Documente Academic

Documente Profesional

Documente Cultură

13-HPCL Vizag Soil Report-VOL.V

Încărcat de

Dhananjay KumarDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

13-HPCL Vizag Soil Report-VOL.V

Încărcat de

Dhananjay KumarDrepturi de autor:

Formate disponibile

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

REPORT ON GEOTECHNICAL INVESTIGATION FOR LPG MOUNDED STORAGE AT VISAKHA REFINERY, MALKAPURAM, VISAKHAPATNAM (A.P) FOR HINDUSTAN PETROLEUM CORPORATION LIMITED

CONTENTS SR.NO. 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 DESCRIPTION INTRODUCTION SCOPE OF WORK EXECUTION OF FIELD WORK LABORATORY TESTS FINDINGS OF THE GEOTECHNICAL INVESTIGATION DISCUSSIONS AND RECOMMENDATION SAMPLE CALCULATION REFERENCES PAGE NO. 1 2 2 8 9 16 21 27

ANNEXURE A B C D E F G LOCATION PLAN BORE LOGS TRIAL PIT LOGS STATIC CONE PENETRATION TESTS DYNAMIC CONE PEENTRATION TESTS LABORATORY TEST RESULTS SUB SOIL PROFILE

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

REPORT ON GEOTECHNICAL INVESTIGATION FOR LPG MOUNDED STORAGE AT VISAKHA REFINERY, MALKAPURAM, VISAKHAPATNAM (A.P) FOR HINDUSTAN PETROLEUM CORPORATION LIMITED

1.0

INTRODUCTION

1.1

HINDUSTAN PETROLEUM CORPORATION LIMITED, VISAKHA REFINERY, VISKHAPATNAM plans construction of one LPG mounded bullet (proposed) and one Propylene mounded bullet (future) storage as part of their refinery expansion project. PDIL is the main consultant for this project. For this purpose it was decided to conduct Geotechnical Investigation at the two mounded bullet locations. Total nine boreholes were planned to be carried out for the Geotechnical investigation and from that to obtain the relevant foundation design parameters for the proposed mounded bullet.

1.2

Hindustan Petroleum Corporation Limited, Visakha have awarded the contract to M/s. DBM Geotechnics and Construction Pvt. Ltd., (DBM) Mumbai to carry out the Geotechnical Investigation for the proposed mounded Bullet structures.

1.3

DBM carried out fieldwork during September and November 2006 and subsequently laboratory tests were conducted on selected disturbed soil (D/S), undisturbed soil samples and rock core samples

1.4

Geotechnical investigation report is prepared based on the field investigation data, laboratory test results, analysis and interpretation of all field and laboratory test data.

Prepared by T.V.Suresh Kumar

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

2.0 2.1

SCOPE OF WORK To investigate the subsurface soil conditions at the site nine boreholes were carried out. The detailed scope of investigation is as follows.

2.2

Setting up boring rig at each bore hole location and boring 150 mm diameter bore holes through all kinds of soils.

2.3

Drilling vertically through the rock using NX size (76 mm) with double tube core barrel fitted with diamond studded drill bits. The boreholes were terminated in hard rock.

2.4

Conducting Standard Penetration Tests (SPT) in over burden at an interval of 1.5m.

2.5 2.6 2.7 2.8 2.9

Collecting 100 mm undisturbed soil samples in suitable cohesive stratum Conducting five nos of Static Cone Penetration tests Conducting five nos of Dynamic cone penetration tests. Conducting three nos of Trial pits. Arranging all soil samples and rock cores in the core boxes as per the borehole logging, labeling properly in sequence indicating number of core sample, depth of core sample and direction of drilling on each rock core piece.

2.10

Transporting the selected soil and rock samples to the laboratory for conducting tests as per the scope of the work.

2.11

Analysis and interpretation of field & laboratory test data for the preparation of Geotechnical investigation report.

2.12

Handing over all the rock core samples in core boxes to Clients representative for safe storage and future reference.

3.0 3.1

EXECUTION OF FIELD WORK Location: All the nine boreholes were executed as per the Clients location plan. Location plan for the boreholes is enclosed in the Annexure.

Prepared by T.V.Suresh Kumar

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

3.2

Period of Execution: The fieldwork was commenced on 14-09-2006 and completed on 09-11-2006.

3.3

FIELD METHODOLOGY OF INVESTIGATION

3.3.1 Erecting and setting up of Boring rig At each bore hole location as per the Clients location plan, Calyx type boring rig was shifted, assembled and erected. 3.3.2 Boring in Overburden Boring was done in accordance with IS: 1892 -1979. Standard rotary type drilling rig coupled with 8 H.P capacity diesel engine, which is fitted to a tripod frame and with all drilling accessories was used for boring. The rig deployed was generally suitable for all Geotechnical Investigation work and had an arrangement for driving and extraction of casing, boring and drilling by mud circulation method. Collecting D/S, UDS, conducting SPT and carrying out permeability test with this rig was possible. Rotary method of boring was used for boring in soil. Boring was commenced by driving a SX casing in the upper layers of the borehole. Boring was carried out in soil using 6 dia core barrel up to the top of the hard surface. Diameter of the borehole in soil was 150mm. SX casing was lowered in overburden as boring progressed. Advancement of borehole in soil was done by removing soil with help of water circulation under rotary action of the Core barrel. Boring in all types of soil was continued till the hard stratum was met with. Standard penetration tests were conducted at an interval of 1.0m. When ever the hard stratum was encountered the size of the borehole was reduced from SX (150 mm) size to NX (76 mm) size. Drilling was carried out in hard stratum / rock vertically, by using NX size double tube core barrel fitted with diamond studded drill bits. The boreholes were terminated in hard rock as per the scope of work. During investigation, soil and ground water samples were also collected for chemical analysis to determine their pH, sulphates, and chlorides. Any

Prepared by T.V.Suresh Kumar

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

precautionary measures for protecting concrete and reinforcement steel can be decided based on these chemical results.

3.4.0 IN SITU TESTS IN OVERBURDEN Standard penetration tests were conducted in overburden and also in completely weathered rock, wherever rock cores were not recovered. Disturbed soil samples were collected through split spoon sampler of SPT test for field observations and to determine the index properties from laboratory tests. 3.4.1 Standard Penetration Test (SPT) : SPTs were conducted as per IS 2131-1981. Disturbed Samples were collected through Split Spoon Sampler at 1.0 m or 1.5m interval or wherever the Strata changed. A standard split spoon sampler was driven at the bottom of the hole. The penetration resistance in terms of blows for 300mm penetration of the split spoon sampler was measured as N Value. The blows were imparted by a standard weight of 65 kg falling through a height of 750 mm. The resistance was measured for 150 mm, 300 mm and 450 mm penetrations. The resistance of first 150 mm was ignored and the resistance of next 300 mm was recorded as standard penetration value N`. If the sampler was driven less than 450 mm (total) then the penetration resistance was given for the last 300 mm of penetration. If the penetration depth was less than 150 mm and the blow count was more than 50 then the N value was considered as Refusal or more than 100 blows for less than 30cms penetration. 3.4.2 Undisturbed samples: In all boreholes undisturbed samples were collected. These samples were packed suitably and transported to the laboratory for conducting as per the scope of work. 3.4.3 Ground water table (G.W.T) : Ground water table is encountered in between 1.6m and 2.20m below existing ground level. Seasonal and annual fluctuations in water levels can be expected to occur.

3.5

DRILLING IN HARD STRATUM / ROCK Once the hard stratum or rock surface was met the size of the bore hole was reduced to NX size (76mm). The hard stratum or top of the rock surface was

Prepared by T.V.Suresh Kumar

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

confirmed, either by the refusal from standard penetration test N value or due to resistance during the drilling operation. In this hard stratum further work was carried out by using NX core drilling with TC/Diamond studded bits. The work was done generally as per IS: 6926-1973. The maximum length of the drill (run) was maintained as 1.50m. At the end of each run the drill rod string with core barrel was extracted from the bore hole and core was recovered from the core barrel. Recovered rock cores were numbered and labeled serially and carefully transferred to in good quality, sturdy, wooden core boxes and preserved. The core recovery percentage was recorded. Core Recovery percentage = {C.R. % = (Length of Core / Length of run) x 100}. Rock Quality Designation (RQD) was also recorded. Rock Quality Designation (RQD) = (Total Length of core pieces of 100mm & above in Length / length of run) x 100}. Core recovery percentage and RQD were computed for every drilled run based on the length of cores retrieved.

3.6

INDIAN STANDARD CODES USED FOR THE FIELD INVESTIGATION Field Geotechnical investigation was executed in accordance with the Indian standard Codes listed below. a) IS: 1892: Code of practice for subsurface investigation of foundation b) IS: 1498: Classification and identification of soil for general engineering purpose. c) IS: 2131: Method for standard penetration test for soil d) IS: 2132: Method for collecting undisturbed soil samples e) IS: 4968( part -1): Method for subsurface sounding of soils by Dynamic cone penetration tests f) IS: 4968( part III): Method for subsurface sounding of soils by Static cone penetration tests d) IS: 5313: Guide for Core Drilling Observations e) IS: 6926: Code of Practice for Diamond Core Drilling for Site Investigations f) IS: 4078: Code of practice for indexing and storage of drill core.

Prepared by T.V.Suresh Kumar

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

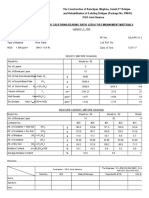

3.7 The summary of the field investigation results of boreholes and in situ tests are give below. TABLE 1 The summary of field investigation results of boreholes Depth of S NO Borehole No 1 2 3 4 5 6 7 8 9 BH-1 BH-2 BH-3 BH-4 BH-5 BH - 6 BH-7 BH-8 BH-9 7.609 8.014 8.349 8.349 8.789 9.174 10.384 10.499 8.354 R. L (m) GWT(BGL) in m 2.20 1.75 2.15 1.90 3.00 1.60 1.75 1.75 -Thickness of Termination Over burden BGL(m) 11.00 5.50 6.05 9.50 5.50 4.50 5.00 7.00 4.60 depth BGL (m) 24.30 20.00 25.50 20.00 23.25 21.00 19.00 13.00 13.00

Prepared by T.V.Suresh Kumar

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

TABLE 2 TABLE SHOWING SUMMARY OF STATIC CONE PENETRATION TESTS SR NO 1 2 3 4 5 SCPT NO SCPT1 SCPT 2 SCPT 3 SCPT 4 SCPT 5 GROUND R.L (m) 7.614 9.993 8.754 9.154 10.319 NEAR BH-1 FOR PROPYLENE BULLET NEAR BH-3 FOR PROPYLENE BULLET FOR LPG BULLET NEAR BH-5 FOR LPG BULLET NEAR BH-7 FOR LPG BULLET LOCATION

TABLE 3 TABLE SHOWING SUMMARY OF DYNAMIC CONE PENETRATION TESTS SR NO 1 2 3 4 5 DCPT1 DCPT 2 DCPT 3 DCPT 4 DCPT 5 DCPT NO GROUND R.L (m) 7.464 8.134 8.424 9.549 9.810 FOR PROPYLENE BULLET FOR PROPYLENE BULLET NEAR BH-4 FOR PUMP HOUSE FOR LPG BULLET FOR LPG BULLET 5.05 4.7 5.1 5.24 LOCATION REFUSAL DEPTH BGL (m) 5.1

Prepared by T.V.Suresh Kumar

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

TABLE 4 TABLE SHOWING SUMMARY OF TRIAL PITS TP NO GROUND R.L (m) TP 1 7.584 SIZE (m) LXBXD 2.5 X 2.5 X 1.8 FOR PROPYLENE BULLET NEAR DC-1 TP 2 TP 3 8.324 10.179 2.5 X 2.5 X 2.0 2.5 X 2.5 X 1.5 FOR PUMP HOUSE NEAR BH4 FOR LPG BULLET 1.40 1.90 LOCATION GROUND WATER TABLE (m) 1.80

4.0

LABORATORY TESTS The laboratory tests are conducted in DBMs well equipped soil testing laboratory under the supervision of well qualified and experienced engineers. The laboratory tests aim to obtain the following characteristics of different layers a) Grain size analysis, hydrometer analysis, liquid limit, plastic limit, specific gravity tests were conducted for obtaining Index properties of the disturbed soil samples. b) For obtain cohesion, friction, natural density, compressible characters of soil etc, tests were conducted as per the IS codes listed below. c) Compressive strength, Porosity, water absorption, dry density and modulus of elasticity tests were conducted on selected rock core samples and the results were shown in the annexure

Prepared by T.V.Suresh Kumar

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

Table -5 Summary of List of IS codes a) b) c) d) e) g) h) i) j) k) Grain Size Distribution by Sieve Analysis and Hydrometer Analysis Consistency limit determination to obtain liquid limit and plastic limit. Specific Gravity determination Natural moisture content and in-situ density tests on UDS samples Shear strength and consolidation tests on UDS samples Chemical analysis of soil to determine pH, Sulphate (SO3) and Chloride (Cl) Chemical analysis of water to determine pH, Sulphate (SO3) and Chloride (Cl) Soaked crushing strength of rock Porosity, Density and specific gravity test on rock Engineering classification of soil IS 2720 (Part IV) IS 2720 (Part V) IS2720 (Part III) IS 2720 (Part II) IS 2720 (Part XI, XII & XVI) IS 2720 (Part XXIV& XXVI) IS 3025 IS 9143 IS 13013 IS 1498

5.0 5.1

FINDINGS OF THE GEOTECHNICAL INVESTIGATION Sub Soil Stratification From nine boreholes investigation and their laboratory test results following sub soil stratification is obtained. Layer I Layer II : Residual Soil : Completely weathered to Highly weathered/ Khondalite Amphibolite/Granite Gneiss Layer III : Moderately weathered to Slightly weathered Kondalite

Layer I: Residual Soil: The top subsurface layer is Residual Soil. This layer is observed in all the boreholes. This layer is consisting of Silty Clay and Clayey Sand. Thickness of this layer is varying between 4.50m and 7.00m. Standard

Prepared by T.V.Suresh Kumar

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

penetration tests were conducted in this layer and SPT values are varying between 4 and 53. Disturbed soil samples were collected through split spoon sampler and the samples were tested in the laboratory. Undisturbed soil samples were collected by conducting separate borehole just adjacent to the boreholes at an alternative depths with respect to the SPT depths below ground level. SPT and UDS samples were tested in the laboratory and results are summarized below. Silty Clay Gravel Sand Silt Clay Liquid limit Plastic limit Plasticity Index Cohesion Cu (Tuu) Cohesion Cu (UC) Classification Silty Sand Gravel Sand Silt + Clay Engineering Classification % 30 to 35 % 51 to 52 % 14 to 18 SM % % % % % % % Kg/cm2 Kg/cm2 0 to 20 21 to 45 24 to 40 16 to 38 35 to 49 13 to 23 16 to 29 0.69 to 1.03 2.86 to 3.60 0.70 to 2.27 CI / SC

Angle of Internal Friction (Tuu) Degrees

Layer II: Completely weathered to Highly weathered khondalites / Amphibolite/Granite Gneiss: Second layer of the subsurface layer is Completely weathered to Highly weathered Amphibolite/ Granite. This layer is encountered in all boreholes. Top level of this layer varies between 4.50m and 7.00m below the existing ground level bottom level of this layer is varying between 10.10m and 23.00m below the existing ground level Standard penetration tests were conducted in this layer and SPT N values are varying

Prepared by T.V.Suresh Kumar

10

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

between 35 and Refusal. Rock Core Recovery of this Amphibolite/ Granite is varying between Nil and 50%.Rock Quality Designation of this Amphibolite/Granite is varying between NIL and 19. Some rock samples were selected for conducting tests in laboratory. The results are summarized below. Table -6 Summary of laboratory test results of Highly weathered rock Core samples. Parameter Soaked Uniaxial compressive strength Soaked Point load Index strength Porosity Water Absorption Dry density Unit kg / cm2 kg / cm2 % % gm/ cc Range 466 to 648 2.82 to 11.73 0.52 to 4.56 0.19 to 1.76 2.56 to 2.93

Layer III: Moderately weathered to Slightly weathered Khondalite: The third subsurface layer is Moderately weathered to Slightly weathered Khondalite. This layer is observed in all the boreholes. Top level of this layer is varying between 13.10m and 24.30m. Top level of the layer varying between 2.00m and 3.60m and exist up to the termination depth of the boreholes. Rock Core Recovery of this Khondalite is varying between 55% and 100%.Rock Quality Designation of this Khondalite is varying between NIL and 72%. Rock samples were tested and results of testing are summarized below Some rock samples were selected for conducting tests in laboratory. The results are summarized below.

Prepared by T.V.Suresh Kumar

11

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

Table -7 Summary of laboratory test results of Moderately weathered to Slightly weathered Rock Core Samples Parameter Soaked Uniaxial compressive strength Soaked Point load Index strength Porosity Water Absorption Dry density 5.2 Unit kg / cm2 kg / cm2 % % gm/ cc Range 357 to 1306 0.00 to 11.73 0.08 to 2.89 0.03 to 1.42 2.03 to 2.96

Static Cone Penetration Tests: Static Cone Penetration Tests were conducted with 20 tones capacity hydraulic equipment and using a 60 degree cone of 10 sq. cm base area. This cone was pushed vertically in to the ground by static thrust required to cause a bearing capacity failure of soil immediately around the point where the measurements were made. Such measurements were made for every 10 cm interval to provide a continuous bearing capacity profile and hence shear strength profile of the soils around the test locations. The cone point was advanced by two rod system. Outer mantle tube provides structural strength and protects inner rod from soil friction and buckling. The protected inner rod advances the point during the thrust. This thrust was measured using pressure gauges. Cone resistance and friction are corrected and reported. The procedure is generally in accordance with IS- 4968 ( Part III ) and the manufacturers guidelines. Results obtained from SCPT tests are consistent with borehole SPT N values. Soil type as inferred from SCPT results is silty clay and clayey sand. The

Prepared by T.V.Suresh Kumar

12

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

following correlation between SCPT results and SPT N values can be utilized (Reference No. 5): SPT N value = Ckd/C, Where C = 2. Table -8 Summary of the SCPT test results PRESSURE AT TERMINATED SCPT NO GROUND R.L (m) LOCATION TERMINATED BGL (m) DEPTH CORRECTED CONE RESISTANC E (kg/cm2) NEAR BH-1 FOR SCPT1 7.614 PROPYLENE BULLET NEAR BH-3 FOR SCPT 2 SCPT 3 SCPT 4 SCPT 5 9.993 8.754 9.154 10.319 PROPYLENE BULLET FOR LPG BULLET NEAR BH-5 FOR LPG BULLET NEAR BH-7 FOR LPG BULLET 5.3 Dynamic Cone Penetration Test (i.e. DCPT) : Dynamic Cone Penetration Test were carried out at this site as per IS:4968. Using this procedure, a solid cone of diameter 65mm and attached to the end of a rod is driven vertically downward into the soil by a 65 kg. weight falling 75cm. The number of blows required to drive the cone by 30 cms, is noted as the Cone penetration resistance (Ncbr). This can be correlated with SPT N values using relation Ncbr/1.5 = SPT N value. 5.00 900.44 2.746 5.60 880.44 16.444 5.00 900.44 6.855 5.80 900.44 5.485 5.80 900.525 8.225 CORRECTED SHAFT RESISTANCE (kg/cm2)

Prepared by T.V.Suresh Kumar

13

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

Table -9 Summary of the DCPT test results DCPT NO GROUND R.L (m) DCPT1 DCPT 2 DCPT 3 DCPT 4 DCPT 5 7.464 8.134 8.424 9.549 9.810 FOR PROPYLENE BULLET FOR PROPYLENE BULLET NEAR BH-4 FOR PUMP HOUSE FOR LPG BULLET FOR LPG BULLET 5.05 4.68 103 152 5.16 102 5.14 148 LOCATION REFUSAL DEPTH BGL (m) 5.1 Ncbr AT REFUSAL 209

Prepared by T.V.Suresh Kumar

14

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

5.4

TRIAL PITS Three Trial pits were excavated. The details of the trial pits were given in the table below. Table 10 TABLE SHOWING SUMMARY OF TRIAL PITS

TP NO

GROUND R.L (m)

SIZE (m) LXBXD

LOCATION

GROUND WATER TABLE (m)

Strata description

Clay with sand TP 1 7.584 2.5 X 2.5 X FOR PROPYLENE 1.8 BULLET NEAR DC-1 TP 2 8.324 2.5 X 2.5 X 2.0 FOR PUMP HOUSE NEAR BH4 1.90 1.80 up to 1.0m BGL Stiff Clay up to 1.80m BGL Clay with sand up to 1.0m BGL Stiff Clay up to 2.00m BGL Clay with sand TP 3 10.179 2.5 X 2.5 X FOR LPG BULLET 1.5 1.40 up to 1.0m BGL Stiff Clay up to 1.50m BGL

Prepared by T.V.Suresh Kumar

15

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

6.0

DISCUSSIONS AND RECOMMENDATIONS Three boreholes, ( BH1 to BH3) were carried out at the Future project (Mounded bullet for propylene), two boreholes, BH-4and BH9 were carried out at Pump house location and four bore holes, BH 5 to BH 8 were carried out at the proposed Mounded bullet (for LPG storage) location. At present Visakha refinery is planning to construct one mounded Bullet for LPG storage. Size of the proposed mounded bullet area is 83m x 49.4m and height of the mound is 10.260m above ground level with 1:2500 downward slope. The maximum weight under hydro test per bullet (LPG) is 3527 tones and for propylene is 2728 tones. The approximate working load per LPG and propylene Bullets is worked out as 25 t/m2. Based on the four bore hole investigation (BH-5 to BH-8) the top subsurface layer is medium stiff to hard silty clay layer. BH-5 to BH-7 boreholes were carried out with in the boundary of proposed LPG Bullet area and BH-8 borehole is approximately 20m to 25m away from the boundary of proposed LPG plant. Based on these three boreholes (BH-5 to BH-7), the top layer up to 3.50m is medium stiff layer and SPT N values varies between 6 and 15. Very stiff layer is observed from 3.50m to 5.50m BGL. Hence for the proposed LPG mounded storage the stratum below 3.50m is capable to take the loads. The strata from existing ground level to 3.50m is relatively more compressible hence this soil of 3.50m thickness should be replaced with sand layer. The safe bearing capacity is calculated based on shear failure criteria and settlement criteria. The foundation of LPG mounded storage may be designed for 25 t/m2.The settlements are calculated based on laboratory test results

6.1

6.2

6.3

6.4

The total vertical consolidation settlement is 218 mm and differential settlement is 81mm (based on laboratory test results) under the pressure of 25 t/m2.

6.5

If Open cast footing is considered, for an allowable pressure of 25 t/m2 and for allowable differentials settlement of 50mm, the clay layer up to 5.0m should be removed and filled with well compacted sand layers.

Prepared by T.V.Suresh Kumar

16

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

6.6

Since the depth of excavation is about minimum 5.00m below existing ground level and also considering the high ground water table (1.60m to 2.20m BGL), extensive dewatering and protection to the sides in the form of shoring and strutting for the excavation pits will be required. During excavation, first the top compressible clay layer above ground water table will be removed. Later the ground water should be lowered below the bottom of the proposed excavation depth of 5.00m by using dewatering pumps located at the corners of the proposed excavated area. After lowering the ground water below 6.00m BGL, further excavation of the soil will be commenced. After completion of the excavation, graded sand will be placed in loose layers of 225mm to 250mm thickness and shall be compacted to 150mm by 10ton vibratory roller. The degree of compaction should be 95% of the modified compaction achieved in the laboratory. This process will continue till the sand bed comes to the ground level or as per the design requirement.

6.7

Another option is adopting Pile foundation for the site. Considering the subsoil stratification and also hydraulic conditions of the existing site, deep foundations are more suitable than the shallow footing system. In these Pile foundations Bored Cast-In-Situ Concrete Piles as per IS-2911 (part 1/sec-2) are recommended and installed preferably by direct mud circulation (DMC) method. The Safe structural Pile capacity should be limited to 500 t/m2 acting on the nominal Pile cross section.

6.8

Weathering of rock strata at this site is completely to highly weathered form up to the depth of approximately 20m below existing ground level. Hence Pile lengths at this site would vary depending upon the core recovery, RQD, Crushing strength of rock etc. The chisel penetration response test is suggested to evolve a pile termination level. Chiseling criteria can be utilised to determine the level of hard bedrock. Hard bedrock can be inferred when chisel penetration is less than 10cms for chisel energy of 2250 t-m /m2 of Pile cross section. A minimum of 2 trials should be carried out to determined Pile termination. Wherever the chiseling energy of 2250 t-m /m2 per less than 10cms is confirmed, socketing of the pile may be adopted with minimum 1 x D length in this stratum. Where, D is the dia of Pile.

Prepared by T.V.Suresh Kumar

17

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

Sample calculation to calculate chisel energy are given below For example Consider a Pile of 500 mm diameter. Area of Pile 0.19625 m2 Let, Weight of chisel 1.0 tons If fall of chisel is limited to 2.0m, energy of each blow = 1.0 x 2.0 = 2.0 ton m The energy of 2250 t-m /m2 is converted into equivalent energy for 500 mm dia of Pile. Equivalent energy = 2250 x 0.19625 = 440 t - m To achieve this, no of blows required of 1.0 ton chisel with 2.0m fall = 440/2 = 220 blows. The no. blows are increased to account for submerged weight of chisel with weight of 1.0 ton tension while releasing the chisel. So , chiseling criteria for 500mm dia will be as follows. The penetration shall be less than 10cms for 260 blows of chisel with weight of 1.0 ton and falling through a height of 2.0 meters. Generally, 300 blows can be applied within 30 minutes. While checking the chiseling criteria, the chisel shall be with drawn after 30 minutes, hole cleaned and penetration measured. 6.9 The safe load carrying capacity of different dia of piles is given in table below. Table 11 Dia of pile (mm) 500 600 750 Safe load carrying capacity of pile (tons) 100 140 200

Prepared by T.V.Suresh Kumar

18

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

6.10

FOR PROPYLENE BULLETS For this mounded structure the foundation may be placed at a depth of 6.00 m below existing ground level. Allowable bearing pressure may be considered 25t/m2. Pile foundations are more suitable at this location.

6.11

Spread and continuous foundations for retaining wall and other structures at this site will be installed at a depth of minimum 2.0m below ground surface. The allowable bearing for different breadths are given below. Table 12 Depth BGL Breadth SBC (t/m2) Settlement (m) (m) 2.0 3.0 3.0 23.16 72.08 12 25 (mm) 67.19 Allowable bearing pressure (ABP) for 40mm settlement 15

6.12

Lateral Earth pressure The retaining walls to mound the soil will subject to lateral earth pressures due to retained earth. A total soil unit weight and lateral earth pressure parameter (Ka) of 2.0 t/m3 And 0.33, respectively, can be used for design of retaining wall.

6.13

Pump Houses Excavations below ground will be required to complete proposed pump houses. Shallow groundwater table of between 1.6m and 2.2m below ground surface, was encountered at this site. Hence, extensive dewatering will be required. Adequate uplift resistance in the form of dead weight or anchors should be provided on pump house rafts.

6.14

Temporary excavation sides below water table should be sloped at a maximum slope of 2:1 (horizontal: vertical) or flatter to minimize side sloughing and collapse. Excavations above water table can be maintained near vertical.

Prepared by T.V.Suresh Kumar

19

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

6.15

Parameters for design of dynamic foundations (footing area > 10m2) installed in accordance with Table B above are given below (Reference IS2974). Coefficient of Elastic Uniform Compression (Cz) = Coefficient of Elastic Non-Uniform Compression (C) = 2Cz = Coefficient of Elastic Uniform Shear (C) = 0.5Cz = Coefficient of Elastic Non-Uniform Shear (C) = 0.75Cz = Poissons Ratio = Dynamic Shear Modulus = G = 4 x 103 t/m3 8.0 x 103 t/m3 2 x 103 t/m3 3 x 103 t/m3 0.33 1850 t/m2

P.S.Bansod Director- Technical

Prepared by T.V.Suresh Kumar

20

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

FINAL RECOMMENDATIONS FOR FOUNDATION TYPE FOR PROJECT OF MOUNDED LPG & PROPYLENE FACILTES AT HPCL, VISKHA REFINERY

Subsequent to the earlier submitted draft final report along with addendum sent on 27-11-2006, following is the final recommendations as regards Pile capacity and SBC of shallow foundations for minor structures. We are recommending only Pile Foundations based on soil investigation data for the mounded storage (LPG and Propylene area), Pump House and for all major heavily loaded structures, Equipment foundations. The details are as follows. Recommended foundation type is RCC Cast in Situ Bored Pile foundations Safe Vertical, lateral and uplift capacity of different dia of Piles are given below in table. Dia of Pile (mm) Safe vertical capacity of Pile (tons) 300 400 450 500 600 750 35 50 70 1000 140 2000 Safe Uplift Capacity of Pile (tons) 25 45 50 55 70 836 Safe lateral capacity of Pile (tons) 3.4 4.6 5.2 538 6.9 86

All Piles should be terminated in moderately weathered rock o0nly. (Layer lll as discussed in soil investigation). In LPG, Pump house and propylene area. The minimum length of pile will be 20m / up to moderately weathered rock, which ever is higher.

Socketing of Pile should be minimum 3x Dia in Moderately weathered rock.

Prepared by T.V.Suresh Kumar

21

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

The pile capacity has also taken in to account maximum permissible deflection of 12 mm. As per soil data the maximum differential settlement has been found to be 9mm in propylene and LPG mound area.

For minor (lightly loaded ) foundations shallow foundations may be used as per Soil bearing capacity given in table below. However a cushion of minimum 230mm thick boulder soling has to be kept with 230mm projection all along below the shallow foundation.

Net Safe Bearing pressure (SBP) for Proposed foundation depth BGL (m) Size of footing ( m x m ) 2x2 1.0 1.5 2.0 2.5 3.3 3.9 4x4 4.0 4.5 5.0 25mm permissible settlement (t/m2)ed

T. V. Suresh Kumar Manager Geotechnical DBM Geotechnics and Constructions Pvt Ltd Santacruz, Mumbai

Prepared by T.V.Suresh Kumar

22

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

7.0

SAMPLE CALCULATION FOR ALLOWABLE BEARING CAPACITY FOR LPG MOUNDED BULLET

REFERENCE BH 5 (Considered on conservative side) SUB SOIL STRATIFICATION G.L, 0.0 m

SILTY CLAY LAYER SPT 1 at 1.50m SPT 2 at 2.50m UDS 1 at 3.20m SPT 3 at 3.50m SPT 4 at 4.50m SPT 5 at 5.50m N=6 N = 10 Cu =10 t/m2 N = 15 N = 19 N=R

Completely weathered rock, N>50 - 16.00 m

Highly weathered rock, N>100 - 21.10 m

Moderately to slightly weathered - 23.25 m

Prepared by T.V.Suresh Kumar

23

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

7.1 A

CALCULATION OF SAFE BEARING CAPACPCITY (SBC) BASED ON SHEAR FAILURE CRITERIA Type of Footing : Shallow and spread : : : : : : : : 2.5 m 70 m 3.50 m 0.00m (assumed conservatively at ground level) Load Inclination Bulk Unit Weight Field N Value Undrained Cohesion, Cu 0 1.8 t/m3 (Minimum value = 15 (Minimum considered

Size of pedestal where Bullet rest Breadth of LPG Bullet pedestal Length of LPG Bullet Pedestal Depth of Proposed Foundation Depth of Water Table

considered from Laboratory tests) after checking with DCPT and SCPT by correlations) 15/1.5 = 10.00 t/m2 (Based on N value) = 10.3 t/m2 Cohesion from lab tests (from BH 5 at 3.50m) i) From Triaxial compression test, Cu Minimum value is considered from above two, say cu = 10.00 t/m2 Bearing capacity factor Shape Factors Inclination factors Depth Factors : : : : Nc = 5.14, Sc = 1.30 iq = i = 1.0 dc = 1.28

The net ultimate bearing Capacity, qnu= Cu x Nc x Sc x ic x dc = 10.00 x 5.14 x 1.30 x 1.0 x 1.28 = 85.53 t/m2 Consider factor of safety = 3 The net safe bearing Capacity qns = 85.53/3 = 28.5 t/m2 say 25 t/m2

Prepared by T.V.Suresh Kumar

24

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

B) SETTLEMENT AT THE CENTER OF BULLET ( Based on lab test results) {(Reference IS: 8009)

I) Silty Clay from 3.50m to 5.50m below ground surface Consolidation Settlement Where H = 2.00m = 1.80 t/m3 o = 3.6 kg/cm2 o = 17.61 t/m2 Compression index = 0.18 Initila void ratio = e0 = 0.37 Settlement = c1 = Cc /1+ e0 x H x log (o + o) / o = 202 mm II) Completely weathered rock from 5.50m to - 16.00m below ground surface Immediate settlement, i = (q*B*(1-2)*m*Is*If)/E (Ref: Foundation analysis and design, Bowles) say, N = 50 for soft rock Where, q = 13.5 t / m2 B = 1.25 m = 0.30 m=4 For H/B = 8.4 and L/B = 28 & D/B = 1.8 I1 = 0.672 and I2 = 0.151 Is= 0.758 If = 1.0, considered conservatively Taking E = 50 (N + 15) = 3250 t / m2, for average N value 50 Therefore i = 14.33 mm

Prepared by T.V.Suresh Kumar

= c1 = H/CI x log (o + o) / o

25

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

III)Highly weathered rock from 16.00m to - 21.10m below ground surface Immediate settlement, i = (q*B*(1-2)*m*Is*If)/E (Ref: Foundation analysis and design, Bowles) say, N = 100 for highly weathered rock Where, q = 3.56 t / m2 B = 1.25 m = 0.30 m=4 For H/B = 4.08 and L/B = 28 & D/B = 1.8 I1 = 0.453 and I2 = 0.154 Is= 0.541 If = 1.0, considered conservatively Taking E = 50 (N + 15) = 5750 t / m2, for N value 100 Therefore i = 1.52 mm IVI) Moderately weathered rock from 21.1 m to 30m below ground surface Where, q = 2.5 t / m2 B = 1.25 m = 0.30 m=4 For H/B = 7.1 and L/B = 28 & D/B = 1.8 I1 = 0.628 and I2 = 0.152 Is= 0.715 If = 1.0, considered conservatively Taking E =20000 t/m2 Therefore i = 0.41 mm TOTAL SETTLEMENT UNDER SBC OF 25 t/m2 AT CENTER OF LPG BULLET = 202 + 14.33 + 1.52 + 0.41 = 218.26 mm

Prepared by T.V.Suresh Kumar

26

Reviewed by P.S.Bansod

1686-HPCL/VIZAG REFINERY/FINAL/ TVS REPORTS

REFERENCES 1) IS: 6403- 1981, Code of Practice for Determination of Bearing Capacity of Shallow Foundation 2) IS: 8009 (Part I) 1976, code of practice for calculation of settlements of Foundations. 3) 4) 5) IS 456:2000 Code of Practice For Plain and Reinforced Concrete. Foundation Design Manual, N V. Nayak, 4th Edition, 1996. Foundation Analysis and Design, J. Bowles, 4th Edition

Prepared by T.V.Suresh Kumar

27

Reviewed by P.S.Bansod

S-ar putea să vă placă și

- Methodology For Soil Geotechnical InvestigationDocument4 paginiMethodology For Soil Geotechnical InvestigationShyama Prasad SamantaÎncă nu există evaluări

- Liquid Limit TestsDocument41 paginiLiquid Limit Testsindu_lidooÎncă nu există evaluări

- National Highways Authority of India: Bitumen Extraction TestDocument2 paginiNational Highways Authority of India: Bitumen Extraction Testmanish upadhyayÎncă nu există evaluări

- 3.3 Planning The Exploration ProgramDocument11 pagini3.3 Planning The Exploration Programlianne lizardoÎncă nu există evaluări

- Bituminous Macadam (BM) : Grading Requirement (MORTH V Table 500-10)Document4 paginiBituminous Macadam (BM) : Grading Requirement (MORTH V Table 500-10)Mozibur RahmanÎncă nu există evaluări

- Vane Shear TestDocument4 paginiVane Shear TestMuhammad Faiz Zafuan Idrus100% (1)

- Flexible Pavement DesignDocument33 paginiFlexible Pavement DesignLalith Koushik GanganapalliÎncă nu există evaluări

- PP2-Execution Methodology of Flexible PavementDocument45 paginiPP2-Execution Methodology of Flexible PavementSrinivas PÎncă nu există evaluări

- Astm D422 Sieve Analysis: Client: ProjectDocument1 paginăAstm D422 Sieve Analysis: Client: ProjectHassan RazaÎncă nu există evaluări

- Plate Load Test Is.1888.1982Document16 paginiPlate Load Test Is.1888.1982cmthebossÎncă nu există evaluări

- NCC Report 2015 - Corrected by NCCLJDocument64 paginiNCC Report 2015 - Corrected by NCCLJPhani Krishna BadipatiÎncă nu există evaluări

- MIHIR 7th Sem. Civil ProjectDocument19 paginiMIHIR 7th Sem. Civil ProjectKUNAL SHAHÎncă nu există evaluări

- Bardiya Soil ReportDocument50 paginiBardiya Soil ReportSubash BastolaÎncă nu există evaluări

- Final Report 00 - 1187-Rev00Document31 paginiFinal Report 00 - 1187-Rev00wafikmh4Încă nu există evaluări

- Laboratory Manual On Geotechnical Engineering/Foundation Engineering/Soil Mechanics:Test of SoilDocument18 paginiLaboratory Manual On Geotechnical Engineering/Foundation Engineering/Soil Mechanics:Test of SoilSantosh KumarÎncă nu există evaluări

- Soil Test Report KhagariaDocument28 paginiSoil Test Report KhagariaSajan SinghÎncă nu există evaluări

- Excel Workbook No. 06 Relative CompactionDocument6 paginiExcel Workbook No. 06 Relative CompactionBig Boss100% (1)

- Soil Stabilization by Using: Fly AshDocument12 paginiSoil Stabilization by Using: Fly AshRavi HirulkarÎncă nu există evaluări

- Indian HighwaysDocument95 paginiIndian HighwaysTLOFFICE PATNAÎncă nu există evaluări

- Ayni-Panjakent-Uzbekistan Border Road: List of Test FormsDocument58 paginiAyni-Panjakent-Uzbekistan Border Road: List of Test FormsGolam Masud100% (1)

- CE-452 CBR TestDocument15 paginiCE-452 CBR TestNandon RoyÎncă nu există evaluări

- Bitumen Lab Test ChargesDocument7 paginiBitumen Lab Test ChargesRenga PandiÎncă nu există evaluări

- CBR Test ManualDocument6 paginiCBR Test ManualmmÎncă nu există evaluări

- Transportation Engineering: Approaches To Pavement DesignDocument15 paginiTransportation Engineering: Approaches To Pavement DesignSaddaqatÎncă nu există evaluări

- Ground Improvement Technioques For High WaysDocument31 paginiGround Improvement Technioques For High WaysDevendra Sharma100% (1)

- Geostrap 2022Document26 paginiGeostrap 2022Sumit GuptaÎncă nu există evaluări

- Determination of Field Density of Soil by Core Cutter MethodDocument3 paginiDetermination of Field Density of Soil by Core Cutter MethodsiddiqueakbarÎncă nu există evaluări

- Methodology of UPVDocument3 paginiMethodology of UPVAnonymous eKt1FCDÎncă nu există evaluări

- 400kv Sanand (Charal) - SBC ReportDocument65 pagini400kv Sanand (Charal) - SBC Report400KVÎncă nu există evaluări

- Case Studies in GGeotech Engineering Constructionseotech Engineering Constructions - B.R.srinivasa MurthyDocument34 paginiCase Studies in GGeotech Engineering Constructionseotech Engineering Constructions - B.R.srinivasa MurthyTHULASI MÎncă nu există evaluări

- Soil Testing 25-08-2011Document14 paginiSoil Testing 25-08-2011PiyushÎncă nu există evaluări

- Is 15284 Part I - 2003Document22 paginiIs 15284 Part I - 2003231340Încă nu există evaluări

- StabilizationDocument57 paginiStabilizationNurul Izzati Raihan Ramzi100% (1)

- CBR ProjectDocument46 paginiCBR ProjectChau Suktana EnlingÎncă nu există evaluări

- 31 02 20 Final ReportDocument36 pagini31 02 20 Final Reportharsh kakadiyaÎncă nu există evaluări

- Soil Investigation Report (Package-3)Document59 paginiSoil Investigation Report (Package-3)Vashav Pandey0% (1)

- Symbol Chart: Soil Classification Engineering Geology Texture Grain Size Soil UnconsolidatedDocument2 paginiSymbol Chart: Soil Classification Engineering Geology Texture Grain Size Soil UnconsolidatedPrashant Dhotre100% (1)

- Sr. No. Name of Test IS Code Rate: Shree Bala Ji Test House Pvt. LTDDocument6 paginiSr. No. Name of Test IS Code Rate: Shree Bala Ji Test House Pvt. LTDAyan DuttaÎncă nu există evaluări

- Soil Report of Mini Stadium KathmanduDocument88 paginiSoil Report of Mini Stadium Kathmandurajendra timalsinaÎncă nu există evaluări

- Constant Head Permeability Test Lab ManualDocument3 paginiConstant Head Permeability Test Lab ManualmmÎncă nu există evaluări

- CRRI Presentation On GeosyntheticsDocument51 paginiCRRI Presentation On GeosyntheticsGautam RaiÎncă nu există evaluări

- 3.lab Test Stress Anlysis - WEEK 3 PDFDocument90 pagini3.lab Test Stress Anlysis - WEEK 3 PDFAnanda GautamaÎncă nu există evaluări

- Lecture 05 RoundaboutsDocument36 paginiLecture 05 Roundaboutsarsitektur90Încă nu există evaluări

- Flexible Pavement (Bituminous Road) : Compacted Soil SubgradeDocument3 paginiFlexible Pavement (Bituminous Road) : Compacted Soil SubgradeDinesh Kumar PatelÎncă nu există evaluări

- PWD UPDATdEDocument41 paginiPWD UPDATdEmukeshÎncă nu există evaluări

- Subgrade Soil Stabilization Through The Introduction of Goetextile & Natural Coir Fibre AlternativelyDocument50 paginiSubgrade Soil Stabilization Through The Introduction of Goetextile & Natural Coir Fibre AlternativelyPrince FerdousÎncă nu există evaluări

- An Experimental Study On Stabilization of Black Cotton Soil by Using Bio PolymersDocument4 paginiAn Experimental Study On Stabilization of Black Cotton Soil by Using Bio PolymersEditor IJTSRDÎncă nu există evaluări

- Class Soil Stabilization TechniquesDocument24 paginiClass Soil Stabilization TechniquesPraveen SamarthiÎncă nu există evaluări

- 08 - Footings On SandDocument16 pagini08 - Footings On SandHoshear Bakr100% (1)

- 2015 Estimating MDD and OMCDocument9 pagini2015 Estimating MDD and OMCKrmt Goji SamaratunggadewaÎncă nu există evaluări

- Pull Out TestDocument4 paginiPull Out TestsubbaraoÎncă nu există evaluări

- Irc Gov in SP 078 2008Document16 paginiIrc Gov in SP 078 2008surendraÎncă nu există evaluări

- Foundation-I HandoutDocument63 paginiFoundation-I Handoutrahel abrahamÎncă nu există evaluări

- Stabilization of Expansive Soil Using Fly AshSVNITDocument10 paginiStabilization of Expansive Soil Using Fly AshSVNITkaushal yadavÎncă nu există evaluări

- CBR OsjiDocument6 paginiCBR OsjiSA023Încă nu există evaluări

- Vibroreplacement PDFDocument9 paginiVibroreplacement PDFthadikkaranÎncă nu există evaluări

- How To Calculate Bearing Capacity of Soil From Plate Load TestDocument5 paginiHow To Calculate Bearing Capacity of Soil From Plate Load TestDEBOPRASAD BISWASÎncă nu există evaluări

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985De la EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Încă nu există evaluări

- International Society for Rock Mechanics: List of Members 1980De la EverandInternational Society for Rock Mechanics: List of Members 1980Evaluare: 3.5 din 5 stele3.5/5 (2)

- May 29 - 17..Document61 paginiMay 29 - 17..Dhananjay Kumar0% (1)

- Principle of StructureDocument3 paginiPrinciple of StructureDhananjay KumarÎncă nu există evaluări

- File 2701Document28 paginiFile 2701Dhananjay KumarÎncă nu există evaluări

- Design of Halving JointDocument5 paginiDesign of Halving JointDhananjay KumarÎncă nu există evaluări

- Transport Bhawan, 1, Parliament Street, New Delhi-110001: RFP Regarding Bid CapacityDocument3 paginiTransport Bhawan, 1, Parliament Street, New Delhi-110001: RFP Regarding Bid CapacityDhananjay KumarÎncă nu există evaluări

- File 3233Document6 paginiFile 3233Dhananjay Kumar100% (1)

- ITE Toll Plaza SafetyDocument21 paginiITE Toll Plaza SafetyDhananjay KumarÎncă nu există evaluări

- Bridge and Tunnel ConceptDocument76 paginiBridge and Tunnel ConceptDhananjay KumarÎncă nu există evaluări

- Arch Bridge Ultra High ProDocument366 paginiArch Bridge Ultra High ProDhananjay KumarÎncă nu există evaluări

- Namin PDFDocument162 paginiNamin PDFDhananjay KumarÎncă nu există evaluări

- Design Study of A Three Span Continuous Tied BridgeDocument72 paginiDesign Study of A Three Span Continuous Tied BridgeDhananjay KumarÎncă nu există evaluări

- Cement Concrete 1-19Document20 paginiCement Concrete 1-19Dhananjay KumarÎncă nu există evaluări

- Tied Arch BridgesDocument13 paginiTied Arch BridgesDhananjay KumarÎncă nu există evaluări

- Comparative Study On Normal and Skew Bridge of PSC Box GirderDocument6 paginiComparative Study On Normal and Skew Bridge of PSC Box GirderDhananjay KumarÎncă nu există evaluări

- Brochure Alcohol Ethox StepanDocument24 paginiBrochure Alcohol Ethox StepanMiguel Angel Diaz100% (2)

- Mortar Test ReportDocument3 paginiMortar Test ReportMuhd FaridÎncă nu există evaluări

- PythonDocument28 paginiPythonWerner SchulzÎncă nu există evaluări

- Orthodontic WiresDocument35 paginiOrthodontic WiresSadhu Abhijeet100% (1)

- What Is A Grinding AidDocument1 paginăWhat Is A Grinding Aidabosede2013Încă nu există evaluări

- Pedoman CBR Ke DDT 2Document12 paginiPedoman CBR Ke DDT 2nanangÎncă nu există evaluări

- On Modified BitumenDocument19 paginiOn Modified BitumenTejeshwini SÎncă nu există evaluări

- Prof. Francisco 2010Document5 paginiProf. Francisco 2010Cirilo SantosÎncă nu există evaluări

- Comparison of Static and Dynamic Load Test of PileDocument11 paginiComparison of Static and Dynamic Load Test of PilehangÎncă nu există evaluări

- Solvent Based Troubleshooting - RevisedDocument5 paginiSolvent Based Troubleshooting - RevisedWillen Christia M. Madulid100% (1)

- 8sem Civil Structural Engineering Design-1 DineshChandra AssignmentsDocument10 pagini8sem Civil Structural Engineering Design-1 DineshChandra AssignmentsAnitha Hassan KabeerÎncă nu există evaluări

- MCQ Metallurgy Question PaperDocument11 paginiMCQ Metallurgy Question PaperAshutosh AvasekarÎncă nu există evaluări

- Présentation - Cnes - Icam - Materiaux - Structuraux - 2021 PDFDocument62 paginiPrésentation - Cnes - Icam - Materiaux - Structuraux - 2021 PDFJoshua VUITTENEZÎncă nu există evaluări

- D2619Document3 paginiD2619rimi7al100% (1)

- IF SteelsDocument20 paginiIF SteelsZubair AhmadÎncă nu există evaluări

- Floor MatsDocument2 paginiFloor MatsCasper MuñozÎncă nu există evaluări

- Me Gate Books Highly RecommendedDocument3 paginiMe Gate Books Highly RecommendedMusycal FynncÎncă nu există evaluări

- Plugin Chapter16Document45 paginiPlugin Chapter16Akshay GatkalÎncă nu există evaluări

- Lecture10 AllDocument38 paginiLecture10 AlladeelyjÎncă nu există evaluări

- Sieve Analysis of Fine and Coarse Aggregates: Standard Test Method ForDocument5 paginiSieve Analysis of Fine and Coarse Aggregates: Standard Test Method ForAkkshay ChadhaÎncă nu există evaluări

- Literature Review - The Design of Buried Flexible PipesDocument47 paginiLiterature Review - The Design of Buried Flexible PipesxbeldaÎncă nu există evaluări

- 04 CreepDocument58 pagini04 Creepzaneliu100% (1)

- Viscosity Ratio of SlurriesDocument17 paginiViscosity Ratio of SlurriesradanpetricaÎncă nu există evaluări

- 4140 Final Exam Fa16Document2 pagini4140 Final Exam Fa16AdamÎncă nu există evaluări

- ELV Guide To Electric Cables and Cables Which Cable Cable To Use For WhatDocument4 paginiELV Guide To Electric Cables and Cables Which Cable Cable To Use For WhatAKISÎncă nu există evaluări

- WBUT B. Tech Mechanical Engineering Fifth Semester Design of Machine Elements (ME-503) Exam4 - PaDocument5 paginiWBUT B. Tech Mechanical Engineering Fifth Semester Design of Machine Elements (ME-503) Exam4 - PaSaYani SamaDdarÎncă nu există evaluări

- Cabkoma Carbon Fibre RodsDocument22 paginiCabkoma Carbon Fibre RodsTRESA ROSE100% (3)

- Gearsand GearingDocument57 paginiGearsand Gearingcamohunter71Încă nu există evaluări

- Ficha Técnica KBM 403Document1 paginăFicha Técnica KBM 403Rafael SilvaÎncă nu există evaluări

- RWPR 900 Pellet Mill BrochureDocument4 paginiRWPR 900 Pellet Mill Brochuregrupa2904Încă nu există evaluări