Documente Academic

Documente Profesional

Documente Cultură

TD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)

Încărcat de

Rupesh DesaiDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)

Încărcat de

Rupesh DesaiDrepturi de autor:

Formate disponibile

TI-P068-08

ST Issue 8

Cert. No. LRQ 0963008 ISO 9001

TD62LM and TD62M Thermodynamic Steam Traps with replaceable seats (Screwed /Socket Weld)

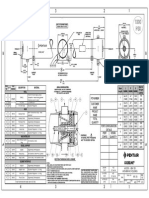

5 9 2 6 10 7 + 15 13 14 8

Description

The TD62LM and TD62M are maintainable high pressure thermodynamic steam traps with integral strainer and a replaceable seat to ease maintenance. They have been specifically designed for mains drainage applications up to 62 bar g. The TD62LM is specifically designed for relatively small condensate loads on superheat and mains drainage applications. An insulating cover is fitted as standard to prevent the trap being unduly influenced by excessive heat loss when subjected to low outside temperatures, wind, rain etc. Standards This product fully complies with the requirements of the European Pressure Equipment Directive 97/23/EC. Certification This product is available with certification to EN 10204 3.1. Note: All certification / inspection requirements must be stated at the time of order placement.

11

Sizes and pipe connections Optional extras

", " and 1" screwed ends NPT. ", " and 1" socket weld ends to ANSI B 16.11 Class 3000.

1 4

An optional blowdown/depressurisation valve can be supplied at extra cost - please consult Spirax Sarco.

12 3

Pressure / temperature limits

Temperature C Steam saturation curve Pressure bar g The product must not be used in this region. The product should not be used in this region or beyond its operating range as damage to the internals may occur. Body design conditions PMA Maximum allowable pressure TMA Maximum allowable temperature Minimum allowable temperature PMO Maximum operating pressure for steam service ANSI 600 103 bar g @ 93C 525C @ 42.7 bar g 0C 62 bar g @ 482C

Materials

No. 1 2 3 4 5 6 *7 8 9 10 11 12 13 14 Part Body Cover Strainer cap Strainer screen Insulating cover Disc Seat Cover studs Cover nuts Cover gasket Material Steel ASTM A217 Gr. WC 6 Steel ASTM A217 Gr. WC 6 Steel ASTM A217 Gr. WC 6 Stainless steel 100 mesh 316L Aluminium Chromium steel Chromium steel Steel ASTM A193 Gr. B16 Steel ASTM A194 Gr. 8M Spirally wound stainless steel with exfoliated graphite ller

TMO Maximum operating temperature 525C @ 42.7 bar g Minimum operating temperature 0C Maximum operating TD62LM 50% of upstream pressure PMOB backpressure TD62M 80% of upstream pressure TD62LM 8 bar g Minimum operating pressure TD62M 1.4 bar g Designed for a maximum cold hydraulic test pressure of 155 bar g

Name-plate Stainless steel Strainer cap gasket Reinforced exfoliated graphite Spirally wound stainless steel Inner seat gasket with exfoliated graphite ller Outer seat gasket Spirally wound stainless steel with exfoliated graphite ller

Stainless steel * 15 Ferrule * Note: Item 15 (ferrule) is pressed into item 7 (seat).

Local regulations may restrict the use of this product to below the conditions quoted. In the interests of development and improvement of the product, we reserve the right to change the specification without notice.

Copyright 2006

Dimensions /weights (approximate) in mm and kg

Size " " 1" A 80 80 85 B 92 92 100 C 92 92 92 D 52 52 47 E 20 20 20 F 51 51 51 Weight 2.08 2.08 2.43

Spare parts

The spare parts available are shown in solid outline. Parts drawn in broken line are not supplied as spares. Available spares Insulating cover Set of cover studs and nuts (set of 4) Seat and disc assembly Strainer screen 100 mesh Set of gaskets (packet of 3 sets) Strainer cap gasket (3 off) 5 8, 9 6, 7, 10, 13, 14, 15 4 10, 12, 13, 14 12

F Withdrawal distance

How to order spares Always order spares by using the description given in the column headed 'Available spares' and state the size and type of trap. Example: 1 - Strainer screen for a Spirax Sarco " TD62LM thermodynamic steam trap.

A

5

B

10

E Withdrawal distance

7 + 15

14

Capacities

Condensate kg /h

13

8

Minimum operating pressure 8 bar for the TD62LM Differential pressure bar (x 100 = kPa)

Safety information, installation and maintenance

For full details see the Installation and Maintenance Instructions (IM-P068-58) supplied with the product. Installation note: Preferably install in horizontal pipelines with the insulating cover uppermost although it can be fitted in other positions. After 24 hours in service the cover nuts should be checked for tightness. Disposal The product is recyclable no ecological hazard is anitcipated with the disposal of this product, providing due care is taken. 12

Recommended tightening torques or Item No. mm 3 8 9 32 A /F M10 x 1.5 17 A /F

Nm

Example: 1 off Spirax Sarco " TD62LM thermodynamic steam trap with integral strainer having screwed NPT connections, suitable for steam main drainage. An aluminium insulating cover shall be fitted as standard.

How to order

142 - 158 20 - 25 45 - 50

TD62LM and TD62M Thermodynamic Steam Traps with replaceable seats (Screwed / Socket Weld)

TI-P068-08 ST Issue 8

S-ar putea să vă placă și

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Steam TrapsDocument2 paginiSteam Trapslaxmans20Încă nu există evaluări

- Trampa Socket WeldDocument2 paginiTrampa Socket WeldOscar Nieves ZamoraÎncă nu există evaluări

- Steam TrapDocument2 paginiSteam TrapJozsef MagyariÎncă nu există evaluări

- Spirax Sarco TD62Document2 paginiSpirax Sarco TD62JUANITOPYTÎncă nu există evaluări

- Trampa Termodinamica PDFDocument2 paginiTrampa Termodinamica PDFriquelme0788Încă nu există evaluări

- Steam TrapDocument2 paginiSteam TrapAmpornchai PhupolÎncă nu există evaluări

- Ti 2 516 UsDocument2 paginiTi 2 516 Uswill_streetÎncă nu există evaluări

- For Harsh and Hazardous Locations: Exe EnclosuresDocument79 paginiFor Harsh and Hazardous Locations: Exe EnclosuresSimon LyonÎncă nu există evaluări

- GDS134Document4 paginiGDS134Saurabh VermaÎncă nu există evaluări

- Spirax Sarco BTM-7Document3 paginiSpirax Sarco BTM-7Bambang Agung LaxmonoÎncă nu există evaluări

- 02 Circular Duct SystemsDocument42 pagini02 Circular Duct SystemsDiki PrayogoÎncă nu există evaluări

- Drawing 80H30Document3 paginiDrawing 80H30kpranjal15Încă nu există evaluări

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 paginiDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiÎncă nu există evaluări

- Spirax Sarco PDFDocument4 paginiSpirax Sarco PDFandresaroÎncă nu există evaluări

- Asco S V7394R5Document16 paginiAsco S V7394R5Jorge Jarpa VÎncă nu există evaluări

- Torqueo Pikotek PDFDocument4 paginiTorqueo Pikotek PDFjast111100% (1)

- Codeline, 150 PSI, Drawing - 80S15Document3 paginiCodeline, 150 PSI, Drawing - 80S15RamanNegiÎncă nu există evaluări

- (2012) Complete IELTS Bands 5-6.5 Student's BookDocument3 pagini(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- AV13 Air Vent For Steam Systems: DescriptionDocument2 paginiAV13 Air Vent For Steam Systems: DescriptionUtku KepcenÎncă nu există evaluări

- Parker Solenoid ValveDocument9 paginiParker Solenoid ValveHamza BayatÎncă nu există evaluări

- Parker Solenoid ValveDocument9 paginiParker Solenoid ValveFlorian_AngererÎncă nu există evaluări

- TermocuplasDocument4 paginiTermocuplasMijin28Încă nu există evaluări

- Rising DiscDocument8 paginiRising DiscwenigmaÎncă nu există evaluări

- A1200 Red Thread II PipingDocument0 paginiA1200 Red Thread II PipingjimmycabreraÎncă nu există evaluări

- GPT 1-3 PGE Tech SpecificationsDocument4 paginiGPT 1-3 PGE Tech SpecificationsEhtisham AndrAbiÎncă nu există evaluări

- Thermodynamic Steam TrapsDocument12 paginiThermodynamic Steam TrapsbuddhansamratÎncă nu există evaluări

- Motor Ys11Document3 paginiMotor Ys11mspd2003Încă nu există evaluări

- Thermodynamic Steam Traps: DescriptionDocument2 paginiThermodynamic Steam Traps: DescriptionAlim Ur RahmanÎncă nu există evaluări

- PE Yellow Gas - WebDocument16 paginiPE Yellow Gas - WebGavin KwanÎncă nu există evaluări

- Mechanical Seals in AgitatorsDocument6 paginiMechanical Seals in AgitatorsLy Ca TieuÎncă nu există evaluări

- KSB Valvula Diafragma SISTO10Document4 paginiKSB Valvula Diafragma SISTO10Sarah PerezÎncă nu există evaluări

- Datasheet Sisto-Kbs Valve - KSBDocument4 paginiDatasheet Sisto-Kbs Valve - KSBSarah PerezÎncă nu există evaluări

- Tyco Catalogue NetDocument34 paginiTyco Catalogue NetAhmad Nasser0% (1)

- Oilfield Hoses Fittings AccembliesDocument29 paginiOilfield Hoses Fittings Accembliesthapa786mÎncă nu există evaluări

- Diapham Valve PDFDocument8 paginiDiapham Valve PDFthouche007Încă nu există evaluări

- Automatic Valve Gemue DB - 512 - GBDocument6 paginiAutomatic Valve Gemue DB - 512 - GBTaher Yusuf100% (1)

- 03 Claw CouplingsDocument16 pagini03 Claw CouplingsMehman NasibovÎncă nu există evaluări

- Kumho Gas Meter CatalogueDocument8 paginiKumho Gas Meter CatalogueChelito IxÎncă nu există evaluări

- Válvula de BolaDocument2 paginiVálvula de BolaeduarshÎncă nu există evaluări

- Steam TrapTD55Document3 paginiSteam TrapTD55Avneet MaanÎncă nu există evaluări

- Local Solutions For Individual Customers Worldwide: Accumulators & AccessoriesDocument20 paginiLocal Solutions For Individual Customers Worldwide: Accumulators & Accessoriesamjed_de_enimÎncă nu există evaluări

- CS310ADocument4 paginiCS310Arabacet2923Încă nu există evaluări

- SevereEnviroment CatalogDocument8 paginiSevereEnviroment CatalogSteven HungÎncă nu există evaluări

- Nor GrenDocument5 paginiNor GrenSarlo11Încă nu există evaluări

- Tuberias Hdpe PDFDocument5 paginiTuberias Hdpe PDFA. C. V.Încă nu există evaluări

- Breather/Drain Plugs: SeriesDocument1 paginăBreather/Drain Plugs: SeriesGolfkung PairojÎncă nu există evaluări

- Nicholson Thermostatic Steam TrapsDocument18 paginiNicholson Thermostatic Steam TrapsAli Fanani100% (1)

- Valvula Borboleta Lug z411 ADocument6 paginiValvula Borboleta Lug z411 AWellington S. FrançaÎncă nu există evaluări

- Wedge and Slab Gate ValvesDocument8 paginiWedge and Slab Gate Valvesgad30Încă nu există evaluări

- H1000e K FJDocument8 paginiH1000e K FJSyarif HidayatullahÎncă nu există evaluări

- Pulse Valves - Turbocontrols - It PDFDocument40 paginiPulse Valves - Turbocontrols - It PDFRicardo Ferrari TrevisanÎncă nu există evaluări

- Balanced Pressure Thermostatic Steam Trap: BPT21YDocument2 paginiBalanced Pressure Thermostatic Steam Trap: BPT21YJozsef MagyariÎncă nu există evaluări

- ASCO SolenoidDocument10 paginiASCO Solenoidsharib26Încă nu există evaluări

- Automatic Air Vent Valve Spirax SarcoDocument4 paginiAutomatic Air Vent Valve Spirax SarcosrshahÎncă nu există evaluări

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDe la EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesEvaluare: 3.5 din 5 stele3.5/5 (3)

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- Cooling Tower SeminarDocument67 paginiCooling Tower SeminarRupesh Desai100% (1)

- Marley Cooling Tower Basics Marley PDFDocument4 paginiMarley Cooling Tower Basics Marley PDFnabilÎncă nu există evaluări

- Bolt TorqueDocument1 paginăBolt TorqueRupesh DesaiÎncă nu există evaluări

- Timken Seal Specification GuideDocument204 paginiTimken Seal Specification GuideRupesh DesaiÎncă nu există evaluări

- Sydney, NSW - Australia, March 8-9, 2010: E-Mail: Phone: +6053687732 Mobile: +60125012590Document19 paginiSydney, NSW - Australia, March 8-9, 2010: E-Mail: Phone: +6053687732 Mobile: +60125012590Rupesh Desai100% (1)

- 02 Req App 01 Drawing & SpecificationDocument4 pagini02 Req App 01 Drawing & Specificationjaimejulio69Încă nu există evaluări

- SLD of MDB-3 Last Update For Print-ModelDocument1 paginăSLD of MDB-3 Last Update For Print-ModelSharif 087Încă nu există evaluări

- 37.H. P. Khungar Semistic Sternghring of Softsteroy Using DamperDocument1 pagină37.H. P. Khungar Semistic Sternghring of Softsteroy Using DamperPREMALATHA JÎncă nu există evaluări

- Analysis of Mechanical Properties of Aluminium Based Metal Matrix Composites Reinforced With Alumina and Sic IJERTV6IS030506Document6 paginiAnalysis of Mechanical Properties of Aluminium Based Metal Matrix Composites Reinforced With Alumina and Sic IJERTV6IS030506Gona sunil kumar reddyÎncă nu există evaluări

- Actionair Iris DamperDocument12 paginiActionair Iris DamperPeterOLearyÎncă nu există evaluări

- THAIOIL - BEAM TO BEAM - FIN PLATE - BOLTED - 001 - Rev ADocument10 paginiTHAIOIL - BEAM TO BEAM - FIN PLATE - BOLTED - 001 - Rev ACivil StructureÎncă nu există evaluări

- Chap. 3 - Split Air Conditioning SystemDocument17 paginiChap. 3 - Split Air Conditioning SystemSparsh ShukalÎncă nu există evaluări

- A1 Fence Specs For WebsiteDocument22 paginiA1 Fence Specs For WebsitetajlandÎncă nu există evaluări

- Gypsemna BrochureDocument6 paginiGypsemna BrochureCarthage Capital100% (1)

- RVC05 150FLG Ex PDFDocument5 paginiRVC05 150FLG Ex PDFengp3077Încă nu există evaluări

- Astm F758-14Document6 paginiAstm F758-14Muhamad HamandiÎncă nu există evaluări

- Manual Calefa 1 PlantaDocument29 paginiManual Calefa 1 PlantanegrorocksÎncă nu există evaluări

- Control Valve Interview Questions and AnswersDocument11 paginiControl Valve Interview Questions and Answersakmal100% (2)

- Home Construction Cost Calculator - UltratechDocument7 paginiHome Construction Cost Calculator - UltratechAkshayÎncă nu există evaluări

- Trailer Heater Wiring DiagramDocument28 paginiTrailer Heater Wiring DiagramBaton Rouge100% (1)

- ME2030 - 20160406 - Plastic Shaping (Groover Slides Partial)Document43 paginiME2030 - 20160406 - Plastic Shaping (Groover Slides Partial)Vamshi KrishnaÎncă nu există evaluări

- Heating Ventilation and Air Conditioning Engineering and Design PDFDocument377 paginiHeating Ventilation and Air Conditioning Engineering and Design PDFSaurav Kumar SinghÎncă nu există evaluări

- Module 2 Bernoulli's Equation - ME 319-ME32S3 - Fluid MachineriesDocument8 paginiModule 2 Bernoulli's Equation - ME 319-ME32S3 - Fluid MachineriesOkay Printing100% (1)

- Ymfe (24-60) Bnjmcmo(s) - X 14 Seer Solo FrioDocument4 paginiYmfe (24-60) Bnjmcmo(s) - X 14 Seer Solo FrioAb CaamañoÎncă nu există evaluări

- Corrosion ResistanceDocument482 paginiCorrosion ResistanceJosé Ramírez100% (1)

- Serie KGDocument10 paginiSerie KGDanner Rodolfo Santisteban CheroÎncă nu există evaluări

- Department of Applied Physics Question Bank-I Semester PH6151-Engineering Physics - I UNIT-II - Properties of Matter and Thermal PhysicsDocument4 paginiDepartment of Applied Physics Question Bank-I Semester PH6151-Engineering Physics - I UNIT-II - Properties of Matter and Thermal PhysicsJohn Ernie SelmarÎncă nu există evaluări

- Rockassist TrainingDocument18 paginiRockassist TrainingDương HoàngÎncă nu există evaluări

- Trane Air-To-Water HP Application GuideDocument28 paginiTrane Air-To-Water HP Application GuideCarlos NetoÎncă nu există evaluări

- A Review On Effective Stabilization of Expansive Soils PDFDocument25 paginiA Review On Effective Stabilization of Expansive Soils PDFshabbar abbasÎncă nu există evaluări

- Pilot Es Dina MicaDocument8 paginiPilot Es Dina MicaPedro GarciaÎncă nu există evaluări

- Estimating & Costing - C2 PDFDocument8 paginiEstimating & Costing - C2 PDFkumarÎncă nu există evaluări

- ALTECH PE-HD A 2010/506 GF10: Technical Data SheetDocument2 paginiALTECH PE-HD A 2010/506 GF10: Technical Data SheetPhung LucÎncă nu există evaluări

- Cyprus National Annex en 1993-1-1Document11 paginiCyprus National Annex en 1993-1-1Atalay YordamÎncă nu există evaluări

- Wan Mohammad 2017 IOP Conf. Ser.3A Mater. Sci. Eng. 271 012059 PDFDocument8 paginiWan Mohammad 2017 IOP Conf. Ser.3A Mater. Sci. Eng. 271 012059 PDFCess IshaÎncă nu există evaluări