Documente Academic

Documente Profesional

Documente Cultură

HTTP WWW - Textileschool.com School Spinning YarnFormation - Aspx

Încărcat de

Shoaib ArifDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

HTTP WWW - Textileschool.com School Spinning YarnFormation - Aspx

Încărcat de

Shoaib ArifDrepturi de autor:

Formate disponibile

Yarn Formation/Spinning

Loading

Home Store School Articles Live News TexCalc Login Register

You are here: School > Spinning > Yarn Formation

Related Topics

Yarn Forma

Systems: There

various commonl

popular Yarn For

Systems .Some o

are Cotton woolle

worsted,staple,Fi

yarn formation sy Als...

Twist inserti

and Different Spinning

Techniques: T

new spinning sys clearly avoid the

limitations produc

the twist insertion mechanism. It is

possible to increa

twist insertion rat

Textile Yarn

Types: Details o

http://www.textileschool.com/School/Spinning/YarnFormation.aspx (1 of 12) [6/10/2012 11:17:18 PM]

Yarn Formation/Spinning

Yarn Formation/ Spinning

The Fibre formation process includes change in shape, structure and properties of the thermoplastic polymer. The polymer pellets or granules are fed into an extruder where, through heating, their melting temperature is exceeded. The polymeric melt is then transported, under pressure, to the spinneret..Yarn formation methods were originally developed for spinning of natural fibres including cotton, linen, wool and silk. Previous Topic Yarn Spinning Next Topic Yarn Formation Systems

types of yarn suc

spun yarn and fila

yarn also differen

of cotton such as

island cotton, Pim

cotton, U.S. cotto Asian...

Constructio

Textile Yarn: Y

construction bein

classified into sim

conventional yarn

complex/novelty y

metallic yarns, te

yarns, bulked/hig

bulked yarns and

Textile Yarn

size/substanc

How to find out th

sizes and popula

YARN

The thickness of yarn is measured as

yarn sizes, techn

to identify substa textile yarn...

Thread

Counts. Yarns are made in different counts like 2s, 4s, 10s, 16s, 20s, 24s, 25s, 30s, 34s, 36s, 38s, 40s, 60s, 80s, 100s, etc. We can consider

Numbering

System: Thread

usually made up

several single str twisted or plied

like this. 0s counts are cotton fiber. 20s counts yarn is thicker than 24s yarn. Likewise 30s yarn is thicker than 34s.

http://www.textileschool.com/School/Spinning/YarnFormation.aspx (2 of 12) [6/10/2012 11:17:18 PM]

together. The

numbering system

threads has two p

Yarn Formation/Spinning

So when the yarn counts are increasing, the thickness becomes lesser. We can see, the higher the counts, the lesser the thickness.

one related to the

Filament Ya

Spinning: For

transforming filam

fibres to yarns inv

Yarn prices based on the thickness. Price of 20s yarn is lesser than 24s. Price of 30s yarn is lesser than 34s yarn. We must know, higher the counts, higher the prices. There are 2 qualities of yarn. Combed and Carded.

processes such a

spinning, Dry spin

Melt spinning, Bi-

component spinn constituent s...

Staple Yarn

Spinning: The

part of staple fibre

Combed is superior quality. The cotton fibers are in different lengths from 0.25 inches to 2.5 inches. According to the technical parameters, the fibers with more length are considered to be better. These long fibers give more evenness

approx. 33 mio to

processed in sho

staple spinning. T

part of the spinnin

industry therefore great ...

Ring Spinni

and more strength for yarns. Also the short fibers are increasing hairiness whereas the long fibers are decreasing hairiness in yarns. Hence in order to get uniformity in fiber lengths, the short length fibers are to be eliminated from

The Ring Spinnin

the most widely u form of spinning machine due to

significant advant

in comparison wit new spinning

the long length fibers. For this purpose, a special process is being done. This

processes. The ri

process is called Combing. Because of the same longer length of fibers, the

http://www.textileschool.com/School/Spinning/YarnFormation.aspx (3 of 12) [6/10/2012 11:17:18 PM]

Arrangeme

and Schemti

Ring Spinning

Yarn Formation/Spinning

yarn will be very even with lesser

Problems a

hairiness. Hence after knitting or weaving, the fabric will have very even look.

Success fact

Ring Spinning

Process of R

Spinning: ...

Carded yarn is inferior in quality. As the above said combing process is not being done, the carded yarn will be made of the fibers in different lengths. Hence the yarn strength will be lesser than combed yarn. Also carded yarn will have more hairiness and due to this, the

quality yarns it

Ring Spinni

Pros and Con

The ring spinning

system is the olde

spinning system t

remains dominan

because of the hi

fabric made with carded yarns will have

produces. Ring s has various ...

Categories

Textile

Textile is a type of material composed of natural or synthet...

Textile - An introduction

more unevenness. Because of this extra process, the Combed yarn price is higher than Carded yarn. Also Combed yarn quality is superior to Carded yarn.

Winding: Th

which is prepared ring frame is not

suitable for furthe

Fiber

Fiber is a hair-like strand of material. It is flexible and ...

The building block of the textile industry - Textile Fibres.

processing. So th

Yarn Formation

is converted into

shape of cone wh prepared ...

Textile Yarns

Yarns are continuous strands of fibers that can be woven or ...

Textile Yarns

Winding

Calculation a

objective: Ho

do the winding

calcutaions is des

Spinning

Yarn spinning is the process of manufacturing yarn from diff...

http://www.textileschool.com/School/Spinning/YarnFormation.aspx (4 of 12) [6/10/2012 11:17:18 PM]

here .And also th

objective of windi

Yarn is continous strand which is made up of filaments or fibers. It is used to

specified....

Yarn Formation/Spinning Yarn Spinning

Fabrics

The major methods for fabric manufacture are weaving and kni...

Fabric Formation

make fabric/textiles of different kinds.

Types of

Winding: Basic

Yarn formation methods were originally developed for spinning of natural fibers including cotton, linen, wool and silk. Since the overall physical

there are two type

winding machines

precision winders

Weaving

The weaving is a process of formation of fabric with interla...

Fabric Weaving

drum winders. Pr

widers, used prim for filament yarn, tra...

characteristics of the fibers and processing factors needed differed from fiber to fiber, separate processing systems were developed. As synthetic fibers were introduced, synthetic spinning systems for texturized and untexturized cut staple were developed as modifications of existing staple systems, whereas spinning systems for texturized and untexturized filament were developed separately.

Knitting

Knitting is a method by which thread or yarn may be turned i...

Knitting

Winding

Machines an

Faults: Different

of winding machin

Embroidery

Embroidery is the art or handicraft of making or decorating ...

Embroidery - machine embroidery

are discussed he

They can be clas

on the basis of ...

the various faults

Textile Finishing

Textile Finishing is any operation (other than preparation a...

Textile Finishing

winding are spec

Optimum

Spinning

Apparel

Textile products used for clothing is broadly termed as Appa...

Apparel/Garments

condition: Fac

Mixing and Blending

Mixing: It is generally meant as the intermingling of different classes of fibers of the same grade e.g. USA Pima grade2, CIS

governing Optimu

Spinning conditio Yarn quality

Lingerie

Lingerie industry has been growing prosperously and the d...

Lingerie

assessment, Cau

end breakage/ en down...

Blow Room

Technical Textiles

Technical textile are textile products manufactured for non-...

Technical Textiles http://www.textileschool.com/School/Spinning/YarnFormation.aspx (5 of 12) [6/10/2012 11:17:18 PM]

Functions: Blo

Blending: IT is meant as the intermingling of different kinds of fibers

room is the startin

the spinning oper

where the fibre is

Yarn Formation/Spinning

Eco Textiles

The textile industry is considered as the most ecologically ...

Eco Textiles

or different grade of same fibers e.g. polyester & cotton, Viscose & cotton.

opened, cleaned,

mixed , micro dus

removed and eve

Objectives of missing or blending

thus passed to ca m...

Fashion

Fashion is not defined solely by clothing choices, but it is...

Fashion

Economy Processing performance Functional properties

Objectives

blow room:

objectives, action

ConversionFormulas

Interactive, table style conversion calculator to determine ...

Count Conversion Calculators and Formulas

blow room, wasta

Grams per Square Metre (GSM)

GSM is the short form of Grams per Square Metre. GSM is the very most important thing which defines the weight of the fabrics of knit garments.

and faults in blow

types of beater in room...

Costing

Costing is the system of computing cost of production or of ...

Costing

Functions o

Carding: Card

a mechanical pro

that breaks up loc and unorganised

Dispatch

Dispatching is the process of delivering the products to the...

Dispatch

clumps of fibre an

Garment price and quality based on many things like GSM, fabric quality, colours, finishing, prints, embroidery,

aligns the individu

fibres so that they more or le...

style, etc. But GSM is the most important thing to be decided when confirming the prices between the sellers and buyers.

Objectives

carding: Objec

of carding, main a

of carding machin

Useful sliver hank

different counts a

GSM is the weight of 1mtr x 1mtr fabric. It means 100cm x 100cm = 10,000 sq. cms. It can be found out by any one of the below ways.

http://www.textileschool.com/School/Spinning/YarnFormation.aspx (6 of 12) [6/10/2012 11:17:18 PM]

wastage in cardin

Draw frame

Functions: Ca

Slivers are fed int

Draw-Frame and

Yarn Formation/Spinning

stretched/Straigh

By the weight of 100cm x 100cm fabric bit.

and made in to a sliver. Also fibre

blending can be d this stag...

By the weight of 50cm x 50cm fabric bit multiplied by 4.

Combing:

Necessity of com

objectives of com

By the weight of 25cm x 25cm fabric bit multiplied by 16.

Combers Noel...

Roving: The

of roving frame is

that comes from d

By the weight of 10cm x 10cm fabric bit multiplied by 100. reduce the linear

frame section wh

only parallel of co

sliver. In roving s

We must be aware that if we use the smaller size bit, accurate GSM can not be achieved. The bigger size of fabric bit is better used to get exact or closer GSM.

Lap Former

Process: In Lap

former machine, are fed to form a 20 inches wide

condensed with a

draft and weighin

If we have fabrics, then we dont have any problem in finding GSM, as we can cut any dimension to find GSM. But most of the times, we will have only the garments to find GSM. And we will have to keep the garment for style, making and other references. So we will be allowed to cut a small bit from the

http://www.textileschool.com/School/Spinning/YarnFormation.aspx (7 of 12) [6/10/2012 11:17:18 PM]

per set length. Th machine run s...

Speed fram

Objectives of spe

frame, operations

involved in speed frame...

Open-End

Yarn Formation/Spinning

Spinning: The

garments. Hence nowadays, round cutters are used. This system is used worldwide. With the help of this round cutter, the fabric will be cut into a small bit.

functioning of roto

spinning ,machin presented at the

in 1967.Yarn spin

according to the r

spinning principle

Then the GSM of the fabric can be found out by multiplying the weight of this round bit by 100. This round bit is to be weighed in an electronic scale with milligram accuracy. As this bit is very small and as the weight has to be multiplied by 100, the fabric has to be cut very sharply to get the exact GSM. Hence the blades of this round cutter are to be sharp and new to get the exact GSM.

predominate...

Substrate

Formation: Te

substrates are for

from yarns or fibr

by several techni

including weaving

knitting, tufting, a

nonwoven format Composites ...

Air Jet Spin

Air jet spinning ha offered yarn

manufacturers th

Previous Topic Yarn Spinning Yarn spinning is the process of manufacturing yarn from different types of fibres into a continuous length from one or more type of fibers. Spinning is the most important and the initial step in fabric manufacturing. The major goals of spinning is to

http://www.textileschool.com/School/Spinning/YarnFormation.aspx (8 of 12) [6/10/2012 11:17:18 PM]

Next Topic Yarn Formation Systems

opportunity to pro yarn at relatively

production rate. U

other spinning me in w...

Twist Inserti

There are various commonly used popular Yarn Formation Systems . Some of them are Cotton woollen or worsted,staple, Filament yarn

and Different Spinning

Techniques: T

new spinning sys clearly avoid the

Yarn Formation/Spinning

produce the quality yarn from raw material, then remove the process faults followed by winding the short length bobbins on Cones. There are different types of spinning, the most commonly forms of spinning are: Ring, Rotor, Air Jet, Friction etc.

formation systems. Also some of the common types of yarns like mercerdised ,dyed, grindle or twisted, yarns are discussed in this page.

limitations produc

the twist insertion mechanism. It is

possible to increa

twist insertion rat

Characteris

of Textile and fabric:

Blended yarn

characteristics of

blended yarns lik

shrinks or not, wa

absorbent , has c or not, has luster

soft/hard. Each k fibre ...

Textile knit

production: T

knot yarn product

Faults and remed Uniformity ratio, Micronnaire and maturity, Fiber maturity...

Sampling o

Bales of Cott

(Bulk Sample

Sampling proced bales,No.of tests

critical difference various fiber properties...

http://www.textileschool.com/School/Spinning/YarnFormation.aspx (9 of 12) [6/10/2012 11:17:18 PM]

Yarn Formation/Spinning

Home | Terms Of Use | Privacy Statement | About TextileSchool.Com | Contact Us (c) Copyright 2010 by TextileSchool.com , in Association with Ganitrus.com | Texociation.com

http://www.textileschool.com/School/Spinning/YarnFormation.aspx (10 of 12) [6/10/2012 11:17:18 PM]

Yarn Formation/Spinning

http://www.textileschool.com/School/Spinning/YarnFormation.aspx (11 of 12) [6/10/2012 11:17:18 PM]

Yarn Formation/Spinning

http://www.textileschool.com/School/Spinning/YarnFormation.aspx (12 of 12) [6/10/2012 11:17:18 PM]

S-ar putea să vă placă și

- Case - Outsourcing (A)Document5 paginiCase - Outsourcing (A)Athah0% (1)

- Weaving Preparatory ProcessDocument5 paginiWeaving Preparatory ProcessKhubab Shaker100% (10)

- Jute Manufacturing ProcessDocument8 paginiJute Manufacturing Processhabibitltd50% (2)

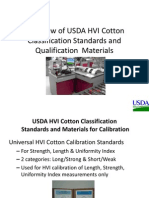

- Overivew of USDA HVI Cotton Classification-DeatherageDocument36 paginiOverivew of USDA HVI Cotton Classification-DeatherageGhandi AhmadÎncă nu există evaluări

- Drawing CombingDocument29 paginiDrawing CombingShoaib ArifÎncă nu există evaluări

- Junior Explorer 5 Unit 4 Test A Group 1Document3 paginiJunior Explorer 5 Unit 4 Test A Group 1tomek100% (1)

- Amsterdam Reflow Booklet - Chapter 10Document7 paginiAmsterdam Reflow Booklet - Chapter 10rim3lÎncă nu există evaluări

- Auto ConnerDocument8 paginiAuto ConnerMian MubeenÎncă nu există evaluări

- Conversion of Fibre Into A YarnDocument32 paginiConversion of Fibre Into A YarnMohammed Atiqul Hoque ChowdhuryÎncă nu există evaluări

- Manufacturing ProcessDocument6 paginiManufacturing ProcessKennaa BekeleÎncă nu există evaluări

- Fundamentals of TextilesDocument25 paginiFundamentals of TextilesKunst LiefdeÎncă nu există evaluări

- Sewing ThreadsDocument39 paginiSewing ThreadsAnkit ChandorkarÎncă nu există evaluări

- Important Topics-Ts2-Unit-2Document82 paginiImportant Topics-Ts2-Unit-2ISHITAÎncă nu există evaluări

- Fibre & FabricsDocument6 paginiFibre & FabricsVarun GuptaÎncă nu există evaluări

- Jute ProcessingDocument7 paginiJute Processingtulika_ajwaniÎncă nu există evaluări

- Module 114 Basic Textile - 001-KnittingDocument60 paginiModule 114 Basic Textile - 001-KnittingTran Quoc VietÎncă nu există evaluări

- Bgmea University of Fashion and Technology: Final SubmissionDocument34 paginiBgmea University of Fashion and Technology: Final Submissionmortuza hasanÎncă nu există evaluări

- Special YarnDocument42 paginiSpecial YarnMd. Nasir UddinÎncă nu există evaluări

- Denim - ProcessDocument28 paginiDenim - ProcessSajjad Ashraf100% (1)

- Knitting LatestDocument39 paginiKnitting Latestgopica3448Încă nu există evaluări

- Change of Fabric GSM With Yarn CountDocument21 paginiChange of Fabric GSM With Yarn CountOptimisticPerson100% (2)

- Sewing Threa: BY Pooja MishraDocument31 paginiSewing Threa: BY Pooja MishraRabi KantÎncă nu există evaluări

- Presented By: Elfa RajaDocument32 paginiPresented By: Elfa RajaSreenithiRavichandranÎncă nu există evaluări

- 10 Mechanical FinishesDocument6 pagini10 Mechanical Finishesইমরানুল শহীদ আলভীÎncă nu există evaluări

- Knits LudhianaDocument25 paginiKnits LudhianaRoha RohaÎncă nu există evaluări

- How Jeans Are Made?: Cotton Harvesti NG Cotton Blendin G Doublin G& Drafting Beamin GDocument4 paginiHow Jeans Are Made?: Cotton Harvesti NG Cotton Blendin G Doublin G& Drafting Beamin GAbulHasanÎncă nu există evaluări

- Yarn Preparation For WeavingDocument56 paginiYarn Preparation For WeavingteegalajyothiÎncă nu există evaluări

- Weaving: by S Naavendhan 20MT31Document124 paginiWeaving: by S Naavendhan 20MT3120MT31 - NAAVENDHAN SÎncă nu există evaluări

- Introduction To WeavingDocument17 paginiIntroduction To WeavingJahaziÎncă nu există evaluări

- Recent Development in Denim ManufacturingDocument24 paginiRecent Development in Denim ManufacturingMichael LiuÎncă nu există evaluări

- Warp KnittingDocument44 paginiWarp KnittingEngineer WaleedÎncă nu există evaluări

- Textile Spinning To Finishing Process: Business English ProgramDocument41 paginiTextile Spinning To Finishing Process: Business English ProgramM.TauqeerÎncă nu există evaluări

- Sewing ThreadDocument11 paginiSewing Threadmoorthy-sweetyÎncă nu există evaluări

- Comber: The Combing ProcessDocument21 paginiComber: The Combing ProcessAmir Shahzad100% (4)

- Lecture 8Document62 paginiLecture 8fekadeÎncă nu există evaluări

- 1 # Introduction: Principles of Fashion Marketing - Yarn SectorDocument22 pagini1 # Introduction: Principles of Fashion Marketing - Yarn SectorSeveshÎncă nu există evaluări

- SpinningDocument8 paginiSpinningAishee BhowmickÎncă nu există evaluări

- Factors Which Affect The Cost ofDocument19 paginiFactors Which Affect The Cost ofsuchi_mohan08Încă nu există evaluări

- Knitting IntroductionDocument24 paginiKnitting IntroductionShreyansh Jha100% (2)

- SFPDocument89 paginiSFPKomol Kabir100% (1)

- Lab AssignmentDocument7 paginiLab AssignmentAftab AminÎncă nu există evaluări

- Fabric KnittingDocument19 paginiFabric KnittingRaja manimaranÎncă nu există evaluări

- Session 5Document12 paginiSession 5ARYAN RATHOREÎncă nu există evaluări

- Textile Internship Report AlokDocument39 paginiTextile Internship Report AlokRahul TelangÎncă nu există evaluări

- Tezera Kassa Import and Export Company: Study OnDocument6 paginiTezera Kassa Import and Export Company: Study Onwubishet beleteÎncă nu există evaluări

- Study of Comber MachineDocument6 paginiStudy of Comber MachineNaimul Hasan0% (1)

- Latest Technologies and Developments in Spinning, Weaving, and ProcessingDocument8 paginiLatest Technologies and Developments in Spinning, Weaving, and Processingkhushi savlaÎncă nu există evaluări

- To Study The Impact On Process Parameter of Knitted Fabric: April 2011Document20 paginiTo Study The Impact On Process Parameter of Knitted Fabric: April 2011Fahad AshfaqÎncă nu există evaluări

- Yarn Numbering and Sewing ThreadsDocument44 paginiYarn Numbering and Sewing Threadsnitishkohli100% (9)

- Yarns Fabric KnowledgeDocument15 paginiYarns Fabric Knowledgeishajain11Încă nu există evaluări

- BGMEA University of Fashion & Technology (BUFT) : Assignment. (k-3)Document19 paginiBGMEA University of Fashion & Technology (BUFT) : Assignment. (k-3)NeFariOus ArYan AraFat AnikÎncă nu există evaluări

- Upholestry DetailsDocument26 paginiUpholestry DetailsShri DhaaraniÎncă nu există evaluări

- Types of YarnDocument10 paginiTypes of YarnnomanÎncă nu există evaluări

- YEM 2 (LAB) Group-2Document32 paginiYEM 2 (LAB) Group-2mortuza hasanÎncă nu există evaluări

- Fabric Manufacturing StepsDocument15 paginiFabric Manufacturing StepsFazlul AzimÎncă nu există evaluări

- Textile Mid TopicDocument20 paginiTextile Mid Topictahasheikh822Încă nu există evaluări

- Responsibility of QADocument20 paginiResponsibility of QAMonjur Hossain100% (1)

- Knitted FabricsDocument24 paginiKnitted Fabricsapi-232403733Încă nu există evaluări

- Aspects of Knitting ScienceDocument3 paginiAspects of Knitting ScienceNiaz IslamÎncă nu există evaluări

- Yarns From EpgpathshalaDocument22 paginiYarns From EpgpathshalakabuÎncă nu există evaluări

- Sewing Supplies Handy Pocket Guide: 65+ Tips & Facts for Tools, Notions & MaterialsDe la EverandSewing Supplies Handy Pocket Guide: 65+ Tips & Facts for Tools, Notions & MaterialsÎncă nu există evaluări

- Sewing Knits from Fit to Finish: Proven Methods for Conventional Machine and SergerDe la EverandSewing Knits from Fit to Finish: Proven Methods for Conventional Machine and SergerEvaluare: 4 din 5 stele4/5 (3)

- Knitting for beginners: The Ultimate Complete Guide To Learning Knitting Fast!De la EverandKnitting for beginners: The Ultimate Complete Guide To Learning Knitting Fast!Evaluare: 5 din 5 stele5/5 (1)

- Ftee 83 54Document6 paginiFtee 83 54Shoaib ArifÎncă nu există evaluări

- Comparative Study of Different Test Methods Used For The Measurement of Physical Properties of CottonDocument7 paginiComparative Study of Different Test Methods Used For The Measurement of Physical Properties of CottonShoaib ArifÎncă nu există evaluări

- MAU08 Fiber Cross-Sectioning MethodsDocument3 paginiMAU08 Fiber Cross-Sectioning MethodsShoaib ArifÎncă nu există evaluări

- Mercerization 140503095002 Phpapp01Document74 paginiMercerization 140503095002 Phpapp01Alvinur Rahman AlviÎncă nu există evaluări

- jcs11 293Document7 paginijcs11 293Shoaib ArifÎncă nu există evaluări

- Cotton BollsDocument58 paginiCotton BollsShoaib ArifÎncă nu există evaluări

- Fibre Properties Relationships To Fabric QualityDocument206 paginiFibre Properties Relationships To Fabric QualityShoaib ArifÎncă nu există evaluări

- Vortrag-Hequet 2012Document66 paginiVortrag-Hequet 2012Shoaib ArifÎncă nu există evaluări

- Cotton Fiber Treatment With EnzymeDocument6 paginiCotton Fiber Treatment With EnzymeShoaib ArifÎncă nu există evaluări

- Cotton TreatmentDocument7 paginiCotton TreatmentShoaib ArifÎncă nu există evaluări

- Neps and Trash IndicatorDocument8 paginiNeps and Trash IndicatorShoaib ArifÎncă nu există evaluări

- Cotton Research in Uzbekistan: Elite Varieties and Future of Cotton BreedingDocument12 paginiCotton Research in Uzbekistan: Elite Varieties and Future of Cotton BreedingShoaib ArifÎncă nu există evaluări

- Azo DyesDocument5 paginiAzo DyesShoaib ArifÎncă nu există evaluări

- Predicting Yarn Quality: An Indispensable Tool For Cotton Breeders E. F. Hequet and B. KellyDocument14 paginiPredicting Yarn Quality: An Indispensable Tool For Cotton Breeders E. F. Hequet and B. KellyShoaib ArifÎncă nu există evaluări

- The Australian Cotton Industry Naturally World's BestDocument5 paginiThe Australian Cotton Industry Naturally World's BestShoaib ArifÎncă nu există evaluări

- Spectogram Hata PDFDocument9 paginiSpectogram Hata PDFahmetygtÎncă nu există evaluări

- Spinning Performance of ELS Egyptian Cotton: Full Length Research PaperDocument8 paginiSpinning Performance of ELS Egyptian Cotton: Full Length Research PaperShoaib ArifÎncă nu există evaluări

- Cotton Germplasm Collection of UzbekistanDocument15 paginiCotton Germplasm Collection of UzbekistanShoaib ArifÎncă nu există evaluări

- Pima CottonDocument2 paginiPima CottonArka MitraÎncă nu există evaluări

- Approach Development For Surveillance Assistance: Spinning Mill ApplicationDocument13 paginiApproach Development For Surveillance Assistance: Spinning Mill ApplicationShoaib ArifÎncă nu există evaluări

- IGATEXDocument1 paginăIGATEXShoaib ArifÎncă nu există evaluări

- Predicting Yarn Quality: An Indispensable Tool For Cotton Breeders E. F. Hequet and B. KellyDocument14 paginiPredicting Yarn Quality: An Indispensable Tool For Cotton Breeders E. F. Hequet and B. KellyShoaib ArifÎncă nu există evaluări

- India Itme UsterDocument1 paginăIndia Itme UsterShoaib ArifÎncă nu există evaluări

- Igatex Uster NewDocument1 paginăIgatex Uster NewShoaib ArifÎncă nu există evaluări

- Chinese Review DR NoorDocument2 paginiChinese Review DR NoorShoaib ArifÎncă nu există evaluări

- AR Physical Properties of Sun Yarns 01Document36 paginiAR Physical Properties of Sun Yarns 01Neeraj BhardwajÎncă nu există evaluări

- Uster Classimat 5Document9 paginiUster Classimat 5Shoaib ArifÎncă nu există evaluări

- Color SchemesDocument23 paginiColor SchemesShoaib ArifÎncă nu există evaluări

- Primark IndiaDocument18 paginiPrimark IndiaKrutika MahindrakarÎncă nu există evaluări

- Gabriel-Lesson 10 Activity 10.2, Activity 10.2, & Post-AssessmentDocument4 paginiGabriel-Lesson 10 Activity 10.2, Activity 10.2, & Post-AssessmentLucille May GabrielÎncă nu există evaluări

- Cinnamon Miles - Idiot's Guides - Sewing (2013, ALPHA) PDFDocument275 paginiCinnamon Miles - Idiot's Guides - Sewing (2013, ALPHA) PDFLisete Alves100% (3)

- Happy Cactus Crochet Pocahontas-1Document9 paginiHappy Cactus Crochet Pocahontas-1Nguyễn Hoa100% (1)

- Dry Cleaning Business PlanDocument49 paginiDry Cleaning Business PlanJoseph QuillÎncă nu există evaluări

- LKN22 02Document2 paginiLKN22 02biddut782Încă nu există evaluări

- Free Pattern: Little COWDocument8 paginiFree Pattern: Little COWWork workÎncă nu există evaluări

- "Direct / Residual Shear Test Apparatus, Digital "Touch Screen"Document45 pagini"Direct / Residual Shear Test Apparatus, Digital "Touch Screen"quequma7202Încă nu există evaluări

- A0 Milkmaid DressDocument2 paginiA0 Milkmaid DressKevin AndersonÎncă nu există evaluări

- Diesel BrandDocument42 paginiDiesel Brandnehakool2050% (2)

- Lingerie Insight June 2011Document64 paginiLingerie Insight June 2011gab2029% (7)

- Ladies Skirt PDFDocument13 paginiLadies Skirt PDFshailja sundaramÎncă nu există evaluări

- LISD 2023-2024 Dress Code - English As of 7.25.2023Document5 paginiLISD 2023-2024 Dress Code - English As of 7.25.2023Roger UvalleÎncă nu există evaluări

- 1: Clothing Guessing GameDocument4 pagini1: Clothing Guessing GameMert ÖzdağÎncă nu există evaluări

- The Strawberry Milk Run - Colour Block Bikini Pattern DetailsDocument3 paginiThe Strawberry Milk Run - Colour Block Bikini Pattern Detailsanastarkey0% (1)

- 03 - Form - PPE StockDocument5 pagini03 - Form - PPE StockAli Rizki BudimanÎncă nu există evaluări

- Legally Blonde Costume List in Order of Appearance 2Document5 paginiLegally Blonde Costume List in Order of Appearance 2chester_858061501Încă nu există evaluări

- Tizz Crochet Star Snuggle BAG: Take + MakeDocument3 paginiTizz Crochet Star Snuggle BAG: Take + MakeJudithÎncă nu există evaluări

- Ajrakh PrintingDocument25 paginiAjrakh PrintingNamrata Lenka100% (4)

- Nature of Business Clothing MarketingDocument1 paginăNature of Business Clothing MarketingAurelia Riji0% (1)

- Block PrintingDocument28 paginiBlock PrintingRhea SharmaÎncă nu există evaluări

- Final Report EthicsDocument18 paginiFinal Report EthicsAshiqul Karim AnikÎncă nu există evaluări

- Sewing Room in Apparel IndustryDocument46 paginiSewing Room in Apparel IndustryP. Lakshmanakanth100% (3)

- Perfect Dress For Your Body TypeDocument3 paginiPerfect Dress For Your Body TypeDonatella India100% (1)

- Additional Races & Cultures of Middle-EarthDocument23 paginiAdditional Races & Cultures of Middle-EarthErszebeth83% (6)

- Traditional Clothing of T' Boli Grade 7 ArtsDocument28 paginiTraditional Clothing of T' Boli Grade 7 Artsmienrado biguerasÎncă nu există evaluări

- Vintage LingerieDocument4 paginiVintage Lingeriejulie bennett100% (2)

- CrinolineperiodDocument41 paginiCrinolineperiodpoulomi royÎncă nu există evaluări