Documente Academic

Documente Profesional

Documente Cultură

Tip-Edge, Canal Posterior

Încărcat de

Victor BorrayoDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tip-Edge, Canal Posterior

Încărcat de

Victor BorrayoDrepturi de autor:

Formate disponibile

Journal of Orthodontics, Vol.

34, 2007, 5968

FEATURES SECTION

Current products and practice: Tip-Edge Plus

Richard C. Parkhouse

Glan Clwyd Hospital Conwy and Denbighshire NHS Trust, UK

A recent modification to the Tip-Edge bracket system now enables torque and tip corrections to be achieved without the use of auxiliary springs. This article describes the new Tip-Edge Plus. Key words: Tip-Edge, Plus, deep tunnel, torque and tip control, root uprighting

Refereed paper

Introduction

The Tip-Edge bracket was invented by Dr P. C. Kesling in 1986.1,2 It introduced differential tooth movement within a modied straight-wire bracket system. As such, it represented a major advance over the Begg system in terms of patient comfort and ease of handling, utilizing the convenience of labially inserted archwires with conventional tie-wings and elastomerics, in place of gingivally inserted wires retained with brass pins. While Tip-Edge quickly established itself among many previous Begg users as a rapid tooth mover, it remained, in its original form, a round-wire technique. Therefore, although each bracket contained an individualized straightwire prescription, only tip correction was selflimited. The appliance could not be regarded as fully pre-adjusted; neither could effective torque control be applied to the buccal segments. Nevertheless, the concept of a dynamic bracket slot, which increased the available vertical archwire space as each tooth tipped, opened up exciting possibilities. These were exploited with the discovery, in 1992,3 that the use of passive rectangular archwires, of almost full thickness, would not only impart accurate molar control, but would allow the Side-Winder second-order uprighting springs to express third-order torque, concurrently with the tip, during the root-uprighting nishing phase. The result was a truly pre-adjusted appliance, capable of automatic recovery from up to 14u of torque discrepancy from either direction, without signicant archwire deection, and therefore without any unwanted torque reactions against adjacent teeth. Furthermore, all nal uprighting could now be achieved with a common auxiliary (the Side-Winder spring). The passive rectangular archwires would not normally

Address for correspondence: Richard C. Parkhouse, Bryn Tirion, Penmaen Park, Llanfairfechan, Conwy, LL33 0RN, UK. Email: richard.parkhouse@homecall.co.uk # 2007 British Orthodontic Society

require adjustment, since the springs were the active component. The undoubted ease of tooth movement with light anchorage demands became quickly recognized, making conventional bodily movement mechanics appear suddenly pedestrian, particularly in the more difcult cases.4 Nevertheless, its subsequent uptake by orthodontists proved disappointing in relation to its merits. Much of this might be ascribed to conservatism and a reluctance to tackle a new learning curve. However, one of the greatest disincentives to using Tip-Edge has been that each bracket requires an auxiliary spring to deliver its nal prescription. Also, some of the advantage that Tip-Edge formerly enjoyed over straight wire in its economy of archwires (normally three in each arch per treatment), has been lost with the advent of super-elastic nickel titanium wires. These have been widely adopted with traditional appliances to help streamline treatment, but without hitherto nding a place in Tip-Edge. Might not such new technology in metallurgy benet Tip-Edge too? Such was the thinking behind the development of Plus.

Development

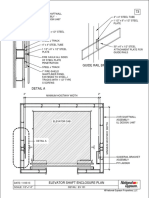

The aim was to eliminate the use of auxiliary springs in the nal root-uprighting phase of treatment (Stage III). The concept began in North Wales in 1999, with a simple typodont experiment to test clinical feasibility. Special brackets were prepared that utilized deep grooves throughout, consisting of an auxiliary archwire slot, cut deep to the main arch slot, into which a superelastic wire could readily be tted to achieve the desired mesiodistal uprighting (Figure 1). While the concept appeared promising, a clinical trial revealed that the

DOI 10.1179/146531207225021933

60

R. C. Parkhouse

Features Section

JO March 2007

(a)

Figure 1

(b)

(a,b) A typodont experiment in 1999 used deep grooves as a simple test for clinical feasibility

auxiliary wire readily escaped from its slot beneath the main archwire. Also, the bracket itself was weakened by the combined depth of two slots. So it was that TP Orthodontics took the principle, and from it developed the deep tunnel. This is an entirely novel concept in orthodontics, made possible by the physical properties of the latest generation of nickel titanium archwires.

How it works

The existing Rx-1 Tip-Edge bracket carries a vertical slot up its long axis, cut into its base, for insertion of an auxiliary spring. In the Plus bracket (Figure 2), an additional slot (the deep tunnel) is cut horizontally, intersecting the vertical tube almost at right angles. Seen from the lingual direction without the mesh pad

(Figure 3), the two grooves describe a plus sign; hence the name. Both have the same internal dimension (0.020-inch round). When a light exible wire is passed through the tunnel (Figure 4), a second-order uprighting force is generated by the deection of the wire, comparable in degree to that produced by a SideWinder in conventional Tip-Edge. However, the principle of simultaneous torque and tip delivery,3 unique to Tip-Edge, is enshrined in the Plus system also, in that torque is derived concurrently, each bracket conforming to the passive torque setting in the rectangular main arch-wire. The deep tunnel wire is doing the work previously done by the individual Side-Winders (Figures 5 and 6). In clinical use, both Tip-Edge and Plus remain identical throughout the rst two stages, during which the vertical slots remain available for the possible use of

Figure 2 The Plus bracket has a deep tunnel running beneath the main arch-wire slot

Figure 3 The Plus bracket seen from the lingual direction without the mesh pad. The deep tunnel and the vertical slot intersect almost at right angles

JO March 2007

Features Section

Tip-Edge Plus

61

Figure 4 A second-order uprighting force is generated by the deection of a light exible wire within the deep tunnel

the occasional Side-Winder brake, as may be useful for increasing anterior anchorage, when the operator chooses, or for correcting centrelines. Likewise, the rectangular archwires for Stage III with Plus are exactly as before. The face of the Plus bracket is geometrically identical to that of the former Rx-1 bracket, so that Plus is compatible with the former system, although obviously the deep tunnels can only be utilized if all brackets are so equipped. The tunnel is easily visualized for identication. Also, the keen observer will note that the Plus bracket has a squared-off back plate to maximize the effective width of the deep tunnel. In fact, this is considerably greater than the narrow frontal aspect of

Figure 5 The deep tunnel wire is doing the work previously done by individual Side-Winders

Figure 6 The Tip-Edge principle of simultaneous torque and tip delivery is maintained, each bracket conforming to the passive torque setting in the rectangular main archwire

62

R. C. Parkhouse

Features Section

JO March 2007

Figure 7 Threading the auxiliary archwire from the midline. Engaging the four incisor deep tunnels ensures safety of the ends Figure 8 The upper right buccal segment is threaded

the bracket face would suggest. The vertical tolerance of a 0.014-inch auxiliary wire in a deep tunnel amounts to 6u, which equates to 3u of tip slop. In the design of the deep tunnels, allowance has been made for this in the vertical angulation, which incorporates a cant in the upper central incisors of 5u of overcorrection. In clinical use, actual over-correction will be prevented by the self-limiting effect of the main rectangular archwire; the purpose of the cant is therefore to ensure that some activation remains in the auxiliary wire, right up to the prescribed nishing position. A similar cant of 3u is present in the remaining incisors. This feature has recently been extended, with 5u cants in the premolars.

How to do it

Because the deep tunnel is not accessible from the labial direction, it needs to be threaded.5 With familiarity, this is a simple process, and quicker than the placement of multiple springs. At the Kesling-Rocke Orthodontic Center in Westville, Indiana, this procedure is routinely undertaken by chairside assistants. The auxiliary deep tunnel wire should rst be trimmed for arch length. (Measuring it through the main archwire slots, the distal ends can be cut half-way along the molar tubes.) The auxiliary wire is generally threaded from the midline, in reverse curvature, right side to left, and vice versa. Inserting it through the incisors rst will secure both ends safely. The wire still to be threaded forms a circle at the front (Figure 7). Each buccal segment can then be threaded in turn, using a ne beak light wire plier. The penetration of each tunnel should be without resistance. This is achieved by guidance of the insertion pathway. Failure to do this can result in impaction of the advancing end of the wire at the crossroads, where the vertical tube intersects the

deep tunnel, particularly when the brackets are distally tipped. Once the end of the wire is safely in the mesial tunnel mouth, a gentle deection of the wire in the mesial interspace, generally occlusally and buccally, will direct the end through the crossroads without resistance. (In a second premolar, where the rst premolar has been extracted, the deection may be gingivally and buccally.) Once one buccal segment is fully threaded (Figure 8), the other side is threaded similarly, during which the small remaining circle of wire at the midline further shrinks (Figure 9) and will eventually ip (Figure 10), as the auxiliary wire rotates along its long axis, to assume its preformed arch shape. Care should be taken at this potential pressure point. If necessary, the coil can be encouraged to unfold in the required direction with gentle nger pressure. In the mandibular arch, if tooth size is small, and the space between the lower central incisors is inadequate, it may be preferable to thread the auxiliary archwire from

Figure 9 As the remaining buccal segment is threaded, the midline circle of auxiliary wire shrinks further

JO March 2007

Features Section

Tip-Edge Plus

63

Figure 12 Where rst premolars have been extracted, the distal ends of the auxiliary wire utilize the round molar tubes Figure 10 The midline circle of auxiliary wire nally ips as the auxiliary archwire is fully seated

between the lateral incisor and the canine, where the inter-bracket space will be larger. Once the auxiliary wire is in place, the 0.021560.028inch main archwire is prepared and tted in exactly the same way as with existing Tip-Edge, retained with elastomeric ligatures (Figure 11). Placement of the distal end of the auxiliary wire relative to the molar depends on the extraction pattern. If a rst premolar has been extracted, the second premolar will require mesial root uprighting. This will be aided by placing the distal end of the deep tunnel wire in the gingivally placed round molar tube (Figure 12). If the extraction is a second premolar or rst molar, or the case is non-extraction, the distal end requires occlusal deection to ensure full distal movement of the second premolar apex. The distal end will then be routed through the occlusal tie-wing (Figure 13). Because the deep tunnels run lingual to the main archwire, the distal ends do not tend to escape buccally, so that a retaining

ligature should seldom be necessary. Even if a nonconvertible buccal tube with no tie-wings is used, stability of the distal ends is not apparently a problem.6 Experience of Plus so far suggests that a 0.014-inch auxiliary wire is the optimum choice, although it is sometimes possible to t a 0.016-inch auxiliary wire in the upper. In mild-to-moderate cases where the teeth are not severely tipped, ordinary nickel titanium, such as Reex (TP Orthodontics), may be entirely adequate. A 0.012-inch auxiliary wire has been tried in difcult cases, giving a good initial response, although so thin a wire is likely to level out before the case is nished, due to tolerance within the tunnels. This will then require upgrading, mid-stage, which is to be avoided if possible. Instead, 0.014-inch thermally activated nickel titanium wires have proved easy to thread, even in the most severe cases (in which the canine bracket is generally the most tipped). These are very easy to thread in the martensitic phase, and theoretically they exert less pressure under large deections. Good results have been achieved with Copper Ni-Ti 27u (Ormco) and Sentalloy (GAC).

Figure 11 The main arch-wires are identical to those in previous Stage III Tip-Edge

Figure 13 If rst premolars have not been extracted, the distal auxiliary ends reside in the occlusal tie-wing of the rst molar

64

R. C. Parkhouse

Features Section

JO March 2007

(a)

(b)

Figure 14 (a,b) A clinical case: a Class 1 base but with 9.5 mm of overjet

Unfortunately, it is well recognized that thermally activated wires are subject to variations in quality, even within the same batch. Before tting such a wire, it is worth testing its properties. Cooling with an air syringe should induce the martensitic state, while immersion in warm water will restore the working resilience. During tting, cool air should be directed to the wire mesial to the bracket being threaded. When the auxiliary arch is nearly fully home, the midline area should be cooled to aid the nal unwinding of the small remaining circle of wire.

Clinical case

A female aged 14 years 7 months presented with an overjet of 9.5 mm and severe crowding on a Class I base (Figure 14). She had bimaxillary proclination, and the incisor overbite was increased and complete. The crowding involved all four canines, made worse in the upper right quadrant by the presence of a supplemental right lateral incisor (Figure 15). In the mandibular arch, both canines were virtually excluded, and the lateral

(a)

(b)

(c)

Figure 15 (ac) The occlusion before treatment

JO March 2007

Features Section

Tip-Edge Plus

65

(a)

(b)

(c)

Figure 16 (ac) Stage I begins, using high-tensile 0.016-inch main archwires with bite-opening anchorage bends and very light Class II elastic traction; 0.014-inch nickel titanium underarches align the instanding incisors as the overjet and overbite reduce

(a)

(b)

(c)

Figure 17 (ac) Four months into treatment, the remaining spaces will be closed with 0.020-inch stainless archwires and intramaxillary elastomerics

(a)

(b)

(c)

Figure 18 (ac) Stage III begins, 7 months into treatment, using 0.021560.028-inch main archwires. The deep tunnel auxiliary wires are 0.014-inch Sentalloy (upper) and Copper Ni-Ti (lower)

incisors bodily displaced lingually. The upper left central incisor had sustained a crown fracture. Treatment was planned around the extraction of four rst premolars and the supernumerary (the distal of the two upper right lateral incisors, since this had an inferior crown shape). It was decided to accept the proclination of the lower incisors to preserve the rm prole, reducing the overjet and aligning the crowded teeth within the limited space available. Tip-Edge Plus appliances were used. Stages I (Figure 16) and II (Figure 17) were accomplished in the established manner, with no anchorage reinforcement required, apart from very light Class II intermaxillary elastics. Overjet reduction, arch alignment, overbite reduction and space closure were thus achieved in 7 months.

Third-stage 0.021560.028-inch archwires were then prepared, exactly as would be prescribed with Rx-1 brackets. Shallow bite sweeps were indicated to retain overbite reduction, but without torque compensation at the front, so as to allow some incisor proclination to be maintained. Auxiliary archwires (0.014 inch) were then threaded through the deep tunnels, terminating in the gingivally-placed round molar tubes, before the rectangular main archwires were tted in the usual way (Figure 18). Note the distal crown inclinations of the lower canines and upper right lateral incisor, as well as the lingual apical positions of the lower lateral incisors. After 5 months of root uprighting, appliances were removed (Figure 19). The active treatment time was 13 months, involving nine adjustments and seven

66

R. C. Parkhouse

Features Section

JO March 2007

(a)

(b)

(c)

Figure 19 (ac) The nished result after 13 months of active treatment

archwires (four upper, three lower). Space has been left for distal augmentation of the slightly diminutive upper right lateral incisor. The proclination of the lower incisors has been maintained (Figure 20). There has been a marked improvement in prole (Figure 21) and facial aesthetics (Figure 22).

Advantages of Plus Stage III

For the patient, these are obvious. The aesthetics in Stage III are far superior and the appliance is easier to keep clean without auxiliary springs. It is also more comfortable, without the added labial prole of Side-Winders.

For the orthodontist and his or her assistant, there are major handling advantages. With practice, the auxiliary archwire is less ddly and and takes less time to thread than is needed for the individual placement of SideWinder springs. Whereas auxiliary springs can be prone to detachment, there is no chance of the auxiliary archwire getting lost, during tting or between adjustments; likewise, the risk of confusion between clockwise and counter-clockwise springs is eliminated. Cooperation is improved because the patient is not tempted to interfere with the springs. Furthermore, all bracketed teeth are automatically included in the uprighting process. The auxiliary archwire imparts positive rotational control during root uprighting (which was sometimes a problem with individual springs). Finally, while a correctly adjusted rectangular archwire should be capable of completing Stage III without removal, if an adjustment is found to be required, access to it is immediate, without having to remove and replace all the springs.

Disadvantages of Plus

It is expensive to manufacture. (The Plus bracket is metal injection moulded and therefore of superior quality to its predecessor.) At the time of writing, however, the undiscounted price of a Plus bracket is 4.00, which is the same as that of the Rx-1 bracket, which is to be discontinued. Some of the cost difference between Tip-Edge and conventional bracket systems is reduced by the fact that Side-Winders are no longer required during Stage III with Plus. The variable quality of thermally activated nickel titanium wires is of concern, requiring watchfulness before insertion, as failure to regain the starting shape will inevitably result in incomplete treatment. Also, even when wires of optimum performance are used, the residual activation at the end of root uprighting is open

Figure 20 The initial proclination of the lower incisors has been maintained. Black: pre-treatment; red: end-of-treatment

JO March 2007

Features Section

Tip-Edge Plus

67

(a)

Figure 21 (a,b) Improved facial features

(b)

(a)

Figure 22 (a,b) Facial aesthetics, before and after treatment

(b)

68

R. C. Parkhouse

Features Section

JO March 2007

to question, compared with Side-Winder springs. This is because the activation of springs can be boosted (hyperactivated) by the operator, if it is desired to maintain a bodily controlling force after a tooth has reached its nished position, such as when reinforcing anchorage on lower incisors.

Conclusion

The manufacturers of Plus (TP Orthodontics) claim it to be the next direction in straight wire. Is this likely? In terms of the original concept of straight wire, Tip-Edge with rectangular wire can truly claim to be a straightwire appliance, in that it produces a zero tolerance nish with no torque slop. There is, therefore, no requirement to individualize the nishing archwires. However, the term straight wire will for ever be associated with edgewise-derived bracket systems. Nevertheless, in the materials and methods used to gain the nal result, the two techniques are undeniably closer than ever before. The main difference is the treatment sequence. The straight-wire technique begins with levelling and aligning, generally using nickel titanium wire, subsequently translating the teeth by bodily movement, against inherently heavy anchorage forces. Plus reverses the order by translating the crowns rst, with very light forces permitted by limited tipping, before uprighting each

root individually to its nishing position. Both techniques now employ nickel titanium for root uprighting. The concept of Plus is undeniably attractive, and it is likely to appeal to a wider user base than its predecessor, particularly now that it is available with ceramic brackets. Although it shows considerable clinical promise, it must be remembered that, while Tip-Edge is thoroughly proven clinically, the Plus bracket is early in its development, although its potential for the future would seem immense, particularly with further advances in metallurgy. Further information: www.plusbrackets.com.

References

1. Kesling PC. Expanding the horizons of the edgewise arch wire slot. Am J Orthod Dentofacial Orthop 1988; 94: 2637. 2. Kesling PC. Dynamics of the Tip-Edge bracket. Am J Orthod Dentofacial Orthop 1989; 96: 1628. 3. Parkhouse RC. Rectangular wire and third order torque: a new perspective. Am J Orthod Dentofacial Orthop 1998; 113: 42130. 4. Parkhouse RC. Tip-Edge Orthodontics. Edinburgh: Mosby, 2003. 5. Kesling PC. Guide to the Differential Straight Arch Technique, 6th Edn. Westville, Indiana: Two Swan Advertising, 2003. 6. Kesling CK. Personal communication.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Game Audio - Tales of A Technical Sound Designer Volume 02Document154 paginiGame Audio - Tales of A Technical Sound Designer Volume 02Joshua HuÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Fuel Injection PDFDocument11 paginiFuel Injection PDFscaniaÎncă nu există evaluări

- RISO RZ User GuideDocument112 paginiRISO RZ User GuideJojo AritallaÎncă nu există evaluări

- LOMA FLMI CoursesDocument4 paginiLOMA FLMI CoursesCeleste Joy C. LinsanganÎncă nu există evaluări

- Materials Selection in Mechanical Design - EPDF - TipsDocument1 paginăMaterials Selection in Mechanical Design - EPDF - TipsbannetÎncă nu există evaluări

- MCQs + SEQs Medical Physics Midterm Exam Paper-Fall 2020Document3 paginiMCQs + SEQs Medical Physics Midterm Exam Paper-Fall 2020Ali Nouman100% (1)

- Mathematical Method For Physicists Ch. 1 & 2 Selected Solutions Webber and ArfkenDocument7 paginiMathematical Method For Physicists Ch. 1 & 2 Selected Solutions Webber and ArfkenJosh Brewer100% (3)

- LS3954A LS3954 LS3955 LS3956 LS3958: Linear Integrated SystemsDocument3 paginiLS3954A LS3954 LS3955 LS3956 LS3958: Linear Integrated SystemsJCMÎncă nu există evaluări

- Preprints201808 0216 v1Document15 paginiPreprints201808 0216 v1Baptista Jaime MilioneÎncă nu există evaluări

- Guide Rail Bracket AssemblyDocument1 paginăGuide Rail Bracket AssemblyPrasanth VarrierÎncă nu există evaluări

- APPSC GR I Initial Key Paper IIDocument52 paginiAPPSC GR I Initial Key Paper IIdarimaduguÎncă nu există evaluări

- Law MCQ 25Document3 paginiLaw MCQ 25nonoÎncă nu există evaluări

- Almutairy / Musa MR: Boarding PassDocument1 paginăAlmutairy / Musa MR: Boarding PassMusaÎncă nu există evaluări

- ECDIS Presentation Library 4Document16 paginiECDIS Presentation Library 4Orlando QuevedoÎncă nu există evaluări

- Minimization Z Z Z Z Maximization Z Z : LP IPDocument13 paginiMinimization Z Z Z Z Maximization Z Z : LP IPSandeep Kumar JhaÎncă nu există evaluări

- Lesson Plan Outline - Rebounding - Perez - JoseDocument7 paginiLesson Plan Outline - Rebounding - Perez - JoseJose PerezÎncă nu există evaluări

- Study of Bond Properties of Concrete Utilizing Fly Ash, Marble and Granite PowderDocument3 paginiStudy of Bond Properties of Concrete Utilizing Fly Ash, Marble and Granite PowderLegaldevil LlabsÎncă nu există evaluări

- Iot Practical 1Document15 paginiIot Practical 1A26Harsh KalokheÎncă nu există evaluări

- CV - Zohaib Hussain KaziDocument2 paginiCV - Zohaib Hussain KaziEngr. Zohaib Hussain KaziÎncă nu există evaluări

- BCSS Sec Unit 1 Listening and Speaking SkillsDocument16 paginiBCSS Sec Unit 1 Listening and Speaking Skillsjiny benÎncă nu există evaluări

- SrsDocument7 paginiSrsRahul Malhotra50% (2)

- Dbe Bes100 ZZ XXXX YyyDocument3 paginiDbe Bes100 ZZ XXXX Yyyjavierdb2012Încă nu există evaluări

- Methods of Data Collection MSC N I YrDocument256 paginiMethods of Data Collection MSC N I Yrdr.anu RkÎncă nu există evaluări

- 1and5.microscopes, Specializedstem Cells, Homeostasis - Answer KeyDocument1 pagină1and5.microscopes, Specializedstem Cells, Homeostasis - Answer KeyMCarmen López CastroÎncă nu există evaluări

- RAMSCRAM-A Flexible RAMJET/SCRAMJET Engine Simulation ProgramDocument4 paginiRAMSCRAM-A Flexible RAMJET/SCRAMJET Engine Simulation ProgramSamrat JanjanamÎncă nu există evaluări

- Antibiotic I and II HWDocument4 paginiAntibiotic I and II HWAsma AhmedÎncă nu există evaluări

- Man of The House Faq: About MothDocument2 paginiMan of The House Faq: About MothPrapya BarmanÎncă nu există evaluări

- Put Them Into A Big Bowl. Serve The Salad in Small Bowls. Squeeze Some Lemon Juice. Cut The Fruits Into Small Pieces. Wash The Fruits. Mix The FruitsDocument2 paginiPut Them Into A Big Bowl. Serve The Salad in Small Bowls. Squeeze Some Lemon Juice. Cut The Fruits Into Small Pieces. Wash The Fruits. Mix The FruitsNithya SweetieÎncă nu există evaluări

- Gulf Case Study SolnDocument9 paginiGulf Case Study SolnHarsh SÎncă nu există evaluări