Documente Academic

Documente Profesional

Documente Cultură

Ii D App2

Încărcat de

Riduan HutajuluDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ii D App2

Încărcat de

Riduan HutajuluDrepturi de autor:

Formate disponibile

APPENDIX 2 BASIS FOR ESTABLISHING DESIGN STRESS INTENSITY VALUES FOR TABLES 2A, 2B, 3, AND 4

2-100 DERIVATION OF STRESS INTENSITY VALUES

2-100(a), 2-100(b), and 2-100(c). The mechanical properties considered, and the factors applied to establish the maximum allowable stresses, are given in 2-110 through 2-130.

In the determination of design stress intensity values for nonnuclear materials, the Committee is guided by successful experience in service, insofar as evidence of satisfactory performance is available. Such evidence is considered equivalent to test data where operating conditions are known with reasonable certainty. In the evaluation of new materials for both nuclear and nonnuclear applications, it is sometimes necessary to be guided to a certain extent by the comparison of test information with available data on successful applications of similar materials. The factors employed to determine design stress intensity values are provided in Tables 2-100(a), 2-100(b), and 2-100(c). Nomenclature for these Tables is as follows: Favg p multiplier applied to average stress for rupture in 100,000 hr. At 1500F and below, Favg p 0.67. Above 1500F, it is determined from the slope of the log time-to-rupture versus log stress plot at 100,000 hr such that log Favg p 1/n, but it may not exceed 0.67. RT p ratio of the average temperature dependent trend curve value of tensile strength to the room temperature tensile strength RY p ratio of the average temperature dependent trend curve value of yield strength to the room temperature yield strength ST p specied minimum tensile strength at room temperature, ksi SY p specied minimum yield strength at room temperature, ksi n p a negative number equal to log time-torupture divided by log stress at 100,000 hr NA p not applicable The maximum design stress intensity shall be the lowest value obtained from the criteria in Tables

764

2-110

CRITERIA FOR MATERIALS OTHER THAN BOLTING: TABLES 2A AND 2B

The design stress intensity values at any temperature are no larger than the least of the following: (a) one-third of the specied minimum tensile strength at room temperature; (b) one-third of the tensile strength at temperature; (c) two-thirds of the specied minimum yield strength at room temperature; (d) two-thirds of the yield strength at temperature, except that for austenitic stainless steels and specic nonferrous materials, as indicated in Tables 2A and 2B, this value may be as large as 90% of the yield strength at temperature (but never more than two-thirds of the specied minimum yield strength). (e) In the application of these criteria, the Committee considers the yield strength at temperature to be SYRY, and the tensile strength at temperature to be 1.1STRT.

2-120

CRITERIA FOR BOLTING MATERIALS IN TABLE 3 FOR USE WITH SECTION VIII, DIVISION 1; SECTION VIII, DIVISION 2 (APPENDIX 3 RULES); AND SECTION III (CLASS 2 AND 3 RULES)

(a) For materials whose strength has not been enhanced by heat treatment or by strain hardening, the

COPYRIGHT American Society of Mechanical Engineers Licensed by Information Handling Services

Table 2-100(a)

PART D PROPERTIES

Table 2-100(c)

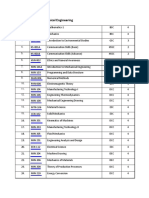

TABLE 2-100(a) CRITERIA FOR ESTABLISHING DESIGN STRESS INTENSITY VALUES FOR TABLES 2A AND 2B

Product/Material Wrought or cast, ferrous and nonferrous

1

Tensile Strength 3 ST 1.1 S R 3 T T (1.1 0.85) STRT 3

2

Yield Strength 3 SY

2

3 SYRY or 0.9SYRY [Note (1)]

Welded pipe or tube, ferrous and nonferrous

0.85 ST 3

0.85 S 1.5 Y

0.85 S R or 1.5 Y Y (0.9 0.85)SYRY [Note (1)]

NOTE: (1) For austenitic materials in Table 2A and for specic nonferrous alloys in Table 2B, the design stress intensity values may exceed two-thirds and may be as high as 90% of the yield strength at temperature.

TABLE 2-100(b) CRITERIA FOR ESTABLISHING ALLOWABLE STRESS VALUES FOR TABLE 3

Below Room Temperature Product/Material Bolting annealed ferrous and nonferrous Bolting, with strength enhanced by heat treatment or strain hardening, ferrous and nonferrous [Note (1)] Tensile Strength Yield Strength

2

Room Temperature and Above Tensile Strength Yield Strength

2

Stress Rupture

Creep Rate 1.0Sc

ST 4 ST 5

3 SY

ST 4

1

1.1 S R 4 T T 1.1 S R 4 T T

3 S Y

3 SYRY

FavgSR avg

0.8SR min

SY 4

5 S T

4 S Y

3 SYRY

FavgSR avg

0.8SR min

1.0Sc

NOTE: (1) For materials whose strength has been enhanced by heat treatment or by strain hardening, the criteria shown shall govern unless the values are lower than for the annealed material, in which case the annealed values shall be used.

TABLE 2-100(c) CRITERIA FOR ESTABLISHING DESIGN STRESS INTENSITY VALUES FOR TABLE 4

Product/Material Bolting, with strength enhanced by heat treatment or strain hardening [Note (1)] Tensile Strength Yield Strength NA NA 13 SY

1

3 SYRY

NOTE: (1) This applies only to ferrous materials for Section VIII, Division 2 application.

765

COPYRIGHT American Society of Mechanical Engineers Licensed by Information Handling Services

2-120

2001 SECTION II

2-130

design stress intensity value shown at any temperature in Table 3 is the least of the following: (1) one-fourth of the specied minimum tensile strength at room temperature; (2) one-fourth of the tensile strength at temperature; (3) two-thirds of the specied minimum yield strength at room temperature; (4) two-thirds of the yield strength at temperature. (b) For materials whose strength has been enhanced by heat treatment or by strain hardening, the design stress intensity value shown at any temperature in Table 3 is the least of the following, unless these values are lower than the annealed values, in which case the annealed values shall be used: (1) one-fth of the specied minimum tensile strength at room temperature; (2) one-fourth of the tensile strength at temperature; (3) one-fourth of the specied minimum yield strength at room temperature; (4) two-thirds of the yield strength at temperature. (c) In the application of these criteria, the Committee considers the yield strength at temperature to be SYRY, and the tensile strength at temperature to be 1.1STRT. (d) At temperatures in the range where creep and stress rupture strength govern the selection of stresses, the maximum allowable stress value for all materials

is established by the Committee not to exceed the lowest of the following: (1) 100% of the average stress to produce a creep rate of 0.01%/1000 hr; (2) 100Favg% of the average stress to cause rupture at the end of 100,000 hr; (3) 80% of the minimum stress to cause rupture at the end of 100,000 hr. Stress values for high temperatures are based, whenever possible, on representative uniaxial properties of the materials obtained under standard ASTM testing conditions or equivalent. The stress values are based on basic properties of the materials and no consideration is given for corrosive environment, for abnormal temperature and stress conditions, or for other design considerations. 2-130 CRITERIA FOR BOLTING MATERIALS FOR USE WITH APPENDICES 4, 5, AND 6 OF SECTION VIII, DIVISION 2 AND SECTION III, SUBSECTION NB

The design stress intensity value shown at any temperature in Table 4 is the least of the following, with credit being granted for enhancement of properties by heat treatment or by strain hardening: (a) one-third of the specied minimum yield strength at room temperature; (b) one-third of the yield strength at temperature.

766

COPYRIGHT American Society of Mechanical Engineers Licensed by Information Handling Services

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Chapter 8 - Electric Current & ResistivityDocument5 paginiChapter 8 - Electric Current & ResistivityFritz NatividadÎncă nu există evaluări

- Entropy and Free EnergyDocument32 paginiEntropy and Free EnergyNitya DewiÎncă nu există evaluări

- Fluid Flow in Porous MediaDocument160 paginiFluid Flow in Porous MediaCedric Kimloaz100% (1)

- FLOCALC Calc DetailsDocument15 paginiFLOCALC Calc DetailsLuanLTÎncă nu există evaluări

- Ultrasonic PhysicsDocument16 paginiUltrasonic PhysicsCarlos AlviarezÎncă nu există evaluări

- Radiation Heat Transfer in Combustion Systems - Viskanta - Menguc - 1987Document64 paginiRadiation Heat Transfer in Combustion Systems - Viskanta - Menguc - 1987Martin Martin MartinÎncă nu există evaluări

- B Tech Mechanical Engineering Syllabus For Batch 2013-14Document30 paginiB Tech Mechanical Engineering Syllabus For Batch 2013-14ra44993541Încă nu există evaluări

- Simple MachinesDocument39 paginiSimple MachinesOriol LloberaÎncă nu există evaluări

- Projectile MotionDocument16 paginiProjectile MotionLastschoolkingZÎncă nu există evaluări

- Quiz 49Document5 paginiQuiz 49Niño YbañezÎncă nu există evaluări

- Physics Paper 1 M:J 2009Document5 paginiPhysics Paper 1 M:J 2009Faisal Iqbal KhanÎncă nu există evaluări

- Aadesh Pathare Tom Micro ProjectDocument18 paginiAadesh Pathare Tom Micro ProjectAKASH THORATÎncă nu există evaluări

- Guide 08Document40 paginiGuide 08Christopher ThaiÎncă nu există evaluări

- N. M. Belyaev - Strength of Materials - MirDocument650 paginiN. M. Belyaev - Strength of Materials - Mircentscoup1Încă nu există evaluări

- Hybrid Locomotion of Leg-Wheel ASTERISK H: Takenobu Yoshioka, Tomohito Takubo, Tatsuo Arai, and Kenji InoueDocument2 paginiHybrid Locomotion of Leg-Wheel ASTERISK H: Takenobu Yoshioka, Tomohito Takubo, Tatsuo Arai, and Kenji InoueJuan NarvaezÎncă nu există evaluări

- AvcDocument18 paginiAvcgulshanÎncă nu există evaluări

- Advanced Survey MethodsDocument83 paginiAdvanced Survey MethodsMaxine MukokiÎncă nu există evaluări

- Energies: Investigation of Stratified Thermal Storage Tank Performance For Heating and Cooling ApplicationsDocument15 paginiEnergies: Investigation of Stratified Thermal Storage Tank Performance For Heating and Cooling ApplicationsRicardo Chegwin HillembrandÎncă nu există evaluări

- Moment-Distribution Method: Clifford Jay C. Ansino Theory of Structure Ii 5-BSCE-BDocument7 paginiMoment-Distribution Method: Clifford Jay C. Ansino Theory of Structure Ii 5-BSCE-BKhen CatayasÎncă nu există evaluări

- Sec 10.6 PDFDocument7 paginiSec 10.6 PDFنزار الدهاميÎncă nu există evaluări

- Biomechanical Analysis of The ShotDocument20 paginiBiomechanical Analysis of The Shotapi-286492938Încă nu există evaluări

- PREDICTION OF TEMPERATURE PROFILE IN OIL WELLS, A. Laderian, 1999, 14 PGDocument14 paginiPREDICTION OF TEMPERATURE PROFILE IN OIL WELLS, A. Laderian, 1999, 14 PGjoselosse desantosÎncă nu există evaluări

- Code - Aster: FDLV111 - Absorption of A Wave of Pressure in A Fluid ColumnDocument10 paginiCode - Aster: FDLV111 - Absorption of A Wave of Pressure in A Fluid ColumnStefano MilaniÎncă nu există evaluări

- CHM271 Thermodynamics: Lecturer's Name E-Mail AddressDocument47 paginiCHM271 Thermodynamics: Lecturer's Name E-Mail AddressNUR EDRYANA FARISHA MUHAMAD NAZRIÎncă nu există evaluări

- Sheet 2-Pressure DropDocument2 paginiSheet 2-Pressure Dropmohelg83Încă nu există evaluări

- Continuum Mech ProblemsDocument85 paginiContinuum Mech ProblemsDeepak Verma100% (1)

- A Critical Reappraisal of Preconsolidation Pressure Interpretations Using The Oedometer TestDocument3 paginiA Critical Reappraisal of Preconsolidation Pressure Interpretations Using The Oedometer TestUsman HasanÎncă nu există evaluări

- Me PDFDocument340 paginiMe PDFShyam ChoudharyÎncă nu există evaluări

- (English) Gibbs Phase RuleDocument2 pagini(English) Gibbs Phase RuleSahand ShafeeiÎncă nu există evaluări

- Theme 2 Newtonian Mechanics Part 1Document9 paginiTheme 2 Newtonian Mechanics Part 1Iedah Mohd100% (2)