Documente Academic

Documente Profesional

Documente Cultură

Sys 3 CW

Încărcat de

Baugh Graphic DesignDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sys 3 CW

Încărcat de

Baugh Graphic DesignDrepturi de autor:

Formate disponibile

epro System III CW Concrete or CMU Wall Waterproofing

Excellent Strength & Flexibility Seamless Exceptional Adhesion Extremely Durable Redundant Protection

System Description

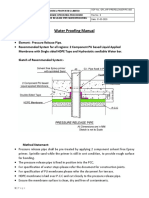

System III CW is a field installed composite waterproofing system that is comprised of waterbased, polymer modified asphalt (PMA) membrane reinforced with polyester fabric laminated to a polyolefin geomembrane covered by an HDPE core and polypropylene fabric drainage composite which provides excellent resistance to chemicals and root damage with redundant water protection. System Components Ecoline-S or R (Interior Course): A spray fluid applied, water-based polymer modified asphalt (PMA) membrane. Ecoshield-E (Middle Course): A tough polyolefin geomembrane. Ecodrain-E (Exterior Course): A HDPE core and non-woven polypropylene fabric drainage composite or Ecodrain-S: A polypropylene core and polypropylene fabric drainage composite. Additional Information: Specification Reference - Concrete/CMU Wall Specification Detail Drawings - Reference all WP labeled details Installation Guidelines - Reference 1. Waterproofing Membrane Installation (Vertical). 2. Ecoshield Installation. 3. Ecodrain Installation. Product Information - Reference: Ecoline-S, EcolineR, Ecoshield-E, Ecodrain-E or Ecodrain-S product brochures.

W a te r p r oo f i n g Sys tems

Excellent Strength and Flexibility - the result of the unique field installed composite system design. Seamless - The highly flexible spray or fluid applied membrane forms a monolithic barrier. Exceptional Adhesion - The sprayer or fluid applied membrane bonds tenaciously to almost any substrate in almost any condition including green concrete or a damp substrate. Extremely Durable - The HDPE, polypropylene and polyolefin geomembranes and geocomposites are resistant to chemical attack and root damage. Redundant Protection - Multiple waterproofing protection courses and drainage plane.

W

A

OR

LD

OF DIFFE RE N

CE

S

EA

LW ND ORLD CO

800-882-1896

rev. sys3cw_0113b09

www.eproserv.com

TI

ON

FO

R

R

epro System III CW Concrete & CM U Walls

Epro CW Waterproofing System Testing

Water-based, polymer modified asphalt (PMA) membrane reinforced with polyester fabric laminated to a polyolefin geomembrane which is covered by HDPE core and polypropylene fabric drainage composite which provides excellent resistance to chemicals and root damage with redundant water protection. ( Ecoline-S or R / Ecoshield-E / Ecodrain-E )

Tensile Strength* ......................... ASTM D-412 .... 619 psi Elongation* .................................. ASTM D-412 .... 774% Adhesion to Concrete*** .............. ASTM C-836 .... 11 lbf/in Adhesion to Film .......................... ASTM E-96 ...... 0.0046 perms Puncture Resistance .................... ASTM D-5385 .. 231 ft. Soil Burial* ................................... ASTM D-4068 Weight change ..................... See Note 1 ...... 1.2% .......... passed Tensile Strength ................... See Note 1 ...... 9.89% ........ passed Elongation ............................ See Note 1 ...... 2.2% .......... passed Heat Aging* ................................. ASTM D-4068 Tensile Strength .................. See Note 1 ...... 8.6% .......... passed Elongation .......................... See Note 1 ...... 8.9% .......... passed Environmental Stress Cracking* .. ASTM D-1693 Failure ................................ See Note 2 ...... 620 hrs. ..... passed Oil Resistance* .......................... ASTM D-543 & ASTM D-412 Weight change ..................... See Note 1 ...... 7.6% .......... passed Tensile Strength ................. See Note 1 ...... 1.1% .......... passed Elongation .......................... See Note 1 ...... 4.4% .......... passed Methane Transmission* .............. ASTM D-1434 See Note 3 ...... 3.70xE-15... passed * Tests performed by SGS / US Testing ** Tests performed by TRI Environmental *** Tests performed by Momentum Technologies Note 1: LA requires less than 10% Note 2: LA requires over 500 hrs. Note 3: LA requires less than 3 ml per day

Wa te r p r oo f i n g Sys tems

OR

Chemical Permeation** .... ASTM F-739

Perm Rate Perm Rate Ug/cm2 ml/day

Chlorinated Solvent Perchloroethylene ................................... 69.4 .......... 0.0008 Trichloroethylene .................................... 89.8 .......... 0.0012 Aromatic Hydrocarbon Benzene .................... ............................ 59.3 .......... 0.0013 Chemical Resistance** ...... ASTM D-543 Net change

Chlorinated Solvents ......... ASTM D-882 Mod. (Less 10% pass) Perchloroethylene Weight ........................ ............................ 4.1% Tensile Strength ......... ............................ 6.5% Tricholorethylene Weight ........................ ............................ 5.4% Tensile Strength ......... ............................ 6.0% Aromatic Hydrocarbon Benzene Weight ........................ ............................. 4.1% Tensile Strength ......... ............................ 4.4% Gases Hydrogen Sulfide Weight ........................ ............................. 0.6% Tensile Strength ......... ............................. 0.8%

LD

OF DIFFE RE N

CE

EA

LW

O RL D C O

ND

800-882-1896

www.eproserv.com

rev.sys3cw_011413

TI

I

ON

FO

R

R

S-ar putea să vă placă și

- System III GRBDocument2 paginiSystem III GRBBaugh Graphic DesignÎncă nu există evaluări

- BB 1Document1 paginăBB 1Baugh Graphic DesignÎncă nu există evaluări

- Ecoshield HDocument2 paginiEcoshield HBaugh Graphic DesignÎncă nu există evaluări

- Epro Bento-Pro PlusDocument2 paginiEpro Bento-Pro PlusBaugh Graphic DesignÎncă nu există evaluări

- Epro Bento-Pro PlusDocument2 paginiEpro Bento-Pro PlusBaugh Graphic DesignÎncă nu există evaluări

- Ecobase HVDocument2 paginiEcobase HVBaugh Graphic DesignÎncă nu există evaluări

- Ecoshield EBDocument2 paginiEcoshield EBBaugh Graphic DesignÎncă nu există evaluări

- Specification Concrete and Cmu Walls With BentoniteDocument8 paginiSpecification Concrete and Cmu Walls With BentoniteBaugh Graphic DesignÎncă nu există evaluări

- CDBSBEDocument9 paginiCDBSBEBaugh Graphic DesignÎncă nu există evaluări

- Ecoshield PBDocument2 paginiEcoshield PBBaugh Graphic DesignÎncă nu există evaluări

- Sys3 CWBDocument2 paginiSys3 CWBBaugh Graphic DesignÎncă nu există evaluări

- Iso 13485Document1 paginăIso 13485Baugh Graphic DesignÎncă nu există evaluări

- Sys3 RDBDocument2 paginiSys3 RDBBaugh Graphic DesignÎncă nu există evaluări

- Epro Services, System III - MBBDocument2 paginiEpro Services, System III - MBBBaugh Graphic DesignÎncă nu există evaluări

- Specifications Waterproofing Tunnels/Underground StructuresDocument14 paginiSpecifications Waterproofing Tunnels/Underground StructuresBaugh Graphic DesignÎncă nu există evaluări

- BSBEDocument6 paginiBSBEBaugh Graphic DesignÎncă nu există evaluări

- Specification Blindside Waterproofing With BentoniteDocument9 paginiSpecification Blindside Waterproofing With BentoniteBaugh Graphic DesignÎncă nu există evaluări

- R BaughDocument1 paginăR BaughBaugh Graphic DesignÎncă nu există evaluări

- Sys3 LWBDocument2 paginiSys3 LWBBaugh Graphic DesignÎncă nu există evaluări

- EprostophplDocument2 paginiEprostophplBaugh Graphic DesignÎncă nu există evaluări

- AD55M Drum Pump: Sold Exclusively by Epro Services, Inc. Wichita, KS (800) 882-1896Document1 paginăAD55M Drum Pump: Sold Exclusively by Epro Services, Inc. Wichita, KS (800) 882-1896Baugh Graphic DesignÎncă nu există evaluări

- AS9100BDocument1 paginăAS9100BBaugh Graphic DesignÎncă nu există evaluări

- Ecosil Series Material Safety Data Sheet: 1. Product IdentificationDocument2 paginiEcosil Series Material Safety Data Sheet: 1. Product IdentificationBaugh Graphic DesignÎncă nu există evaluări

- MSDBSDocument2 paginiMSDBSBaugh Graphic DesignÎncă nu există evaluări

- MSDPPDocument2 paginiMSDPPBaugh Graphic DesignÎncă nu există evaluări

- Eprosil Material Safety Data Sheet: 1. Product IdentificationDocument2 paginiEprosil Material Safety Data Sheet: 1. Product IdentificationBaugh Graphic DesignÎncă nu există evaluări

- Eco TapeDocument1 paginăEco TapeBaugh Graphic DesignÎncă nu există evaluări

- Eco Membrane Series Material Safety Data Sheet: 1. Product IdentificationDocument2 paginiEco Membrane Series Material Safety Data Sheet: 1. Product IdentificationBaugh Graphic DesignÎncă nu există evaluări

- Fast Set Green Adhesive: General DescriptionDocument1 paginăFast Set Green Adhesive: General DescriptionBaugh Graphic DesignÎncă nu există evaluări

- Polymer Mix Material Safety Data Sheet: 1. Product IdentificationDocument2 paginiPolymer Mix Material Safety Data Sheet: 1. Product IdentificationBaugh Graphic DesignÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- FinishingDocument68 paginiFinishingARYAN RATHORE100% (4)

- Water ProofingDocument3 paginiWater ProofingmichaelÎncă nu există evaluări

- Jeep Roof Top Tent - Making Camping All The More Fun.Document3 paginiJeep Roof Top Tent - Making Camping All The More Fun.Farheen AhmedÎncă nu există evaluări

- Tds-Ws-801-En (1) VS 01Document3 paginiTds-Ws-801-En (1) VS 01paola choquehuancaÎncă nu există evaluări

- DITRA Installation HandbookDocument32 paginiDITRA Installation HandbookJoannaPappasÎncă nu există evaluări

- Pentens: Water-Based PU Bituminous Waterproofing Membrane Description Technical & Physical DataDocument2 paginiPentens: Water-Based PU Bituminous Waterproofing Membrane Description Technical & Physical Datarobi setiawanÎncă nu există evaluări

- Manual Book 1000L Rain Spray Test ChamberDocument12 paginiManual Book 1000L Rain Spray Test ChamberAbid FadlullahÎncă nu există evaluări

- 195-SAM - Particular Architectural SpecificationDocument70 pagini195-SAM - Particular Architectural SpecificationWeam JamalÎncă nu există evaluări

- Final Billing For Waterproofing WorksDocument117 paginiFinal Billing For Waterproofing Worksarchie_728Încă nu există evaluări

- Masterseal hlm5000r TdsDocument3 paginiMasterseal hlm5000r TdsHabib ArifnurÎncă nu există evaluări

- Water Proofing Manual: BasementDocument3 paginiWater Proofing Manual: Basementannayya.chandrashekar Civil EngineerÎncă nu există evaluări

- Car ParkDocument28 paginiCar ParkSudhakar Krishnamurthy100% (2)

- Concrete Foundations For Tropical ClimatesDocument6 paginiConcrete Foundations For Tropical ClimatesSuryasis DasguptaÎncă nu există evaluări

- Water Proofing MethodologyDocument1 paginăWater Proofing MethodologyMaSh Joaconcho Ybañez100% (2)

- Smart, Waterproof, Breathable Sportsware - A ReviewDocument13 paginiSmart, Waterproof, Breathable Sportsware - A ReviewKrergkrai ChantalertvittayaÎncă nu există evaluări

- Mastic Asphalt, Asphalt Hot Mix + Grouting Asphalt PavementsDocument44 paginiMastic Asphalt, Asphalt Hot Mix + Grouting Asphalt PavementsMM NNÎncă nu există evaluări

- Myk LaticreteDocument75 paginiMyk LaticreteAnand AnandÎncă nu există evaluări

- TDS - Masterseal 420Document2 paginiTDS - Masterseal 420Venkata RaoÎncă nu există evaluări

- Ce168p-2 E01 Policarpio ReportDocument7 paginiCe168p-2 E01 Policarpio ReportJericho MaganaÎncă nu există evaluări

- Water Proofing of HouseDocument3 paginiWater Proofing of HouselineshÎncă nu există evaluări

- Akfix General Product Catalogue 2023 Rev11Document84 paginiAkfix General Product Catalogue 2023 Rev11ahmed.serefÎncă nu există evaluări

- AS 1860.2-2006 Particleboard Flooring - InstallationDocument30 paginiAS 1860.2-2006 Particleboard Flooring - InstallationMorten PedersenÎncă nu există evaluări

- Sika WarrantyDocument2 paginiSika WarrantyMatt CerosÎncă nu există evaluări

- Fully Adhered Insulated Concrete Roof Specification TemplateDocument7 paginiFully Adhered Insulated Concrete Roof Specification TemplateLEONARDOÎncă nu există evaluări

- Astm D-3393-91Document2 paginiAstm D-3393-91Abhishek KumarÎncă nu există evaluări

- J.J.Shah PaperDocument10 paginiJ.J.Shah Paperइंजि कौस्तुभ पवारÎncă nu există evaluări

- Application of Astec Ceramic Insulating CoatingsDocument12 paginiApplication of Astec Ceramic Insulating CoatingsBer Salazar JrÎncă nu există evaluări

- Velosit CW 111: High Strength Crystalline Waterproofing SlurryDocument4 paginiVelosit CW 111: High Strength Crystalline Waterproofing SlurryZammar ShahidÎncă nu există evaluări

- 10 Fabrics Used in Sport Wear 1 Lycra: SportswearDocument9 pagini10 Fabrics Used in Sport Wear 1 Lycra: SportswearTejaswini SinghÎncă nu există evaluări

- MasterSeal HLM 5000RDocument45 paginiMasterSeal HLM 5000RKhin Sandi KoÎncă nu există evaluări