Documente Academic

Documente Profesional

Documente Cultură

HPLC Troubleshooting Guide

Încărcat de

Naresh BabuDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

HPLC Troubleshooting Guide

Încărcat de

Naresh BabuDrepturi de autor:

Formate disponibile

HPLC troubleshooting Guide

Email Related links: Cleaning Dirty columns Changing column Frit

Column leaks, Retention time, Back pressure, peaks and baseline problems

Click to jump to the relevant info :

Leaks Retention times Baseline Pressure Peaks

Start up - Preliminary checks

Problem Possible cause Detector off No peaks or very small peaks Check detector Broken connections Check connections to recorder No sample/Wrong sample Check sample. Be sure it is not deteriorated. Check for bubbles in the vials Solution

Wrong settings on Check attenuation. Check gain recorder or detector Pump off Flow interrupted No Flow Leak Air trapped in the system Start Pump Check reservoirs. Check position of the inlet tubing. Check loop for obstruction or air. Check degasing of mobile phase. Check compatibility of the mobile phase components. Check fittings. Check pump for leaks and precipitates. Check pump seals. Disconnect column and prime pump. Flush system with 100% methanol or isopropanol. Contact servicing if necessary.

Column and Fittings Leaks

Problem Column end leaks

Possible cause Loose fitting White powder at loose fitting

Solution Tighten or replace fitting Cut tubing and replace ferrule; disassemble fitting, rinse and reassemble.

Leak at detector Detector-seal failure Replace detector seal or gaskets. Leak at injection Worn or scratched valve valve rotor Leak at pump Pump seal failure Replace valve rotor Replace pump seal; check piston for scratches and, if necessary, replace

Change in Retention time

Problem Possible cause Buffer retention times Contamination buildup Solution Use buffer with concentration greater than 20 mM. Flush column occasionally with strong solvent

Equilibration time Pass at least 10 column volumes insufficient for gradient run through the column for gradient or changes in isocratic mobile regeneration or after solvent changes phase Changing Retention Times First few injections - active sites Inconsistent on-line mobilephase mixing Selective evaporation of mobile-phase component Varying column temperature Condition column by injecting concentrated sample Ensure gradient system is delivering a constant composition; compare with manually prepared mobile phase; partially premix mobile phase Cover solvent reservoirs; use lessvigorous helium purging; prepare fresh mobile phase Thermostat or insulate column; ensure laboratory temperature is constant. Use mobil-phase modifier, competing base (basic compounds), or increase buffer strength; use higher coverage column packing. Decrease sample amount or use larger-diameter column.

Decreasing Retention Times

Active sites on column packing Column overloaded with sample

Increasing flow rate Loss of bonded stationary phase or base silica Varying column temperature

Check and reset pump flow rate. Use mobile-phase pH between pH 2 and pH 8 Thermostat or insulate column; ensure laboratory temperature is constant Check and reset pump flow rate; check for pump cavitation; check for leaking pump seals and other leaks in system Cover solvent reservoirs; ensure that gradient system is delivering correct composition. Use mobile-phase pH between pH 2 and pH 8 Use ion-pairing reagent with shorter alkyl chain length

Decreasing flow rate Increasing Retention Times

Changing mobile-phase composition Loss of bonded stationary phase

Slow column equilibration time

Reversed phase ion pairing long chain ion pairing reagents require longer equilibration time

Baseline

Problem Possible cause Air bubbles in mobile phase Void Time noise Positive-negative difference in refractive index of injection solvent and mobile phase Solution Degas or use back pressure restricor on detector Normal with many samples; use mobile phase as sample solvent

Use non-UV absorbing mobile phase Negative direction (gradient solvents; use HPLC grade mobile phase elution) - absorbance of solvents; add UV absorbing compound to mobile-phase A mobile phase B. Drifting baseline Positive direction (gradient elution) - absorbance of mobile phase B Positive direction contamination buildup and Use higher UV absorbance detector wavelength; use non-UV absorbing mobile phase solvents; use HPLC grade mobile phase solvents; add UV absorbing compound to modile phase A. Flush column with strong solvent; clean up sample; use HPLC grade solvents

elution Wavy or undulating temperature changes in room Continous - detector lamp problem or dirty cell Gradient or isocratic proportioning - lack of solvent mixing Gradient or isocratic proportioning malfunctioning proportioning valvesl Baseline noise Occasional sharp spikes external electrical interference Periodic - pump pulses Random - contamination buildup Spikes - bubble in detector Spikes - column temperature higher than boiling point of solvent Monitor and control changes in room temperature; insulate column or use column oven; cover refractive index detector and keep it out of air currents. Replace UV lamp( each should last 2000 h; clean and flush flow cell. Use proper mixing device; check proportioning precision by spiking one solvent with UV absorbing compound and mointor UV absorbance detector outputl. Clean or replace proportioning precision valves; partially remix solventsl. Use voltage stabilizer for LC system; use independent electrical circuit. Service or replace pulse damper; purge air from pump; clean or replace check valves. Flush column with strong solvent; clean up sample; use HPLC grade solvent Degas mobile phase; use back pressure restrictor at detector outlet. Use lower column temperature.

Pressure

Problem Possible cause Insufficient flow from pump Solution Loosen cap on mobile phase reservior

Decreasing Pressure

Leak in hydralic lines from pump to Tighten or replace fittings; tighten column rotor in injection valve Leaking pump check valve or seals Pump cavitation Replace or clean check valves; replace pump seals. Degas solvent; check for obstruction in line from solvent

reservoir to pump; replace inlet-line frit Fluctuating pressurre Bubble in pump Leaking pump check valve or seals Column blocked wth irreversibly adorbed sample Column particle size too small (for example 3 micrometers) Degas solvent; purge solvent with helium Replace or clean check valves; replace pump seals Improve sample cleanup; use guard column; reverse-flush column with strong solvent to dissolve blockage Use larger particle size (for example 5 micrometer) Use at least 10% organic modifier in mobile phase; use fresh buffer daily; add 0.02% sodium azide to aqueous mobile phase; store column in at least 25% organic solvent without buffer Use lower viscosity solvents or higher temperature

Microbial growth on column

Mobile phase viscosity too high

High Back Pressure

Plugged frit in in-line filter or guard Replace frit or guard column column Plugged inlet frit Replace endfitting or frit assembly Use correct solvent with column; change to proper solvent compositionl consult manufacturer's solventcompatibility chartl use a column with a higher percentage of crosslinking Ensure mobile phase compatibility with buffer concentration; decrease ionic strength and water-organic solvent ratio; premix mobile phase Clean injector or replace rotor Systematically disconnect components from detector end to column end to find blockage; replace or clean blocked component

Polymetric columns - solvent change causes swelling of packing

Salt precipitation (especially in reversed-phase chromatography with high concentration of organic solvent in mobile phase) concentration of organic solvent in mobile phase) When injector disconnected from column - blockage in injector Increasing Pressure Blocked flow lines

Particulate buildup at head of column Water-organic solvent systems buffer precipitation

Filter sample; use .5 micrometer inline filter; disconnect and backflush column; replace inlet frit Ensure mobile phase compatibility with buffer concentration; decrease ionic strength or water organic solvent ratio

Peaks

Problem Possible cause Solution

Analytes eluted early due Dilute sample 1:10 and reinject to sample overload Use smallest possible cell volume consistent Detector-cell volume too with sensitivity needs; use detector with no large heat exchanger in system Injection volume too large Large extra column volume Mobile-phase solvent viscosity too high Broad peaks Peak dispersion in injector valve Poor column efficiency Retention time too long Sampling rate of data system too low Slow detector time constant Some peaks broad - late elution of analytes retained from previous injection Decrease solvent strength of injection solvent to focus solute; inject smaller volume Use low- or zero-dead-volume endfittings and connectors; use smallest possible diameter of connecting tubing (<0.10 in. i.d.); connect tubing with matched fittings Increase column temperature; change to lower viscosity solvent Decrease injector sample loop size; introduce air bubble in front and back of sample in loop Use smaller-particle-diameter packing, lowerviscosity mobile phase, higher column temperature, or lower flow rate Use gradient elution or stronger isocratic mobile phase Increase sampling frequency. Adjust time constant to match peak width Flush column with strong solvent at end of run; end gradient at higher solvent concentration

Contamination Elution of analytes retained from previous injection

Flush column to remove contaminatint; use HPLC-grade solven Flush column with strong solvent at end of run; end gradient at higher solvent concentration

Ion-pair chromatography Prepare sample in mobile phase; reduce - upset equilibrium injection volume Ghost peaks Oxidation of trifluoroacetic acid in peptide mapping Reversed-phase chromatography contaminated water Prepare trifluoroacetic acid solutions fresh daily; use antioxidant Check suitability of water by running different amounts through column and measure peak height of interferences as function of enrichment time; clean water by running it through old reversed-phase column; use HPLC-grade water.

Unknown interferences in Use sample cleanup or prefractionation before sample injection. Refractive index detection - refractive index of solute less than that of mobile phase Reverse polarity to make peak positive

Negative peaks

UV-absorbance detection Use mobile phase with lower UV absorbance; - absorbance of solute if recycling solvent, stop recycling when less than that of mobile recycled solvent affects detection phase Replace or clean frit; install 0.5-um porosity in-line filter between pump and injector to eliminate mobile-phase contaminants or between injector and column to eliminate sample contaminants Use sample cleanup or prefractionation; adjust selectivity by changing mobile or stationary phase

Blocked Frit

Peak Doubling

Coelution of interfering compound

Coelution of interfering Flush column with strong solvent at end of ran; compound from previous end gradient at higher solvent concentration injection Column overloaded Column void or channeling Use higher-capacity stationary phase; increase column diameter; decrease sample amount Replace column, or, if possible, open top endfitting and clean and fill void with glass

beads or same column packing; repack column Injection solvent too strong Use weaker injection solvent or stronger mobile phase

Use injection volume equal to one-sixth of Sample volume too large column volume when sample prepared in mobile phase for injection Unswept injector flow path Peak Fronting Channeling in column Column overloaded Basic solutes - silanol interactions Beginning of peak doubling Chelating solutes - trace metals in base silica Replace injector rotor Replace or repack column Use higher-capacity stationary phase; increase column diameter; decrease sample amount Use competing base such as triethylamine; use a stronger mobile phase; use base-deactivated silica-based reversed-phase column; use polymeric column See peak doubling Use high purity silica-based column with low trace-metal content; add EDTA or chelating compound to mobile phase; use polymeric column Use polymeric, sterically protected, or highcoverage reversed-phase column; install silica gel saturatorcolumn between pump and injector Reduce temperature to less than 50 C Decrease mobile-phase pH to suppress silanol ionization; increase buffer concentration; derivatize solute to change polar interactions Minimize number of connections; ensure injector rotor seal is tight; ensure all compression fittings arecorrectly seated

Silica-based column degradation at high pH Tailing Peaks Silica-based column degradation at high temperature Silica-based column silanol interactions Unswept dead volume

Replace column, or, if possible, open top endfitting and clean and fill in void with glass Void formation at head of beads or samecolumn packing; rotate injection column valve quickly; use injection valve with pressure bypass; avoid pressure shock Spikes Bubbles in mobile phase Degas mobile phase; use back-pressure

restrictor at detector outlet; ensure that all fittings are tight Column stored without caps Store column tightly capped; flush reversedphase columns with degassed methanol

S-ar putea să vă placă și

- HPLC Troubleshooting: Problem Possible Cause SolutionDocument9 paginiHPLC Troubleshooting: Problem Possible Cause SolutionAbhishek RajÎncă nu există evaluări

- HPLC Opt ManualDocument21 paginiHPLC Opt ManualHà Lê HảiÎncă nu există evaluări

- HPLC TroubleshootingDocument27 paginiHPLC TroubleshootingwingroupsÎncă nu există evaluări

- RS Testing Procedure PDFDocument36 paginiRS Testing Procedure PDFsiddhu444Încă nu există evaluări

- Gas Chromatography - 2 OVIDocument32 paginiGas Chromatography - 2 OVIyashpandya01Încă nu există evaluări

- Coulometric Water Determination According To Karl FischerDocument6 paginiCoulometric Water Determination According To Karl Fischerlarrylchu100% (9)

- GC Tips Tricks-Agilent (Compatibility Mode)Document43 paginiGC Tips Tricks-Agilent (Compatibility Mode)Sneha PatelÎncă nu există evaluări

- Care of HPLC ColumnsDocument4 paginiCare of HPLC ColumnsKavisa GhoshÎncă nu există evaluări

- Care Maintenance and HPLC Column TroubleshootingDocument52 paginiCare Maintenance and HPLC Column TroubleshootingducngoctrinhÎncă nu există evaluări

- HPLC Trouble ShootingDocument47 paginiHPLC Trouble Shootingtamilsam1986Încă nu există evaluări

- Validating Dissolution MethodsDocument51 paginiValidating Dissolution MethodshenryÎncă nu există evaluări

- Troubleshooting of GC SystemsDocument16 paginiTroubleshooting of GC SystemsAmit PrakashÎncă nu există evaluări

- Natural Science Laws Experience "Live" - Learn Easily: For Karl Fischer TitrationDocument20 paginiNatural Science Laws Experience "Live" - Learn Easily: For Karl Fischer Titrationstepark28Încă nu există evaluări

- How To Ensure Trouble-Free HPLC System OperationDocument3 paginiHow To Ensure Trouble-Free HPLC System OperationKavisa GhoshÎncă nu există evaluări

- Forced Degradation Studies or Stress Testing Studies:: What Are The Objectives ?Document40 paginiForced Degradation Studies or Stress Testing Studies:: What Are The Objectives ?samsnuÎncă nu există evaluări

- HPLC ForumDocument12 paginiHPLC ForumkiranfoodÎncă nu există evaluări

- Mobile Phase Optimization Strategies For Reversed Phase HPLCDocument41 paginiMobile Phase Optimization Strategies For Reversed Phase HPLCqncargbÎncă nu există evaluări

- Instrumentation of HPLC Autosamplers PDFDocument31 paginiInstrumentation of HPLC Autosamplers PDFlinus77Încă nu există evaluări

- Split and Splitless InjectionDocument44 paginiSplit and Splitless InjectionBishoy F. YoussefÎncă nu există evaluări

- Gedruckt: Instrumentation of HPLC DetectorsDocument40 paginiGedruckt: Instrumentation of HPLC DetectorsDimitri KinÎncă nu există evaluări

- Ion Pairing Reagents and BuffersDocument6 paginiIon Pairing Reagents and BuffersipatoffÎncă nu există evaluări

- Huber 1 Method ValidationDocument38 paginiHuber 1 Method ValidationhasnanursÎncă nu există evaluări

- Disolution TestDocument80 paginiDisolution TestAsnakeÎncă nu există evaluări

- HPLC Column Instru TroubleshootingDocument61 paginiHPLC Column Instru TroubleshootinglabanacabreraÎncă nu există evaluări

- HPLC Guide: A Concise Overview of High Performance Liquid ChromatographyDocument12 paginiHPLC Guide: A Concise Overview of High Performance Liquid ChromatographykushalÎncă nu există evaluări

- Dissolution ApparatusDocument31 paginiDissolution Apparatustigerblaster82100% (1)

- Theory of HPLC HilicDocument33 paginiTheory of HPLC HilicNguyen Duc Khanh ThoÎncă nu există evaluări

- Column ClassificationDocument51 paginiColumn ClassificationHyunjung KimÎncă nu există evaluări

- Quantification and Chromatogram IntegrationDocument33 paginiQuantification and Chromatogram Integrationalen19819072Încă nu există evaluări

- GC Troubleshooting TipsDocument44 paginiGC Troubleshooting TipsmlaorrcÎncă nu există evaluări

- USP Medicines Compendium publishes Eflornithine Topical Cream monographDocument3 paginiUSP Medicines Compendium publishes Eflornithine Topical Cream monographamin138irÎncă nu există evaluări

- J. System Suitability Specifications and TestsDocument7 paginiJ. System Suitability Specifications and Testsjljimenez1969Încă nu există evaluări

- ICH Guideline For Elemental ImpuritiesDocument77 paginiICH Guideline For Elemental ImpuritiesMohd AfzanizamÎncă nu există evaluări

- National Measurement System 1997-2000 Valid Analytical Measurement (VAM) ProgrammeDocument29 paginiNational Measurement System 1997-2000 Valid Analytical Measurement (VAM) Programmenguyen lee100% (1)

- 2.2.46. Chromatographic Separation TechniquesDocument5 pagini2.2.46. Chromatographic Separation TechniquesFemmes RêveurÎncă nu există evaluări

- HPLC Final Ed 6 PDFDocument170 paginiHPLC Final Ed 6 PDFSoheil MoghadamÎncă nu există evaluări

- Extraneous Peaks in HPLCDocument40 paginiExtraneous Peaks in HPLCshulalevin0% (1)

- Fe School CodesDocument58 paginiFe School Codesvzimak2355Încă nu există evaluări

- SOP For Washing of HPLC ColumnsDocument2 paginiSOP For Washing of HPLC Columnsziaddd100% (1)

- DA NUT2013 B4 Rune Frederiksen PDFDocument56 paginiDA NUT2013 B4 Rune Frederiksen PDFMaheshÎncă nu există evaluări

- Potentiometric Titration - Theory and Basic OperationDocument42 paginiPotentiometric Titration - Theory and Basic OperationTaurusVõÎncă nu există evaluări

- Troubleshooting Common HPLC ProblemsDocument19 paginiTroubleshooting Common HPLC ProblemslimereiÎncă nu există evaluări

- UV Performance QualificationDocument8 paginiUV Performance Qualificationtrueindian28Încă nu există evaluări

- Introduction To Custom FieldsDocument60 paginiIntroduction To Custom Fieldssaldanhalopes666Încă nu există evaluări

- 02 KF TheoryDocument33 pagini02 KF Theoryliska ramdanawatiÎncă nu există evaluări

- Volumetric Measurement in The LaboratoryDocument43 paginiVolumetric Measurement in The LaboratoryKiran ChokshiÎncă nu există evaluări

- Waters Synapt g2 Mass Spectrometry System OomgraDocument236 paginiWaters Synapt g2 Mass Spectrometry System OomgraFafa AlunksÎncă nu există evaluări

- ChemStation E-Seminar AgendaDocument50 paginiChemStation E-Seminar AgendaWilliam QuiroaÎncă nu există evaluări

- The Ultimate Guide To: Hplc/UhplcDocument32 paginiThe Ultimate Guide To: Hplc/UhplcDavid SantiagoÎncă nu există evaluări

- Analytical Method and Processes ValidationDocument21 paginiAnalytical Method and Processes ValidationYub Raj NeupaneÎncă nu există evaluări

- Simultaneous Determination of Methylparaben + Propylparaben + Hidrocortisone Topical Cream PDFDocument7 paginiSimultaneous Determination of Methylparaben + Propylparaben + Hidrocortisone Topical Cream PDFNájla KassabÎncă nu există evaluări

- Fundamental LC-MS Orbitrap Mass Analyzers PDFDocument30 paginiFundamental LC-MS Orbitrap Mass Analyzers PDFAlonso HurtadoÎncă nu există evaluări

- Chpt13 Quality Control AssuranceDocument7 paginiChpt13 Quality Control Assurancevisini100% (1)

- Processing Internal Standards in EmpowerDocument6 paginiProcessing Internal Standards in Empowersaldanhalopes666Încă nu există evaluări

- Pharmaceutical and Biomedical Applications of Capillary ElectrophoresisDe la EverandPharmaceutical and Biomedical Applications of Capillary ElectrophoresisÎncă nu există evaluări

- LC ApplicationsDocument129 paginiLC Applicationshaben9036Încă nu există evaluări

- Agilent CE System: A Quick Start Guide To Maintenance and TroubleshootingDocument12 paginiAgilent CE System: A Quick Start Guide To Maintenance and TroubleshootingThanh Thanh Hai LeÎncă nu există evaluări

- HPLC TroubleshootingDocument6 paginiHPLC TroubleshootingsenkatuukaÎncă nu există evaluări

- Phenol: Carboxylation of Phenol: Kolb-Schmitt ReactionDocument9 paginiPhenol: Carboxylation of Phenol: Kolb-Schmitt ReactionAkhilaÎncă nu există evaluări

- 11 Chemistry Notes ch12 Organic Chemistry PDFDocument3 pagini11 Chemistry Notes ch12 Organic Chemistry PDFRangbaaz DA FIRENZEÎncă nu există evaluări

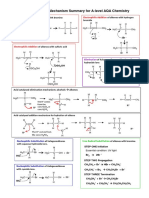

- Aqa Mechanisms A Level SummaryDocument5 paginiAqa Mechanisms A Level SummaryRS JÎncă nu există evaluări

- Pheonwj M Spe 0025 1Document48 paginiPheonwj M Spe 0025 1Iksan Adityo Mulyo100% (1)

- Materials Selection For Corrosion PreventionDocument61 paginiMaterials Selection For Corrosion PreventionJeremy Coleman100% (1)

- Chloride: Silver Nitrate Method Method 8207 10 To 10,000 MG/L As CL Digital TitratorDocument6 paginiChloride: Silver Nitrate Method Method 8207 10 To 10,000 MG/L As CL Digital TitratorAlbertoÎncă nu există evaluări

- Effect of PH On Corrosion RateDocument8 paginiEffect of PH On Corrosion RateياسرشلالالحسنيÎncă nu există evaluări

- Group 4 Biological Membranes RevisedDocument20 paginiGroup 4 Biological Membranes RevisedDjanelle Mei San MiguelÎncă nu există evaluări

- SDS Hydrochloric Acid InhibitorDocument4 paginiSDS Hydrochloric Acid InhibitorJahidul IslamÎncă nu există evaluări

- Hydrolysis Worksheet Chemistry Unit 4.13Document3 paginiHydrolysis Worksheet Chemistry Unit 4.13Gideon CavidaÎncă nu există evaluări

- Chemistry of Carbon CompoundsDocument12 paginiChemistry of Carbon CompoundsSubhadip HaldarÎncă nu există evaluări

- Packaging N Labelling of Packaged Drinking WaterDocument10 paginiPackaging N Labelling of Packaged Drinking WaterISHFAQ ASHRAFÎncă nu există evaluări

- Pre-Medical: Chemistry Allen: Carbonyl Compounds, Acids and It'S Derivatives Carbonyl CompoundsDocument18 paginiPre-Medical: Chemistry Allen: Carbonyl Compounds, Acids and It'S Derivatives Carbonyl CompoundsJK JHAÎncă nu există evaluări

- Terathane: Properties, Uses, Storage and Handling of Dupont GlycolsDocument12 paginiTerathane: Properties, Uses, Storage and Handling of Dupont GlycolsA MahmoodÎncă nu există evaluări

- Disolutions PDFDocument28 paginiDisolutions PDFarcilalilianaÎncă nu există evaluări

- Pko Cno PDFDocument26 paginiPko Cno PDFmindcrÎncă nu există evaluări

- 25 Macro & Micro InspectionDocument2 pagini25 Macro & Micro InspectionSampath KumarÎncă nu există evaluări

- Chap4 CALCULATIONS USED IN ANALYTICAL CHEMISTRYDocument20 paginiChap4 CALCULATIONS USED IN ANALYTICAL CHEMISTRYDave Marimon100% (1)

- Test 2 - Carbohydrates, Lipids, Proteins and Nucleic AcidsDocument7 paginiTest 2 - Carbohydrates, Lipids, Proteins and Nucleic AcidsChrisÎncă nu există evaluări

- Coventya Pop Sempa 2015Document28 paginiCoventya Pop Sempa 2015LukeÎncă nu există evaluări

- Benzene Quiz Questions - Footprints-Science GCSE Science Animations and Quizzes GCSE Science RevisionDocument1 paginăBenzene Quiz Questions - Footprints-Science GCSE Science Animations and Quizzes GCSE Science RevisionlollÎncă nu există evaluări

- Vocabulary Practice: Chapter 2 - Chemistry of LifeDocument5 paginiVocabulary Practice: Chapter 2 - Chemistry of LifeJordyÎncă nu există evaluări

- EN-standardi Za AluminijDocument31 paginiEN-standardi Za AluminijRenato PericÎncă nu există evaluări

- Us2160626 1Document3 paginiUs2160626 1خبر عاجل وتحليلاتÎncă nu există evaluări

- Ds Rewomid Ipp 240 eDocument3 paginiDs Rewomid Ipp 240 eEleany Antonieta Loayza MendocillaÎncă nu există evaluări

- ChemistryDocument22 paginiChemistrymacaronloverÎncă nu există evaluări

- Chemolube H - Product DescriptionDocument6 paginiChemolube H - Product DescriptionJulio VargasÎncă nu există evaluări

- TautomerismDocument2 paginiTautomerismZIdanÎncă nu există evaluări

- Thermodynamics and Kinetic Stability of Coordination ComplexesDocument27 paginiThermodynamics and Kinetic Stability of Coordination ComplexesMONIRUZZAMAN MONIR100% (1)

- Failure Analysis of Refractory Anchors of A PowerDocument8 paginiFailure Analysis of Refractory Anchors of A PowerVinh Do ThanhÎncă nu există evaluări