Documente Academic

Documente Profesional

Documente Cultură

Article 16 Magnetic Flux Leakage (MFL) Examination

Încărcat de

leonciomavarezDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Article 16 Magnetic Flux Leakage (MFL) Examination

Încărcat de

leonciomavarezDrepturi de autor:

Formate disponibile

A05

ARTICLE 16 MAGNETIC FLUX LEAKAGE (MFL) EXAMINATION

T-1610 SCOPE T-1622.1.1. The reference specimen for pipe or tubing shall consist of a pipe or tube that is made from a material of the same nominal pipe or tube sizes, product form, and composition as the component to be examined. The pipe or tube specimen shall have notch discontinuities machined into the inside and outside surfaces as shown in Fig. T-1622.1.2. The depths and widths of the articial discontinuities should be similar to the sizes and physical characteristics of discontinuities to be detected. If nonmagnetic coatings or temporary coverings will be present during the examination, the reference specimen shall be coated or covered with the nonmagnetic coatings or covers representative of the maximum thickness that will be encountered during the examination. T-1622.2 System Verication and Function Checks. The manufacturers verication procedure shall be conducted initially to ensure that the system is functioning as designed. The functional check shall be made by scanning the reference plate over the range of scanning speeds to be utilized during the examination. Equipment settings shall be documented. T-1622.3 Performance Conrmation. A functional check shall be conducted at the beginning and end of each examination, every 8 hr, or when equipment has malfunctioned and been repaired. If it is determined that the equipment is not functioning properly, needed adjustments shall be made and all areas examined since the last performance check shall be reexamined. T-1623 Written Procedure Requirements T-1623.1 Requirements. MFL examination shall be performed in accordance with a written procedure that shall, as a minimum, contain the requirements listed in Table T-1623. The written procedure shall establish a single value, or range of values, for each requirement. The procedure shall address, as a minimum, the identication of imperfections, reference materials used to set up equipment, location and mapping of imperfections, and the extent of coverage. The procedure shall address the eld strength of the magnets, the functioning of the sensors, and the operation of the signal-processing unit.

234

This Article describes the Magnetic Flux Leakage (MFL) examination method equipment requirements applicable for performing MFL examinations on coated and uncoated ferromagnetic materials from one surface. MFL is used in the examination of tube and piping to nd unwelded areas of longitudinal weld joints. It is also used as a post construction examination method to evaluate the condition of plate materials, such as storage tank oors, and piping for corrosion or other forms of degradation. Other imperfections that may be detected are cracks, seams, incomplete fusion, incomplete penetration, dents, laps, and nonmetallic inclusions, etc. When this Article is specied by a referencing Code Section, the MFL method described in this Article shall be used together with Article 1, General Requirements.

--``,,`,`,,,,``,,,,``,,`,,``,,-`-`,,`,,`,`,,`---

T-1620 T-1621

GENERAL Personnel Qualication Requirements

The user of this Article shall be responsible for documented training, qualication, and certication of personnel performing MFL examination. Personnel performing supplemental examinations, such as ultrasonic (UT) examinations, shall be qualied in accordance with the referencing Code Section. T-1622 Equipment Qualication Requirements

The equipment operation shall be demonstrated by successfully completing the unit verication and function tests outlined as follows. T-1622.1 Reference Specimen. All MFL examinations shall have a reference plate or pipe section to ensure the equipment is performing in accordance with the manufacturers specications prior to use. The reference specimen for plate shall consist of a plate that is made from a material of the same nominal thickness, product form, and composition as the component to be examined. The plate specimen shall have notches or other discontinuities machined into the bottom of the plate, as shown in Fig.

Copyright ASME International Provided by IHS under license with ASME No reproduction or networking permitted without license from IHS

Licensee=ExxonMobil/1890500101 Not for Resale, 03/18/2006 01:59:15 MST

ARTICLE 16 MAGNETIC FLUX LEAKAGE (MFL) EXAMINATION

Plate Thickness

1/ 4

Hole Number

1 2 1 2 1 2

Number of Steps

3 4 4 5 4 5

Step Size

.032 (0.8) .032 (0.8) .032 (0.8) .032 (0.8) .039 (1) .039 (1)

Diameter D1

.47 (12) .62 (16) .62 (16) .78 (20) .78 (20) .96 (24)

Diameter D2

.32 (8) .47 (12) .47 (12) .62 (16) .59 (15) .78 (20)

Diameter D3

.12 (3) .32 (8) .32 (8) .47 (12) .39 (10) .59 (15)

Diameter D4 .12 (3) .16 (4) .32 (8) .2 (5) .39 (10)

Diameter D5

(6)

5/16

(8)

.16 (4)

3/

(10)

.2 (5)

30 (750) 6 (150) 12 (300) D3

D1 D2

9 (225) Holes 1 2

Step

Typical 3-Step Pit 18 (450) Hole 1 2

--``,,`,`,,,,``,,,,``,,`,,``,,-`-`,,`,,`,`,,`---

%Loss 40% 50%

GENERAL NOTE: Dimensions of references are in in. (mm).

FIG. T-1622.1.1 REFERENCE PLATE DIMENSIONS

L

Typical Block Dimensions Minimum length L 8 in. (200 mm) or 8T, whichever is greater Full circumference

Specific Notch Dimensions Length L 1 in. (25 mm) maximum Depth D 10% T with tolerance (+10% 20%) of depth Width 0.010 in. (0.25 mm) maximum Location not closer than 3T from any block edge or other notch in axial direction Minimum 90 deg from adjacent notch(es)

FIG. T-1622.1.2 REFERENCE PIPE OR TUBE DIMENSIONS 234.1

Copyright ASME International Provided by IHS under license with ASME No reproduction or networking permitted without license from IHS

Licensee=ExxonMobil/1890500101 Not for Resale, 03/18/2006 01:59:15 MST

T-1623.1 TABLE T-1623 REQUIREMENTS OF AN MFL EXAMINATION PROCEDURE

--``,,`,`,,,,``,,,,``,,`,,``,,-`-`,,`,,`,`,,`---

2004 SECTION V

T-1660

T-1640

REQUIREMENTS

Requirement

Equipment manufacturer/model Sensor type: manufacturer and model Scanning speed/speed range Overlap Lift-off Material examined Material thickness range and dimensions Reference specimen and calibration materials Software Evaluation of indications Surface conditioning Coating/sheet thickness Performance demonstration requirements, when required Scanning technique (remote control/ manual) Scanning equipment/xtures Personnel qualication requirements

Essential Variable

X X X X X X X X X X X X X ... ... ...

NonEssential Variable

... ... ... ... ... ... ... ... ... ... ... ... ... X X X

(a) The surface shall be cleaned of all loose scale and debris that could interfere with the examination and movement of the scanner. The surface should be sufciently at to minimize excessive changes in lift-off and vibration. Alternate techniques will be required to handle variables exceeding those specied in the procedure. (b) Cleaning may be accomplished using high-pressure water blast or by sandblasting. If the material is coated and the coating is not removed, it shall be demonstrated that the MFL equipment can detect the specied imperfections through the maximum thickness of the temporary sheet or coating. (c) If a temporary sheet or coating is applied between the scanner and plate to provide a smooth surface, for example, on a heavily pitted surface, it shall be demonstrated that the equipment can nd the specied imperfections through the maximum thickness of the temporary sheet or coating.

T-1650

CALIBRATION

Other examination methods that will be used to supplement the MFL examination shall be identied in the procedure. T-1623.2 Procedure Qualication. When procedure qualication is specied, a change of a requirement in Table T-1623 identied as an essential variable shall require requalication of the written procedure by demonstration. A change in a requirement identied as a nonessential variable does not require requalication of the written procedure. All changes of essential or nonessential variables from those specied within the written procedure shall require revision of, or an addendum to, the written procedure.

The MFL equipment shall be recalibrated annually and whenever the equipment is subjected to major damage following required repairs. If equipment has not been in use for 1 year or more, calibration shall be done prior to rst use.

T-1660

EXAMINATION

T-1630

EQUIPMENT

The equipment shall consist of magnets, sensor or sensor array, and related electronic circuitry. A reference indicator, such as a ruled scale or linear array of illuminated light-emitting diodes, should be used to provide a means for identifying the approximate lateral position of indications. The equipment may be designed for manual scanning or may be motor driven. Software may be incorporated to assist in detection and characterization of discontinuities.

234.2

(a) Areas to be examined shall be scanned in accordance with a written procedure. Each pass of the sensing unit shall be overlapped in accordance with the written procedure. (b) The unit shall be scanned manually or by a motordriven system. Other examination methods may be used to provide coverage in areas not accessible to MFL examinations, in accordance with the written procedure. Typical examples of inaccessible areas in storage tanks are lap welds and corner welds adjacent to the shell or other obstructions, such as roof columns and sumps. (c) Imperfections detected with MFL exceeding the acceptance standard signal shall be conrmed by supplemental examination(s) or be rejected. Supplemental examination shall be performed in accordance with written procedures. (d) Where detection of linear imperfections is required, an additional scan shall be performed in a direction approximately perpendicular to the initial scanning direction.

Copyright ASME International Provided by IHS under license with ASME No reproduction or networking permitted without license from IHS

Licensee=ExxonMobil/1890500101 Not for Resale, 03/18/2006 01:59:15 MST

T-1670

ARTICLE 16 MAGNETIC FLUX LEAKAGE (MFL) EXAMINATION

T-1680

T-1670

EVALUATION

All indications shall be evaluated in accordance with the referencing Code Section. T-1680 DOCUMENTATION

A report of the examination shall contain the following information: (a) plate material specication, nominal wall thickness, pipe diameter, as applicable; (b) description, such as drawing/sketches, documenting areas examined, and/or areas inaccessible; (c) identication of the procedure used for the examination;

(d) system detection sensitivity (minimum size of imperfections detectable); (e) location, depth, and type of all imperfections that meet or exceed the reporting criteria; (f) examination personnel identity and, when required by referencing Code Section, qualication level; (g) model and serial number of equipment utilized for the examination, including supplemental equipment; (h) date and time of examination; (i) date and time of performance verication checks; and (j) supplemental methods utilized and reference to associated reports.

234.3

Copyright ASME International Provided by IHS under license with ASME No reproduction or networking permitted without license from IHS

Licensee=ExxonMobil/1890500101 Not for Resale, 03/18/2006 01:59:15 MST

Copyright ASME International Provided by IHS under license with ASME No reproduction or networking permitted without license from IHS

Licensee=ExxonMobil/1890500101 Not for Resale, 03/18/2006 01:59:15 MST

S-ar putea să vă placă și

- Sims ManualDocument76 paginiSims Manualjose ocanaÎncă nu există evaluări

- Recommended Practice AsntDocument11 paginiRecommended Practice AsntzulzainalÎncă nu există evaluări

- Updoc - Tips Level III Exams Topical OutlinesDocument6 paginiUpdoc - Tips Level III Exams Topical OutlinesJulio Cesar Cardozo BrachoÎncă nu există evaluări

- NDT MAGNETIC FLUX LEAKAGE LEVEL IIDocument102 paginiNDT MAGNETIC FLUX LEAKAGE LEVEL IIsaenal rapi100% (2)

- E 2007 - 10 (2016)Document23 paginiE 2007 - 10 (2016)Enrique Antonio100% (1)

- LG5003 OpsDocument20 paginiLG5003 Opstamilmalar08Încă nu există evaluări

- MFL Tank Floor Scanning 2009Document28 paginiMFL Tank Floor Scanning 2009Justin Diraviraj100% (3)

- E 2033 - 99 (2013)Document11 paginiE 2033 - 99 (2013)Enrique Antonio100% (2)

- E1254-98 Film StorageDocument3 paginiE1254-98 Film Storageaakash100% (3)

- 38DL Plus Ultrasonic Thickness Gage User's ManualDocument308 pagini38DL Plus Ultrasonic Thickness Gage User's ManualJake Sparrow100% (3)

- NDT Audit E1359 PDFDocument8 paginiNDT Audit E1359 PDFreiazhÎncă nu există evaluări

- MFL PDFDocument11 paginiMFL PDFJai Patel100% (1)

- Axess - Ultrassonic Thickness Measurement ProcedureDocument7 paginiAxess - Ultrassonic Thickness Measurement Procedurevsnaiduqc100% (1)

- Basic Nondestructive Testing Exam ReviewDocument9 paginiBasic Nondestructive Testing Exam Reviewmohamed100% (1)

- Astm E1065Document21 paginiAstm E1065Jiten KarmakarÎncă nu există evaluări

- C.V Utekar Assistant Manager ASNT Level IIIDocument4 paginiC.V Utekar Assistant Manager ASNT Level IIIShrikant UtekarÎncă nu există evaluări

- MT Level III QuestionsDocument12 paginiMT Level III QuestionsAnu Anoop100% (2)

- Summary of Changes For The Application of SNT TC 1A 2016 Under ASME V 2019Document15 paginiSummary of Changes For The Application of SNT TC 1A 2016 Under ASME V 2019nathaniel ekaiko100% (6)

- ASNT Level III AnnouncementDocument4 paginiASNT Level III AnnouncementSelvaraj MaduraiÎncă nu există evaluări

- Interpreting SNT TC 1ADocument30 paginiInterpreting SNT TC 1Aneno2405Încă nu există evaluări

- SNT 2020 ChangesDocument4 paginiSNT 2020 ChangesAnagha BhideÎncă nu există evaluări

- Magnetic Flux Leakage MFL Inspection LimitationsDocument30 paginiMagnetic Flux Leakage MFL Inspection LimitationsWigand Junior100% (2)

- Nital EtchDocument2 paginiNital Etchjaime huertasÎncă nu există evaluări

- PT Q&aDocument40 paginiPT Q&aJoe BetkerÎncă nu există evaluări

- 7.5.5.2asme Sec Viii Div 2 2017Document3 pagini7.5.5.2asme Sec Viii Div 2 2017James100% (2)

- PT and MT SpecificationsDocument2 paginiPT and MT SpecificationsAnonymous KfS1AiNhRÎncă nu există evaluări

- Asnt Level Iii NDT Basic OutlineDocument3 paginiAsnt Level Iii NDT Basic OutlineMohamed Ibrahim50% (2)

- Asnt Snt-Tc-1aDocument1 paginăAsnt Snt-Tc-1aMoisés Ramón50% (2)

- PT - Snt-Tc-1a 2006 (Study Test)Document8 paginiPT - Snt-Tc-1a 2006 (Study Test)DESTINY SIMON67% (3)

- MFL Nava NDT Level III TipsDocument5 paginiMFL Nava NDT Level III TipsShanmuga Navaneethan100% (1)

- ASNT L III ExamDocument1 paginăASNT L III ExamPabitramohan PandaÎncă nu există evaluări

- Se 273Document4 paginiSe 273solrac4371Încă nu există evaluări

- SNT-TC-1A Certification SchemeDocument1 paginăSNT-TC-1A Certification Schemebacabacabaca100% (1)

- When Is CP-189 RequiredDocument3 paginiWhen Is CP-189 RequiredAhmad DanielÎncă nu există evaluări

- Pirt Asnt Leiii MT Spe 11aDocument12 paginiPirt Asnt Leiii MT Spe 11aeldobie3100% (1)

- The MFL Compendium Articles On Magnetic Flux Leakage (Ebook)Document120 paginiThe MFL Compendium Articles On Magnetic Flux Leakage (Ebook)gmulapaka100% (2)

- Astm e 1158Document5 paginiAstm e 1158KEN KÎncă nu există evaluări

- NDE Level III Basic Sample QuestionsDocument3 paginiNDE Level III Basic Sample Questionskmohan6750% (2)

- NDT AuditDocument1 paginăNDT AuditShanmuga NavaneethanÎncă nu există evaluări

- Ruane MTDocument40 paginiRuane MT9703422499Încă nu există evaluări

- Ultrasonic ExaminationDocument14 paginiUltrasonic ExaminationLiliÎncă nu există evaluări

- Astm e 317-21Document13 paginiAstm e 317-21hashem Al-NasserÎncă nu există evaluări

- Profile Radiography IAEADocument14 paginiProfile Radiography IAEAPaolo Ng100% (1)

- E 2446 - 16Document14 paginiE 2446 - 16Enrique Antonio100% (2)

- MFL Techniques for Accurate Wire Rope TestingDocument59 paginiMFL Techniques for Accurate Wire Rope Testingkingston67% (3)

- ASTM E 1030 00 Radiographic Examination of Metallic Castings1Document11 paginiASTM E 1030 00 Radiographic Examination of Metallic Castings1jra9090100% (1)

- En Nas InterpretationDocument10 paginiEn Nas InterpretationKaung MyatToeÎncă nu există evaluări

- Sonatest Equipment CatalogueDocument105 paginiSonatest Equipment Cataloguejimmy david espinoza mejiaÎncă nu există evaluări

- A Guide To Personnel Qualification and Certification (Fourth Edition)Document25 paginiA Guide To Personnel Qualification and Certification (Fourth Edition)Aswin Nash100% (1)

- MT Classroom Training HandbookDocument56 paginiMT Classroom Training HandbookaspoiaspoiÎncă nu există evaluări

- Methodology On Technical Inspection: Equipment NDT Procedure Inspection DevicesDocument1 paginăMethodology On Technical Inspection: Equipment NDT Procedure Inspection DevicesEphraim John Tangelon AquinoÎncă nu există evaluări

- Astm e 426Document4 paginiAstm e 426김경은Încă nu există evaluări

- SNT-TC-1A Vs cp-189Document7 paginiSNT-TC-1A Vs cp-189safeer ahmadÎncă nu există evaluări

- ASNT NDT LEVEL III INSPECTION ENGINEERDocument14 paginiASNT NDT LEVEL III INSPECTION ENGINEERwalitedison100% (1)

- E1135 PDFDocument5 paginiE1135 PDFalfonso_comimsaÎncă nu există evaluări

- NDT of Composite MaterialsDocument50 paginiNDT of Composite MaterialsDhaval KondhiyaÎncă nu există evaluări

- Industrial radiography A Complete Guide - 2019 EditionDe la EverandIndustrial radiography A Complete Guide - 2019 EditionÎncă nu există evaluări

- Article 16 Magnetic Flux Leakage (MFL) ExaminationDocument4 paginiArticle 16 Magnetic Flux Leakage (MFL) ExaminationAnonymous ihanyMJÎncă nu există evaluări

- Caracterisiticas Perfiles LIDocument2 paginiCaracterisiticas Perfiles LIleonciomavarezÎncă nu există evaluări

- Caracterisiticas Perfiles IeDocument15 paginiCaracterisiticas Perfiles IeleonciomavarezÎncă nu există evaluări

- Caracterisiticas Perfiles LDDocument1 paginăCaracterisiticas Perfiles LDleonciomavarezÎncă nu există evaluări

- Ultrasonic Inspection of Welds in Tubes & Pipes: Educational NoteDocument13 paginiUltrasonic Inspection of Welds in Tubes & Pipes: Educational NoteleonciomavarezÎncă nu există evaluări

- Ultrasonic Inspection of Welds in Nozzles, Nodes, Curved Surfaces & TKY JointsDocument14 paginiUltrasonic Inspection of Welds in Nozzles, Nodes, Curved Surfaces & TKY Jointsleonciomavarez100% (1)

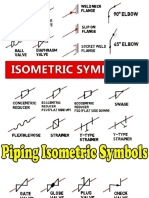

- Piping Isometric SymbolsDocument15 paginiPiping Isometric SymbolsleonciomavarezÎncă nu există evaluări

- Astron: MFL Testing Procedure For Tank FloorDocument16 paginiAstron: MFL Testing Procedure For Tank FloorleonciomavarezÎncă nu există evaluări

- Copia de Weld Consumable Calculator 1Document9 paginiCopia de Weld Consumable Calculator 1leonciomavarezÎncă nu există evaluări

- Andamios PDFDocument69 paginiAndamios PDFleonciomavarez100% (1)

- Copia de Weld Consumable Calculator 1Document9 paginiCopia de Weld Consumable Calculator 1leonciomavarezÎncă nu există evaluări

- TAPPI - 0402 - 16 (Guidelines For The Inspection and Nondestructive Examination of Paper Mchine Dryers)Document12 paginiTAPPI - 0402 - 16 (Guidelines For The Inspection and Nondestructive Examination of Paper Mchine Dryers)leonciomavarez100% (1)

- ASME B30-9 InterpretationsDocument9 paginiASME B30-9 InterpretationsleonciomavarezÎncă nu există evaluări

- Informacion CladingDocument36 paginiInformacion Cladingleonciomavarez100% (1)

- Electrolysis Cell Student ActivityDocument3 paginiElectrolysis Cell Student ActivityPersonnumberunoo0% (2)

- CHAPTER 4 Introduction To ChromatographyDocument62 paginiCHAPTER 4 Introduction To ChromatographyfieyaÎncă nu există evaluări

- Hardness Testing Comparison Table enDocument1 paginăHardness Testing Comparison Table ennedim cılız100% (1)

- Ecosystem Lesson PlanDocument3 paginiEcosystem Lesson PlanClarence RiveraÎncă nu există evaluări

- UeeDocument4 paginiUeeAditya ShrivastavÎncă nu există evaluări

- Hexane and WaterDocument4 paginiHexane and WaterFrancis Adu-marfoÎncă nu există evaluări

- Numerical Calculation of Psychrometric Properties On A CalculatorDocument5 paginiNumerical Calculation of Psychrometric Properties On A CalculatorBetoAdauta100% (1)

- Wind Asce7 16Document7 paginiWind Asce7 16MIHDI PALAPUZÎncă nu există evaluări

- Gamma Attenuation and ShieldingDocument11 paginiGamma Attenuation and ShieldingAhmedAmer1Încă nu există evaluări

- Gen. Physics 2 USLeM Week 1 Version 4Document10 paginiGen. Physics 2 USLeM Week 1 Version 4xibol14985Încă nu există evaluări

- Sliding and Rolling Bearing ArrangementsDocument23 paginiSliding and Rolling Bearing ArrangementsSartaj SinghÎncă nu există evaluări

- Applied Physics Unit 1 Notes (Lasers & OFC) CS StreamDocument32 paginiApplied Physics Unit 1 Notes (Lasers & OFC) CS StreamRaghavÎncă nu există evaluări

- Sonoluminescence by F. Ronald YoungDocument256 paginiSonoluminescence by F. Ronald Youngbennhallett100% (1)

- HW 01 SolutionDocument12 paginiHW 01 SolutionJuan Sebastian Suarez Ospina63% (8)

- The Guiding Star Free of Charge Special Coaching Class Pre-ExaminationDocument4 paginiThe Guiding Star Free of Charge Special Coaching Class Pre-ExaminationSANLU HTUTÎncă nu există evaluări

- International Journal of Coal Geology: John Coggan, Fuqiang Gao, Doug Stead, Davide ElmoDocument10 paginiInternational Journal of Coal Geology: John Coggan, Fuqiang Gao, Doug Stead, Davide Elmopradhith kattaÎncă nu există evaluări

- Heat Input Effects in WeldingDocument34 paginiHeat Input Effects in WeldingMohammed SulemanÎncă nu există evaluări

- The Earth by TELEMAC: Sébastien E. Bourban, Michael S. Turnbull and Alan J. CooperDocument8 paginiThe Earth by TELEMAC: Sébastien E. Bourban, Michael S. Turnbull and Alan J. CooperCHANDAN MAITYÎncă nu există evaluări

- B62 0030 (Rev. B 2003.05) EN - THERMOPLASTIC, THERMOSETTING MATERIALS AND THERMOPLASTIC ELASTOMERS SPECIFICATIONS - SYMBOLSDocument10 paginiB62 0030 (Rev. B 2003.05) EN - THERMOPLASTIC, THERMOSETTING MATERIALS AND THERMOPLASTIC ELASTOMERS SPECIFICATIONS - SYMBOLSDiego CamargoÎncă nu există evaluări

- Ch22 h3 Solutions PDFDocument4 paginiCh22 h3 Solutions PDFld393563Încă nu există evaluări

- HDPE Typical Pipe SizesDocument2 paginiHDPE Typical Pipe SizesSamet Belli100% (2)

- 5th IJSO-Test Solution PDFDocument7 pagini5th IJSO-Test Solution PDFВук РадовићÎncă nu există evaluări

- Ballistic impact responses of textile materialsDocument3 paginiBallistic impact responses of textile materialsLary LysuÎncă nu există evaluări

- PAPER 2222 With Final AnswersDocument24 paginiPAPER 2222 With Final AnswersAbhijeet GholapÎncă nu există evaluări

- Overview of Solid State PhysicsDocument1 paginăOverview of Solid State PhysicsHenkVriesÎncă nu există evaluări

- Difference Between Dry Type Transformers VsDocument4 paginiDifference Between Dry Type Transformers Vsmilad rouhiniaÎncă nu există evaluări

- The Reactive System Screening Tool (RSST) : An Inexpensive and Practical Approach To Sizing Emergency Relief SystemsDocument6 paginiThe Reactive System Screening Tool (RSST) : An Inexpensive and Practical Approach To Sizing Emergency Relief SystemsKam KamÎncă nu există evaluări

- Vibration and Shock Isolation-Advanced Antivibration ComponentsDocument55 paginiVibration and Shock Isolation-Advanced Antivibration Componentshiginio.moro6182Încă nu există evaluări

- Fonko Staro UpatstvoDocument27 paginiFonko Staro UpatstvoToni TalevskiÎncă nu există evaluări

- AP Physics Atwood's Machine LabDocument3 paginiAP Physics Atwood's Machine LabBipinÎncă nu există evaluări