Documente Academic

Documente Profesional

Documente Cultură

DR CompressorOilPiping Guidelines

Încărcat de

Madhana GopalDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

DR CompressorOilPiping Guidelines

Încărcat de

Madhana GopalDrepturi de autor:

Formate disponibile

Dresser-Rand Packager Guidelines Compressor Crankcase Oil System

Page 1 of 3

Home | Products | Separable Compressors | Databook | General Information | Packager Guidelines

Packager Guidelines Compressor Crankcase Oil System

5-1.Frame Oil Recommendations General Requirements The oil must be well-refined petroleum product with low carbon residue. It should not contain fats or fixed oil compounding. Oil containing rust and oxidation inhibitors and a foam depressant is preferred. The oil selected must be substantially non-corrosive to the common bearing metals, with a pour point at least 10F (5.6C) below ambient temperature when the unit is started for engine drives. The Compressor Cylinder and Packing Lubrication System on new units is designed at the factory based upon the specific application. In most cases, the system is designed to draw lubricating oil from the compressor crankcase to supply the lubricator pumps unless there are specific reasons why a different type lubricating oil is required for the cylinders. Packager should define on the Distributor Order Form where they wish to obtain the oil supply to the lubricator. (See Compressor Cylinder and Packing Lubrication Guidelines.) Multiviscosity lubricants may be used in the crankcase where widely variable ambient temperatures are encountered, provided that the lubricant maintains a viscosity of 115 to 150 SSU (23.7 to 31.8 cSt) at normal operating sump temperature. When heavier lubricants are used to accomodate higher sump temperatures, crankcase heaters may be required if ambient temperatures fall below 50F (10C) to maintain the sump temperature above the pour point. It is recognized that the oil recommended by the engine manufacturer (when an engine drive is supplied) is normally heavier (in the SAE 40 viscosity range). When this is the case and the user desires to stock only one oil for use in both the engine and compressor crankcases, the heavier weight oil recommended for the engine may also be used in the compressor crankcase. Under cold ambient starting conditions, it is recommended that the oil sump temperature be at least 10 to 20F (5.6 to 11C) above the pour point prior to starting the engine drives. This may require the use of auxiliary crankcase heaters. If sump temperatures above 165F (74C) are experienced, the lubricant should be monitored more closely for nitration effects and more frequent oil changes should be scheduled to prevent an increase in long term maintenance programs. Viscosity Requirements The viscosity requirements for the crankcase oil are as shown in Table 2-1. Inspection Conduct all testing of the lubricating oil in accordance with the Standard Methods (latest edition) of the American Society for Testing Materials (ASTM). Oil Change Schedule The oil should be changed every 2000 to 4000 hours, or every 6 months, depending on local conditions, or as indicated by oil analysis. Most reputable oil companies offer laboratory analysis services of oil samples on request. We highly recommend the use of this type service. A once-a-month analysis schedule is recommended when the compressor is operated under severe conditions. Where the compressor is operated in an extremely dirty atmosphere, installed outdoors, operated intermittently, handling foul gas or where the oil reaches high temperatures in a very hot atmosphere, it may be necessary to change the oil more often. Dry Sump Requirements Any requirements outside these limitations require an auxiliary oil pump and a deep independent oil sump within the

https://www.dresser-rand.com/products/gfc/databook/allfrontmatter/packagerguidelines... 30/3/2012

Dresser-Rand Packager Guidelines Compressor Crankcase Oil System

Page 2 of 3

package.

Frame Size 6 HOS 2 6 HOS 4 6 HOS 6 6 HOSS 2 6 HOSS 4 6 HOSS 6

Max Pitch 3.0 1.5 1.0 2.0 1.2 0.8

Max Roll 13 13 13 11 11 11

5-2.Oil Cooler and Filter All units have frame mounted oil filters that are installed at the factory and should not be removed for any reason. These filters are normally mounted off the oil pump end of the compressor; alternate locations may be used to suit a particular installation. Filter internals should be checked for cleanliness and correct positioning. Piping connections to the cooler and filter must line up properly before they are tightened. Do not spring the piping to make connections, as this may cause leaking joints or result in fatigue failures. Some customers require duplex type oil filters. In these instances, Dresser-Rand recommends the original frame mounted filter be left in place. After 200 hours of run time, the element should be removed and continue flowing through this filter. This insures the oil system has removed any contaminants which may have been introduced during the packaging of the unit. 5-3.Oil Piping The oil piping in the frame lubrication system downstream of the cooler to the filter must be closely examined and cleaned before charging the system with oil. Where the customer is supplying external oil piping, it is his responsibility to provide piping that has been thoroughly cleaned and completely examined throughout. Any foreign material loosened by the flow of oil through the piping can seriously damage the compressor. All external oil piping that is supplied by the customer should be the same size as the connection on the frame. The piping size should NEVER be stepped down for any reason. Any check valves included in the oil system should be flapper type FULL flow check valves. A piston check should NEVER be used since this can act as a restriction. Any type restriction can cause severe damage to the frame internals. 5-4.Prelube Pumps Prelube pumps are required on frames that are driven by an electric motor or whenever the compressor may start-up while unattended. These prelube pumps may be electric or pneumatic driven, but require a permissive which will disable the start-up sequence if oil pressure is below 10 lbs. This is the normal range, but some applications may require a different permissive set point due to specifics of that machine; ie, across-the line starts at full speed. The prelube pump should be sized for the minimum recommended flow rates listed below for each frame model.

https://www.dresser-rand.com/products/gfc/databook/allfrontmatter/packagerguidelines... 30/3/2012

Dresser-Rand Packager Guidelines Compressor Crankcase Oil System

Page 3 of 3

Recommended minimum prelube capacity @35 psi (241 kPa) (on electric motor driven machines only):

5-5.Oil Parameter Recommendations

2012 Dresser-Rand. All Rights Reserved.

https://www.dresser-rand.com/products/gfc/databook/allfrontmatter/packagerguidelines... 30/3/2012

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- D39E-1 Shop ManualDocument636 paginiD39E-1 Shop ManualthuanÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- S10 Service ManualDocument53 paginiS10 Service ManualDave M67% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Case Crawler Excavator Cx75sr Cx80 Tier 3 Service ManualDocument630 paginiCase Crawler Excavator Cx75sr Cx80 Tier 3 Service ManualPirates Ars100% (15)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Alarm and Trouble ShootingDocument20 paginiAlarm and Trouble ShootingENGHUSSEIN78100% (5)

- Petroleum Hydrocarbon Ranges FlyerDocument1 paginăPetroleum Hydrocarbon Ranges FlyerAsadAliÎncă nu există evaluări

- PEUGEOT 3008 HYbrid4Document21 paginiPEUGEOT 3008 HYbrid4Tom CotterÎncă nu există evaluări

- Shell Bearing Failure GuidelineDocument10 paginiShell Bearing Failure GuidelineMadhana GopalÎncă nu există evaluări

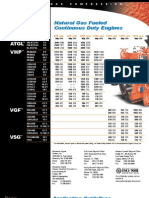

- Waukesha VHPDocument2 paginiWaukesha VHPMadhana GopalÎncă nu există evaluări

- Doosan PDFDocument4 paginiDoosan PDFammar kkÎncă nu există evaluări

- Opposed Piston Engine Modeling in GT SUITE From Pinnacle EnginesDocument16 paginiOpposed Piston Engine Modeling in GT SUITE From Pinnacle EnginesArchanakarthikÎncă nu există evaluări

- SSP 823603 3.2 - 3.6-FsiDocument72 paginiSSP 823603 3.2 - 3.6-Fsiaulin64_845645735Încă nu există evaluări

- Turbo Dry CleanDocument12 paginiTurbo Dry CleanMadhana GopalÎncă nu există evaluări

- Waukesha Gas Engine Ratings For Compression ApplicationDocument2 paginiWaukesha Gas Engine Ratings For Compression ApplicationMadhana Gopal100% (3)

- WWW GasmachineryjournalDocument9 paginiWWW GasmachineryjournalMadhana GopalÎncă nu există evaluări

- 301 SSDocument5 pagini301 SSMadhana GopalÎncă nu există evaluări

- URAI ManualDocument28 paginiURAI ManualSesFasabiSaavedraÎncă nu există evaluări

- ASTronic Product BrochureDocument8 paginiASTronic Product BrochureRajib BiswasÎncă nu există evaluări

- Introduction To ENERGY: Overdevelopment and The Delusion of Endless GrowthDocument6 paginiIntroduction To ENERGY: Overdevelopment and The Delusion of Endless GrowthPost Carbon InstituteÎncă nu există evaluări

- Toll Road Project - Specifications Section 9 - PavementsDocument32 paginiToll Road Project - Specifications Section 9 - PavementsadhystiraÎncă nu există evaluări

- Regin CO Sensor (COF)Document2 paginiRegin CO Sensor (COF)ckyee88Încă nu există evaluări

- Inter Cars Consumabile - Update 16.05.2015Document52 paginiInter Cars Consumabile - Update 16.05.2015Valentin Nedelea100% (1)

- Hydroprocessing/FCC Synergy: Number 101 Spring 2007Document38 paginiHydroprocessing/FCC Synergy: Number 101 Spring 2007Món Quà Vô GiáÎncă nu există evaluări

- Taylor 2008Document11 paginiTaylor 2008Gunawan HariantoÎncă nu există evaluări

- Trans-Mini - AMF Eng Man v11Document69 paginiTrans-Mini - AMF Eng Man v11alperdaÎncă nu există evaluări

- GNC Rfid PDFDocument66 paginiGNC Rfid PDFFederico Manuel Pujol100% (1)

- NTPC Badarpur PPT 2012Document33 paginiNTPC Badarpur PPT 2012hemantparjapatiÎncă nu există evaluări

- 60ZV Cl0605xe07 PDFDocument8 pagini60ZV Cl0605xe07 PDFHao Minh KhueÎncă nu există evaluări

- Primus Green Energy Gasoline Brochure 2Document8 paginiPrimus Green Energy Gasoline Brochure 2luis_may22Încă nu există evaluări

- Engine Oil Additive Technology Summary.Document4 paginiEngine Oil Additive Technology Summary.Adid PunyaÎncă nu există evaluări

- Boomer 281-1238 PDFDocument4 paginiBoomer 281-1238 PDFbrendsÎncă nu există evaluări

- Orc Waste Heat RecoveryDocument20 paginiOrc Waste Heat RecoveryPasquale Cutri100% (1)

- Chemical Dictionary PDFDocument79 paginiChemical Dictionary PDFafb40% (1)

- Concentrate Solar Energy by MirrorsDocument8 paginiConcentrate Solar Energy by MirrorsAsad Iqbal100% (1)

- Namirda Survey 161214 FinalDocument11 paginiNamirda Survey 161214 Finalapi-174747054Încă nu există evaluări

- Renewable Energy ResourcesDocument12 paginiRenewable Energy Resourcesashish kumarÎncă nu există evaluări