Documente Academic

Documente Profesional

Documente Cultură

Synventive Hot Sprue MK PRM BRM US P TSR 16

Încărcat de

watnaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Synventive Hot Sprue MK PRM BRM US P TSR 16

Încărcat de

watnaDrepturi de autor:

Formate disponibile

SR16 Series Features

SR16 Hot Runner Nozzles are for medium part applications and are available with band heaters. In most cases one heater is required for operation. An installed spare may be installed if space allows. They are available in lengths from 75 to 375 (J dimension). Suitable for all materials and available with eight Synventive Controlled Vestige (CV) tip options including valve gates for zero gate vestige applications.

8-16

Replaceable Heaters Thermocouple

Heat Pipes

Threaded Tips

Features: 16mm maximum flow channel maximum 75 - 375 mold depth ("J" dimension) Replaceable long life heater and thermocouple 500W or 600W /240V heaters 8 controlled v estige tip styles Replaceable threaded tips Internal heat pipes for temperature uniformity For all plastics including those w ith fillers 24 tip dia

All Dimensions in mm

SR16-1

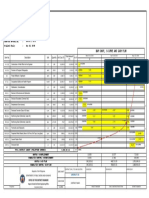

SR16 Series Band Heater

Band Heater

8-16 41 5 H6

In most cases one heater is required for operation. If mold thickness allows a spare band heater and thermocouple will be installed. J Minimum = 75 J Maximum = 375

59 (J 75 to 149.9) 134 (J 150 to 375)

68 J

120 46

SR16-2

SR16 Series Overview

Thermal Gate Nozzle CV10

- Filled and unfilled materials - Open flow channel/higher flow - 1.5 to 5.2 orifice diameter - Patented seal - Easier mold geometry Dimensional data on Pages SR16-10, 11 & 12

CV11

- Filled and unfilled materials - Cone point delivers more heat to gate - 1.0 to 3.5 orifice diameter - Patented seal - Reduced vestige - Easier mold geometry Dimensional data on Pages SR16-13, 14 & 15

CV20

- Filled and unfilled materials - Open flow channel/Higher flow - 1.5 to 5.2 orifice diameter - Patented seal - No witness mark - Easier color change Dimensional data on Pages SR16-16, 17 & 18

CV21

- Filled and unfilled materials - Cone point delivers more heat to the gate - 1.0 to 3.5 orifice diameter - Patented seal - Reduced vestige - No witness mark Dimensional data on Pages SR16-19, 20 & 21

See page T16-5 to select a tip that suits your application

SR16-3

SR16 Series Overview

Valve Gate Nozzle VG12

- Filled and unfilled materials - 0 vestige - Tapered shut off - 3.9 orifice diameter - Patented seal - Easier mold geometry Dimensional data on Pages SR16-22 & 23

VG12S

- Filled and unfilled materials - 0 vestige - Diametric shut off - Materials having glass fibers - 5.0 orifice diameter - Patented seal - Easier mold geometry Dimensional data on Pages SR16-24 & 25

VG23

- Filled and unfilled materials - 0 vestige - Tapered shut off - 3.9 orifice diameter - Patented seal - No witness mark Dimensional data on Pages SR16-26 & 27

VG23S

- Filled and unfilled materials - 0 vestige - Diametric shut off - Materials having glass fibers - 5.0 orifice diameter - Patented seal - No witness mark Dimensional data on Pages SR16-28 & 29

See page T16-6 to select a tip that suits your application

SR16-4

SR16 Series Material Compatibility

Material Semi-crystalline Amorphous

Additives

PPO/PA

PC/ABS

PMMA

PEEK

POM

PPO + + + +

+ + + +

+ + + +

+ + + +

SAN

PPA

PBT

ASA

PSU

CV10

A B C D

+ + + +

+ 0 0 +

+ + + +

+ + + +

+ + + +

+ 0 0 +

+ + + +

+ + + +

+ -

+ + -

+ + -

+ + -

+ + -

+ + + + +

0 0 0 0

+ + + +

+ + +

+ +

0 0 0 0

+ + + +

+ + + +

+ + + +

+ 0 0 0

+ + + + +

+ +

+ -

+ + +

+ + + + -

+ + +

+ + + +

+ + + +

+ + + +

+ + + +

+ + + +

+ 0 0 0

+ + + +

+ + + +

+ + + +

+ 0 0 0

PEI

PA

PC

PP

PE

PS

Tip Style

CV11

A B C D

CV20

A B C D

CV21

A B C D

The above table defines which tip styles are best suited for a given material.

Note: The selection table is meant to be a guide for the initial selection of the tip style. It is based on the more common grades of material. Synventive will verify the correct tip selection as part of the quote/order process.

Additive Index A - None B - Fillers C - Glass Fiber D - Flame retardants + 0 Very suitable Suitable Not suitable

SR16-5

TPE + + + +

+ + + +

PET

ABS

PPS

PES

SR16 Series Material Compatibility

Material Semi-crystalline Amorphous

Additives

PPO/PA

PC/ABS

PMMA

PEEK

POM

PPO + +

SAN

PPA

PBT

PSU

ASA

PET

VG12

A B C D

+ 0

+ 0

+ 0

+ 0

+ -

+ 0

+ -

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

+ 0

PEI

PA

PC

PP

PE

PS

Tip Style

VG12S

A B C D

+ + -

+ + -

0 + -

0 + -

0 + -

0 + -

+ -

+ + -

+ -

+ + -

+ -

+ + -

+ + -

+ + -

+ + -

+ + -

VG23

A B C D

+ +

+ +

+ 0

+ 0

+ 0

+ 0

+ -

+ 0

+ 0

+ +

+ 0

+ 0

+ +

+ +

+ +

+ +

VG23S

A B C D

+ + -

+ + -

+ + -

+ + -

0 + -

+ + -

+ -

0 + -

0 + -

+ + -

+ -

0 + -

+ + -

+ + -

+ + -

+ + -

Additive Index Note: The selection table is meant to be a guide for the initial selection of the tip style. It is based on the more common grades of material. Synventive will verify the correct tip selection as part of the quote/order process. A - None B - Fillers C - Glass Fiber D - Flame retardants + 0 Very suitable Suitable Not suitable

The above table defines which tip styles are best suited for a given material.

SR16-6

TPE + 0

ABS

PPS

PES

0 0 -

+ +

0 0 -

SR16 Series Flow Rate

Maximum flow rate of hot runner nozzles varies depending on the melt index of the material being processed. The flow rate of any hot runner nozzle is controlled by three factors: 1) Flow bore size 2) Melt temperature, viscosity vs shear rate relationship. 3) The cavity wall thickness, flow length from the gate, mold temperature and required fill rate. The last two factors can combine to change the maximum shot capacity by a factor of 5 or more. Synventive uses computerized flow analysis to assure the correct nozzle is chosen.

Tip Style Ma teria l

CV10/CV20 A BS PC PPO PB T PB T/PC PC/A B S PS PP PA POM PE A c rylic PVC TPR 485 gm/sec 550 gm/sec 525 gm/sec 775 gm/sec 320 gm/sec 550 gm/sec 525 gm/sec 1000 gm/sec 1025 gm/sec 340 gm/sec 985 gm/sec 575 gm/sec 340 gm/sec CV11(NS)/CV21(NS) 100 gm/sec 100 gm/sec 100 gm/sec 150 gm/sec 100 gm/sec 100 gm/sec 100 gm/sec 200 gm/sec 200 gm/sec 50 gm/sec 200 gm/sec 100 gm/sec 50 gm/sec 100 gm/sec VG12(S)/VG23(S) 210 gm/sec 105 gm/sec 225 gm/sec 125 gm/sec 250 gm/sec 250 gm/sec 225 gm/sec 425 gm/sec 400 gm/sec 140 gm/sec 400 gm/sec 200 gm/sec 140 gm/sec 225 gm/sec

Example Material: PE Tip style: CV10 Maximum flow rate: 985 grams/second Note: Values in the table do not include reinforced materials or materials with fillers.

SR16-7

SR16 Series Orifice Guidelines

This table lists the normal gate orifice required to fill an average cavity of the listed wall thickness and surface area. The orifice diameter is based on the flow and freeze characteristics of each type of plastic at its normal processing conditions. It is not dependent on whether the cavity is fed by a hot or cold runner. Some of the listed wall thickness and surface area combinations are not applicable to all plastics because of the flow length to wall ratios of each material. Consult plastic suppliers processing recommendations. Due to the gate limitations of each hot runner nozzle, the actual gate may be slightly smaller or larger than the tabulated orifice.

Orific e Diameter Guideline mm(inc h)

Part Area sq mm sq inch Wall thickness mm/(inch)

600 1.0 1200 2.0 1800 3.0 2400 4.0 3000 5.0 6000 10.0 12,000 20.0 18,000 30.0 24,000 40.0 30,000 50.0 36,000 60.0 42,000 70.0 48,000 80.0 54,000 90.0 60,000 100.0 90,000 120.0 120,000 200.0 180,000 300.0 240,000 400.0

0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 3.00 4.00 (0.03) (0.04) (0.05) (0.06) (0.07) (0.08) (0.09) (0.10) (0.13) (0.16) 0.90 0.90 0.90 0.90 0.90 0.90 0.95 1.00 1.12 1.27 0.035 0.035 0.035 0.035 0.035 0.035 0.037 0.039 0.044 0.050 0.90 0.90 0.90 0.90 1.00 1.17 1.30 1.37 1.45 1.53 1.58 0.062 1.65 1.70 1.73 1.93 0.90 0.90 0.90 0.95 1.12 1.32 1.47 1.58 1.65 1.73 1.80 1.88 1.93 1.98 2.18 2.36 0.90 0.95 1.02 1.07 1.27 1.53 1.68 1.80 1.90 1.98 2.08 2.13 2.21 2.26 2.51 2.70 2.97 0.92 1.02 1.10 1.17 1.37 1.65 1.83 1.96 2.06 2.16 2.26 2.34 2.39 2.46 2.72 2.92 3.23 3.48 0.137 1.00 1.10 1.20 1.25 1.50 1.78 1.96 2.10 2.24 2.34 2.41 2.51 2.60 2.64 2.92 3.10 3.48 3.76 .148 1.05 1.17 1.25 1.32 1.58 1.88 2.06 2.24 2.36 2.46 2.57 2.64 2.72 2.80 3.10 3.33 3.68 3.98 1.12 1.25 1.35 1.42 1.68 2.00) 2.21 2.39 2.51 2.64 2.75 2.82 2.92 3.00 3.30 3.56 3.94 4.22 1.17 1.30 1.40 1.47 1.76 2.08 2.31 2.49 2.64 2.77 2.87 2.97 3.05 3.12 3.45 3.73 4.15 4.42 1.32 1.47 1.58 1.65 1.98 2.36 2.62 2.80 2.95 3.10 3.23 3.33 3.43 3.53 3.89 4.20 4.62 4.98 1.50 1.68 1.78 1.88 2.26 2.67 2.97 3.18 3.35 3.53 3.66 3.79 3.89 3.99 4.42 4.75 .187 5.26 5.54 0.035 0.035 0.035 0.036 0.039 0.041 0.044 0.046 0.052 0.059 0.051 0.058 0.066

0.035 0.035 0.037 0.040 0.043 0.046 0.049

0.035 0.035 0.040 0.043 0.047 0.049 0.053 0.055 0.062 0.070 0.035 0.037 0.042 0.046 0.049 0.052 0.056 0.058 0.065 0.074 0.038 0.044 0.050 0.054 0.059 0.062 0.066 0.069 0.078 0.089 0.046 0.052 0.060 0.065 0.070 0.074 0.079 0.082 0.093 0.105 0.051 0.058 0.066 0.072 0.077 0.054 0.062 0.081 0.087 0.091 0.103 0.117

0.071 0.077 0.083 0.088 0.094 0.098 0.110 0.125 0.081 0.088 0.093 0.099 0.104 0.116 0.132

0.057 0.065 0.075

0.060 0.068 0.078 0.085 0.092 0.097 0.104 0.109 0.122 0.139 0.071 0.082 0.089 0.095 0.101 0.108 0.113 0.127 0.144 0.111 0.117 0.131 0.149

0.065 0.074 0.084 0.092 0.099 0.104

0.067 0.076 0.087 0.094 0.102 0.107 0.115 0.120 0.135 0.153 0.068 0.078 0.089 0.097 0.104 0.110 0.118 0.123 0.139 0.157 0.076 0.086 0.099 0.107 0.115 0.122 0.130 0.136 0.153 0.174 0.093 0.106 0.115 0.124 0.131 0.155 0.147 0.165

0.117 0.127 0.137 0.145 0.155 0.162 0.182 0.207 0.156 0.166 0.174 0.196 0.218

Material Factors Use tabulated orifice for PE, PP, PS, SAN and PUR. Use tabulated orifice x 1.15 for POM, PC, PPO and ABS. Use tabulated orifice x 1.30 for Acrylic, PA, PET, and PBT Use tabulated orifice x 1.50 for PVC.

For non-reinforced PA, PET and PBT the minimum orifice diameter should be 4.0. For reinforced PA, PET and PBT the minimum orifice diameter should be 4.0. Part Area is total outside area and not the projected area of the part.

SR16-8

SR16 Series Manifold Integration

SR16 hot runner systems are designed with a preload between the thrust pads and the mold plates in the cold condition. As the manifold heats an additional sealing force is created. The thrust pads are made of a low conductivity material and should only be replaced with an equivalent Synventive part. Excessive contact with the mold will cause heat sinks and affect the system performance. Contact with the mold must be limited to specified areas.

TCP Thrust Pad Preload cold

Center Locator

T Rail height 65

6 16 H6

Crush ring J

Minimum rail height = 81 (thermal gates). Support ring nozzles do not line up with the sub-runners in the manifold in the cold condition. As the manifold heats up the manifold subrunner locations expand to the correct location.

Variable T J T CP Top air gap M old depth

Description

T = Rail height - 6 - 65 (manifold) Minimum T = 10 (thermal gates)

Top clamp plate

SR16-9

SR16 Series Manifold Nozzle

SR16 CV10

Filled and unfilled materials. Easy orifice size changes by straight reaming Open flow bore Heat pipes for isothermal operation.

6

J 120 30

1.5-5.2 24 15.9 46 6 Contact H6

9.7 Ref

The front face of the tip must be in contact with plastic. Cooling is required in the gate area.

Hea ter Style

Band (38 long) Band (51 long)

J Mi n

75 150

J Ma x

149.9 375

Hea ter Qty

1 2

Wa tts/ Vo lts

500W /240V 600W /240V (each)

SR16-10

SR16 Series CV10 Recess

Recessed gates are used to reduce vestige height above the part surface or keep the vestige below the part surface. For most materials CV10 vestige height is equal to 2.0 + orifice/2. If the vestige height relative to the possible gate recess depth (h) is too great, use of a CV11 tip is recommended.

orifice 2 2.0 + orifice 2

Co nic al Rec ess

h 1.0 1.5 2.0 2.5 3.0 D 16.5 18.2 20.0 21.8 23.5

30

Orifice

4 Min contact

2 Land

13 D

h Max = 3 D = 13 + 3.5h h Recess

Conical Recess

Spheric al Rec ess

h 1.0 1.5 2.0

Values in tables are for materials not having glass fibers. Consult Synventive for vestige height when using glass fillers.

D 14.0 17.1 19.6 21.8 23.8

2.5 3.0

4 Min contact

h Max = 3 2 Land D R25 D = 2 h(50-h) h Recess

Spherical Recess

SR16-11

SR16 Series CV10 Angled Mold Contour

When gating onto an angled mold contour the vestige height may be increased depending on the angle. K is the increase in vestige height required to maintain 1.6 wall, 6 wall and/or 4 minimum contact.

2 Land 6 Min L 1.6 Min

E K

4 Min contact

6; K= 0 E = 12TAN L = 2 - Orifice Dia. TAN 2

26; K= 4.2TAN

1.6 COS

-2

26; K= 23TAN

- 9.9

E = K + 12TAN L = 2 + K - Orifice Dia. TAN 2

E = K + 12TAN L = 2 + K - Orifice Dia. TAN 2

Angled Mold Contour

SR16-12

SR16 Series Manifold Nozzle

SR16 CV11

Filled and unfilled materials. More heat in gate area for semicrystalline materials Heat pipes for isothermal operation.

45

0.08 Land 0.13 1-3.5

J 120 30

24 15.9 46 6 Contact

H6

9.7 Ref

The front face of the tip must be in contact with plastic. Cooling is required in the gate area.

Hea ter Style

Band (38 long) Band (51 long)

J Mi n

75 150

J Ma x

149.9 375

Hea ter Qty

1 2

Wa tts/ Vo lts

500W /240V 600W /240V (each)

SR16-13

SR16 Series CV11 Recess

Recessed gates are used to reduce vestige height above the part surface or keep the vestige below the part surface.

Co nic a l Rec ess

Orific e 1.0 1.5 2.0

2

h 0.59 0.76 0.93 1.09 1.26 1.43

D 15.1 15.7 16.3 16.8 17.4 18.0

2.5 3.0 3.5

Orifice

0.08 Land 0.13

30 4 Min contact

13 D

h Max = 3 D = 13 + 3.5h h Recess

Conical Recess

Spheric a l Rec ess

Orific e 1.0-1.2 1.2-1.4 h 0.65 0.72 0.79 0.86 0.93 1.00 1.06 1.12 1.18 1.26 1.32 1.40 d 1.45 1.65 1.85 2.05 2.25 2.45 2.65 2.85 3.05 3.25 3.45 3.65 D 11.33 11.91 12.47 13.00 13.51 14.00 14.41 14.80 15.18 15.67 16.03 16.50

Values in tables are for materials not having glass fibers. Consult Synventive for vestige height when using glass fillers.

1.4-1.6

45

1.6-1.8 1.8-2.0

0.08 Land 0.13

2.0-2.2 2.2-2.4 2.4-2.6 2.6-2.8 2.8-3.0 3.0-3.2 3.2-3.5

Orifice d (flat)

4 Min contact

d D R25

h Max = 3 D = 2 h(50-h) h Recess

Spherical Recess

SR16-14

SR16 Series CV11 Angled Mold Contour

When gating onto an angled mold contour the vestige height may be increased depending on the angle. K is the increase in vestige height required to maintain 0.13 land, 1.6 wall, 6 wall and/or 4 minimum contact.

6 Min 1.6 Min

E K

4 Min contact

7; K=

Orifice Dia. TAN 2

27; K= 4.2TAN

1.6 COS

+ Orifice Dia. - 1 Tan -2 2

27; K= 23TAN - 9.9 E = K + 12TAN L = 0.13 + K Orifice Dia. TAN 2

24 + Orifice Dia. E= TAN 2 L = 0.13

E = K + 12TAN L = 0.13 + K - Orifice Dia. TAN 2

Angled Mold Contour

SR16-15

SR16 Series Manifold Nozzle

SR16 CV20

Filled and unfilled materials. Easy orifice size changes by straight reaming . No tip witness mark on part. Open flow bore. Heat pipes for isothermal operation.

6

J 120 30

46 R 0.8 R 0.8 1 40

8.46 1.5-5.2 24 17.4 H6 11.2 Ref 4.5

Cooling is required in the gate area.

Hea ter Style

Band (38 long) Band (51 long)

J Mi n

75 150

J Ma x

149.9 375

Hea ter Qty

1 2

Wa tts/ Vo lts

500W /240V 600W /240V (each)

SR16-16

SR16 Series CV20 Recess

Recessed gates are used to reduce vestige height above the part surface or keep the vestige below the part surface. For most materials CV10 vestige height is equal to 2.0 + orifice/2. If the vestige height relative to the possible gate recess depth (h) is too great, use of a CV11 tip is recommended.

orifice 2 2.0 + orifice 2

Co nic al Rec ess

h 1.0 1.5 D 16.5 18.2

30

Orifice

2 Land

13 D

h Max = 1.5 D = 2 13 + 3.5h h Recess

Conical Recess

Spheric a l Rec ess

h 1.0 1.5 D 14.0 17.1

Values in tables are for materials not having glass fibers. Consult Synventive for vestige height when using glass fillers.

h Max = 1.5 2 Land D R25 D = 2 h(50-h) h Recess

Spherical Recess

SR16-17

SR16 Series CV20 Angled Mold Contour

When gating onto an angled mold contour the vestige height may be increased depending on the angle. K is the increase in vestige height required to maintain 1.6 wall, 2 wall or 6 wall thickness.

2 Land L

6 Min

2 Min 1.6 Min

6; K= 0 L = 2 - Orifice Dia. TAN 2

16; K= 4.2TAN

1.6 COS

-2

16; K= 12TAN

2 COS

- 4.5

L = 2 + K - Orifice Dia. TAN 2

L = 2 + K - Orifice Dia. TAN 2

Angled Mold Contour

SR16-18

SR16 Series Manifold Nozzle

SR16 CV21

Filled and unfilled materials. No tip witness mark on part. More heat in gate area for semicrystalline materials. Heat pipes for isothermal operation.

6 R 0.8

45

1-3.5 2

0.08 0.13 Land

J 120 30

46 R 0.8 1 40

8.46 H6 11.2 Ref 4.5

24 17.4

Cooling is required in the gate area.

Hea ter Style

Band (38 long) Band (51 long)

J Mi n

75 150

J Ma x

149.9 375

Hea ter Qty

1 2

Wa tts/ Vo lts

500W /240V 600W /240V (each)

SR16-19

SR16 Series CV21 Recess

Recessed gates are used to reduce vestige height above the part surface or keep the vestige below the part surface. Maintain 0.13 land when machining gate recess.

Co nic a l Rec ess

Orific e 1.0 1.5 2.0 2.5 3.0 3.5 h 0.59 0.76 0.93 1.09 1.26 1.43 D 15.1 15.7 16.3 16.8 17.4 18.0

30

2 Land

13 D

h Max = 1.5 D = 2 13 + 3.5h h Recess

Conical Recess

Spheric a l Rec ess

Orific e 1.0-1.2 1.2-1.4 h 0.65 0.72 0.79 0.86 0.93 1.00 1.06 1.12 1.18 1.26 1.32 1.40 d 1.45 1.65 1.85 2.05 2.25 2.45 2.65 2.85 3.05 3.25 3.45 3.65 D 11.33 11.91 12.47 13.00 13.51 14.00 14.41 14.80 15.18 15.67 16.03 16.50

Values in tables are for materials not having glass fibers. Consult Synventive for vestige height when using glass fillers.

1.4-1.6 1.6-1.8 1.8-2.0 2.0-2.2 2.2-2.4 2.4-2.6 2.6-2.8 2.8-3.0 3.0-3.2 3.2-3.5

5 Min contact

h Max = 1.5 2 Land D R25 D = 2 h(50-h) h Recess

Spherical Recess

SR16-20

SR16 Series CV21 Angled Mold Contour

When gating onto an angled mold contour the vestige height may be increased depending on the angle. K is the increase in vestige height required to maintain 0.13 land, 2 and/or 7 minimum wall.

2

0.08 0.13 Land

7 Min

2 Land L 1.3 Min

6; K= Orifice Dia. TAN 2 L = 0.13

16; K= 4.2TAN

1.6 COS

Orifice Dia. - 1 + TAN - 2 2

16; K= 12TAN

2 COS

- 4.5

L = 0.13 + K - Orifice Dia. TAN 2

L = 0.13 + K - Orifice Dia. TAN 2

Angled Mold Contour

SR16-21

SR16 Series Manifold Nozzle

SR16 VG12 Tapered

Filled and unfilled materials.

5

Heat pipes for isothermal operation. Tapered valve pin to eliminate gate flash.

15

2 Land

3.9 R0.13

0.13 Pin protrusion

J

120 30

24

H6

9.7 Ref

15.9

46

6 Contact

The front face of the tip must be in contact with plastic. Cooling is required in the gate area.

Hea ter Style

Band (38 long) Band (51 long)

J Mi n

75 150

J Ma x

149.9 375

Hea ter Qty

1 2

Wa tts/ Vo lts

500W /240V 600W /240V (each)

SR16-22

SR16 Series VG12 Angled Mold Contour

When gating on an angled mold contour the vestige height may be increased depending on the angle. K is the increase in land required to maintain 1.6 wall, 6 wall and/or 4 minimum contact.

R0.13 3.9 15

0.13

6 Min 2 Land

1.6 Min

E K

4 Min contact

6; K= 0 E = 12TAN

27; K= 4.2TAN

1.6 COS

-2

27; K= 23TAN

- 9.9

E = K + 12TAN

E = K + 12TAN

Angled Mold Contour

SR16-23

SR16 Series Manifold Nozzle

SR16 VG12S Straight

Filled and unfilled materials. Heat pipes for isothermal operation. Straight valve pin in gate for nonadjustable actuators and glass filled materials.

5

30

0.3 4.999 5.009 R0.13 J 120 30 2 Land 0.13 Pin protrusion

24 15.9 46 6 Contact

H6

9.7 Ref

The front face of the tip must be in contact with plastic. Cooling is required in the gate area.

Hea ter Style

Band (38 long) Band (51 long)

J Mi n

75 150

J Ma x

149.9 375

Hea ter Qty

1 2

Wa tts/ Vo lts

500W /240V 600W /240V (each)

SR16-24

SR16 Series VG12S Angled Mold Contour

When gating on an angled mold contour the vestige height may be increased depending on the angle. K is the increase in land required to maintain 1.6 wall, 6 wall and/or 4 minimum contact.

R0.13 4.999 5.009 30

0.13

6 Min 2 Land

1.6 Min

E K

4 Min contact

6; K= 0 E = 12TAN

27; K= 4.2TAN

1.6 COS

-2

27; K= 23TAN

- 9.9

E = K + 12TAN

E = K + 12TAN

Angled Mold Contour

SR16-25

SR16 Series Manifold Nozzle

SR16 VG23 Tapered

Filled and unfilled materials. No tip witness mark on part. Heat pipes for isothermal operation. Tapered valve pin to eliminate gate flash.

6 5

15

2 Land

3.9 R0.13 J 120 30

0.13 Pin protrusion

46 R 0.8 R 0.8 1 40

8.46 24 17.4 H6 11.2 Ref 4.5

Cooling is required in the gate area.

Hea ter Style

Band (38 long) Band (51 long)

J Mi n

75 150

J Ma x

149.9 375

Hea ter Qty

1 2

Wa tts/ Vo lts

500W /240V 600W /240V (each)

SR16-26

SR16 Series VG23 Angled Mold Contour

When gating on an angled mold contour the vestige height may be increased depending on the angle. K is the increase in land required to maintain 1.6 wall, 2 wall and/or 6 wall.

15

0.13

R0.13

3.9

2 Land

6 Min

2 Min

6; K= 0

16; K= 4.2TAN

1.6 COS

-2

16; K= 12TAN

2.0 COS

- 4.5

SR16-27

SR16 Series Manifold Nozzle

SR16 VG23S Straight

Filled and unfilled materials. No tip witness mark on part. Heat pipes for isothermal operation. Straight valve pin in gate for nonadjustable actuators and glass filled materials.

6 5

15

0.3 4.999 5.009 R0.13 J 120 30 2 Land 0.13 Pin protrusion

46 R 0.8 R 0.8 1 40

8.46 24 17.4 H6 11.2 Ref 4.5

Cooling is required in the gate area.

Hea ter Style

Band (38 long) Band (51 long)

J Mi n

75 150

J Ma x

149.9 375

Hea ter Qty

1 2

Wa tts/ Vo lts

500W /240V 600W /240V (each)

SR16-28

SR16 Series VG23S Angle Contour

When gating onto an angled mold contour the vestige height may be increased depending on the angle. K is the increase in land required to maintain 1.6 wall, 2 wall and/or 4.0 minimum wall.

R0.13 15

0.13

4.999 5.009

2 Land

1.3 Min

Extension K

8; K= 0 E = 13TAN L = 2 - Orifice Dia. TAN 2

8; K= 4.75TAN E = K + 13TAN

1.3 + COS

-2

L = 2 + K - Orifice Dia. TAN 2

Angled Mold Contour

SR16-29

S-ar putea să vă placă și

- APQP ChecklistDocument18 paginiAPQP ChecklistmichaelbarkovicÎncă nu există evaluări

- TraneDocument33 paginiTranejake1000100% (1)

- Din 17175 PDFDocument22 paginiDin 17175 PDFluap161256Încă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- RTP Design GuideDocument9 paginiRTP Design GuideprasathbalaÎncă nu există evaluări

- VDA FMEA TemplateDocument53 paginiVDA FMEA Templatewatna0% (2)

- Polymer DegradationDocument8 paginiPolymer DegradationFayza SyedÎncă nu există evaluări

- Bar Chart and S-Curve 17rg0113 - SampleDocument1 paginăBar Chart and S-Curve 17rg0113 - SampleRyan Macayan100% (1)

- Fits & TolerancesDocument6 paginiFits & Tolerancessuperman92makÎncă nu există evaluări

- John Crane 502Document6 paginiJohn Crane 502Eh OngÎncă nu există evaluări

- Informations Techniques: Caractéristiques DimensionnellesDocument8 paginiInformations Techniques: Caractéristiques Dimensionnellesanto90kÎncă nu există evaluări

- Pressure Pipe Fittings PDFDocument64 paginiPressure Pipe Fittings PDFmonkeyDivanÎncă nu există evaluări

- Ss 01059 eDocument8 paginiSs 01059 eDavid LapacaÎncă nu există evaluări

- Custom Engineering Part Number: Series Dial SizeDocument2 paginiCustom Engineering Part Number: Series Dial SizeJose Fabio Gamboa BarraganÎncă nu există evaluări

- Technical Data 37 FlaredDocument13 paginiTechnical Data 37 FlaredhernychtÎncă nu există evaluări

- PVC Pipe Flow Chart To Purchase Short Pieces of Rigid PVC Pipe Click HereDocument5 paginiPVC Pipe Flow Chart To Purchase Short Pieces of Rigid PVC Pipe Click HerePooja GolechaÎncă nu există evaluări

- Groth Calaouge 31-05-15Document6 paginiGroth Calaouge 31-05-15Alberto CorticelliÎncă nu există evaluări

- 15-74 Hot Taps 100622Document4 pagini15-74 Hot Taps 100622SL24980Încă nu există evaluări

- 7721 Tee Mecanica Rosc Marca Americana Shurjoint TycoDocument3 pagini7721 Tee Mecanica Rosc Marca Americana Shurjoint TycoDavid EnríquezÎncă nu există evaluări

- Tescom Series 44-2200Document2 paginiTescom Series 44-2200liamcsÎncă nu există evaluări

- V SeguridadDocument8 paginiV SeguridadARJONA_JGÎncă nu există evaluări

- Roberts Oxygen Welding Industrial Catalog 2011Document104 paginiRoberts Oxygen Welding Industrial Catalog 2011sanjibkrjanaÎncă nu există evaluări

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDocument6 paginiElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkÎncă nu există evaluări

- SS2 Agv200 0300 01Document12 paginiSS2 Agv200 0300 01RaymondIlyasÎncă nu există evaluări

- 015 Pipe Flanges Schedule 40Document4 pagini015 Pipe Flanges Schedule 40MOHAMMAD ASIFÎncă nu există evaluări

- Especificaciones Tecnicas DezurikDocument24 paginiEspecificaciones Tecnicas DezurikdieferjimenezÎncă nu există evaluări

- Flowmeter DatasheetDocument8 paginiFlowmeter DatasheetBhoopendra SinghÎncă nu există evaluări

- Example Vessel Re RatingDocument9 paginiExample Vessel Re RatingRBKUMARÎncă nu există evaluări

- En10028 2Document12 paginiEn10028 2Patilea Daniela100% (1)

- Odular YPE A F S AF: IR Ilter EriesDocument9 paginiOdular YPE A F S AF: IR Ilter ErieshadeÎncă nu există evaluări

- Antamount: Vishay SpragueDocument22 paginiAntamount: Vishay SpraguemohamedÎncă nu există evaluări

- Shurjoint Acople de TransiciónDocument2 paginiShurjoint Acople de TransiciónRoger Cuipal PereaÎncă nu există evaluări

- Catalogo - Cilindros Hidraulicos VEGADocument24 paginiCatalogo - Cilindros Hidraulicos VEGARaul Izquierdo MoralesÎncă nu există evaluări

- Sandvik 316 Plate, Sheet and CoilDocument2 paginiSandvik 316 Plate, Sheet and CoilJesús Leal CarvajalinoÎncă nu există evaluări

- AE AccessoriesDocument16 paginiAE AccessoriesmisaelzaÎncă nu există evaluări

- Gate Valve CataogueDocument4 paginiGate Valve CataogueAditya B. RyantoÎncă nu există evaluări

- TG-73, DS - TM7301 - en - Co - 2146Document15 paginiTG-73, DS - TM7301 - en - Co - 2146Paulkumar RamaiahÎncă nu există evaluări

- Stainless Steel Seamless TubingDocument2 paginiStainless Steel Seamless Tubingtoxa0707Încă nu există evaluări

- Jack HammerDocument60 paginiJack HammerDanudear DanielÎncă nu există evaluări

- Dezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bDocument24 paginiDezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bjasonlaiymÎncă nu există evaluări

- Astm A228Document2 paginiAstm A228Rakesh S IndiaÎncă nu există evaluări

- Jaw Crusher 2013Document8 paginiJaw Crusher 2013dexsaÎncă nu există evaluări

- Principle of Operation: Target Inline FlowmeterDocument7 paginiPrinciple of Operation: Target Inline Flowmeterابزار دقیقÎncă nu există evaluări

- Vitomax 200HSDocument14 paginiVitomax 200HSDamir ĆavarÎncă nu există evaluări

- Wevic 0001 enDocument5 paginiWevic 0001 enamekkehÎncă nu există evaluări

- Boq - HotelDocument8 paginiBoq - HotelTiffany CombsÎncă nu există evaluări

- Din 2095Document42 paginiDin 2095Eduardo ValenciaÎncă nu există evaluări

- RMG by Honeywell BD 277 Hi-Flo GB 2010-10Document8 paginiRMG by Honeywell BD 277 Hi-Flo GB 2010-10Jorge Henostroza IntiÎncă nu există evaluări

- A3a Specs Eil PDFDocument7 paginiA3a Specs Eil PDFAlvin Smith100% (2)

- BPE Technical DataDocument5 paginiBPE Technical Datasmtamaskar2277Încă nu există evaluări

- Style 77 Standard Flexible Coupling: Product DescriptionDocument0 paginiStyle 77 Standard Flexible Coupling: Product DescriptionAnibal MoralesÎncă nu există evaluări

- Pressure Pipe FittingsDocument52 paginiPressure Pipe FittingslissandovalÎncă nu există evaluări

- Rexworth Hydraulic MotorDocument28 paginiRexworth Hydraulic MotorSorin-Adrian Learschi100% (1)

- Jis G4051Document7 paginiJis G4051tnchsgÎncă nu există evaluări

- Rubberexp ConnectallDocument6 paginiRubberexp ConnectallThaiminh VoÎncă nu există evaluări

- Plate Boiler A516 Grade 70 Datasheet PDF Beyond-SteelDocument2 paginiPlate Boiler A516 Grade 70 Datasheet PDF Beyond-SteelMugiyonoÎncă nu există evaluări

- Style 808 Duo-Lock High Pressure Coupling: Product DescriptionDocument2 paginiStyle 808 Duo-Lock High Pressure Coupling: Product Descriptionnrd9771Încă nu există evaluări

- FT MedPress AutoclaveDocument12 paginiFT MedPress AutoclaveAymeeenÎncă nu există evaluări

- 4410 - Section E - Technical PDFDocument45 pagini4410 - Section E - Technical PDFArnaldo BenitezÎncă nu există evaluări

- Dimargrow ManometrosDocument75 paginiDimargrow ManometrosStalinÎncă nu există evaluări

- AccuDraw - 2006 - CDNPLDocument16 paginiAccuDraw - 2006 - CDNPLJulio CésarÎncă nu există evaluări

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDe la EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryÎncă nu există evaluări

- Pose 100Document16 paginiPose 100watnaÎncă nu există evaluări

- Alphard (Chassis) IndDocument70 paginiAlphard (Chassis) Indwatna100% (2)

- PA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66Document2 paginiPA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66watnaÎncă nu există evaluări

- AutomotiveDocument2 paginiAutomotivewatnaÎncă nu există evaluări

- Vortex TubesDocument10 paginiVortex TubeswatnaÎncă nu există evaluări

- Zytel (TM) HTN Moulding GuideDocument20 paginiZytel (TM) HTN Moulding GuidewatnaÎncă nu există evaluări

- Zytel (TM) HTN Moulding GuideDocument20 paginiZytel (TM) HTN Moulding GuidewatnaÎncă nu există evaluări

- Ths 2Document24 paginiThs 2gabi18051991Încă nu există evaluări

- Tech Span GroupDocument14 paginiTech Span GroupwatnaÎncă nu există evaluări

- IMM BR IR enDocument13 paginiIMM BR IR enwatnaÎncă nu există evaluări

- Measure Example Auto KTDocument8 paginiMeasure Example Auto KTwatnaÎncă nu există evaluări

- Why Water Assisted Injection MouldingDocument43 paginiWhy Water Assisted Injection MouldingwatnaÎncă nu există evaluări

- Radiator 01Document1 paginăRadiator 01watnaÎncă nu există evaluări

- Apqp PpapDocument50 paginiApqp PpapEvandro Ribeiro50% (2)

- MazegetDocument73 paginiMazegetwatnaÎncă nu există evaluări

- ArtiosCAD UsDocument4 paginiArtiosCAD Uswatna100% (1)

- FMEA Risk ManagementDocument64 paginiFMEA Risk ManagementAbhishek Singh TomarÎncă nu există evaluări

- CMTP Light Duty Domestic1Document1 paginăCMTP Light Duty Domestic1watnaÎncă nu există evaluări

- TTP-244p User Manual EDocument37 paginiTTP-244p User Manual EwatnaÎncă nu există evaluări

- Measure Example Auto KTDocument8 paginiMeasure Example Auto KTwatnaÎncă nu există evaluări

- CMTP Heavy Duty Domestic1Document1 paginăCMTP Heavy Duty Domestic1watnaÎncă nu există evaluări

- Tool Steel Comparison ChartDocument1 paginăTool Steel Comparison ChartSree Raj75% (4)

- NX7 ManualDocument232 paginiNX7 ManualArun SreedharÎncă nu există evaluări

- CX-One R134Document24 paginiCX-One R134watnaÎncă nu există evaluări

- 2012 Cleaning MaintenanceDocument33 pagini2012 Cleaning MaintenancewatnaÎncă nu există evaluări

- How To Select Plastic Injection Moulding MachineDocument48 paginiHow To Select Plastic Injection Moulding MachineDiego Sáchica60% (5)

- BS 5911-230-1994Document19 paginiBS 5911-230-1994laurentiuÎncă nu există evaluări

- Plumbing GlossaryDocument45 paginiPlumbing GlossarydonvantuongÎncă nu există evaluări

- Grey Iron A Unique MaterialDocument13 paginiGrey Iron A Unique MaterialmetkarthikÎncă nu există evaluări

- Deluxe Test Probe Kit Assembly Instruction by KK4HXJ - RevisedDocument6 paginiDeluxe Test Probe Kit Assembly Instruction by KK4HXJ - ReviseddonsterthemonsterÎncă nu există evaluări

- Portland Cement: Wednesday, March 25, 2015Document35 paginiPortland Cement: Wednesday, March 25, 2015EFRA BINIÎncă nu există evaluări

- ZCP Mu13947 PDFDocument36 paginiZCP Mu13947 PDFsugirinÎncă nu există evaluări

- Processing of Aerospace Materials - I (ME772) : Fracture Toughness and High Cycle Fatigue Date: 11 January 2022Document23 paginiProcessing of Aerospace Materials - I (ME772) : Fracture Toughness and High Cycle Fatigue Date: 11 January 2022B RITHIKAÎncă nu există evaluări

- 50ucupv PSD enDocument58 pagini50ucupv PSD enMohd AzharÎncă nu există evaluări

- Exergy AnalysisDocument58 paginiExergy Analysismohammed yaseenÎncă nu există evaluări

- Tran Cor H PDFDocument37 paginiTran Cor H PDFFernando Moreira LagosÎncă nu există evaluări

- Group Action of PilesDocument19 paginiGroup Action of PilesRachit Khandelwal0% (1)

- AssII 466Document2 paginiAssII 466Amr TawfikÎncă nu există evaluări

- Names of All Materials WRT ASTM No.Document6 paginiNames of All Materials WRT ASTM No.روشان فاطمة روشانÎncă nu există evaluări

- DVM S Technical Bulletins - DVM S System Refrigerant Pump Down Guideline PDFDocument2 paginiDVM S Technical Bulletins - DVM S System Refrigerant Pump Down Guideline PDFDavid AlmeidaÎncă nu există evaluări

- MWA Airfoil BrochureDocument2 paginiMWA Airfoil BrochureDanÎncă nu există evaluări

- ProductCatalogue en 2020 Web EmailDocument57 paginiProductCatalogue en 2020 Web EmailAlexandru NeatuÎncă nu există evaluări

- Corrotherm International Brochure 2019Document8 paginiCorrotherm International Brochure 2019colourhutÎncă nu există evaluări

- ALTECH PE-HD A 2010/506 GF10: Technical Data SheetDocument2 paginiALTECH PE-HD A 2010/506 GF10: Technical Data SheetPhung LucÎncă nu există evaluări

- BME301 - Material Engineering Notes - 2023 - 24Document15 paginiBME301 - Material Engineering Notes - 2023 - 24kec.abhishek463Încă nu există evaluări

- Merge From Ofoct (4) CompressedDocument38 paginiMerge From Ofoct (4) CompressedKalyani ingoleÎncă nu există evaluări

- Heat PumpsDocument317 paginiHeat PumpsDiana SoareÎncă nu există evaluări

- Dev. 9-Garden and Landscape.: DescriptionDocument9 paginiDev. 9-Garden and Landscape.: DescriptionrafabdÎncă nu există evaluări

- Product Information F737 OberonDocument2 paginiProduct Information F737 OberonCosmic TitusÎncă nu există evaluări

- Fluid Mechanics PDFDocument73 paginiFluid Mechanics PDFSanjan KSÎncă nu există evaluări

- 02 Req App 01 Drawing & SpecificationDocument4 pagini02 Req App 01 Drawing & Specificationjaimejulio69Încă nu există evaluări

- Avtl 104 Instructions For UseDocument72 paginiAvtl 104 Instructions For Usechirayus_3Încă nu există evaluări

- CH 02 Load EstimationDocument19 paginiCH 02 Load EstimationMuhammed FekryÎncă nu există evaluări

- Polystone P Homopolymer: Technical Data SheetDocument1 paginăPolystone P Homopolymer: Technical Data Sheetmuchamad yasinÎncă nu există evaluări