Documente Academic

Documente Profesional

Documente Cultură

1,5P

Încărcat de

20070705Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1,5P

Încărcat de

20070705Drepturi de autor:

Formate disponibile

TRAINING REPORT

Name: CAO VN T E.code: 20122665 Department: PE Position: Engineer Date join HOGV: 25/6/2012 Report Date: 30/6/2012 Subject: 1,5P Process (First Polishing Process) Object: Comprehension of flow and process in 1,5P process 1, Purpose: Polishing surface of disks to make them very smooth and flat, increase flatness, parallel and remove waviness. 2, Principle: Using slurry and force of pads with pressure to polish surface of disks. Movement of disk and joban (pad) is rotation. The direction rotation of two pads is opposite.

Pads

Input disk

Force

Slurry

Output disk

Before and after the process, disks are kept in water to prevent dust and chemical on

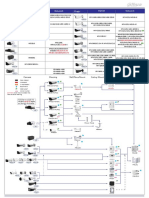

surface of them. 3, Flow: Machine Cleaning Machine Dressing Change slurry

At batch 1

Receive disks from EP QC check thickness before (1 disk/batch)

Re-polishing

Polishing

Shower NG thickness QC check thickness after (1 disk/batch) Cleaning 2P NG thin

Put in Bin 4, Machine: 4.1 Machine

Including two joban, pad is pasted on surface of joban. Jobans are cooled in the polishing process , otherwise heating producing will make uneven pads. Tempature of coolant solution in jobans are 17oC in VA and 15oC in VB, that of out jobans are 20oC in VA and 26oC in VB.

Pad: NP 515, pad life: 70 hours. Having carrier to contain disks. 100 disks are polished each process. Weight: 480 kg, rpm: 18/12

P time = ( thickness before thickness target) / Polishing rate setting batch 1. Now Prate setting = 0.00120 mm / min = 1.2 um/ min. After polishing batch 1:P time = Prate (n)

actual rate

= (thickness before thickness after)/ Polishing

Batches after: Polishing time(n+1) = (thickness before thickness target) / Prate(n) Pads are dressed by dressers. Carriers contain the dressers. Having 2 kinds of dresser are D325 and D600. Principle dressing process is similar to polishing process but slurry is not used and having difference about polishing time. D325 dresser is used for new pad and pad life which is larger than 30 hours.

4.2, Slurry: Recipe: compound of TE98 and RO VA: 1.6 kg TE98 + 11 kg RO + 12 g add A + 12 g add B. VB: 1.8 kg TE98 + 11 kg RO + 14 g add A + 14 g add B. Slurry life: after 13 batches.

5, Important Data Thickness Flatness : Waviness Parallel : machine

6, Defect:

Broken, crack, chip, defects due to collision of disk, carrier, pads. polishing machines are cleaned more frequently.

To prevent bad effects of dust, disks in this process are sunk into water, and

S-ar putea să vă placă și

- Drilling Problems Prevention and Remedial ActionDocument54 paginiDrilling Problems Prevention and Remedial Actiongeraroooooo100% (1)

- Ball Mill OptimizationDocument82 paginiBall Mill OptimizationRashek_119588% (16)

- Rotary Vacuum Drum Filter DesignDocument34 paginiRotary Vacuum Drum Filter Designksharma294Încă nu există evaluări

- G 26 Building Using ETABS 1673077361Document68 paginiG 26 Building Using ETABS 1673077361md hussainÎncă nu există evaluări

- Hi - Temp 900Document5 paginiHi - Temp 900bhavesh solankiÎncă nu există evaluări

- The Fabrication of Materials: Materials TechnologyDe la EverandThe Fabrication of Materials: Materials TechnologyEvaluare: 5 din 5 stele5/5 (1)

- Symbols For Signalling Circuit DiagramsDocument27 paginiSymbols For Signalling Circuit DiagramsrobievÎncă nu există evaluări

- Casting Technology: DC School Text BookDocument22 paginiCasting Technology: DC School Text BookTrang Anh ToànÎncă nu există evaluări

- Meat & Potatoes of Plastic Injection Moulding, Explanation & Guides TroubleshootingDe la EverandMeat & Potatoes of Plastic Injection Moulding, Explanation & Guides TroubleshootingÎncă nu există evaluări

- POWER PLANT MAINTENANCE EQUIPMENT CLEANINGDocument25 paginiPOWER PLANT MAINTENANCE EQUIPMENT CLEANINGMariusDragoescuÎncă nu există evaluări

- Proses Pembuatan KertasDocument124 paginiProses Pembuatan Kertasgarispante07100% (7)

- Pro-Coat Case StudyDocument6 paginiPro-Coat Case StudyKaranPahawaÎncă nu există evaluări

- Work Process Assessment PresentationDocument12 paginiWork Process Assessment PresentationOmkar ManapureÎncă nu există evaluări

- Episode:: Sajjad Khudhur Abbas Ceo, Founder & Head of AcademyDocument34 paginiEpisode:: Sajjad Khudhur Abbas Ceo, Founder & Head of Academyjigneshprajapati2029Încă nu există evaluări

- Exam Paper Format Tech.Document8 paginiExam Paper Format Tech.shashi100% (1)

- Final Mill Tariniggng ReportDocument53 paginiFinal Mill Tariniggng ReportPriyanka VishnoiÎncă nu există evaluări

- Civil & Environmental Engineering Lab Consolidation TestDocument14 paginiCivil & Environmental Engineering Lab Consolidation TestSapria AdiÎncă nu există evaluări

- Apch312 Practical 3Document10 paginiApch312 Practical 3phiwayinkosi PwaÎncă nu există evaluări

- Internal Mixer Desin Lab Ex 1Document9 paginiInternal Mixer Desin Lab Ex 1tabish mirajÎncă nu există evaluări

- Atish Vishwas Supekar 5Document21 paginiAtish Vishwas Supekar 5Sudhanshu ShekharÎncă nu există evaluări

- Compression Lab ReportDocument8 paginiCompression Lab ReportfatinzalilaÎncă nu există evaluări

- En20424282 - Dilakshi HKHT - Sand ConeDocument15 paginiEn20424282 - Dilakshi HKHT - Sand ConehirushiÎncă nu există evaluări

- 1.1 Palm Oil MillDocument31 pagini1.1 Palm Oil MillChee Yen ChiaÎncă nu există evaluări

- Fire Proofing - ChartekDocument37 paginiFire Proofing - ChartekOsama KheadryÎncă nu există evaluări

- ForgingDocument4 paginiForgingIbraheem KhressÎncă nu există evaluări

- Drying ProcessDocument17 paginiDrying Processsiti irdinaÎncă nu există evaluări

- Work Instruction of Workability Test of Concrete (Slump)Document1 paginăWork Instruction of Workability Test of Concrete (Slump)Biplab dattaÎncă nu există evaluări

- Sigmazinc 158Document6 paginiSigmazinc 158EngineeringTopChannelÎncă nu există evaluări

- To Be PrintedDocument91 paginiTo Be PrintedPreet Inder SinghÎncă nu există evaluări

- Scotch KoteDocument4 paginiScotch KoteJavier Gomez ReyesÎncă nu există evaluări

- Sigmacover 280 (Primer) For HDG SurfaceDocument6 paginiSigmacover 280 (Primer) For HDG SurfaceRauf AliyevÎncă nu există evaluări

- G217 Resin Instruction Aa1f7b2a c036 45a5 A5e8 A50accffcae6Document4 paginiG217 Resin Instruction Aa1f7b2a c036 45a5 A5e8 A50accffcae6a.ntaflosÎncă nu există evaluări

- Dr.N.G.P. Institute Lean Manufacturing CourseDocument22 paginiDr.N.G.P. Institute Lean Manufacturing Coursevasanthmech092664Încă nu există evaluări

- Injection MoldingDocument17 paginiInjection MoldingAnoj pahathkumburaÎncă nu există evaluări

- BST 110 Cube TestDocument13 paginiBST 110 Cube Test2022624672Încă nu există evaluări

- Slide TSP308 TSP 308 005 Metoda Dan Peralatan KonstruksiDocument29 paginiSlide TSP308 TSP 308 005 Metoda Dan Peralatan KonstruksiMOHD SALMANÎncă nu există evaluări

- PPG Hi-Temp™ 500Document6 paginiPPG Hi-Temp™ 500Marleo MorenoÎncă nu există evaluări

- Jazeera Epo-Mortar NBDocument3 paginiJazeera Epo-Mortar NBAhmad BougeisÎncă nu există evaluări

- Kodak, Single-Use Chemistry Kit, ProcessDocument8 paginiKodak, Single-Use Chemistry Kit, ProcessErden Sizgek100% (2)

- Laboratory Report: PTT 366 / Polymer Processing TechnologyDocument7 paginiLaboratory Report: PTT 366 / Polymer Processing TechnologyDKÎncă nu există evaluări

- High Strength Epoxy Floor CoatingDocument3 paginiHigh Strength Epoxy Floor CoatingAhmad BougeisÎncă nu există evaluări

- Trial Mixing ConcreteDocument12 paginiTrial Mixing Concreteen21447648 Perera W.P.D.UÎncă nu există evaluări

- Extrusion of Tape Draft 2Document6 paginiExtrusion of Tape Draft 2CiaraÎncă nu există evaluări

- Experiment 5Document9 paginiExperiment 5kang1995100% (1)

- Buffing Process in ManufacturingDocument4 paginiBuffing Process in ManufacturingParmar DivyangÎncă nu există evaluări

- Pickling Work InstructionDocument1 paginăPickling Work InstructionmanesarkarÎncă nu există evaluări

- Lab 1 Report Material ScienceDocument10 paginiLab 1 Report Material ScienceLEKA THOBEJANEÎncă nu există evaluări

- Sigmafast 278Document6 paginiSigmafast 278stolemkd3Încă nu există evaluări

- Zinc Primer Product Data SheetDocument7 paginiZinc Primer Product Data Sheethk168Încă nu există evaluări

- 221021 Peel Off 불량 개선 대책 (Hab Dong)Document4 pagini221021 Peel Off 불량 개선 대책 (Hab Dong)luthfi ppicÎncă nu există evaluări

- Internship ReportDocument24 paginiInternship ReportSumaiya AltafÎncă nu există evaluări

- Dayanand Tiwari@$Document15 paginiDayanand Tiwari@$Navdeep SinghÎncă nu există evaluări

- Optimizing The Performance of Rotary Disc FilterDocument13 paginiOptimizing The Performance of Rotary Disc FilterMohammad Rizki FebriantoÎncă nu există evaluări

- TDS - Jotamastic 87 - English (Uk) - Issued.21.12.2011 PDFDocument5 paginiTDS - Jotamastic 87 - English (Uk) - Issued.21.12.2011 PDFNPTÎncă nu există evaluări

- Worksheet: Diploma in Mechanical EngineeringDocument13 paginiWorksheet: Diploma in Mechanical EngineeringGuna SelanÎncă nu există evaluări

- Liquid Epoxy Coating (3M)Document5 paginiLiquid Epoxy Coating (3M)Thamaraikani ManiÎncă nu există evaluări

- PURGING SYSTEM 2 - DUPONT Disco - Purge - ProcedureDocument6 paginiPURGING SYSTEM 2 - DUPONT Disco - Purge - ProcedureGunawan SasmitoÎncă nu există evaluări

- Activity No. 1 PCB ETCHING AND ENGRAVINGDocument4 paginiActivity No. 1 PCB ETCHING AND ENGRAVINGADRIAN GABRIEL DIAZÎncă nu există evaluări

- Experiment 3 (BFL)Document7 paginiExperiment 3 (BFL)wajahat rasoolÎncă nu există evaluări

- Al Mgreport (NagasakiUniversity)Document36 paginiAl Mgreport (NagasakiUniversity)huychungngÎncă nu există evaluări

- Design of CPP Manufacturing Plant and Study its DefectsDocument49 paginiDesign of CPP Manufacturing Plant and Study its DefectsAbdullah AbbasÎncă nu există evaluări

- Physics SyllabusDocument85 paginiPhysics Syllabusalex demskoyÎncă nu există evaluări

- Vincent Hoa's English 101 PortfolioDocument24 paginiVincent Hoa's English 101 PortfoliovincentÎncă nu există evaluări

- History: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHDocument3 paginiHistory: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHPatrizio MassaroÎncă nu există evaluări

- Unit 4.2Document45 paginiUnit 4.2Gundrathi Narendra GoudÎncă nu există evaluări

- Bajaj Auto Company NewDocument94 paginiBajaj Auto Company Newbhas_786Încă nu există evaluări

- 9701 s12 QP 11 PDFDocument16 pagini9701 s12 QP 11 PDFHubbak KhanÎncă nu există evaluări

- Elements of Plane and Spherical Trigonometry With Numerous Practical Problems - Horatio N. RobinsonDocument228 paginiElements of Plane and Spherical Trigonometry With Numerous Practical Problems - Horatio N. RobinsonjorgeÎncă nu există evaluări

- 3 Variable Cramers Rule PDFDocument4 pagini3 Variable Cramers Rule PDFElton DiocsonÎncă nu există evaluări

- Khasi Community of MeghalayaDocument3 paginiKhasi Community of MeghalayaMidhat FatimaÎncă nu există evaluări

- Mahle KFWA MAIN Data SheetDocument4 paginiMahle KFWA MAIN Data SheetRudnikÎncă nu există evaluări

- ME 2141 - Complete ModuleDocument114 paginiME 2141 - Complete ModuleNICOLE ANN MARCELINOÎncă nu există evaluări

- 841 Specific GravityDocument1 pagină841 Specific GravityJam SkyÎncă nu există evaluări

- Kingspan Spectrum™: Premium Organic Coating SystemDocument4 paginiKingspan Spectrum™: Premium Organic Coating SystemNikolaÎncă nu există evaluări

- Weber Grills - FinalDocument12 paginiWeber Grills - FinalDIVYANSHU SHEKHARÎncă nu există evaluări

- The Baptismal Liturgy in The Easter Vigil According To The Sacramentary of Fulda (10th Century)Document7 paginiThe Baptismal Liturgy in The Easter Vigil According To The Sacramentary of Fulda (10th Century)Henry DonascoÎncă nu există evaluări

- Time and Work Assignments PDFDocument8 paginiTime and Work Assignments PDFpavan0% (1)

- Tipologie Break in OutDocument17 paginiTipologie Break in OutGiorgio FantauzziÎncă nu există evaluări

- Ub40 LyricsDocument76 paginiUb40 LyricsJose Lucio Flores SantosÎncă nu există evaluări

- r32 - Rb26dett Ecu PinoutDocument1 paginăr32 - Rb26dett Ecu PinouttospotÎncă nu există evaluări

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocument5 paginiDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakÎncă nu există evaluări

- Schaeffler - Account Insights - Mar 2020Document13 paginiSchaeffler - Account Insights - Mar 2020mohit negiÎncă nu există evaluări

- The Creators College of Science & Commerce: 1 TermDocument2 paginiThe Creators College of Science & Commerce: 1 TermJhangir Awan33% (3)

- Presentation 123Document13 paginiPresentation 123Harishitha ManivannanÎncă nu există evaluări

- BiologyDocument21 paginiBiologyHrituraj banikÎncă nu există evaluări

- Products and Services For Consumers: True / False QuestionsDocument65 paginiProducts and Services For Consumers: True / False QuestionsThúy HiềnÎncă nu există evaluări

- Chapter 1Document33 paginiChapter 1Salihah AbdullahÎncă nu există evaluări

- REMEDIATION-Focus BDocument13 paginiREMEDIATION-Focus BCharmaine PerioÎncă nu există evaluări

- National Gypsum Purple Book Fire Rated Assemblies in Commercial Construction 1189979Document106 paginiNational Gypsum Purple Book Fire Rated Assemblies in Commercial Construction 1189979alvychuÎncă nu există evaluări