Documente Academic

Documente Profesional

Documente Cultură

Parametric Design of Rocket Engine Turbopumps With Genetic Algorithms

Încărcat de

joojoo987654321Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Parametric Design of Rocket Engine Turbopumps With Genetic Algorithms

Încărcat de

joojoo987654321Drepturi de autor:

Formate disponibile

Parametric Design of Rocket Engine Turbopumps with Genetic Algorithms

R. Burian*, A. Hetem**, J. Miraglia* and C.A.C. Caetano*

*

Faculdade de Informtica e Administrao Paulista / FIAP, So Paulo, Brazil ** Universidade Federal do ABC-UFABC/CECS, So Paulo, Brazil profburian@uol.com.br

Abstract - In a rocket engine, the main turbopump parameters must be estimated considering that the power output of the turbine essentially has to equal the power demand of the pump. Considering the properties of the turbine drive gas (specific heat, temperature and other features), the strength limits of the turbine materials, and the likely pressure drop, it is possible to determine the basic dimensions of the blades like pitch line velocity, turbine nozzle outlet velocity, number of rows of blades, turbine type or turbine efficiency. The particular arrangement or geometry of the major turbopump components is related to their selection process. Most propellant pumps have a single-stage main impeller. Usually some design limit is reached which requires one or more iterations, each with a new changed approach or parameter. The present work considers the development of a software tool based on genetic algorithms to assist the determination of the excellent parameters of configuration of turbopumps in engines for liquid propellant rockets. We present results for alcohol/LOX propellant mixture, some discussion on its applications on rocket engines.

TABLE I.

PARAMETERS FROM THE ALCOHOL V2 PUMP (ADAPTED FROM [11])

Parameter value

impeller diameter rotation performance delivery delivery pressure

34 cm 5000 rpm 265 kW 50 kg/s 25 atm

takeoff weight; and thrust chamber specific impulse (based on propellant combination, mixture ratio, and chamber operating efficiency). A pump operating at steady flow creates a lowpressure area at the pump inlet, thus allowing the static head upstream of the pump to push fluid into the inlet at a continuous rate. There are local regions within the pump which are at static pressures even lower than the inlet static pressure. If the static pressure of the fluid at the pump inlet or any regions within the pump is allowed to drop below the local fluid vapor pressure level, these regions will cavitate. The formation of vapor alters the effective flow passages of the fluid and hence seriously affects normal pump performance. So, besides the many parameters present in pump calculation, one must add the needs to avoid cavitation. Actually, new computational tools and materials allow improving the performance of the pump machine. As the designer approaches the limits of what is physically possible, simultaneously the numbers of failure possibilities grow and so the verification of the analysis accuracy increases. It appears more that the effect is that as optimization becomes possible with better computational tools, the projected pumps get better but the time and cost of development is equal. Considering the properties of the turbine drive gas (specific heat, temperature and other features), the strength limits of the turbine materials, and the likely pressure drop, it is possible to determine the basic dimensions of the blades like pitch line velocity, turbine nozzle outlet velocity, number of rows of blades, turbine type or turbine efficiency. The particular arrangement or geometry of the major turbopump components is related to their selection process [8]. Some complex designs, like the SSME-Space

I.

INTRODUCTION

The operation of turbopumps mainly works due to an interaction between the fluid flowing over the surfaces of its stationary and rotating airfoils [1]. In a rocket engine, a turbopump consists of a pump that delivers oxidizer or fuel to the thrust chamber where the propellants are brought to react and increase in temperature. Since the combustion process takes place under constant pressure, the chamber pressure is the net result of the turbopump system [2]. There is a series of documents issued by NASA that guides the turbopump designer in terms of rules and criteria ([3], [4][, 5[6] and [7]). These documents are also very important as they provide insight to solutions adopted for several machine designs and by several different rocket engines [2]. In high-thrust, long-duration liquid propellant rocket engine applications, turbopump feed systems generally result in lower systems weight and higher performance when compared to pressurized gas feed systems. Turbopump feed systems require only relatively low pump-inlet pressures, and thus propellant-tank pressures, while the major portion of the pressure required at the thrust chamber inlets is supplied by the pumps, saving considerable vehicle weight. As stated by [7] the best performing turbopump system is defined as that which affords the heaviest payload for a vehicle with a given thrust level, range or velocity increment: gross stage

Shuttle Main Engine, have a multiple stage pump, but most propellant pumps have a single-stage main impeller. Eventually, one or more design limits are reached which requires more iteration, each with a new changed parameter or approach. For instance, see tab. 1 which presents some data from the V2 (II world war German missile) alcohol pump. The present work considers the development of a software tool based on genetic algorithms to assist the determination of the excellent parameters of configuration of turbopumps in engines for liquid propellant rockets. We present the first version, which considers the calculation of the main parameters of a compressor stage. The technique used to find the pump compressor parameters is a genetic algorithm (GA). GAs are generalized artificial intelligence methods for optimization in searching solutions for NP-problems based on direct analogy with the natural evolution of species. The method can deal with a high number of parameters and is independent of model complexity [9] [10]. II. THE MODEL

To satisfy the GA formalism (described in section III), one must write down the model, or the formalism that describes the necessary transformations to obtain from , or =f(). One can obtain these expressions following [11] model and converting their expressions. First, the pressures should be converted to heads, or the height necessary to the fluid to cause a given pressure, so we define Ht, He and Hf, the tank head, the elevation head and the friction head, respectively, that can be obtained by

Pt = g 0 dh ,

Ht

(1) (2)

Pe = g0 dh ,

He

and

Pf =

g dh .

0 Hf

(3)

The rocket engine requirements give the initial basic design goals for the turbopump, like propellant flow, the pump outlet or discharge pressure, which has to be equal to the chamber pressure plus the pressure drops in the piping, valves, cooling jacket, and injector, the desired engine cycle, which can be gas generator or staged combustion, the start delay, and the need for restart. Also, the propellant properties, like density, vapor pressure, viscosity and boiling point, are inputs to the calculation. The pump compressor model used in this work is based on chapter 10 of [11]. This model provides a coherent basis for the modeling, and is sufficiently complex to be used as a valid test on the further parameter optimizing step. The pump parameters we want to find are: the inlet compressor diameter, d1, the compressor outlet diameter, d2, the fluid input velocity, v1, the suction specific speed, S, the shaft cross section, AS1, the pressure in the main tank, Pt, the total fluid friction (viscosity included) due to flow through the pipes, valves, etc, Pf, the pressure due to the tank elevation from the pump inlet, Pe. In particular, this last parameter leads to project insights concerning the pump position inside the rocket. These are the GA free parameters, formally ={d1,d2,v1,S,dS1,Pt,Pf,Pe}, known as the parameter set. The obtained compressor must & deliver a desired mass rate, m , and, from an input pressure P1, generate a flow with an output pressure P2. Some constants shall be considered, like the fluid mass density, , and the external gravity, g0. We assumed as fluid the ethanol (C2H6OH) due to its green properties and green results. These three parameters are those the rocket engine designer should define to specify the compressor he needs. Differently from the first eight parameters described on the above paragraph, these values cannot be altered by the algorithm, and can be included in another group, the result set & 1 = {m, P , P2 } .

The effective area of the inlet is given by

A1eff

1 d12 = AS 1 , 4

(4)

which determines the volume flow

Q=

v dA .

1 A1eff

(5)

Then, the absolute positive head can be obtained by

H1 = H t + H e H f

(6)

and the net positive suction head or available suction head above vapor pressure can be obtained by

H s = Ht + He H f Hv ,

(7)

where Hv is the combustible vapor pressure. The required suction head will be taken as 80% of the available suction head in order to provide a margin of safety for cavitation, or HSR=0.8H1. To avoid pump cavitation, Hs has to be higher than HSR. If additional head is required by the pump, the propellant may have to be pressurized by external means, such as by the addition of another pump in series (a booster pump) or by gas pressurization of the propellant tanks. A small value of HSR is desirable because it may permit a reduction of the requirements for tank pressurization and, therefore, a lower inert tank mass. The shaft speed is given by

N rpm

SH SR = , uSI Q

(8)

TABLE II.

PUMP TYPES. IMPELLER TYPE AS A FUNCTION OF THE SHAFT SPECIFIC SPEED (ADAPTED FROM TABLE 10-2 FROM [11]) Francis Mixed flow Near axial Axial

Radial

Basic shape (half section)

Specific speed Ns (SI units) Efficiency %

0.2-0.3 50-80

0.4 60-90

0.6-0.8 70-92

1.0-2.0 76-88

above 2.5 75-82

where =3/4 and uSI=17.827459 are constants. uSI is necessary due to SI convertions (see [11] eq. 10-7). This last expression allows us to obtain Nrad/s, the shaft speed in radians per second. The impeller vane tip speed is given by

adaptation level. The other control variable is , the genetic operator. The term generation means all the individuals (or all the solutions) present in a given iteration. A. Implementation The code uses the parameters described in section II, namely ={d1,d2,v1,S,dS1,Pt,Pf,Pe}. Essentially, the GA method presented herein implements a 2 minimization of the comparison between the desired results, & 1 0 = {m, P , P2 } , and the results obtained by the application of expressions (1) to (12), the model results. There are three main advantages of using a GA for this task: (i) the GA method potentially browses the whole permitted parameter space, better avoiding the traps of local minima; (ii) the method is not affected by changes in the model; (iii) the GA implementation does not need to compute the derivatives of 2 (such as 2/P1, for example) required by the usual methods. This fact simplifies the code and minimizes computer errors caused by gradient calculations. The main structures used to manipulate the data are linked lists containing the solutions (parameter set, adaptation level, expressed by

u=

1 d 2 N rad / s . 2

(8)

With u, we can evaluate the head delivered by the pump

H =

u2 , g 0

(9)

where has values between 0.90 and 1.10 for different designs. As for many pumps, = 1.0, we adopt this value. At this point, we are able to obtain all the final results,

& 1 = {m, P , P2 } :

P = H1 g 0 , 1 P2 = (H + H1 ) g 0 ,

and

(10) (11) (12)

& m = Q .

i2

, and the genetic operator, i, (14)

It is also interesting to evaluate the shaft specific speed

Si = {i , i , ( i2 , i )} ,

Ns =

uSI Q , H SR

(13)

which, with the aid of tab. 2, defines the pump and impeller type. III. THE METHOD

This section explains how the GA method was implemented in the pump compressor model described in section 2. We first clarify the GA nomenclature in the field of pump design. A parameter (e.g. inlet diameter) corresponds to the concept of a gene, and a change in a parameter is a mutation. A parameter set that yields a possible solution corresponds to a chromosome, our . An individual is a solution that is composed of one parameter set and two additional GA control variables. One of these variables is 2, which refers to the

where Si denotes the ith solution. Following [12] and [13], the code starts with the construction of the first generation, where all parameters are randomly chosen within an allowed range (for example, 15 cm < d1 30 cm). Here, the number of parameter sets in the first generation is assumed to be 100. In the next step, the evaluation function runs the model for each solution, and compares the synthetic i with the desired data, 0, to find 2, using a modified expression given by [14]:

1 = np

2 i

j 0 ij j =1 0j

np

(15)

TABLE III.

COMPARISON BETWEEN OBTAINED RESULTS (GA) AND CORRECT ANSWER (0) FOR A ETHANOL COMPRESSOR

& m

(kg/s) Correct answer 10 20 50 100 226,8 228,1 227,5 227,1 226,9

P1 (Pa) 342669 342345 342360 342601 342670

P2 (Pa) 6816870 6816450 6816440 6816890 6816880

mean error (%) 0,22 0,13 0,05 0,01

generations

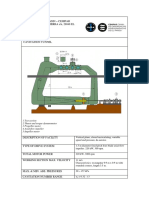

Figure 1. Schematic view of the main steps of a generic GA (adapted from [13])

where np is the number of values in the result set, 0j, is & the desired value on position j (e.g. 01= m ), and ij is the calculated value for the solution Si. The smallest 2 corresponds to the goodness-of-fit, or simply gof. The gof values express how each individual is adapted, or how close each solution is, to the best solution [9]. A judgment function then determines the genetic operator to be applied to a solution. Its values can be copy: the individual remains the same in the next generation; crossover: the individual is elected to change a number of genes (parameters) with another individual, creating a new one; mutation: one of its genes is randomly changed; or termination: none of the genes continue to subsequent generations. The chosen action is expressed by the i variable, associated with each individual. The next step is to evolve the current generation (k) to the next (k + 1) one, which is done through a mlti-dimensional function that considers the solutions and the genetic operators. Formally,

in SI units. Fig. 2 presents the state of a session after 20 generations. The jumps in the red line (the worst individual in the generation) are due to bad mutations. These individuals are quickly extracted from the next generation. The code stops looping when a saturation condition is reached. In this particular case, the saturation is recognized when the gof stops changing for a given number of generations. IV. RESULTS

The resulting parameters obtained from the GA code where in good agreement with what is expected for this kind of project. Some comparisons between GA results and correct results are presented in tab. 3. A typical running with about 100 generation is achieved in 1-2 seconds in a simple laptop computer. V. CONCLUSION

[S1, S2 ,K, S N ]k +1 = . [(S1 , 1 ), (S 2 , 2 ),K , (S N , N )]k

(16)

As soon as a new generation is ready, the evaluation function is reapplied, and the algorithm repeats the described actions until an end-of-loop condition is reached. The end condition can be based on the number of iterations or the quality (a low level for the (see fig. 1). B. The code The code was implemented in C++, using the facilities of LCC Laboratrio de Computao Cientfica from FIAP. The variables were assumed to be

i2

values)

Evidently, for the simple definitions of section III, one does not need a sophisticated method as described to obtain a good result. But, as all designers know very well, there are no simple projects, especially concerning rocket engine pumps. The next step in this work is to enhance the model with more realistic and specific trends. It is expected to incorporate non-linear functions, differential equations and integrals. Also tabled functions are not far from what can be found in a pump project, with its intrinsic interpolations. The overall problem of finding parameters for a pump design can easily turn to a NPProblem, that is a problem that is very difficult to find a solution, but, once one has a candidate to solution it is easy to verify if it is a good solution. The GA proved to be efficient, and due to the method itself being independent of model complexity, it certainly can be used in future implementations. Future evolutions and increasing complexity of the model can benefit of GA robustness and reliability.

Figure 2. The code work window after 20 generations, with plots of log(gof) as a function of the generation, using ethanol as combustible. The blue line represents the best individual and the red line the worst individual. One can see the continuous advance of the best solution through some jumps, as in the 2nd-3th and 3th-4th generation. The text window presents the parameters for the best individual and the gof. [8] Logan, E., Jr., & Roy, R, (eds), Handbook of Turbomachinery (Second Edition Revised and Expanded), 2003, Marcel Dekker, Inc. Koza, J.R., 1992, Genetic Programming: On the Programming of Computers by Means of Natural Selection. MIT Press. Bentley, P.J., & Corne D.W., 2002, Creative Evolutionary Systems. Morgan-Kaufmann, San Francisco. Sutton, G.P., & Biblarz, O., 2001, "Rocket Propulsion Elements" 7th editon, JOHN WILEY & SONS, INC. Goldberg D. E., 1989, Genetic Algorithms in Search, Optimization and Machine Learning. Addison-Wesley Longman, Boston, MA Hetem, A., & Gregorio-Hetem, J., 2007, "The use of genetic algorithms to model protoplanetary discs", Mon. Not. R. Astron. Soc. 382, 17071718 (2007) doi:10.1111/j.13652966.2007.12442.x Press W. H., Teukolsky S. A., Vetterling W. T., Flannery B. P., 1995, Numerical Recipes in C, 2nd edn. Cambridge Univ. Press, New York

ACKNOWLEDGMENT The authors want to thank AEB Agncia Espacial Brasileira / Programa UNIESPAO. REFERENCES

[1] [2] Rangwala, A. S., "Turbo-Machinery Dynamics: Design and Operation", McGRAW-HILL, 2005. Mrtensson, H.; Andersson, S.; Trollheden, S.; Brodin, S. (2008) Rocket Engines: Turbomachinery. In Advances on propulsion Technology for High-Speed Aircraft (pp. 5-1 5-28). Educational Notes RTO-EN-AVT-150, Paper 5. Neuilly-sur-Seine, France: RTO. NASA SP-8107 NASA SP-8109 NASA SP-8110 NASA SP-8125 Huzel, D.K. & Huang, D.H., 1967, "Design of Liquid Propellant Rocket Engines", Rocketdyne Division, North American Aviation, Inc. [9] [10] [11] [12]

[13]

[3] [4] [5] [6] [7]

[14]

S-ar putea să vă placă și

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationDe la EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationÎncă nu există evaluări

- Design of Liquid Propellant Engines TextbookDocument472 paginiDesign of Liquid Propellant Engines TextbookDavid UrieÎncă nu există evaluări

- These Is On Turbopump.Document44 paginiThese Is On Turbopump.Madhusudan SharmaÎncă nu există evaluări

- Experimental Fluid Mechanics: The Commonwealth and International Library: Thermodynamics and Fluid Mechanics DivisionDe la EverandExperimental Fluid Mechanics: The Commonwealth and International Library: Thermodynamics and Fluid Mechanics DivisionEvaluare: 4 din 5 stele4/5 (2)

- Study On Thin Airfoil Theory Performance Test of EDocument10 paginiStudy On Thin Airfoil Theory Performance Test of ENguyen Danh HauÎncă nu există evaluări

- Rarefied Gas DynamicsDe la EverandRarefied Gas DynamicsK KaramchetiEvaluare: 5 din 5 stele5/5 (1)

- TM 5-2036 (Pump, Centrifugal 1.5 Discharge, 125 G.P.M. 300 PDFDocument127 paginiTM 5-2036 (Pump, Centrifugal 1.5 Discharge, 125 G.P.M. 300 PDFferdockmÎncă nu există evaluări

- 10 Development of A High Performance Centrifugal Compressor Using A 3D Inverse Design TechniqueDocument11 pagini10 Development of A High Performance Centrifugal Compressor Using A 3D Inverse Design TechniqueSubhash PadmanabhanÎncă nu există evaluări

- Hypersonic Flow ResearchDe la EverandHypersonic Flow ResearchF.R. RiddellÎncă nu există evaluări

- Nozzle ProgramDocument11 paginiNozzle ProgramGopi Nath100% (2)

- Demystifying Numerical Models: Step-by Step Modeling of Engineering SystemsDe la EverandDemystifying Numerical Models: Step-by Step Modeling of Engineering SystemsEvaluare: 2 din 5 stele2/5 (1)

- Trim Optimisation - Theory and PracticeDocument6 paginiTrim Optimisation - Theory and Practicepoker12345Încă nu există evaluări

- Stabilization and Dynamic of Premixed Swirling Flames: Prevaporized, Stratified, Partially, and Fully Premixed RegimesDe la EverandStabilization and Dynamic of Premixed Swirling Flames: Prevaporized, Stratified, Partially, and Fully Premixed RegimesÎncă nu există evaluări

- Rockets and Launch VehiclesDocument21 paginiRockets and Launch VehicleskevinÎncă nu există evaluări

- NASA SPACE VEHICLE DESIGN CRITERIA (CHEMICAL PROPULSION): LIQUID ROCKET ENGINE FLOW TURBOPUMPS CENTRIFUGALDocument124 paginiNASA SPACE VEHICLE DESIGN CRITERIA (CHEMICAL PROPULSION): LIQUID ROCKET ENGINE FLOW TURBOPUMPS CENTRIFUGALARturo NeuroÎncă nu există evaluări

- H-1 Rocket Engine Technical ManualDocument78 paginiH-1 Rocket Engine Technical ManualrobsonhahnÎncă nu există evaluări

- TLP Global Motion Performance Analysis ProceduresDocument8 paginiTLP Global Motion Performance Analysis ProceduresTee Shi FengÎncă nu există evaluări

- Cavitation Tunnel Tests & Research at EL PARDO Model BasinDocument2 paginiCavitation Tunnel Tests & Research at EL PARDO Model BasinDavid AmayaÎncă nu există evaluări

- Theory and Experiment ProcedureDocument25 paginiTheory and Experiment ProcedureNazrul HafizÎncă nu există evaluări

- Supercavitating Propellers PDFDocument41 paginiSupercavitating Propellers PDFAlex FatecÎncă nu există evaluări

- Theory and Design of Automotive EngineDocument127 paginiTheory and Design of Automotive EnginePrasad RamaniÎncă nu există evaluări

- 76 Notes On Numerical Fluid Mechanics (NNFM)Document382 pagini76 Notes On Numerical Fluid Mechanics (NNFM)VipinBaislaÎncă nu există evaluări

- Cavitation Effects on HydrofoilsDocument13 paginiCavitation Effects on HydrofoilsNaresh JirelÎncă nu există evaluări

- Air Flow ReportDocument6 paginiAir Flow ReportLuke jaggerÎncă nu există evaluări

- Ramjet Rocket Missile DesignDocument34 paginiRamjet Rocket Missile DesignCliff ThriveÎncă nu există evaluări

- Use of CFD Methods For Hullform Ion in A Model BasinDocument11 paginiUse of CFD Methods For Hullform Ion in A Model Basinseckin80Încă nu există evaluări

- Daiflisttati On: (Baticflal Tcraut1CDocument647 paginiDaiflisttati On: (Baticflal Tcraut1CSPUTNIK1958Încă nu există evaluări

- Cavitation PhotographsDocument6 paginiCavitation PhotographsgsmilebamÎncă nu există evaluări

- Low-Cost LOX PumpDocument11 paginiLow-Cost LOX Pumpduheaven100% (1)

- A Mathematical Model For Predicting Fire Spread in Wildland FuelsDocument48 paginiA Mathematical Model For Predicting Fire Spread in Wildland FuelsSaksham AgarwalÎncă nu există evaluări

- 1971019929Document469 pagini1971019929juli_navia3482Încă nu există evaluări

- ADA160718 - AGARD-R-723 - Aircraft Drag Prediction and ReductionDocument270 paginiADA160718 - AGARD-R-723 - Aircraft Drag Prediction and ReductionopedroestebanÎncă nu există evaluări

- Thermodynamics-Full-Catalogue PDFDocument136 paginiThermodynamics-Full-Catalogue PDFKhalid Al-JanabiÎncă nu există evaluări

- Design Inducer PumpDocument2 paginiDesign Inducer PumpnicoÎncă nu există evaluări

- 1-d Ic Engine Model With Python PDFDocument11 pagini1-d Ic Engine Model With Python PDFAhmed SajitÎncă nu există evaluări

- The Elements of Aerofoil and Airscrew Theory by Glauert PDFDocument247 paginiThe Elements of Aerofoil and Airscrew Theory by Glauert PDFDickson LeongÎncă nu există evaluări

- Agard CFD PDFDocument492 paginiAgard CFD PDFVinoth NagarajÎncă nu există evaluări

- Fluid-Dynamic LiftDocument507 paginiFluid-Dynamic LiftMike Corvin100% (1)

- Wal Correction AgardDocument552 paginiWal Correction AgardSrinivasan SiddhamoorthyÎncă nu există evaluări

- Linear Aerospike EngineDocument51 paginiLinear Aerospike EngineSanad ShajahanÎncă nu există evaluări

- Solid Rocket MotorDocument15 paginiSolid Rocket MotorVsm Krishna Sai EturiÎncă nu există evaluări

- Aerodynamic Performance Analysis of A Winged Re-Entry Vehicle From Hypersonic Down To Subsonic SpeedDocument15 paginiAerodynamic Performance Analysis of A Winged Re-Entry Vehicle From Hypersonic Down To Subsonic Speedaoyon100% (1)

- Capsule: TurbopumpsDocument51 paginiCapsule: Turbopumpsvinu k sÎncă nu există evaluări

- Second Law Analysis If IC EnginesDocument16 paginiSecond Law Analysis If IC Enginesdjermounimohamed100% (1)

- Liquid-Propellant Rocket Engine ThrottlingDocument27 paginiLiquid-Propellant Rocket Engine Throttlingbmsprague100% (1)

- 500 Years of Graphical and Symbolical Representation On Marine ChartsDocument13 pagini500 Years of Graphical and Symbolical Representation On Marine ChartsManuel CapdevilaÎncă nu există evaluări

- C-D Nozzle ExperimentDocument3 paginiC-D Nozzle ExperimentKarthick MurugesanÎncă nu există evaluări

- Flow Past NACA AirfoilDocument7 paginiFlow Past NACA AirfoilKarthick Murugesan100% (2)

- Jet Engine Integration Guide for Aircraft DesignDocument8 paginiJet Engine Integration Guide for Aircraft DesignZeeshan100% (1)

- Cavitation ArndtDocument56 paginiCavitation ArndtWilliamÎncă nu există evaluări

- Hybrid PropulsionDocument100 paginiHybrid Propulsionapi-3827338100% (1)

- Aerodynamics - KrasnovDocument760 paginiAerodynamics - KrasnovFabiano HernandesÎncă nu există evaluări

- Liquid Rocket Engine Turbopump InducersDocument116 paginiLiquid Rocket Engine Turbopump Inducersapi-3827338100% (1)

- Hypersonic Glide Vehicle Design ConsderationsDocument35 paginiHypersonic Glide Vehicle Design ConsderationsIan M Mair100% (1)

- (Solid Mechanics and Its Applications 176) O. A. Bauchau (Auth.) - Flexible Multibody Dynamics - Springer Netherlands (2011)Document751 pagini(Solid Mechanics and Its Applications 176) O. A. Bauchau (Auth.) - Flexible Multibody Dynamics - Springer Netherlands (2011)JohnÎncă nu există evaluări

- Design of High Lift Low Reynolds Number Airfoil For Micro Aerial VehicleDocument7 paginiDesign of High Lift Low Reynolds Number Airfoil For Micro Aerial VehicleInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- T-340PL Prime Line PartsDocument144 paginiT-340PL Prime Line PartsMichael Doogie Alburqueque ParedesÎncă nu există evaluări

- Tripartite2015 Session6d LRPedersen BIMCODocument14 paginiTripartite2015 Session6d LRPedersen BIMCObritties69Încă nu există evaluări

- Higher-order spectral/hp FEM for shells and fluid flowsDocument24 paginiHigher-order spectral/hp FEM for shells and fluid flowsjoojoo987654321Încă nu există evaluări

- Orbit Determination Methods For Deep Space Drag-Free Controlled Laser Interferometry Missions PDFDocument226 paginiOrbit Determination Methods For Deep Space Drag-Free Controlled Laser Interferometry Missions PDFjoojoo987654321Încă nu există evaluări

- Multidisciplinary Design Optimization of Dynamic Engineering Systems PDFDocument30 paginiMultidisciplinary Design Optimization of Dynamic Engineering Systems PDFWael SalahÎncă nu există evaluări

- Multidisciplinary Design Optimization A Survey of ArchitecturesDocument27 paginiMultidisciplinary Design Optimization A Survey of Architecturesjoojoo987654321Încă nu există evaluări

- Trading Project Costs and Benefits in Multi-Attribute Tradespace ExplorationDocument16 paginiTrading Project Costs and Benefits in Multi-Attribute Tradespace Explorationjoojoo987654321Încă nu există evaluări

- Umi Umd 3244 PDFDocument94 paginiUmi Umd 3244 PDFjoojoo987654321Încă nu există evaluări

- Multidisciplinary Design Optimization Method ApplDocument9 paginiMultidisciplinary Design Optimization Method Appljoojoo987654321Încă nu există evaluări

- Recent Advances in Engineering Design Optimisation Challenges and Future TrendsDocument19 paginiRecent Advances in Engineering Design Optimisation Challenges and Future Trendsjoojoo987654321Încă nu există evaluări

- Parametric Analysis and Targeting Capabilities For The Planetary Entry Systems Synthesis Tool PDFDocument37 paginiParametric Analysis and Targeting Capabilities For The Planetary Entry Systems Synthesis Tool PDFjoojoo987654321Încă nu există evaluări

- Trading Project Costs and Benefits in Multi-Attribute Tradespace ExplorationDocument16 paginiTrading Project Costs and Benefits in Multi-Attribute Tradespace Explorationjoojoo987654321Încă nu există evaluări

- Reuse in Systems Engineering - Valerdi Gaffney Roedler Rieff - V FINAL 101806 PDFDocument3 paginiReuse in Systems Engineering - Valerdi Gaffney Roedler Rieff - V FINAL 101806 PDFjoojoo987654321Încă nu există evaluări

- Techdoc PDFDocument125 paginiTechdoc PDFjoojoo987654321Încă nu există evaluări

- Aiaa Paper Jpc04chak1 PDFDocument9 paginiAiaa Paper Jpc04chak1 PDFjoojoo987654321Încă nu există evaluări

- Economics of Separated Ascent Stage Launch Vehicles: Jupiter Research and Development, Houston, TX 77043Document12 paginiEconomics of Separated Ascent Stage Launch Vehicles: Jupiter Research and Development, Houston, TX 77043joojoo987654321Încă nu există evaluări

- AIAA Paper PDFDocument28 paginiAIAA Paper PDFjoojoo987654321Încă nu există evaluări

- Pump Catalogue1Document16 paginiPump Catalogue1tr_chÎncă nu există evaluări

- High-Efficiency Turbocharger MET-MA SeriesDocument3 paginiHigh-Efficiency Turbocharger MET-MA Seriescristobal_tl2277Încă nu există evaluări

- Air Preparation Units: Regulator Series R1 AIR REGULATOR - 1/4, 3/8, 1/2, 3/4, 1"Document3 paginiAir Preparation Units: Regulator Series R1 AIR REGULATOR - 1/4, 3/8, 1/2, 3/4, 1"Biswanath LenkaÎncă nu există evaluări

- 27 UnionfiningDocument2 pagini27 Unionfiningali11111Încă nu există evaluări

- 6 - Loss of Energy (Or Head) in PipesDocument21 pagini6 - Loss of Energy (Or Head) in PipesMustafa ZahidÎncă nu există evaluări

- Bleo HolmDocument4 paginiBleo HolmperrychemÎncă nu există evaluări

- Technology of Essential Oils: Presentation By: MR - Ramakant HarlalkaDocument32 paginiTechnology of Essential Oils: Presentation By: MR - Ramakant Harlalkazaryab khanÎncă nu există evaluări

- E38 Fuel Supply SystemDocument4 paginiE38 Fuel Supply SystemNorizwad Shah NasharudinÎncă nu există evaluări

- 3a1335en L PDFDocument56 pagini3a1335en L PDFAlfredo VMÎncă nu există evaluări

- FluidFlow3 OverviewDocument6 paginiFluidFlow3 OverviewHGuruGuruHÎncă nu există evaluări

- Fan & SystemDocument31 paginiFan & SystemAlberto FranciscoÎncă nu există evaluări

- Chapter 7 Pure SubstanceDocument22 paginiChapter 7 Pure SubstanceMUHAMMED FAISALÎncă nu există evaluări

- 9588 PDF C22Document29 pagini9588 PDF C22Juan Pablo CarmonaÎncă nu există evaluări

- Boilers BasicDocument32 paginiBoilers Basicrikhan81Încă nu există evaluări

- Camara CongelaciónDocument44 paginiCamara CongelaciónIgnacio BermúdezÎncă nu există evaluări

- Pumps: Bauzon, Gianpaolo B. Cabangal, DustinmarielDocument47 paginiPumps: Bauzon, Gianpaolo B. Cabangal, DustinmarielJohn Carl GuanlaoÎncă nu există evaluări

- What Is Bhopal Gas Tragedy: Background of UCILDocument11 paginiWhat Is Bhopal Gas Tragedy: Background of UCILdivyam rajput100% (1)

- Centrifugal Pump BasicsDocument124 paginiCentrifugal Pump BasicsJorge Athié Huitrón Moreno100% (1)

- Pre-Read About Basic's of Hydraulics & Pneumatics by Umesh KumarDocument2 paginiPre-Read About Basic's of Hydraulics & Pneumatics by Umesh KumarUmesh JatavÎncă nu există evaluări

- Reflux 819: Pressure RegulatorDocument20 paginiReflux 819: Pressure RegulatorRafael Jose Tasco ZabaletaÎncă nu există evaluări

- Chemistry-FUNGAT+ECAT: (Chapter 1+2+3 B-I)Document2 paginiChemistry-FUNGAT+ECAT: (Chapter 1+2+3 B-I)XXXÎncă nu există evaluări

- Activity 2 Part 2Document3 paginiActivity 2 Part 2Ruzzel PeraltaÎncă nu există evaluări

- Process Modelling and System Dynamic Project 4 Dynamic SimulationDocument12 paginiProcess Modelling and System Dynamic Project 4 Dynamic SimulationHusaini ZaidanÎncă nu există evaluări

- Gas Production OperationsDocument333 paginiGas Production Operationsmarzinus0% (1)

- Directional Solenoid and Pneumatic ValvesDocument176 paginiDirectional Solenoid and Pneumatic ValvesKelvin Viza SoraideÎncă nu există evaluări

- Outline: Reed Valve System (5SE09 Model Compressor) Rotary Valve System (5SER09 Model Compressor)Document2 paginiOutline: Reed Valve System (5SE09 Model Compressor) Rotary Valve System (5SER09 Model Compressor)Вячеслав ГлушакÎncă nu există evaluări

- Energy Saving Presentation Version 2.2 - For Customer - ADocument80 paginiEnergy Saving Presentation Version 2.2 - For Customer - AElsan BalucanÎncă nu există evaluări

- Gas burners one stage technical specifications and dimensionsDocument4 paginiGas burners one stage technical specifications and dimensionsMohamed FazilÎncă nu există evaluări

- "Handing Over Notes To Incoming Junior/Fourth Engineer" Prepared By: 4 Engineer Sajjad AhmedDocument4 pagini"Handing Over Notes To Incoming Junior/Fourth Engineer" Prepared By: 4 Engineer Sajjad AhmedAnoop VijayakumarÎncă nu există evaluări

- Algorithms to Live By: The Computer Science of Human DecisionsDe la EverandAlgorithms to Live By: The Computer Science of Human DecisionsEvaluare: 4.5 din 5 stele4.5/5 (722)

- Fundamentals of Software Architecture: An Engineering ApproachDe la EverandFundamentals of Software Architecture: An Engineering ApproachEvaluare: 4.5 din 5 stele4.5/5 (7)

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityDe la EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityEvaluare: 5 din 5 stele5/5 (1)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveDe la EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveÎncă nu există evaluări

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldDe la EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldEvaluare: 4.5 din 5 stele4.5/5 (107)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyDe la EverandChip War: The Quest to Dominate the World's Most Critical TechnologyEvaluare: 4.5 din 5 stele4.5/5 (227)

- Generative AI: The Insights You Need from Harvard Business ReviewDe la EverandGenerative AI: The Insights You Need from Harvard Business ReviewEvaluare: 4.5 din 5 stele4.5/5 (2)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldDe la EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldEvaluare: 4.5 din 5 stele4.5/5 (54)

- 8-Bit Apocalypse: The Untold Story of Atari's Missile CommandDe la Everand8-Bit Apocalypse: The Untold Story of Atari's Missile CommandEvaluare: 3.5 din 5 stele3.5/5 (10)

- 97 Principles for Software Architects: Axioms for software architecture and development written by industry practitionersDe la Everand97 Principles for Software Architects: Axioms for software architecture and development written by industry practitionersEvaluare: 5 din 5 stele5/5 (21)

- CompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideDe la EverandCompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideEvaluare: 5 din 5 stele5/5 (2)

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessDe la EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessÎncă nu există evaluări

- How to Do Nothing: Resisting the Attention EconomyDe la EverandHow to Do Nothing: Resisting the Attention EconomyEvaluare: 4 din 5 stele4/5 (421)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDe la EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindÎncă nu există evaluări

- Software Engineering at Google: Lessons Learned from Programming Over TimeDe la EverandSoftware Engineering at Google: Lessons Learned from Programming Over TimeEvaluare: 4 din 5 stele4/5 (11)

- So You Want to Start a Podcast: Finding Your Voice, Telling Your Story, and Building a Community that Will ListenDe la EverandSo You Want to Start a Podcast: Finding Your Voice, Telling Your Story, and Building a Community that Will ListenEvaluare: 4.5 din 5 stele4.5/5 (35)

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseDe la EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseEvaluare: 3.5 din 5 stele3.5/5 (12)

- Artificial Intelligence: A Guide for Thinking HumansDe la EverandArtificial Intelligence: A Guide for Thinking HumansEvaluare: 4.5 din 5 stele4.5/5 (30)

- Artificial Intelligence: The Insights You Need from Harvard Business ReviewDe la EverandArtificial Intelligence: The Insights You Need from Harvard Business ReviewEvaluare: 4.5 din 5 stele4.5/5 (104)

- CCNA: 3 in 1- Beginner's Guide+ Tips on Taking the Exam+ Simple and Effective Strategies to Learn About CCNA (Cisco Certified Network Associate) Routing And Switching CertificationDe la EverandCCNA: 3 in 1- Beginner's Guide+ Tips on Taking the Exam+ Simple and Effective Strategies to Learn About CCNA (Cisco Certified Network Associate) Routing And Switching CertificationÎncă nu există evaluări

- AI Money Machine: Unlock the Secrets to Making Money Online with AIDe la EverandAI Money Machine: Unlock the Secrets to Making Money Online with AIÎncă nu există evaluări

- Who's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesDe la EverandWho's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesEvaluare: 4.5 din 5 stele4.5/5 (12)

- Mastering Large Language Models: Advanced techniques, applications, cutting-edge methods, and top LLMs (English Edition)De la EverandMastering Large Language Models: Advanced techniques, applications, cutting-edge methods, and top LLMs (English Edition)Încă nu există evaluări

- Power and Prediction: The Disruptive Economics of Artificial IntelligenceDe la EverandPower and Prediction: The Disruptive Economics of Artificial IntelligenceEvaluare: 4.5 din 5 stele4.5/5 (38)

- SEO: The Ultimate Guide to Optimize Your Website. Learn Effective Techniques to Reach the First Page and Finally Improve Your Organic Traffic.De la EverandSEO: The Ultimate Guide to Optimize Your Website. Learn Effective Techniques to Reach the First Page and Finally Improve Your Organic Traffic.Evaluare: 5 din 5 stele5/5 (5)