of Cotton With Reactive Dye: Prepared By: Tanvir Ahammed RanaMohammed Atiqul Hoque ChowdhuryÎncă nu există evaluări

- One Bath One Stage Dyeing of Polyester/Cellulosic Blends Using Disperse and Reactive DyesDocument31 paginiOne Bath One Stage Dyeing of Polyester/Cellulosic Blends Using Disperse and Reactive Dyessanjay shettiÎncă nu există evaluări

- Cat IonizerDocument6 paginiCat IonizerAnonymous 5HRD46hÎncă nu există evaluări

- Bezaktiv S Matrix DyesDocument25 paginiBezaktiv S Matrix DyesRezoanul HaqueÎncă nu există evaluări

- Everzol Dyes StructuresDocument9 paginiEverzol Dyes StructuresNestor Mauricio Florian RamirezÎncă nu există evaluări

- Precaution Manual For Colour Blooming Auxiliaries Applications On Textiles.Document12 paginiPrecaution Manual For Colour Blooming Auxiliaries Applications On Textiles.L.N.CHEMICAL INDUSTRY100% (1)

- Textile DyesDocument2 paginiTextile DyesAdnan PervaizÎncă nu există evaluări

- DYES: Classification and PropertiesDocument40 paginiDYES: Classification and PropertiesDJÎncă nu există evaluări

- Cationized Cotton DyeingDocument16 paginiCationized Cotton DyeingjitundcÎncă nu există evaluări

- Warp Dyeing With Indigo DyesDocument12 paginiWarp Dyeing With Indigo DyesMohammed Atiqul Hoque ChowdhuryÎncă nu există evaluări

- Test For The Suitability of Thickener in The Print Paste Formulation and Other ConcepttestDocument21 paginiTest For The Suitability of Thickener in The Print Paste Formulation and Other ConcepttestGaurav DhawanÎncă nu există evaluări

- 01703Document3 pagini01703Shaique SiddiqueÎncă nu există evaluări

- Bleaching Textiles ExplainedDocument13 paginiBleaching Textiles ExplainedAnurag VermaÎncă nu există evaluări

- 10 5923 J Textile 20120106 03 PDFDocument9 pagini10 5923 J Textile 20120106 03 PDFsonia aliÎncă nu există evaluări

- Test Method To Check The Concentration of CausticDocument23 paginiTest Method To Check The Concentration of CausticGaurav DhawanÎncă nu există evaluări

- Introduction To DyesDocument12 paginiIntroduction To Dyessathieshwar100% (1)

- How To Identify Dyestuff MixturesDocument20 paginiHow To Identify Dyestuff MixturesMohammed Atiqul Hoque ChowdhuryÎncă nu există evaluări

- Cationization OF Cotton Fabrics - Salt Free Dyeing & Pigment Dyeing by Exhaust.Document19 paginiCationization OF Cotton Fabrics - Salt Free Dyeing & Pigment Dyeing by Exhaust.L.N.CHEMICAL INDUSTRYÎncă nu există evaluări

- Pigments Dyes Product Range2015Document29 paginiPigments Dyes Product Range2015Badre AalamÎncă nu există evaluări

- 418002e - CTI - LANASET Coverage of Barriness PDFDocument5 pagini418002e - CTI - LANASET Coverage of Barriness PDFMarti VincenzoÎncă nu există evaluări

- Cotton DyeingDocument9 paginiCotton DyeingJamal HossenÎncă nu există evaluări

- DyeingDocument3 paginiDyeingKhandaker Sakib FarhadÎncă nu există evaluări

- Disperse PrintingDocument20 paginiDisperse PrintingCamila Suarez100% (1)

- Acid DyeDocument3 paginiAcid DyeMD. Tofazzal HossainÎncă nu există evaluări

- Dyeing LabDocument19 paginiDyeing LabFathi MustafaÎncă nu există evaluări

- Blind DyeingDocument6 paginiBlind Dyeingprabhulean14Încă nu există evaluări

- Important Characteristics of Reactive DyeingDocument5 paginiImportant Characteristics of Reactive DyeingMohammed Atiqul Hoque ChowdhuryÎncă nu există evaluări

- Right First Time Reactive DyeingDocument6 paginiRight First Time Reactive DyeingHafeez UR RehmanÎncă nu există evaluări

- Dyeing Cationic Dyeable Polyester with Cationic DyesDocument2 paginiDyeing Cationic Dyeable Polyester with Cationic DyesFathi Mustafa0% (2)

- Aatcc NewletterDocument52 paginiAatcc NewletterlthyaguÎncă nu există evaluări

- Cold Pad Bleaching of Woven FabricDocument4 paginiCold Pad Bleaching of Woven FabricPavan KumarÎncă nu există evaluări

- The Identification of Vat Dyes on Cellulosic MaterialsDe la EverandThe Identification of Vat Dyes on Cellulosic MaterialsÎncă nu există evaluări

- 4ch1 1cr Rms 20230302Document15 pagini4ch1 1cr Rms 20230302LAITH ROBERT WADIE SWAIDANÎncă nu există evaluări

- Chemistry Assignment and Project 2Document13 paginiChemistry Assignment and Project 2Guru SrinivaasÎncă nu există evaluări

- Jam Cemistry QuestionDocument9 paginiJam Cemistry QuestionPrasad AlexÎncă nu există evaluări

- Density of PlasticsDocument2 paginiDensity of PlasticsMutiara FajarÎncă nu există evaluări

- Catalyst BrochureDocument20 paginiCatalyst Brochuredaraj darajÎncă nu există evaluări

- Vinavil 5406 enDocument2 paginiVinavil 5406 enVladimir Delgado B.Încă nu există evaluări

- Preparation of Cis-Diamminediiodoplatinum (II)Document2 paginiPreparation of Cis-Diamminediiodoplatinum (II)Najwa ZulkifliÎncă nu există evaluări

- Review Article: Harvesting Ambient Environmental Energy For Wireless Sensor Networks: A SurveyDocument21 paginiReview Article: Harvesting Ambient Environmental Energy For Wireless Sensor Networks: A Surveymarc estebanÎncă nu există evaluări

- UPP Piping Install-Small PDFDocument12 paginiUPP Piping Install-Small PDFsk lukoÎncă nu există evaluări

- LintelsDocument18 paginiLintelsBasavaraj hsÎncă nu există evaluări

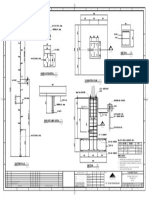

- Bsi Eof DWG Cs 150 (0) - Lighting Pole 10m HeightDocument1 paginăBsi Eof DWG Cs 150 (0) - Lighting Pole 10m HeightdharuÎncă nu există evaluări

- Performance of A Multi-Storey Complex Building With CFST ColumnsDocument7 paginiPerformance of A Multi-Storey Complex Building With CFST ColumnsIvan RubioÎncă nu există evaluări

- Potential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method)Document5 paginiPotential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method)Ahmed AbidÎncă nu există evaluări

- HyResponder - D1 - 1 - H2 Systems and Safety Features - Final 21122021Document54 paginiHyResponder - D1 - 1 - H2 Systems and Safety Features - Final 21122021Theodoor KoenenÎncă nu există evaluări

- CHEMISTRY PROJECT - 1.pngDocument2 paginiCHEMISTRY PROJECT - 1.pngMADAN KIRIÎncă nu există evaluări

- Rectangular Cooling Water Tank Design CalculationsDocument43 paginiRectangular Cooling Water Tank Design CalculationsNguyễn Quốc PhượngÎncă nu există evaluări

- Aise Standard No 9Document17 paginiAise Standard No 9Sos de HoyosÎncă nu există evaluări

- Chemistry: Pearson Edexcel International Advanced LevelDocument24 paginiChemistry: Pearson Edexcel International Advanced LevelMohamedÎncă nu există evaluări

- Molygraph-General EngineeringDocument6 paginiMolygraph-General Engineeringkominthitsar7474Încă nu există evaluări

- Transformer Oil DetailDocument8 paginiTransformer Oil DetailBaSant KohliÎncă nu există evaluări

- Spontaneous Fires in Insulation: Understanding Causes and Preventing RisksDocument18 paginiSpontaneous Fires in Insulation: Understanding Causes and Preventing RisksHimat KhimaniÎncă nu există evaluări

- Liquids, Solids and Intermolecular ForcesDocument41 paginiLiquids, Solids and Intermolecular Forcesade dosmariaÎncă nu există evaluări

- Reservoir Fluid Sampling & RecombinationDocument9 paginiReservoir Fluid Sampling & Recombinationdrojas70Încă nu există evaluări

- Numerical Simulation of A Deep Excavation Near A Shield TunnelDocument9 paginiNumerical Simulation of A Deep Excavation Near A Shield TunnelEfi GusfianaÎncă nu există evaluări

- Ball Data SheetDocument4 paginiBall Data Sheetshashikanth79Încă nu există evaluări

- Microsoft Word - Pressure Vessels Brittle FractureDocument21 paginiMicrosoft Word - Pressure Vessels Brittle FracturekarimÎncă nu există evaluări

- Kerosene: Kerosene (Kerosine, Paraffin Oil Approximately Boiling Range: 205 ToDocument17 paginiKerosene: Kerosene (Kerosine, Paraffin Oil Approximately Boiling Range: 205 Toapi-3774614100% (1)

- 1pCRlAWRVB 50PyNhewz9gl6nwqJMTJP5Document27 pagini1pCRlAWRVB 50PyNhewz9gl6nwqJMTJP5Rica Mae EsmenosÎncă nu există evaluări

- S6 - Q1 - WK3 - D1-5 (1) JHKJDocument8 paginiS6 - Q1 - WK3 - D1-5 (1) JHKJMoi Bieen100% (1)