Documente Academic

Documente Profesional

Documente Cultură

Basic Air Conditioning Formulas

Încărcat de

ravirawat15Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Basic Air Conditioning Formulas

Încărcat de

ravirawat15Drepturi de autor:

Formate disponibile

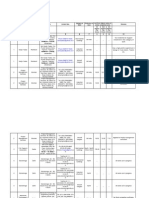

Basic Air Conditioning Formulas Figure 5

Basic Air Conditioning Formulas

TO DETERMINE

Total Airflow

EXPRESSED AS

CFMT CFMo NT No Btuh Btuh Btuh F. D.B.

1. CFMT =

Application Guide

COOLING

NT V 60 min./hr. NO V 60 min./hr. CFMT (60 min./hr.) V CFMo (60 min./hr.) V

HEATING and/or HUMIDIFYING

1. CFMT = 2. CFMo = 3. NT = 4. No = NT V 60 min./hr. No V 60 min./hr. CFMT (60 min./hr.) V CFMo (60 min./hr.) V

Infiltration or Ventilation Number of Air Changes Per Hour Total Number of Air Changes Per Hour Outdoor Air Total Heat (HT) Sensible Heat (HS) Latent Heat (HL) Entering Air Temperature (T1) (Mixed Air)

2. CFMo = 3. NT = 4. No =

5. HT = CFMT x 4.5 x (h1 h2) = Btuh 7. HS = CFMT x 1.08 x (T1 T2) = Btuh 9. HL = CFMT x .68 x (W1 W2) = Btuh 11. T1 = t1 + CFMo x (t2 t1) = F.D.B. 1 CFMT

6. HT = CFMT x 4.5 x (h2 h1) = Btuh 8. HS = CFMT x 1.08 x (T2 T1) = Btuh 10. HL = CFMT x .68 x (W2 W1) = Btuh 12. T1 = t1 CFMo x (t1 t2) = F.D.B. 2 CFMT

1 If duct heat gain is a factor, add to T1: Duct Heat Gain (Btuh) CFMT x 1.08

2 If duct heat loss is a factor, subtract from T1: Duct Heat Loss (Btuh) CFMT x 1.08

Leaving Air D.B. Temperature (T2) Required Airflow

F. D.B. CFMT

13. T2 = T1 15. CFMT = OR CFMT =

HS CFMT x 1.08 HS (total) 1.08 x (T1 T2) HS (internal)3 1.08 x (t1 T2) HT CFMT x 4.5

= F.D.B. = CFM

14. T2 = T1 + 16. CFMT =

HS CFMT x 1.08 HS 1.08 x (T2 T1)

= F.D.B. = CFM

= CFM

3 Sensible load of outside air not included Enthalpy Leaving Air (h2) Leaving Air W.B. Temperature Heat Required to Evaporate Water Vapor Added to Ventilation Air Humidification Requirements Btu/lb. dry air F.W.B. Btuh 17. h2 = h1 = Btu/lb. dry air 18. h2 = h1 + HT CFMT x 4.5 = Btu/lb. dry air

19. Refer to Enthalpy Table and read W.B. temperature corresponding to enthalpy of leaving air (h2) (see #17). 21. HL = CFMo x .68 (W3 Wo) = Btuh

20. Refer to Enthalpy Table and read W.B. temperature corresponding to enthalpy of leaving air (h2) (see #18). 22. HL = CFMo x .68 (W3 Wo) = Btuh 24. Make up = Moisture

Lbs. water/hr.

23.

Excess Latent Capacity Make up = of System x % Run Time 1060 Btu/lb. Moisture (Industrial Process Work)

= lbs./hr.

HL loss Btuh (see #22) 1060 Btu/lb.

= lbs./hr.

LEGEND

CFMT CFMo NT No V HT HS HL * h1 * h2 T1 T2 Tadp t1 t2 W1 W2 W3 Wo = = = = = = = = = = = = = = = = = = = Total airflow cubic feet/min. Outdoor air cubic feet/min. Total air changes per hour Outdoor air, air changes per hour Volume of space cubic feet Total heat Btuh Sensible heat Btuh Latent heat Btuh Enthalpy or total heat of entering air Enthalpy or total heat of leaving air Temperature of entering air Temperature of leaving air Apparatus dewpoint Indoor design temperature Outdoor design temperature Grains of water/lb. of dry air at entering condition Grains of water/lb. of dry air at leaving condition Grains of water/lb. of dry air at indoor design conditions Grains of water/lb. of dry air at outdoor design conditions

DERIVATION OF AIR CONSTANTS

The air constants below apply specifically to standard air which is defined as dry air at 70F and 14.7 P.S.I.A. (29.92 in. mercury column). They can, however, be used in most cooling calculations unless extremely precise results are desired. 4.5 (To convert CFM to lbs./hr.) 4.5 = Btu/lb. Btu/lb. F.D.B. F.D.B. F.D.B. Grains/lb. Grains/lb. Grains/lb. Grains/lb. 60 min./hr. 13.33 or 60 X .075

Where 13.33 is the specific volume of standard air (cu.ft./lb.) and .075 is the density (lbs./cu.ft.) 1.08 = .24 X 60 13.33 60 13.33 or .24 X 4.5

.24 BTU = specific heat of standard air (BTU/LB/F) .68 = X 1060 7000 or 4.5 X 1060 7000

Where: 1060 = Average Latent Heat of water vapor (BTU/LB.). 7000 = Grains per lb.

* See Enthalpy of air (Total Heat Content of Air) Table for exact values.

For complete equipment / combination selections, installation instructions and warranty information, please refer to Product Data/Ratings and/or Installers Guides and Limited Warranty Handbooks.

AC/IN-13

Effective 4/4/11 14-1011-26

S-ar putea să vă placă și

- Hvac Formulas PDFDocument25 paginiHvac Formulas PDFSaraswatapalit0% (1)

- Equations: Hvac Equations, Data, and Rules of ThumbDocument21 paginiEquations: Hvac Equations, Data, and Rules of ThumbzodedÎncă nu există evaluări

- CFM and Capacity Calcs 4.5Document9 paginiCFM and Capacity Calcs 4.5hvacrmedicÎncă nu există evaluări

- 1-Internal Heat GainDocument15 pagini1-Internal Heat GainWunNa100% (1)

- One Btu Equals 1.055 KJ.: Joule (J)Document3 paginiOne Btu Equals 1.055 KJ.: Joule (J)suboo0678Încă nu există evaluări

- Heat Load Calculation Using E20 Form With Hvac DraftingDocument127 paginiHeat Load Calculation Using E20 Form With Hvac DraftingPimd 18Încă nu există evaluări

- Cooling Load Calculation: ME 511 Aircondition and Ventilation SystemsDocument13 paginiCooling Load Calculation: ME 511 Aircondition and Ventilation SystemsErvenjee BascoÎncă nu există evaluări

- Air ConditioningDocument72 paginiAir ConditioningNIKÎncă nu există evaluări

- Heat and Cooling LoadDocument2 paginiHeat and Cooling LoadAshokÎncă nu există evaluări

- Psychrometry Part-2Document11 paginiPsychrometry Part-2Tushar Sharma100% (1)

- Engine Room Ventilation - Necesar AerDocument1 paginăEngine Room Ventilation - Necesar AerBirshopulosÎncă nu există evaluări

- HVAC Thermal Load EstimatingDocument28 paginiHVAC Thermal Load EstimatingIntisar Ali SajjadÎncă nu există evaluări

- Calculating Cooling LoadsDocument2 paginiCalculating Cooling LoadsHerman SubagioÎncă nu există evaluări

- HVAC FormulasDocument7 paginiHVAC Formulasisaiaspaula80Încă nu există evaluări

- Heat Load CalculationDocument3 paginiHeat Load CalculationEditor IJTSRDÎncă nu există evaluări

- GDL Handout 15 Cooling Load CalculationsDocument11 paginiGDL Handout 15 Cooling Load CalculationsPiet100% (3)

- Cooling Load EstimationDocument4 paginiCooling Load Estimationk.vikasÎncă nu există evaluări

- Experimentno.1:The Psychrometric Processes: Relative Humidity RH %Document31 paginiExperimentno.1:The Psychrometric Processes: Relative Humidity RH %JayZx WayÎncă nu există evaluări

- Basic HVAC Formulas - Tech TipDocument2 paginiBasic HVAC Formulas - Tech Tipgauravgujar24100% (1)

- COOLING Load Estimation ReportDocument72 paginiCOOLING Load Estimation ReportDikshit Tomer100% (2)

- Dr. Amr Kaood's Guide to Calculating Cooling LoadsDocument37 paginiDr. Amr Kaood's Guide to Calculating Cooling LoadsHazem MohamedÎncă nu există evaluări

- #HVAC - Five Easy Steps To Estimate External Static Pressure Drop in HVAC Ducts Using Equal Friction MethodDocument5 pagini#HVAC - Five Easy Steps To Estimate External Static Pressure Drop in HVAC Ducts Using Equal Friction MethodAbdulHakeemSKÎncă nu există evaluări

- Water Cooled ChillerDocument7 paginiWater Cooled ChillerKrishna MurariÎncă nu există evaluări

- Design of Ventilation SystemsDocument5 paginiDesign of Ventilation SystemsSimon LaurentÎncă nu există evaluări

- ASHRAE62.1 and FAQsDocument18 paginiASHRAE62.1 and FAQsols3dÎncă nu există evaluări

- Air Conditioning Design FactorsDocument17 paginiAir Conditioning Design FactorsSteve Patrick BesarioÎncă nu există evaluări

- ACMV DESIGN: Sample Heat Load Calculation For General Office Meeting RoomDocument5 paginiACMV DESIGN: Sample Heat Load Calculation For General Office Meeting RoomVenkates Adhinarayanan50% (2)

- Air Conditioning System LectureDocument9 paginiAir Conditioning System LectureammarÎncă nu există evaluări

- Air-Conditioning Load EstimationDocument23 paginiAir-Conditioning Load Estimationtkm2004Încă nu există evaluări

- RTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsDocument2 paginiRTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsJhon LewisÎncă nu există evaluări

- Heat Load Calculations SampleDocument15 paginiHeat Load Calculations SampleleelaÎncă nu există evaluări

- Ahu & Chiller OkDocument40 paginiAhu & Chiller OkAndy DwiÎncă nu există evaluări

- MRI Formulas ConversionsDocument1 paginăMRI Formulas ConversionsJoey ManlangitÎncă nu există evaluări

- Pumb RoomDocument2 paginiPumb RoomMohamed HamzaÎncă nu există evaluări

- 1934-Constitution of Malankara SabhaDocument18 pagini1934-Constitution of Malankara SabhaIssac GeorgeÎncă nu există evaluări

- Hematra Cooling TowerDocument4 paginiHematra Cooling Towerjc CincoÎncă nu există evaluări

- Sizing Boiler Pumps, Fans for 50,000 kg/hr Coal BoilerDocument5 paginiSizing Boiler Pumps, Fans for 50,000 kg/hr Coal BoilerMasih BelajarÎncă nu există evaluări

- L&T MLCP East Block HVAC Heat Load SUMMARYDocument3 paginiL&T MLCP East Block HVAC Heat Load SUMMARYSatheesh Kumar NatarajanÎncă nu există evaluări

- Cooling Tower Calc Efficiency Under 40Document4 paginiCooling Tower Calc Efficiency Under 40Maman HakimÎncă nu există evaluări

- Masterclass duct frictionDocument11 paginiMasterclass duct frictionT Satheesh Kumar100% (1)

- Chapter-3 Air Handling UnitsDocument3 paginiChapter-3 Air Handling UnitsFaquruddin AliÎncă nu există evaluări

- Static Calculation For FansDocument4 paginiStatic Calculation For FansBadrul HishamÎncă nu există evaluări

- The Radiant Time Series Cooling Load Calculation ProcedureDocument14 paginiThe Radiant Time Series Cooling Load Calculation ProcedureNor Firdaus Yunus100% (1)

- Lecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDocument14 paginiLecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDeniell Joyce MarquezÎncă nu există evaluări

- Heat TransferDocument1 paginăHeat TransferhuangjlÎncă nu există evaluări

- Hvac CalcsDocument1 paginăHvac CalcsTim Lawrence100% (1)

- Handout of Compressor 2012Document87 paginiHandout of Compressor 2012Mohamad Aris100% (3)

- Refrigerant Piping Rev2Document31 paginiRefrigerant Piping Rev2123john123Încă nu există evaluări

- Sizing calculations for BFW pumps, FD, SA and ID fans for 50,000 kg/hr boilerDocument5 paginiSizing calculations for BFW pumps, FD, SA and ID fans for 50,000 kg/hr boilerMati Dalam Penantian CintamuÎncă nu există evaluări

- ASHRAE Chiller Course Condenser Water HRDocument36 paginiASHRAE Chiller Course Condenser Water HRabdulzameer100% (1)

- Refrigeration COP and Capacity CalculationDocument12 paginiRefrigeration COP and Capacity CalculationxofigoÎncă nu există evaluări

- Patton Line Size - 2014Document6 paginiPatton Line Size - 2014Rocky James AsildoÎncă nu există evaluări

- Hvac Formulas and ValuesDocument13 paginiHvac Formulas and ValuesRamadan RashadÎncă nu există evaluări

- Cooling Load1111 PDFDocument43 paginiCooling Load1111 PDFJason PaquibulanÎncă nu există evaluări

- Precooled Ahu CalculationDocument3 paginiPrecooled Ahu CalculationEdmund YoongÎncă nu există evaluări

- DEWALT HVACR Professional Reference Master EditionDocument24 paginiDEWALT HVACR Professional Reference Master EditionLorenc Hysa100% (1)

- Latent HeatDocument2 paginiLatent HeatrohitÎncă nu există evaluări

- Cooling Formulas for BTU, SEER, Cost CalculationsDocument1 paginăCooling Formulas for BTU, SEER, Cost CalculationsYoesof HilabyÎncă nu există evaluări

- Equations, Data and Rules ThumbDocument3 paginiEquations, Data and Rules Thumbsripriya01Încă nu există evaluări

- HVAC Supply Airflow Calculation SampleDocument7 paginiHVAC Supply Airflow Calculation Sampletankimsin100% (4)

- Design of Structural Steel Pipe Racks PDFDocument12 paginiDesign of Structural Steel Pipe Racks PDFmobin1978100% (3)

- Tech. Spec. For Seamless ERW EFSW PipesDocument7 paginiTech. Spec. For Seamless ERW EFSW Pipessanjay421Încă nu există evaluări

- ICC Cricket World Cup 2010 Match ScheduleDocument2 paginiICC Cricket World Cup 2010 Match Scheduleravirawat15Încă nu există evaluări

- Construction and Engineering by ABNDocument54 paginiConstruction and Engineering by ABNravirawat15Încă nu există evaluări

- Tech. Spec. For VesselsDocument6 paginiTech. Spec. For Vesselssanjay421Încă nu există evaluări

- Tech. Spec. For Seamless ERW EFSW PipesDocument7 paginiTech. Spec. For Seamless ERW EFSW Pipessanjay421Încă nu există evaluări

- Mutualfund - Basics-0010 by tZaRDocument11 paginiMutualfund - Basics-0010 by tZaRravirawat15Încă nu există evaluări

- Method of Design Cantilever ErectionDocument62 paginiMethod of Design Cantilever Erectionzieq72Încă nu există evaluări

- Problems On SFD & BMDDocument43 paginiProblems On SFD & BMDmal201182% (11)

- Tech. Spec. For Flanges and Spectacle BlindsDocument6 paginiTech. Spec. For Flanges and Spectacle Blindssanjay421Încă nu există evaluări

- Tech. Spec. For Flanges and Spectacle BlindsDocument6 paginiTech. Spec. For Flanges and Spectacle Blindssanjay421Încă nu există evaluări

- List Mep Contractors Company Dubai6 PDFDocument10 paginiList Mep Contractors Company Dubai6 PDFsojuiype50% (8)

- Piping ComponentsDocument39 paginiPiping Componentsbvenky991100% (1)

- Pressure Relief Devices Scott OstrowskiDocument82 paginiPressure Relief Devices Scott OstrowskiAffify AfifyÎncă nu există evaluări

- Piping ComponentsDocument39 paginiPiping Componentsbvenky991100% (1)

- Pressure Relief Devices Scott OstrowskiDocument82 paginiPressure Relief Devices Scott OstrowskiAffify AfifyÎncă nu există evaluări

- Jigs and Fixtures: A Basic LookDocument16 paginiJigs and Fixtures: A Basic Lookravirawat15Încă nu există evaluări

- Tech. Spec. For Flanges and Spectacle BlindsDocument6 paginiTech. Spec. For Flanges and Spectacle Blindssanjay421Încă nu există evaluări

- Speaking EnglishDocument10 paginiSpeaking Englishravirawat15Încă nu există evaluări

- Marketing Research Tactical Plan1Document1 paginăMarketing Research Tactical Plan1aks_anjani100% (2)

- Revenue Reservoir Bills TemplateDocument2 paginiRevenue Reservoir Bills Templateravirawat15Încă nu există evaluări

- Data Bank Consult LoadingDocument151 paginiData Bank Consult Loadingravirawat15Încă nu există evaluări

- Ibr FormsDocument117 paginiIbr Formsshivabtowin3301Încă nu există evaluări

- Revenue Reservoir Bills TemplateDocument2 paginiRevenue Reservoir Bills Templateravirawat15Încă nu există evaluări

- Inventory ControlDocument31 paginiInventory Controlravirawat15Încă nu există evaluări

- Marketing Research Tactical Plan1Document1 paginăMarketing Research Tactical Plan1aks_anjani100% (2)

- UKDocument3 paginiUKravirawat15Încă nu există evaluări

- Caesar IiDocument4 paginiCaesar IiSabu Ekm100% (1)

- IBRDocument37 paginiIBRravirawat15Încă nu există evaluări

- Pipe Stress Analysis ReportsDocument11 paginiPipe Stress Analysis ReportsTony100% (13)

- Veeam BackupDocument5 paginiVeeam BackupregusankarÎncă nu există evaluări

- Look@LAN Setup LogDocument3 paginiLook@LAN Setup LogAlexandre Canal SabariegoÎncă nu există evaluări

- General Structural/Construction Notes and Specifications: Proposed 4-Storey Residential Building W/FenceDocument1 paginăGeneral Structural/Construction Notes and Specifications: Proposed 4-Storey Residential Building W/FenceWilbert ReuyanÎncă nu există evaluări

- High Speed Counter and TimerDocument34 paginiHigh Speed Counter and TimerpaldopalÎncă nu există evaluări

- Issue14final PDFDocument51 paginiIssue14final PDFPOWER NewsÎncă nu există evaluări

- AWT Event Handling ExplainedDocument8 paginiAWT Event Handling ExplainedrutchelinesaritaÎncă nu există evaluări

- DCSDocument3 paginiDCSAnagha MenonÎncă nu există evaluări

- Building Works PDFDocument359 paginiBuilding Works PDFManish Kumar YadavÎncă nu există evaluări

- Apache HIVEDocument105 paginiApache HIVEhemanth kumar p100% (1)

- Apks Count ListDocument5 paginiApks Count ListKevin Moreno MancinazÎncă nu există evaluări

- Proposed Studio: 11 Reno RD, Sandringham, Vic 3191Document11 paginiProposed Studio: 11 Reno RD, Sandringham, Vic 3191Engineer 1122Încă nu există evaluări

- KZNIA-2010-35-1 Moses Mabhida StadiumDocument10 paginiKZNIA-2010-35-1 Moses Mabhida StadiumRiani salma biladÎncă nu există evaluări

- F28335 INTERRUPTDocument63 paginiF28335 INTERRUPTNishita ParuchuriÎncă nu există evaluări

- Division 04: Brick Works, Patent Stone in Floor and Fancy Screen Block WorkDocument3 paginiDivision 04: Brick Works, Patent Stone in Floor and Fancy Screen Block Workamit dasguptaÎncă nu există evaluări

- Common Batch Job FailuresDocument6 paginiCommon Batch Job FailuresSiji SurendranÎncă nu există evaluări

- L2 AND L3 Switch DifferenceDocument6 paginiL2 AND L3 Switch DifferenceVivek GhateÎncă nu există evaluări

- Bidirectional Visitor CounterDocument17 paginiBidirectional Visitor CounterPankaj KumarÎncă nu există evaluări

- Hvac Survey & Calculation Report: Site NameDocument17 paginiHvac Survey & Calculation Report: Site NameMehdi Hasan TararÎncă nu există evaluări

- 32, Jagadesh Nagar SN Palayam Coimbatore-7. Contact No: 9486218417Document3 pagini32, Jagadesh Nagar SN Palayam Coimbatore-7. Contact No: 9486218417Sidharth HariharanÎncă nu există evaluări

- Costing of Steelwork From Feasibility Through To Completion 1996 - Australian Institute of Steel ConstructionDocument53 paginiCosting of Steelwork From Feasibility Through To Completion 1996 - Australian Institute of Steel ConstructionKakoDa100% (2)

- Eisenman Architects - House VIDocument11 paginiEisenman Architects - House VIevelyn oorÎncă nu există evaluări

- Setting Up Sophos + Amavis For Postfix: G.Czaplinski@prioris - Mini.pw - Edu.plDocument5 paginiSetting Up Sophos + Amavis For Postfix: G.Czaplinski@prioris - Mini.pw - Edu.plsolocheruicÎncă nu există evaluări

- RBD-17 09 2020Document137 paginiRBD-17 09 2020hishamndtÎncă nu există evaluări

- ACP SuperCorDocument16 paginiACP SuperCorHaryo WidodoÎncă nu există evaluări

- TreeSize PDFDocument79 paginiTreeSize PDFGustavoVegaÎncă nu există evaluări

- 14 Sebastien Dudek HomePlugAV PLCDocument51 pagini14 Sebastien Dudek HomePlugAV PLCntcaseÎncă nu există evaluări

- Culturally Responsive Built Environments: A Home - Introduction To Vernacular ArchitectureDocument14 paginiCulturally Responsive Built Environments: A Home - Introduction To Vernacular ArchitectureDean School of ArchitectureÎncă nu există evaluări

- Resume - Jeremy DeLaBruereDocument1 paginăResume - Jeremy DeLaBruerejeremyd82Încă nu există evaluări

- 2530 Switch PresentationDocument33 pagini2530 Switch PresentationNgoc The NguyenÎncă nu există evaluări