Documente Academic

Documente Profesional

Documente Cultură

ps441 0604762en

Încărcat de

Himdad TahirDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ps441 0604762en

Încărcat de

Himdad TahirDrepturi de autor:

Formate disponibile

PS 441 Directional Time-Overcurrent Protective Device

Numerical Directional Time-Overcurrent Protection with Definite-Time and Inverse-Time Characteristics PS 441 directional timeovercurrent protective devices are used for selective short-circuit protection in high-voltage networks. The networks can be operated with impedance neutral grounding, with resonant grounding, or with an isolated neutral. The PS 441 directional timeovercurrent protective device has the following features: t four-pole measurement (A, B, C, N), t phase-selective phase current timer module with DTOC and IDMT characteristics (IDMT can be set to normally inverse, very inverse, extremely inverse, long time ground fault or RI inverse), t time-lag high set phase current timer module, t residual current timer module with DTOC and IDMT characteristics (IDMT can be set to normally inverse, very inverse, extremely inverse, long time ground fault or RI inverse), t time-lag high set residual current timer module, t tripping matrix, t optional latching of the individual tripping criteria, t possibility of reverse interlocking, t supplementary short-circuit direction determination feature t signal comparison through pilot wires t circuit-breaker failure protection. The residual current input is designed for standard or for high sensitivity, as desired. In addition to the features listed above, as well as comprehensive self-monitoring and fault diagnosis, the PS 441 is equipped with the following supplementary functions: t measuring circuit monitoring t operating data acquisition t event counting t fault data acquisition t fault logging The PS 441 is constructed with a multifunctional case design that is equally well suited for wall surface mounting or panel flush mounting due to the reversible terminal blocks and reversible mounting brackets. The auxiliary voltage for the power supply can be switched internally from 110-250 V DC to 24-60 V DC. The PS 441 has the following inputs and outputs: t 4 current-measurement and 3 voltage-measurement inputs, t 2 binary signal inputs (optical couplers) with freely configurable function assignment, t 8 output relays with freely configurable function assignment. Control and display: t local control panel, t 12 LED indicators, including 9 with freely configurable function assignment t PC interface. Parameters may be set either from the local control panel, through the PC interface or via the optional ILSA interface, as desired. The ILSA interface supports linking of the PS 441 to an integrated substation control system such as ILS.

1 PS 441 in case for wall surface or panel flush mounting

abcd

PS 441 Directional Time-Overcurrent Protective Device

Functions

Definite or Inverse Time-Delay Short-Circuit Protection The PS 441 directional timeovercurrent protective device is equipped with four currentmeasurement inputs A, B, C and N and has the following overcurrent timer modules: t phase-selective phase current timer module I>/ tI>, t residual current (neutral current) timer module IN>/tI,N> , t high set phase current timer module I>>/tI>>, t high set residual current timer module IN>>/tI,N>> . The modules measured in the ground path have an effect on the general start signal and therefore on the start of a fault record, and this effect can be inhibited, if desired. Formation of the general trip command by the residual current timer modules is then automatically disabled. The phase current timer module tI > and the residual current timer module tI,N> can have a definite-time delay or an inverse-time delay, as desired.

The following triggering time characteristics are available in the inverse time-delay mode: t normally inverse, t very inverse t extremely inverse, t long time ground fault, t RI inverse. Mode, base current, characteristic type and characteristic factor can be set independently for the phase current timer module and the residual current timer module. Tripping Matrix and Latch The tripping matrix is used to decide which of the individual overcurrent timer modules shall participate in forming the general trip command. The phase-selective phase current timer module is permanently assigned to the general trip command; this cannot be changed. Another matrix is used to determine which of the individual tripping criteria shall result in latching of the general trip command.

The function of circuit breaker failure protection is also considered in the tripping matrix and in the matrix for setting the latching function. Reverse Interlocking The individual overcurrent timer modules can be blocked externally by two independent signals. In this connection it is possible by using one selection matrix to determine which of the timer modules shall be included in the block. This makes it possible to add on a feature such as reverse interlocking, for example (busbar protection with starting scan).

Short-Circuit Direction Determination The short-circuit direction determination function makes it possible for the PS 441 to be used as directional timeovercurrent protection. One can select separately for each individual time-overcurrent timer module whether the module shall be forwarddirected, reverse-directed or non-directional. The directions for the phase current timer modules and the residual current timer modules are determined in separate measurement systems. In the direction measuring system for the phase current timer modules the phase-tophase voltage opposite the selected phase current is used for direction determination as a function of the type of fault, and an optimum characteristic angle is used (see Figure 3).

2 Inverse-time characteristics

Normally inverse t= 0.14 characteristic s factor (I /I B )0.02 1

3 Directional characteristics in short-circuit direction determination

forward decision

Measure- Start ment System Imeas P

a

I me

as

Selected V meas IA IB IC IA IC IC

Measurands

Characristic Angle P or N +45 +45 +45 +60 +30 +60 +45

Very inverse 13.5 characteristic t = factor s (I /I B ) 1 Extremely inverse 80 characteristic t = factor s (I /IB )2 1 Long time earth fault 120 t = characteristic s (I /IB ) 1 factor RI inverse t= 1 characteristic s factor 0.339 0.236 (I/IB)

A B C A-B B-C C-A

V B-C = VB-N V C-N V C-A = V C-N V A-N V A-B = V A-N V B-N V B-C = VB-N V C-N V A-B = V A-N V B-N V A-B = V A-N V B-N V A-B = V A-N V B-N

Vmeas (reference quantity)

11717.DS4

backward decision

A - B - C IC N N IN

V NG = 1/3 (VA-N + VB-N + V C-N) 90 to +90 (adjustable)

PS 441 Directional Time-Overcurrent Protective Device

Functions

(continued)

In the direction measuring system for the residual current timer modules, direction is determined using the internally computed neutral displacement voltage; the characteristic angle is adjustable with reference to the various network starpoint treatments. The direction measuring system for the residual current timer modules is not enabled until a set value for neutral displacement voltage is exceeded. In this connection one can select whether the triggering preorientation for a nonenabled direction measuring system for residual current timer modules shall be blocked in the event of phase current starting. Teleprotection Teleprotection can be used in conjunction with short-circuit direction determination. For this purpose the protective devices must be suitably connected by pilot wires on both ends of the line section to be protected. One can select whether teleprotection will be controlled by the direction measuring system of the phase current timer modules only, by the direction measuring system of the residual current timer modules only, or by the direction measuring systems of the phase current and residual current timer modules. For protective devices on the infeed side of radial networks, teleprotection can also be controlled without the short-circuit direction determination function.

Circuit Breaker Failure Protection When the trip command is issued a timer module for monitoring the circuit breaker is also started. When this timer module has elapsed due to a sustained general start condition, then the circuit breaker failure signal is issued. The input of a circuit breaker failure signal through an appropriately configured binary input brings about a non-delayed trip command if the general start signal is present. Measuring-Circuit Monitoring Measuring-circuit monitoring includes phase current and phase-to-phase voltage monitoring. Phase-to-phase voltage monitoring is only active if the short-circuit direction determination function is activated. Phase current monitoring is based on the principle of maximum allowable magnitude unbalance, whereby the arithmetic difference between the maximum and minimum phase currents as referred to the maximum phase current is compared with the set threshold operate value. Even with an economy-type CT connection (CTs in only two phases) it is possible to monitor the phase currents given appropriate settings. Phase-to-phase voltage monitoring is based on a plausibility check involving the phase currents. If a low current threshold setting is exceeded by at least one phase current, the three phase-to-phase voltages are monitored for a set minimum level.

Operating Data Acquisition The PS 441 directional timeovercurrent protective device acquires the following measured operating data, updating them at approximately 1 s intervals, as long as a fault is not being processed at the time: t maximum value of the three phase currents, t phase currents, t residual current, t phase-to-phase voltages, t neutral-to-ground voltage. The measured data are displayed as r.m.s. values and are normalized to the corresponding nominal value of the protective device. Event Counting The PS 441 directional timeovercurrent protective device counts the following events: t tripping on faults, t faults, t warning entries. Fault Data Acquisition After the end of a general start condition, the following measured fault data are acquired: t running time, t short-circuit current. Fault Logging The signals appearing during a fault are logged in chronological order. A total of five faults, each involving a maximum of 63 starting or ending signals, can be stored in a ring memory (signal memory). If there are more than five faults and no faults have been erased in the interim, the oldest fault log with be overwritten. A four-digit resettable counter identifies the individual faults by serial number. The fault logs can be read from the local control panel.

Fault Recording The sampled values of the three phase currents and the three phase-to-ground voltages are recorded during a fault event with additional pre- and post-roll. A memory area of a total of 4 s recording depth is reserved for this purpose in the PS 441. The sampled values of up to five faults may be written to this memory. If there are more than five faults, or if the maximum recording time of 4 s is exeeded, the oldest fault(s) will be overwritten. The most recent fault is stored in nonvolatile memory. The identification of the individual faults by a number is the same as that of the fault event record. Using a personal computer and the analysis and control program FPC the fault recording as well as the protection indications can be read via the PC or ILSA interface and displayed together as a function of time. Self-Monitoring Extensive monitoring routines in the PS 441 ensure that internal hardware or software faults will not lead to malfunctioning of the protective relaying system. When the auxiliary voltage VA is turned on, a function test is carried out. Cyclic self-monitoring tests are run during operation. If test results deviate from the default value, a fault signal is issued. The result of fault diagnosis determines whether a protective block will occur or whether only a warning will be issued. The faults diagnosed in conjunction with self-monitoring are stored in a memory (monitoring signal memory). The contents of the monitoring signal memory can be read from the local control panel.

PS 441 Directional Time-Overcurrent Protective Device

Design

Mechanical Design The PS 441 consists of an aluminum case with reversible plug-in screw-type terminals and reversible side brackets. The case can be used for wall surface mounting or for panel flush mounting, as desired. In either case the unit is connected by screw terminals. The processor module carrying the local control panel is mounted directly on the rear of the removable front panel. It is connected to the combined input-output module by a flat connecting cable. The input-output module contains the voltage supply, the input transducers, the output relays, and the optical couplers for the binary inputs. In the front panel are windows for the display and label strips located behind them. The keyboard for the integrated local control panel and the PC interface are also located in the front panel. Figure 5 on Page 10 shows the case and mounting dimensions.

Local Control Panel The integrated local control panel has two 4-digit 7-segment LCD displays and six keys. The settings, measurands and signals are numerically coded. This code is called the address and is displayed in the lower 4-digit 7-segment display. Accidental or unauthorized modification of settings is impeded by access barriers. Twelve light-emitting diodes are provided as visual indicators. The first three have permanent signal assignments, while the other nine can be configured as desired (see Page 9). The control panel has two label strips. The strip on the left is used to label the LED indicators, and the strip on the right provides a visual record of frequently performed control steps. Both strips can be replaced and labeled by the user as desired.

4 Local control panel

PS 441 Directional Time-Overcurrent Protective Device

Technical Data

Notices

The product designated as PS 441 Directional Time-Overcurrent Protective Device has been designed and manufactured in conformance with international standard EN 60255-6 and also with the EMC Directive and the Low Voltage Directive issued by the Council of the European Community.

General Data

Design Case suitable for wall surface mounting or panel flush mounting. Installation Position Vertical 30 Degree of Protection Per DIN 40 050 IP 51 Weight 4 kg Dimensions See Page 10 Terminal Connection Diagram See Page 10 PC Interface DIN 41652 connector, type Submin-D, 9-pin. A special connector cable is required for electrical isolation. ILSA Interface Optical fiber interface F-SMA Terminals Screw-type M4 terminals, self-centering with wire protection for conductor cross sections of 0.5 to 6 mm2 or 2 x 2.5 mm2 Creepage Distances and Clearances Per IEC 255-5 Group C

Tests

Type Test All tests in accordance with EN 60255-6 and DIN 57435 Part 303 EMC Emitted Interference Per EN 50022 and DIN VDE 0878 Part 3. Class B 1 MHz Burst Per IEC 255 Part 22-1, Class III Common-mode or longitudinal voltage: 2.5 kV Normal-mode or transverse voltage: 1.0 kV Test duration: > 2 s Source impedance: 200 Immunity to Electrostatic Discharge Per EN 60801 Part 2 Severity: 3 Contact discharge, single discharges: > 10 Hold time: > 5 s Test voltage: 6 kV Test generator: 50 to 100 , 150 pF / 330 Immunity to High-Frequency Electromagnetic Fields Per EN 50140 Severity: 3 Antenna-testpiece distance: > 1 m on all sides Field strength in range 80 to 1000 MHz: 10 V/m Test with AM: 1 kHz / 80% Single test at 900 MHz: AM 200 Hz / 100% Burst Immunity Per IEC 801-4 Severity: 3 Rise time: 5 ns Half-value time: 50 ns Amplitude: 2 kV or 1 kV Burst duration: 15 ms Burst period: 300 ms Source impedance: 50 Surge Withstand Capability Per IEC 1000-4-5 Installation class: 3 Test of power supply circuits, asymmetrical or symmetrical lines Open-circuit voltage: 1.2 / 50 s Short-circuit current: 8 / 20 s Amplitude: 1 or 2 kV Pulses: > 5/min Source impedance: 12 or 42 Immunity to Conducted Interference Induced by High-Frequency Fields Per IEC 65A or 77B, Sec.145 or 110 Severity: 2 Test voltage: 3 V Immunity to Magnetic Fields Having Power Engineering Frequencies Per EN 61000-4-8 Severity: 4 Frequency: 50 Hz Field strength: 30 A/m EMC (continued) Immunity to Interruption and Ripple in Auxiliary DC Quantities Per IEC 255-11 12% or 50 ms Insulation Voltage Test Per IEC 255-5 2 kV AC, 60 s Direct voltage (2.8 kV DC) must be used when administering the voltage test to the power supply inputs. The PC interface must not be subjected to the voltage test. Surge Withstand Capability Test Per IEC 255-5 Front time: 1.2 s Time to half-value: 50 s Peak value: 5 kV Source impedance: 500 Mechanical Strength Vibration Test Per IEC 255 Part 21-1 Test severity class 1 Frequency range in operation: 10 to 60 Hz, 0.035 mm 60 to 150 Hz, 0.5 g Frequency range during transport: 10 to 150 Hz, 1 g Shock Test Per IEC 255 Part 21-2 Test severity class 1 Acceleration: 5 g/15 g Pulse duration: 11 ms Seismic Test Per IEC TC 41 B (CO) 54 Class 1 Frequency range: 4 to 8 Hz, 3.5 mm / 1.5 mm 9 to 36 Hz, 1.0 g / 0.5 g Routine Test All tests per EN 60255-6 and DIN 57435 Part 303 Additional Thermal Test 100% controlled temperature-rise test, inputs loaded

DQS Certificate DQS (Deutsche Gesellschaft zur Zertifizierung von Qualittssicherungssystemen), an internationally recognized, independent and neutral association for the certification of quality assurance systems, has awarded AEG the DQS certificate, thereby certifying that AEG has introduced and uses a quality assurance system that conforms to the state of the art and satisfies all requirements stated in DIN ISO 9001 that apply to its products and services.

Environmental Conditions

Allowable Ambient Temperatures Operating temperature: -5C to +55C Storage temperature: -25C to +55C Transport temperature: -25C to +70C Moisture Exposure Relative humidity (annual average), which must not result in moisture condensation: 45 to 75%

PS 441 Directional Time-Overcurrent Protective Device

Technical Data

(continued)

Inputs and Outputs

Measurement Inputs Current Nominal current Inom: 1or 5 A (per order) Nominal consumption per phase: < 0.3 VA at Inom Load rating: continuous: 4 Inom for 10 s: 30 I nom for 1 s: 100 I nom Voltage Nominal voltage V nom: 100 to 130 V AC Nominal consumption per phase: < 0.3 VA at Vnom Load rating: continuous 156 V AC Frequency Nominal frequency f nom: 50 and 60 Hz (switchable) Binary Signal Inputs Equipment: 2 optical coupler inputs (freely configurable) Function assignment: see Page 9 Nominal auxiliary voltage V I,nom: 24 to 250 V DC Operating range: 0.8 to 1.1 V I,nom with a residual ripple of up to 12% of V I,nom Power consumption per input: 35 mA 30% at V I,nom = 24 V DC 15 mA 30% at V I,nom = 48 V DC 4 mA 30% at VI,nom = 60 to 250 V DC Output Relays Equipment: 8 output relays (freely configurable) Function assignment: see Page 9 Contact rating Rated voltage: 300 V DC, 250 V AC Continuous current: 5 A Short-time current: 30 A for 0.5 s Making capacity: 1000 W (VA) at L/R = 40 ms Breaking capacity: 0.2 A at 220 V DC and L/R = 40 ms 4 A at 230 V AC and cos = 0.4 Local Control Panel Input or output of protection data: via six keys and two 4-digit displays State and fault signals: 12 LED indicators (3 permanently assigned, 9 freely configurable) Function assignment: see Page 9 PC Interface Transmission speed: 300 to 9600 baud (adjustable) A special PC connector cable is required for connecting to a PC (see Page 12) ILSA Interface Transmission speed: 50 to 19200 baud (adjustable)

Information Output

Operating Data Acquisition Max. phase current Increments: I P,max primary: 0 to 9999 A 1 0 to 60.00 I nom 0.01 I P,max p.u.: Phase currents I A: 0.00 to 60.00 I nom I B: 0.00 to 60.00 I nom I C: 0.00 to 60.00 I nom Residual (neutral) current I N: 0.000 to 9.999 I nom Phase-to-phase voltage V A-B: 0.00 to 2.00 V B-C: 0.00 to 2.00 V C-A: 0.00 to 2.00 Neutral-to-ground voltage V N-G: 0.00 to 1.50 V nom / 3 Load angle A , B , C: 180 to +180 Energy direction P: A B backward backward backward backward backward forward backward forward forward backward forward backward forward forward forward forward Energy direction N: backward/forward Phase relation IN to I: in opposition/in phase Event Counting Number of trip commands: 0 to 9999 Number of warnings: 0 to 30 Number of faults: 0 to 9999 Fault Data Acquisition Increments: Running time: 0.00 to 99.99 s 0.01 Short-circuit current: 0.01 0.00 to 60.00 I nom Fault Logging Maximum number of faults that can be stored in memory: 5 (then oldest fault is erased) Number of signals per fault that can be stored in memory: 63 (then overflow signal) Real-time tags: via internal clock C backward forward backward forward backward forward backward forward 1 0.01 0.01 0.01 0.001 0.01 0.01 0.01 Fault recording Measurands: Phase currents I A , I B , I C (I N calculated upon output) Phase-to-ground voltages V A-G, VB-G, V C-G, up to 1V nom (V N-G calculated upon output) Dynamic range: 66 I nom and 1.5 V nom Peak value resolution below 6% of dynamic range: at I nom = 1 A: 16 mA r.m.s. at I nom = 5 A: 80 mA r.m.s. or 36,6 mV r.m.s. Peak value resolution above 6% of dynamic range: at I nom = 1 A: 256 mA r.m.s. at I nom = 5 A: 1280 mA r.m.s. or 586 mV r.m.s. Recording time per fault: max 4 s Maximum number of faults stored: 5 (then oldest fault will be cleared) Total recording time: max 4 s (then oldest fault will be cleared) Self monitoring number of storable monitoring indications: max 29 (then overflow indication)

Settings

Default Settings Nominal Frequency 50 Hz 60 Hz Residual Current Determination IN> normal sensitive Measuring-Circuit Connection standard reversed Phase Sequence anti-clockwise clockwise Block tI,N>, tI,N>> none with single-phase starting I> with polyphase starting I> General Start without I N> or IN>> with I N> or IN>> Trip Command 1/2 t I> t I> CBF tI,N> t I> t I> tI,N> CBF t I> tI>> t I> tI>> CBF t I> tI>> tI,N> t I> tI>> tI,N> CBF Latching 1/2 no latching CBF tI,N> tI,N> CBF tI>> tI>> CBF tI>> tI,N> tI>> tI,N> CBF t I> t I> t I> t I> t I> t I> t I> t I> CBF tI,N> tI,N> CBF tI>> tI>> CBF tI>> tI,N> tI>> tI,N> CBF

Trip Command 2/2 without tI,N>> with tI,N>> Latching 2/2 without latching at tI,N>> with latching at tI,N>> Block N1 no block tI,N>> tI,N> tI,N> tI,N>> tI>> tI>> tI,N>> tI>> tI,N> tI>> tI,N> tI,N>> t I> t I> t I> t I> t I> t I> t I> t I> tI,N>> tI,N> tI,N> tI,N>> tI>> tI>> tI,N>> tI>> tI,N> tI>> tI,N> tI,N>>

Block N2 See selection for block N1

PS 441 Directional Time-Overcurrent Protective Device

Technical Data

(continued)

Settings (continued)

Time Overcurrent Protection Phase Currents DTOC Threshold operate value I>: Increments: 0.1 to 40.0/ Inom 0.1 Delay time t I> : 0.00 to 9.99 s 10.0 to 99.9/ s Hold time tI> hold: 0.0 to 9.9 s 10 to 600 s Increments: 0.01 0.1 Increments: 0.1 1 Short-Circuit Direction Determination Activated: no/yes Direction for tI >, tI > >, tI,N>, tI,N>>: forward-directed backward-directed non-directed Charac. angle G : 90 to +90; Increments: 5 Threshold operate value V N-G>: 0.05 to 0.60 V nom/3; Increments: 0.05 Triggering pre-orientation: no/yes Block preorientation N: no/yes Circuit Breaker Failure Protection Increments: 0.01 Increments: 0.01 tCBF: 0.00 to 9.99/ s; Increments: 0.01 Measuring-Circuit Monitoring Mode I diff>: without IA , I C IA , I B, I C Threshold operate value I diff >: 0.25 to 0.50 I Pmax; Increments: 0.05 Increments: 0.1 1 Threshold operate value V min<: 0.40 to 0.90/Vnom; Increments: 0.05 Delay time tMCM: 0.00 to 9.99s; Increments: 0.01 0.0 to 99.9 s; Increments: 0.1 Teleprotection Activated: no/yes Direction dependence: without phase system neutral system phase and neutral system Transmission reset time: 0.00 to 9.99 s; Increments: 0.01 Signal comparison start time: 0.00 to 9.99 s, Increments: 0.01 Transmission, DC loop: Transmission relay with break contact Transmission relay with make contact

Typical Characteristic Data

Time-Overcurrent Protection Starting reset time from 2-fold threshold operating value to 0: 25 ms Shortest tripping time: ca. 30 ms Resetting ratio: 0.95 (starting and measurement) Minimum output pulse for trip command: 100 ms Short-Circuit Direction Determination Nominal acceptance angle for direction decision: 90 Resetting ratio: 7 Phase elements Base point releases for phase currents: 0.05 Inom Base point releases for phase-tophase voltages (direction check): 0.6 Vnom Base point releases for phase-tophase voltages (direction evaluation): 0.001 Vnom Base point release for residual current: Normal range: 0.05 I nom Sensitive range: 0.005 I nom Base point release for ground-toneutral voltage: 0.015 to 0.6 Vnom / 3 (adjustable)

Deviations

Reference conditions Deviation relative to setting for sinusoidal signals, total harmonic distortion 2%, ambient temperature 20 C and nominal auxiliary voltage V A,nom Time-Overcurrent Protection Deviation under reference conditions: 5% Variation at 20C 20 K: 1% Variation at f nom 5%: 5% Variation at VA,nom 20%: 0.5% Time Delays Deviation under reference conditions for inverse time delays: 5% +10 to 20 ms at I 2 I B (7.5% for extremely inverse) for definite time delays: 0.5% +20 to 40 ms Variation at 20C 20 K: 1% Variation at f nom 5%: 2.5% Variation at VA,nom 20%: 0.5% Direction Determination Deviation under reference conditions: 10 Variation at 20C 20 K: 2 Variation at f nom 5%: 1 Variation at VA,nom 20%: 0.5 Base point releases: 10% Operating Value Measurement Currents > 0.2 Inom Deviation: 5% Variation at 20C 20 K: 2.5% Variation at V A,nom 20%: 1% Fault Data Acquisition Fault current Deviation: 5% Variation at 20C 20 K: 2.5% Variation at V A,nom 20%: 1% Internal Clock With free running internal clock Deviation: < 1 min. / month With synchronization via DCF77 clock Deviation: < 10 ms

Threshold operate value I>>: Increments: 0.1 0.1 to 40.0/ Inom Delay time t I>>: 0.00 to 9.99 s 10.0 to 99.9 s IDMT Base current I B: 0.10 to 4.00 I nom Characteristic factor: 0.10 to 4.00 I nom Characteristic type: Normally inverse Very inverse Extremely inverse Long time ground fault RI inverse Hold time tI> hold: 0.0 to 9.9 s 10 to 600 s Increments: 0.01 0.1

Threshold operate value I>> and Delay time tI>>: see DTOC Time Overcurrent Protection Residual Current DTOC Threshold operate value IN>: Increments: 0.01 IN = norm.: 0.02 to 8.00/ Inom IN = sens.: 0.002 to 0.800/ I nom 0.001 Delay time t I,N>: 0.00 to 9.99 s 10.0 to 99.9/ s Hold time tI> hold: 0.0 to 9.9 s 10 to 600 s Increments: 0.01 0.1 Increments: 0.1 1

Threshold operate value IN>>:Increments: 0.01 IN = norm.: 0.02 to 8.00/ Inom IN = sens.: 0.002 to 0.800/ I nom 0.001 Delay time t I,N>>: 0.00 to 9.99 s 10.0 to 99.9/ s IDMT Base current I NB: Increments: 0.01 IN = norm.: 0.02 to 8.00/ Inom IN = sens.: 0.002 to 0.800/ I nom 0.001 Characteristic factor: 0.10 to 4.00 I nom Characteristic type: Normally inverse Very inverse Extremely inverse Long time ground fault RI inverse Hold time tI> hold: 0.0 to 9.9 s 10 to 600 s Increments: 0.1 1 Increments: 0.01 Increments: 0.01 0.1

Power Supply

Nominal auxiliary voltage VA,nom: 24 to 60 V DC and (internally switchable) 110 to 250 V DC or 100 to 230 V AC Operating range for direct voltage: 0.8 to 1.1 V A,nom with a residual ripple of up to 12% of VA,nom For alternating voltage: 0.9 to 1.1 V A,nom Nominal consumption: approx. 8 W / 10 W (initial position / active position) at V A = 220 V DC Start-up peak current: < 13 A, duration 0.25 ms

Threshold operate value IN>> and Delay time t I,N>>: see DTOC

PS 441 Directional Time-Overcurrent Protective Device

Signal List

Signal Inputs The signal inputs allow intervention in the protective sequence. Each input can be set for one of the signals given in Table 1. However, a given signal may be assigned to only one input. The signal names refer to the active state of the input signal. Each input can be set as follows: active = low signal active = high signal.

LED Indicators Three LED indicators on the local control panel have permanently assigned signals (Table 2a). The other nine LED indicators are freely configurable and can be assigned any of the signals listed in Table 2b.

Output Relays The output relays are freely configurable and can be assigned any of the signals listed in Table 3. Any signal can also be assigned to more than one free output relay for contact multiplication purposes. All relays operate in opencircuit arrangement (the make contact is closed when the signal is present) except for the case where an output relay is configured for the signal MAIN: Blocked/ faulty. In this case the contact opens when the device is blocked/faulty.

Abbreviations for Function Groups CBF: circuit breaker failure protection

DTOC: definite-time overcurrent protection FREC: fault recording IDMT: inverse definite minimum time overcurrent protection MAIN: main function MCM; measuring-circuit monitoring MON: self-monitoring PSIG: protective signaling/teleprotection SCDD: short-circuit direction determination

PS 441 Directional Time-Overcurrent Protective Device

Signal List

(continued)

Table 1: Freely Configurable Signal Inputs Input FuncSignal tion Group

U1 U2 w/o Function CBF: ILSA: MAIN: Input EXT Command enable EXT Sig./meas.block EXT Block outp.rel. EXT E2 block EXT E1 block EXT m.c.b.trip V LS EXT Reset indicat. EXT Reset latch. EXT Reset latch.+ind.EXT

Table 2a: Permanently Configured LED Indicators Indi- FuncSignal cator tion Group

H1 H2 H3 MON: Warning MAIN: Operation MAIN: Blocked/faulty

Table 2b: Freely Configurable LED Indicators Indi- FuncSignal cator tion Group

H4 H5 H6 H7 H8 H9 H 10 H 11 H 12 DTOC: w/o Function CBF: Input EXT t CBF elapsed Trip by CBF General starting Starting A Starting B Starting C Starting GF Starting I>> Starting I N>> t I,N>> elapsed t I>> elapsed I> triggered Starting I> t H,I running t H,I,N running t I,N> elapsed t I,N> or tI,N>> t I> elapsed t I> or t I>> E1 block EXT E2 block EXT m.c.b.trip V LS EXT Trip command Meas.circuits faulty SCDD blocked Blocking EXT Enabled Not ready Ready Receive EXT Send Telecom. faulty Trip by PSIG Fault L backward Fault L forward Fault P or G backw. Fault P or G forwd. Ground fault backw. Ground fault forwd.

Table 3: Freely Configurable Output Relays Relay FuncSignal tion Group

K1 K2 K3 K4 K5 K6 K7 K8 DTOC: w/o Function CBF: tCBF elapsed Trip by CBF General starting Starting A Starting B Starting C Starting GF Starting I>> Starting I N>> tI,N>> elapsed tI>> elapsed I> triggered Starting I> tH,I running tH,I,N running tI,N> elapsed tI,N> or tI,N>> tI> elapsed tI> or tI>> Blocked/faulty m.c.b.trip V,LS EXT Trip command Meas.circuits faulty SCDD blocked Warning Enabled Not ready Ready Send Telecom. faulty Trip by PSIG Fault L backward Fault L forward Fault P or G backw. Fault P or G forwd. Ground fault backw. Ground fault forwd.

PC/ILSA: Test mode EXT PSIG: Enable EXT Blocking EXT Disable EXT Receive EXT FREC: IDMT/ DTOC:

FREC: IDMT/ DTOC:

MAIN:

MAIN:

MCM: MON: PSIG:

MCM: PSIG:

SCDD:

SCDD:

PS 441 Directional Time-Overcurrent Protective Device

Dimensional Drawing and Terminal Connection Diagram

5 Dimensional drawing and panel cutout

20.6 20.6

19

X3

X3

6.4

36

PS 441

294.2

254

294.2

299

256 +1

279

309

289

281 +1

X6

!

1 X7 X8 X1

6.4 125

X1

18

48.6

93

65.6

9

162.5

172

0.5

175.6 wall surface mounting wall surface mounting panel flush mounting

panel cutout and mounting frame outline

6 Terminal connection diagram

Power Supply

Aux voltage VA 2) X1 L+ 13 L 14 U100

LED Indicators

H1 H2 MON: Main: Main: Warning Operation Blocked/Faulty

Meas. Inputs

X1 A1 1 A2 2 B1 3 B2 4 C1 5 C2 6 N1 7 N2 8 X1 A 9 T5 B 10 T6 C 11 N 12 T7 T1 T2 T3 T4

H3 H4 H5 H6 H7 H8 H9 H10 H11 H12

IDMT/DTOC: Starting A 1) IDMT/DTOC: Starting B 1) IDMT/DTOC: Starting C 1) IDMT/DTOC: Starting GF 1) IDMT/DTOC: tI> or tI>> 1) IDMT/DTOC: tI,N> or tI,N>> 1) SCDD: SCDD: CBF: Phase fault backw. 1) Ground fault backw. 1) Input EXT 1)

Signal Inputs

MAIN: Reset ind. EXT 1)

1)

Ausgangsrelais

X3 35 36 33 32 34 30 29 31 27 28 22 26 25 24 23 20 19 21 Main: Trip command 1)

L+ L L+ L

X1 15 16 17 18

U1 U2

K1

PC Interface

3)

K2 K3 K4 K5 K6 K7 K8

X6 D1 2 D2 3 E2 5

IDMT/DTOC: General starting 1) MCMON: DTOC: IDMT/DTOC: DTOC: IDMT/DTOC: Main: Meas. circuit faulty 1) tI>> elapsed 1) tI> elapsed 1) tI,N>> elapsed 1) tI,N> elapsed 1) Blocked/Faulty 1)

ILSA Interface (option)

X7 1) Freely assignable (see signal list at page 9, showed assignments are factory default) 2) L+ und L- circuit may be tested only with 2.8 kV DC to ground 3) Internal interface, voltage test is prohibited X8

# #

# #

11719.DS4

PS 441

10

11718.DS4

125

0.5

300

PS 441 Directional Time-Overcurrent Protective Device

Connection Example

7 PS 441 connection example

A B C Power Supply

Aux voltage VA X1 L+ 13 L 14 U100

LED Indicators

H1 H2

Meas. Inputs

X1 A1 1 A2 2 B1 3 B2 4 C1 5 C2 6 N1 7 N2 8 X1 A 9 T5 B 10 T6 C 11 N 12 T7 T1 T2 T3 T4

H3 H4 H5 H6 H7 H8 H9 H10 H11 H12

I>

I>

I>

L+ L L+ L

Signal Inputs

X1 15 16 17 18 U1 U2

Ausgangsrelais

X3 35 36 33 32 34 30 29 31 27 28 22 26 25 24 23 20 19 21

K1

PC Interface

X6 D1 2 D2 3 E2 5

K2 K3 K4 K5 K6 K7 K8

ILSA Interface (option)

X7 X8

# #

# #

11719.DS4

PS 441

11720.DS4

11

PS 441 Directional Time-Overcurrent Protective Device

Ordering Information

Numerical directional time-overcurrent protective device with inverse-time and definite-time characteristics Case for panel surface or flush mounting 4-pole measurement (A, B, C, N) Phase-selective overcurrent timer module and start signals DTOC and IDMT modes, separately adjustable for phase current and residual current modules Time-lag high set phase current and high set residual current modules Short-circuit direction determination with separate measuring systems for phase current and residual current timer modules Tripping matrix Optional latching of individual tripping criteria Teleprotection through pilot wires Possibility of reverse interlocking Circuit breaker failure protection Measuring-circuit monitoring Operating data acquisition Event counting Acquisition of maximum short-circuit current and running time data Fault logging with real-time tagging Fault recording (0,6 kHz, 4 s) of the three phase currents and three phase-to-ground voltages Self-monitoring 2 signal inputs (freely configurable) 8 output relays (freely configurable) Integrated local control panel 12 LED indicators (9 freely configurable) PC interface ILSA interface (option)

Designs

Order No.

Extension No. (append to order no.

PS 441 Case with 36 terminals Variants Case prepared for panel surface mounting panel flush mounting with cover frame Nominal current I nom Phase current input 1 A and residual current input 1 A Phase current input 5 A and residual current input 5 A Phase current input 5 A and residual current input 1 A Nominal frequency f nom 50 Hz and 60 Hz Nominal auxiliary voltage for power supply V A,nom 24 to 60 V DC and 110 to 250 V DC or 100 to 230 V AC Nominal auxiliary voltage for signal inputs VI,nom 24 to 250 V DC Residual current module with sensitive setting range with normal setting range ILSA interface without for plastic fiber optical link for glass fiber optical link Additional options Labeling and documentation in English Accessories PC connector cable ( 2.5 m) FPCC parameterization program FPC control program

89441-0-

1 2 1 2 3 2 3 3 1 2 0 1 2

-598

255 002 096 251 254 271 251 254 675

abcd

12

ALSTOM Energietechnik GmbH Protection and Control Unit Lyoner Strae 44-48, D-60528 Frankfurt Postfach 71 01 07, D-60491 Frankfurt Germany Phone: ++49 - 69 - 66 32-15 21 Fax: ++49 - 69 - 66 32-25 48 http://tde.alstom.com/p-c/afs

AFSV.06.04762PDF/0899EN M\M

Modifications reserved Printed in Germany

S-ar putea să vă placă și

- t35 ManualDocument532 paginit35 ManualkenageÎncă nu există evaluări

- RADSS 3-Phase Busbar Protection (ABB)Document12 paginiRADSS 3-Phase Busbar Protection (ABB)majid_abkoohiÎncă nu există evaluări

- LDP Micom Relays P441 & P442 For Distance ProtectionDocument16 paginiLDP Micom Relays P441 & P442 For Distance ProtectionRakesh MishraÎncă nu există evaluări

- Proposal Setting Gi Tanjung BungaDocument20 paginiProposal Setting Gi Tanjung Bungawandy RJ100% (1)

- Mie11169-Cba2000 Application GuideDocument149 paginiMie11169-Cba2000 Application GuideFuad BurhaniÎncă nu există evaluări

- Ferro ResonanceDocument8 paginiFerro ResonanceDoydoy MeridaÎncă nu există evaluări

- TechRef StaticGeneratorDocument31 paginiTechRef StaticGeneratoradderlyhuertaÎncă nu există evaluări

- Vagm 22Document4 paginiVagm 22AONLAÎncă nu există evaluări

- Unit - 6 Feeder ProtectionDocument24 paginiUnit - 6 Feeder ProtectionAkula VeerrajuÎncă nu există evaluări

- Unbalance Protection of Fuseless, Split-Wye, Grounded, Shunt Capacitor BanksDocument4 paginiUnbalance Protection of Fuseless, Split-Wye, Grounded, Shunt Capacitor BanksgustavopaloÎncă nu există evaluări

- Sinkrotakt Manual 5Document39 paginiSinkrotakt Manual 5Vlado RadojsolicÎncă nu există evaluări

- Fault Fundamentals Rev 080212 160117051103 PDFDocument47 paginiFault Fundamentals Rev 080212 160117051103 PDFYume YumeÎncă nu există evaluări

- 7sd52 7sd62 ConfigurationDocument14 pagini7sd52 7sd62 ConfigurationWilber LucasÎncă nu există evaluări

- Digsilent Powerfactory: Relay Model DescriptionDocument16 paginiDigsilent Powerfactory: Relay Model DescriptionBra BicabaÎncă nu există evaluări

- APN-052 Directional Ground-Fault ProtectionDocument17 paginiAPN-052 Directional Ground-Fault ProtectionWalter Andres Estevez VasquezÎncă nu există evaluări

- CMC 356 Presentation ENUDocument14 paginiCMC 356 Presentation ENUAri100% (1)

- ABB ADVAC Circuit Breaker Manual PDFDocument51 paginiABB ADVAC Circuit Breaker Manual PDFsumitsinha89Încă nu există evaluări

- Nine-Bus System: 1 General DescriptionDocument10 paginiNine-Bus System: 1 General DescriptionJoseLuisPerezÎncă nu există evaluări

- P10Document16 paginiP10Lynskey1973100% (1)

- APN-060 Low Impedance Restricted Ground Fault ProtectionDocument15 paginiAPN-060 Low Impedance Restricted Ground Fault ProtectionCarlos Roberto Hernandez FerrerÎncă nu există evaluări

- BA300Document7 paginiBA300carthic1979Încă nu există evaluări

- Shinshen AcrDocument134 paginiShinshen Acrmd. ahsan habibÎncă nu există evaluări

- Cag 1737Document5 paginiCag 1737Anonymous HuHbq4OR100% (2)

- Testing Quadrilateral Distance ElementsDocument14 paginiTesting Quadrilateral Distance ElementsPandrayar MaruthuÎncă nu există evaluări

- Sotf Logic Schemes-Nerc GuidelinesDocument13 paginiSotf Logic Schemes-Nerc GuidelineshariÎncă nu există evaluări

- TechRef StationControllerDocument28 paginiTechRef StationControllerАлишер ГалиевÎncă nu există evaluări

- Protective Relaying Testing ST6Document6 paginiProtective Relaying Testing ST6Darwin MesaÎncă nu există evaluări

- SM6 - 24 - CT CatalogueDocument20 paginiSM6 - 24 - CT Catalogueluutrudulieu3100% (2)

- iCP-440 Capacitor Bank Protection RelayDocument12 paginiiCP-440 Capacitor Bank Protection Relayqwkerbk090909Încă nu există evaluări

- TechRef StationController PDFDocument28 paginiTechRef StationController PDFmalecad0% (1)

- Dema-Mcr & MVR Protection RelayDocument21 paginiDema-Mcr & MVR Protection Relaydarius perez100% (1)

- PZ1000 EngDocument16 paginiPZ1000 EngMeghavahina100% (1)

- User Manual TPU S420 EnglishDocument521 paginiUser Manual TPU S420 EnglishLuis BritoÎncă nu există evaluări

- Sensitivity of Transient Stability Critical Clearing TimeDocument12 paginiSensitivity of Transient Stability Critical Clearing Timedr.Sabita shresthaÎncă nu există evaluări

- Micom P746: Numerical Busbar ProtectionDocument8 paginiMicom P746: Numerical Busbar Protectionsridhar30481647100% (1)

- 7SG11 Argus 1 2 4 and 6 Catalogue SheetDocument22 pagini7SG11 Argus 1 2 4 and 6 Catalogue SheetGyan SagarÎncă nu există evaluări

- Hands On Relay School Transformer Protection Open Lecture ClassDocument63 paginiHands On Relay School Transformer Protection Open Lecture ClasshiteshkelaÎncă nu există evaluări

- ABB Power Tap-Changer GuideDocument13 paginiABB Power Tap-Changer GuideSellappan MuthusamyÎncă nu există evaluări

- Stub Bus PDFDocument1 paginăStub Bus PDFpgcilÎncă nu există evaluări

- Département Télécommunications - Document Technique: Alspa PLC 1790/B Technical Manual InstallationDocument26 paginiDépartement Télécommunications - Document Technique: Alspa PLC 1790/B Technical Manual Installationjrsk638742Încă nu există evaluări

- Power System Stability LectureDocument17 paginiPower System Stability LectureMuhammad Taufan Yoga P.Încă nu există evaluări

- Distance Protection - Eercise 1 - MemoDocument7 paginiDistance Protection - Eercise 1 - Memomoses kakwenaÎncă nu există evaluări

- Generator Model Validation Using PMU Data For MOD-26, MOD-27 RequirementsDocument34 paginiGenerator Model Validation Using PMU Data For MOD-26, MOD-27 Requirementswvargas926Încă nu există evaluări

- p345 Technical ManualDocument1 paginăp345 Technical ManualabhayambujÎncă nu există evaluări

- Lec-3 Effect of Fault Resistance and Pre-Fault Power Flow On The Performance of Distance RelayDocument5 paginiLec-3 Effect of Fault Resistance and Pre-Fault Power Flow On The Performance of Distance RelayTamjidÎncă nu există evaluări

- PCS 978 Data Sheet PDFDocument45 paginiPCS 978 Data Sheet PDFMateus FrancoÎncă nu există evaluări

- Indice de Relay'sDocument16 paginiIndice de Relay'shectorhscÎncă nu există evaluări

- L90 - Guide Form Specification (Version 5.20) Specification For Transmission Line Current Differential Protection, Control and MonitoringDocument6 paginiL90 - Guide Form Specification (Version 5.20) Specification For Transmission Line Current Differential Protection, Control and MonitoringRodriguez Villalobos NelsonÎncă nu există evaluări

- L90 SpecDocument13 paginiL90 SpecGANESH KÎncă nu există evaluări

- STS365TDocument8 paginiSTS365TĐỗ DũngÎncă nu există evaluări

- MCGG OcrDocument14 paginiMCGG OcrAgus BuchariÎncă nu există evaluări

- PCS 931Document6 paginiPCS 931mentongÎncă nu există evaluări

- Areva PublicationDocument24 paginiAreva PublicationAnonymous BBX2E87aHÎncă nu există evaluări

- Protective Relays for Power SystemsDocument67 paginiProtective Relays for Power Systemsbasudev1978Încă nu există evaluări

- P342 343 Generators ProtectionsDocument16 paginiP342 343 Generators ProtectionshieudaininhÎncă nu există evaluări

- 7sr17 Rho Catalogue SheetDocument20 pagini7sr17 Rho Catalogue Sheetapi-241473079Încă nu există evaluări

- Micom P145Document8 paginiMicom P145Razvan MaresÎncă nu există evaluări

- NM20 Flyer 08 2012 PDFDocument12 paginiNM20 Flyer 08 2012 PDFandy175Încă nu există evaluări

- 1106740701122-KVGC202 en TDDocument12 pagini1106740701122-KVGC202 en TDAnonymous 9VcxlFErfÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- Methodology and Design of An AdaptiveDocument9 paginiMethodology and Design of An AdaptiveHimdad TahirÎncă nu există evaluări

- Application Guide Over-Current Protection TutorialDocument37 paginiApplication Guide Over-Current Protection Tutorialluhusapa-1Încă nu există evaluări

- Etap Validation Cases and Comparison Results: Load FlowDocument66 paginiEtap Validation Cases and Comparison Results: Load FlowK.RamachandranÎncă nu există evaluări

- BOQ Office BuildingsDocument24 paginiBOQ Office BuildingsRonnie Albert MonteroÎncă nu există evaluări

- California Electrician Scope of WorkDocument6 paginiCalifornia Electrician Scope of WorkHimdad TahirÎncă nu există evaluări

- Overcurrent Protection for the IEEE 34 Node Radial Test FeederDocument18 paginiOvercurrent Protection for the IEEE 34 Node Radial Test FeederHenry MichaelÎncă nu există evaluări

- Aero Gener AdoresDocument39 paginiAero Gener AdoresRosa María De Anda Lopez100% (1)

- Underground Power Cables Catalogue 03-2010Document48 paginiUnderground Power Cables Catalogue 03-2010Edgar Sierra Rodriguez100% (1)

- Pcm600 en ManualDocument12 paginiPcm600 en ManualRobert RocafuerteÎncă nu există evaluări

- Circuit Breakers Technical SpecificationDocument97 paginiCircuit Breakers Technical SpecificationHimdad Tahir100% (4)

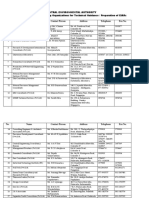

- Suruhanjaya Tenaga - Guidelines For Wiring ResidentialDocument55 paginiSuruhanjaya Tenaga - Guidelines For Wiring Residentialkingcloud7100% (24)

- ECP 11-0209 Interlocks Test Form: 1 General DataDocument3 paginiECP 11-0209 Interlocks Test Form: 1 General DataHimdad TahirÎncă nu există evaluări

- Normal Earth-Earth Fault Current &csa TableDocument37 paginiNormal Earth-Earth Fault Current &csa TableAbraham JyothimonÎncă nu există evaluări

- Cable Sheath Bonding Application Guide Companion PDFDocument45 paginiCable Sheath Bonding Application Guide Companion PDFskylimit.skylimitÎncă nu există evaluări

- 100 Words Kids Need To Read PDFDocument92 pagini100 Words Kids Need To Read PDFHimdad Tahir0% (1)

- Constant of 132 KV and 400 KV Over Head Lines PDFDocument1 paginăConstant of 132 KV and 400 KV Over Head Lines PDFHimdad TahirÎncă nu există evaluări

- 100 Words Kids Need To Read PDFDocument92 pagini100 Words Kids Need To Read PDFHimdad Tahir0% (1)

- Pcm600 en ManualDocument12 paginiPcm600 en ManualRobert RocafuerteÎncă nu există evaluări

- Physics SummaryDocument7 paginiPhysics SummaryHimdad TahirÎncă nu există evaluări

- Power Wiring Diagram 10MVAR PW REV3 250607Document1 paginăPower Wiring Diagram 10MVAR PW REV3 250607Himdad TahirÎncă nu există evaluări

- ACW's Insulator Info - Book Reference Info - Overvoltage and FlashoversDocument44 paginiACW's Insulator Info - Book Reference Info - Overvoltage and FlashoversHimdad TahirÎncă nu există evaluări

- ELECTRICAL LIVE - Wind Solar Hybrid Street LightingDocument2 paginiELECTRICAL LIVE - Wind Solar Hybrid Street LightingHimdad TahirÎncă nu există evaluări

- Normal Earth-Earth Fault Current &csa TableDocument37 paginiNormal Earth-Earth Fault Current &csa TableAbraham JyothimonÎncă nu există evaluări

- Constant of 132 KV and 400 KV Over Head Lines PDFDocument1 paginăConstant of 132 KV and 400 KV Over Head Lines PDFHimdad TahirÎncă nu există evaluări

- Logic Diagrams For Two Section ATSDocument8 paginiLogic Diagrams For Two Section ATSHimdad TahirÎncă nu există evaluări

- Digitally Controlled Wind Turbines in MWDocument10 paginiDigitally Controlled Wind Turbines in MWHimdad TahirÎncă nu există evaluări

- Syllabus of Master of Electrical EngineeringDocument14 paginiSyllabus of Master of Electrical EngineeringHimdad TahirÎncă nu există evaluări

- Digitally Controlled Wind Turbines in MWDocument10 paginiDigitally Controlled Wind Turbines in MWHimdad TahirÎncă nu există evaluări

- PF15 Flyer EN Rev 1Document8 paginiPF15 Flyer EN Rev 1Himdad TahirÎncă nu există evaluări

- 7216Document8 pagini7216siicmorelosÎncă nu există evaluări

- EC 351 AC Analog Communication Lab ManualDocument117 paginiEC 351 AC Analog Communication Lab Manualhodibaaba1Încă nu există evaluări

- Profile Correction of A Helical Gear Shaping CutterDocument11 paginiProfile Correction of A Helical Gear Shaping Cutterdanielk32Încă nu există evaluări

- RtosDocument78 paginiRtossekinÎncă nu există evaluări

- DF PDFDocument8 paginiDF PDFAtif JaveadÎncă nu există evaluări

- DV2P Prog ManualDocument75 paginiDV2P Prog ManualDavis Arturo Pinto PérezÎncă nu există evaluări

- Performance of A Test Embankment Constructed On An Organic Clayey Silt DepositDocument10 paginiPerformance of A Test Embankment Constructed On An Organic Clayey Silt DepositGurtejSinghChanaÎncă nu există evaluări

- New Consultant List 20177 For Cea Website 10.02.2016Document4 paginiNew Consultant List 20177 For Cea Website 10.02.2016hxian.y9333Încă nu există evaluări

- Seismic Analysis of A Valley-Fill Heap Leach PadDocument17 paginiSeismic Analysis of A Valley-Fill Heap Leach PadMARCOS ABRAHAM ALEJANDRO BALDOCEDA HUAYASÎncă nu există evaluări

- Boiler FormulasDocument5 paginiBoiler FormulasAnonymous 6Mb7PZjÎncă nu există evaluări

- RC2 Series Screw Compressor Maintenance ManualDocument161 paginiRC2 Series Screw Compressor Maintenance ManualMichele CassiniÎncă nu există evaluări

- Kinematics equations motion problemsDocument3 paginiKinematics equations motion problemsAhmed HossainÎncă nu există evaluări

- Materials System SpecificationDocument8 paginiMaterials System Specificationnadeem shaikhÎncă nu există evaluări

- Carcass Chilling Systems and Their Impact On Meat Quality - Pig Articles From The Pig SiteDocument3 paginiCarcass Chilling Systems and Their Impact On Meat Quality - Pig Articles From The Pig SiteJose Romanillos VelascoÎncă nu există evaluări

- CM700 Users GuideDocument13 paginiCM700 Users GuidenurazrreenÎncă nu există evaluări

- Substation Filter BankSpecsDocument7 paginiSubstation Filter BankSpecsTudor BostanÎncă nu există evaluări

- FD-SOI and FinFET Technologies ComparedDocument25 paginiFD-SOI and FinFET Technologies ComparedDhanishtha SinghÎncă nu există evaluări

- Aegis Multifunction RelayDocument4 paginiAegis Multifunction RelaySuranjana DasÎncă nu există evaluări

- Killexams HPE0 S46 Real Exam Questions Answers PDFDocument6 paginiKillexams HPE0 S46 Real Exam Questions Answers PDFopen_666Încă nu există evaluări

- MPTO Charts566662Document25 paginiMPTO Charts566662andres ortizÎncă nu există evaluări

- P28 and P128 Series Lube Oil Controls With Built-In Time Delay RelayDocument8 paginiP28 and P128 Series Lube Oil Controls With Built-In Time Delay RelayFreddy de los SantosÎncă nu există evaluări

- Household Electricity End-Use ConsumptionDocument22 paginiHousehold Electricity End-Use ConsumptionEva ViskadourakiÎncă nu există evaluări

- Cutting Guide: Integrated Seat Post (ISP)Document4 paginiCutting Guide: Integrated Seat Post (ISP)Anand sÎncă nu există evaluări

- Coke Bottle Tutorial For MayaDocument42 paginiCoke Bottle Tutorial For MayadumbledoreaaaaÎncă nu există evaluări

- Ussocom 006Document52 paginiUssocom 006RTSLLCÎncă nu există evaluări

- Hotpoint Service Manual Fridge FreezerDocument36 paginiHotpoint Service Manual Fridge FreezerMANUEL RODRIGUEZ HERRERA100% (1)

- Nexans - MPRX (2002)Document63 paginiNexans - MPRX (2002)Dan Ghimbasanu0% (1)

- Main Engine Fuel Pump Drive Roller Damage: Return To TOCDocument2 paginiMain Engine Fuel Pump Drive Roller Damage: Return To TOCTunaÎncă nu există evaluări

- Saudi Technical Trade Test - Welder CategoryDocument4 paginiSaudi Technical Trade Test - Welder CategoryshabashakkimÎncă nu există evaluări

- Design of Foundations On Sensitive Champlain Clay Subjected To Cyclic LoadingDocument9 paginiDesign of Foundations On Sensitive Champlain Clay Subjected To Cyclic LoadingRamiro ChairezÎncă nu există evaluări