Documente Academic

Documente Profesional

Documente Cultură

Bio Ethanol

Încărcat de

Swagat R PyakurelDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bio Ethanol

Încărcat de

Swagat R PyakurelDrepturi de autor:

Formate disponibile

Bio-Ethanol

Bioethanol fuel is produced by the fermentation, distillation and dehydration of starch plants such as corn and wheat, sugar plants and sometimes trees. The alcohol is then formed (with additives to make it unsuitable for drinking) and can be used within cars in one of two ways. The bioethanol fuel can either be blended with petrol or used as a direct substitute for petrol (and occasionally diesel with suitable modifications to the vehicle). From an environmental point of view, bioethanol fuel is completely biodegradable and from well to wheel shows a 70% reduction in carbon dioxide emissions compared to petrol.

TRENDS OF ENERGY CONSUMPTION IN NEPAL (1995-2003)

Total Energy Consumption 1000 TOE 1995 6647.19 Average Rate of Growth 2003 8282,13 Net Increment 2.27 % 24.59 %

Traditional Fuel Consumption 1995 6058.21 Average Rate of Growth 2003 7241.57 Net Increment Commercial Fuel Consumption 1995 581.59 Average Rate of Growth 2003 1002.52 Net Increment Petroleum products Fuel Consumption 1995 448.56 Average rate of Growth 2003 739.72 Net Increment High Speed Diesel Fuel Consumption 1995 201.71 Average Rate of Growth 2003 288.95 Net Increment

2.24 % 19.51 %

8.35 % 72.40 %

6.55 % 64.90 %

3.87 % 32.34 %

Kerosene Oil Fuel Consumption 1995 153.90 Average Rate of Growth 2003 266.95 Net Increment Motor Spirit Fuel Consumption 1995 27.49 Average Rate of Growth 2003 53.00 Net Increment Renewable Energy Consumption 1995 7.49 Average Rate of Growth 2003 39.04 Net Increment Bio-gas Energy Consumption 1995 6.99 Average Rate of Growth 2003 38.00 Net Increment Micro-hydro / Solar Energy Consumption 1995 0.50 Average Rate of Growth 2003 1.03 Net Increment

9.07 % 92.71 %

8.61 % 92.79 %

23.17 % 421.22 %

23.06 % 443.63 %

9.34 % 106.00 %

Source: WECS 2004 / CES 2004

Dr Rhiddi Bir Singh Bio-fuel Laboratory Center for Energy Studies, Institute of Engineering Tribuvan University, Pulchowk Campus,Lalitpur.

STATUS OF ENERGY SITUATION-2004 / 05

Contribution of Renewable & Non-renewable Energy Resources in the Total Energy Consumption

Total Energy Consumed -Traditional Fuels -Commercial Fuels -Renewable Fuels 369.209 million GJ 322.104 million GJ 44.903 million GJ 2.200 million GJ 87.24 % 12.16 % 0.59 %

Total Energy Generated from the Renewable Resources Traditional Bio-mass Fuels 322.104 million GJ Electricity 6.267 million GJ Renewable Fuels 2.200 million GJ 330.571 million GJ Total Energy Generated from the Non-renewable resources Petroleum Products 32.120 million GJ Coal 6.515 million GJ 38.635 million GJ

87.24 % 1.67 % 0.59 % 89.50 %

8.69 % 1.76 % 10.45 %

BIO-MASS FUELS Vs REST OF THE FUELS

Contribution of Bio-mass Based Fuels in Nepal Wood Fuels & Forest Residues 286.960 million GJ Agricultural Residues 13.963 million GJ Cattle Dung 21.181 million GJ Biogas 2.150 million GJ 324.254 million GJ

77.72 % 3.78 % 5.73 % 0.59 % 87.82 %

Contribution of the Non Bio-mass Based Fuels in Nepal Petroleum Products 32.120 million GJ Coal 6.515 million GJ Electricity 6.267 million GJ Micro-hydro & Solar 0.049 million GJ 44.951million GJ

8.69 % 1.76 % 1.69 % 0.01 % 12.15 %

EMERGING ISSUES OF BIO-MASS RELATED RENEWABLE ENERGY DEVELOPMENT

Despite the pressing need of the efficient energy commodity, which could be processed out of the available indigenous resources consistent developmental efforts are seriously lacking in the field of liquid bio-fuels generation in Nepal.

Emerging major issues of liquid bio-fuels, which are exclusively based on the local bio-mass resources

Domestic production and consumption of the bio-hydrocarbon oil from the Pine oleoresin as alternative to the imported non-renewable fossil fuel, the Kerosene oil in the rural areas. Domestic production and consumption of the power ethanol (Absolute Ethanol 99.5- 99.9 % v / v) from the sugarcane molasses as an Alternative to the imported non-renewable fossil fuel the Motor Spirit (MS) in urban areas. Domestic production and consumption of the bio-diesel from the nonconventional seed oil / fat resources as an Alternative to the imported nonrenewable fossil fuel the High Speed Diesel (HSD) in urban / rural areas.

EMERGING ISSUES OF BIO-MASS RELATED RENEWABLE ENERGY DEVELOPMENT

About 9 % of the nation's total energy contributed by the petroleum products consumed about 40 % of the national export earning amounting to Rs 22.60 billion (2004 / 05). The production of power / fuel ethanol in itself is an advanced technical step. The application of bio-ethanol to substitute the petrol / gasoline / motor spirit in the automobile is the advanced application of the agriculture based biomass. The substitution of kerosene oil by the bio-hydrocarbon oil distilled out from the Pine oleoresin will not only save the tree for at least 20 years, but also yield clean renewable liquid bio-fuel having 40 % fuel efficiency in the cooking stove besides, other non-timber forest product. The production of bio-diesel out of the plant based seed oils / fats actually require industrial technical processing system. Application of bio-diesel in place of fossil fuel diesel in the vehicles demonstrates the advanced application of the bio mass based liquid bio-fuel.

Resource Potential for Domestic Bio-ethanol Production in Nepal

About 20 % of the total land area are under agriculture practice in Nepal.

Sugarcane: -cultivated in 59000 hector -Yield: 2.212 million MT. (2004/2005) About 100000 MT of Molasses is estimated to be produced each year from the existing major sugar industries. 2003/04 Ethanol (Rectified Spirit) prod. in Nepal: 9931 KL(50.09% of capacity, 19823 KL)

Rectified Spirit is not the quality Fuel Ethanol and can not fulfill the E-10 E-100 fuel requirement of the nation.

2003: Absolute Ethanol Production Started in Nepal at Sri Ram Sugar Mills Pvt. Ltd., Garuda VDC-6, Rautahat District, with the installed capacity of 30000 (30 KL) per day.

-Production status was limited only at the trial level as the sale and purchase negotiation between the factory and the government could not be materialized.

Resource Potential for Domestic Bio-ethanol Production in Nepal

The factory had the stored stock of 180000 liter of power ethanol ready to use as the fuel bio-ethanol. The Installed Production Capacity can fulfill the 10 % of the total MS imported for E-10 fuel. 300 day x 30 KL = 9000 KL Absolute Ethanol 99.8 % v / v.

ANALYTICAL REPORT OF THE FUEL GRADE BIO-ETHANOL MANUFACTURED IN NEPAL

Parameter Ethanol Content Appearance Water Content Boiling Range Specific Gravity Copper Content Acidity (As Acetic Acid) Unit %v/v -----% oC At 15 o C mg / kg mg / l Observed Value 99.75 Transparent free from Suspended Particles 0.25 7475 o C 0.7925 0.11 6.80

Source: R.B.Singh and R.Bhandari 2006

ECONOMIC BENEFIT OF DOMESTICALLY GENERATED E-10 GASOHOL FUEL

About Rs. 115 million would have been saved in 2004 if the Government declaration (Magh 2060) had been actually implemented.

ENVIRONMENT BENEFFIT OF DOMESTICALLY GENERATED E-10 GASOHOL FUEL

The exhaust emission gases collected after the application of E-10 fuel containing the bio-ethanol produced within the country the decreased level of CO, CO2 and HC (hydrocarbons) were measured and compared with that of pure MS. The emission of CO decreased by The emission of CO2 decreased by The emission of HC decreased by 28.2333.13 % 21.6624.50 % 18.53----29.47 %

Source: R.B.Singh and R.Bhandari 2006

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Telemedicine Guidelines For Registered Medical Practitioners in NepalDocument12 paginiTelemedicine Guidelines For Registered Medical Practitioners in NepalSwagat R PyakurelÎncă nu există evaluări

- The Question Every Entrepreneur Must AnswerDocument10 paginiThe Question Every Entrepreneur Must AnswerSwagat R PyakurelÎncă nu există evaluări

- Technological Paradigms and Technological TrajectoriesDocument11 paginiTechnological Paradigms and Technological TrajectoriesSwagat R PyakurelÎncă nu există evaluări

- Essential Oils Business PlanDocument35 paginiEssential Oils Business PlanSwagat R Pyakurel73% (15)

- Banking Law and PracticeDocument25 paginiBanking Law and PracticeSwagat R PyakurelÎncă nu există evaluări

- Entrepreneurship PresentationDocument30 paginiEntrepreneurship PresentationSwagat R PyakurelÎncă nu există evaluări

- Nepal Standard-Ambient Air Quality (2012)Document3 paginiNepal Standard-Ambient Air Quality (2012)Swagat R PyakurelÎncă nu există evaluări

- Technological Paradigms and Technological TrajectoriesDocument11 paginiTechnological Paradigms and Technological TrajectoriesSwagat R PyakurelÎncă nu există evaluări

- PCO1810 Vs PCO1881Document2 paginiPCO1810 Vs PCO1881Swagat R Pyakurel100% (1)

- Overview of PET ProcessingDocument5 paginiOverview of PET ProcessingSwagat R Pyakurel50% (2)

- Energy Scenario of NepalDocument4 paginiEnergy Scenario of NepalSwagat R PyakurelÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- GT Evaporative Inlet Air Cooling & Fogging PDFDocument35 paginiGT Evaporative Inlet Air Cooling & Fogging PDFVu DuyÎncă nu există evaluări

- Life Cycle Assessment of Large-Scale Compressed Bio-Natural Gas ProductionDocument17 paginiLife Cycle Assessment of Large-Scale Compressed Bio-Natural Gas ProductionIman EbrahimzadeÎncă nu există evaluări

- Aeroderivative Gas TurbinesDocument2 paginiAeroderivative Gas TurbinesTufan Maity100% (1)

- CSP Today Parabolic Trough Report 2014 - PDFDocument188 paginiCSP Today Parabolic Trough Report 2014 - PDFJoherÎncă nu există evaluări

- PDF Waste To Energy ENGDocument4 paginiPDF Waste To Energy ENGpramods_8Încă nu există evaluări

- Energy Transformation at The Shell Rhineland Refinery - Project REFHYNEDocument11 paginiEnergy Transformation at The Shell Rhineland Refinery - Project REFHYNEmsantosu000Încă nu există evaluări

- GE6251-Basic Civil and Mechanical EngineeringDocument10 paginiGE6251-Basic Civil and Mechanical EngineeringpceautohodÎncă nu există evaluări

- Winterization Checklist TemplateDocument1 paginăWinterization Checklist TemplateHowie YangÎncă nu există evaluări

- Examples: Thermal GeneraionDocument7 paginiExamples: Thermal Generaionstubar25Încă nu există evaluări

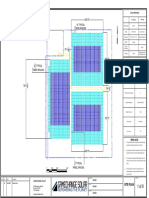

- 630'-5" 16' Typical Row Spacing: LegendDocument9 pagini630'-5" 16' Typical Row Spacing: LegendSmile PlzÎncă nu există evaluări

- Jakarta MP Grid Code Adjusment - DPX - LGC - AlvinDocument22 paginiJakarta MP Grid Code Adjusment - DPX - LGC - AlvinMellaÎncă nu există evaluări

- PP3 - Written ReportDocument6 paginiPP3 - Written ReportneilÎncă nu există evaluări

- 48 Sile-2023 enDocument1 pagină48 Sile-2023 enArun MuraliÎncă nu există evaluări

- RES Unit 1 - IntroductionDocument8 paginiRES Unit 1 - IntroductionVighnesh BhatÎncă nu există evaluări

- Group1 Hydro 1Document24 paginiGroup1 Hydro 1Ethio Dangote TubeÎncă nu există evaluări

- Energy Savings in Flour MillingDocument3 paginiEnergy Savings in Flour MillingNijam JabbarÎncă nu există evaluări

- Rathore Et AlDocument7 paginiRathore Et AlIqra SarfrazÎncă nu există evaluări

- Review Article-Renewable Energies: SciencedirectDocument9 paginiReview Article-Renewable Energies: SciencedirectsumitrochakrabortiÎncă nu există evaluări

- Basics of Hybrid Electric VehiclesDocument2 paginiBasics of Hybrid Electric VehiclesSumanranuÎncă nu există evaluări

- Biogas ProductionDocument19 paginiBiogas ProductiontagoreboopathyÎncă nu există evaluări

- Irr Ra 9513Document48 paginiIrr Ra 9513fatmaaleahÎncă nu există evaluări

- Electric Vehicles 2021 Website VersionDocument52 paginiElectric Vehicles 2021 Website VersionmaheshÎncă nu există evaluări

- Entregable 1 InglesDocument8 paginiEntregable 1 InglesMoisés NouÎncă nu există evaluări

- 1103pei Gas DataDocument4 pagini1103pei Gas DataChuuk KangÎncă nu există evaluări

- Biomass - Products Wood Pellet SpecificationDocument36 paginiBiomass - Products Wood Pellet SpecificationSo NicÎncă nu există evaluări

- Radiative Sky Cooling PresentationDocument17 paginiRadiative Sky Cooling PresentationMark Christian CalumayÎncă nu există evaluări

- Sandvik Desiccant HumidifierDocument2 paginiSandvik Desiccant Humidifierjohnking5555Încă nu există evaluări

- Assignment For G2E 2 1Document2 paginiAssignment For G2E 2 1achok williamÎncă nu există evaluări

- What Is The HES Toolkit?: HES Annual Conference, FITUR, 20 January 2011Document24 paginiWhat Is The HES Toolkit?: HES Annual Conference, FITUR, 20 January 2011gestorinfoÎncă nu există evaluări

- Solar Power PlantDocument65 paginiSolar Power PlantHil GloriosoÎncă nu există evaluări