Documente Academic

Documente Profesional

Documente Cultură

Industrial Training

Încărcat de

Vinamra MittalTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Industrial Training

Încărcat de

Vinamra MittalDrepturi de autor:

Formate disponibile

Industrial Training Presentation

SAM GAS PROJECTS PVT. LTD

Submitted by: Vinamra Mittal Nikhil Mishra Monit Goel Ashish Gupta

DEPARTMENT OF ELECTRICAL ENGINEERING

An Overview

An ISO 9000:2001 certified company manufacturing different gas generators. Deals in Nitrogen Generator, Oxygen Generators, PSA Nitrogen Gas Plants, Oxygen Plants, Ammonia Crackers (Hydrogen Generators) and Compressed Air and Gas Drying Systems. Work done is based on the latest PSA technology and provides avenues for mechanical, electrical, chemical and metallurgical engineering. The Gas Plants manufactured and exported by the company are also in good demand in overseas market finding buyers in Gulf, Asian and European countries.

Products Manufactured

Nitrogen Generator

Oxygen Generators Ammonia Crackers (Hydrogen Generators) Compressed Air and Gas Drying Systems

ProductsNitrogen Generators

Used Across World..

Oxygen Generator..

The PSA Technology

Pressure Swing Adsorption (PSA) is a technology used to separate some gas species from a mixture of gases under pressure according to the species' molecular characteristics and affinity for an adsorbent material.

Special adsorptive materials (e.g., zeolites) are used as a molecular sieve, preferentially adsorbing the target gas species at high pressure. The process then swings to low pressure to desorb the adsorbent

material.

.continued

PSA is an economic choice for small-scale production of reasonable purity oxygen or nitrogen from air.

PSA technology has a major use in the medical industry to produce oxygen. The Generated Oxygen and Nitrogen gases can be easily stored for later use too.

PSA Nitrogen Gas Generators

The Generators are used to generate Nitrogen of desired purity for different commercial uses.

The generators uses the PSA technology and from the mixture of oxygen and nitrogen which is taken from the atmosphere.

PSA Nitrogen plants utilizes mostly a carbon molecular sieve that is quite capable of separating nitrogen and oxygen molecules in the air.

If the adsorption and desorption processes are continuously performed in two separate chambers equipped with carbon molecular sieves, nitrogen gas can continuously be separated out.

The separated gases can be stored in different chambers easily for longer and better use.

Processes which take place..

Compression: Atmospheric air is filtered, compressed and cooled to around 10C in a chillier to reduce the moisture content. Purification Process: Carbon dioxide and residual moisture are removed in activated alumina PSA system, regenerated by the heated excess waste gas that comes out of the cold-box. Separation Process: This is carried out in a cold-box that is filled with prelate or other thermally insulating material.

A Prototype Model..

Features of PSA Nitrogen Plants

Energy Saving Stabilization of Oxygen density Designs are Compact. Automatic Plants Lower maintenance costs.

Minimal Start up time.

Lesser requirement of fuel.

PSA Oxygen Gas Generator

This generator is used to produce dry oxygen, which in turn has several commercial uses.

The PSA Oxygen Gas Generation Plant consist of two absorption vessels and filled with zeolite molecular sieves are alternatively charged with compressed air to absorb the nitrogen.

The Design..

Advantages of PSA Oxygen plants

High efficiency operation (lowers power costs). Fast ramp-up to online production. Full safety unlike hazards involved with bulky gas cylinders. High output pressures. Independent on -site production. Low pressure drops

Applications of PSA Oxygen plants

Glass and enamel industry Steel industry Pulp and paper industry Chemical industry Drinking water supply

Waste water treatment and waste disposal industries

Biotechnology industry

Industrial Applications of PSA based Technologies

In Automobile Industry: Pressure swing Adsorption technology operated dryers are increasingly used on heavy commercial vehicles like trucks and buses for drying the compressed air that operates and controls the brakes and pneumatic accessories.

In Defence : Till recently the Carbon filtration was enough to protect the soldiers from the threats of chemical and biological threats. But with the advancement in the "chemical warfare agents" a new threat is looming large that is known as the Carbon breakers.

Again Pressure Swing Adsorption the remarkable technology has been found to be productive against this type of agents. This is because of the PSA's ability to remove chemical warfare vapors, including carbon breaker class of compounds.

..

In Aviation Industry : Gas separation technology like Onboard Inert Gas Generation System (OBIGGS) is now increasingly getting popular with the Aviation Industry. The basic purpose of this highly efficient system is to remove the fumes from fuel tanks. As the fuel tanks are highly susceptible to explosion due to electrical discharge.

More Industries..

Aquaculture Industry Biogas Plants Chemical Industry Coal Mines Electronics Industry Fertilizer Industry Glass Industry Metal Casting Petro Chemicals Pollution Control Refinery

S-ar putea să vă placă și

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectDe la EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectÎncă nu există evaluări

- Prism Membrane GeneratorsDocument4 paginiPrism Membrane GeneratorspramodtryÎncă nu există evaluări

- High-Purity Oxygen Production Using Mixed Ionic-Electronic Conduc PDFDocument108 paginiHigh-Purity Oxygen Production Using Mixed Ionic-Electronic Conduc PDFJason MandelaÎncă nu există evaluări

- Oxygen Plant Specification (50Nm3)Document6 paginiOxygen Plant Specification (50Nm3)Win MinÎncă nu există evaluări

- Biomedical New Hire OrientationDocument29 paginiBiomedical New Hire OrientationBEJOYÎncă nu există evaluări

- EIGA 151 Prevention of Excessive Pressure During Filling of Cryogenic VesselsDocument14 paginiEIGA 151 Prevention of Excessive Pressure During Filling of Cryogenic VesselsFilipÎncă nu există evaluări

- Cylinder Filling PlantDocument67 paginiCylinder Filling PlantPassmore Dube100% (1)

- Pneumatic NotesDocument5 paginiPneumatic NoteskanscseÎncă nu există evaluări

- Oxygen Cylinder Safety: Do NotDocument1 paginăOxygen Cylinder Safety: Do NotMahammadÎncă nu există evaluări

- OXYGEN PLANT SAFETY PRINCIPLES: THE ROLE OF AIR CONTAMINANTSDocument10 paginiOXYGEN PLANT SAFETY PRINCIPLES: THE ROLE OF AIR CONTAMINANTShwang2Încă nu există evaluări

- Safety and Handling of Organic PeroxidesDocument26 paginiSafety and Handling of Organic PeroxidesМаксим ХилоÎncă nu există evaluări

- OR Medical Devices-Final Participant's Training Manual PDFDocument268 paginiOR Medical Devices-Final Participant's Training Manual PDFYeron GelayeÎncă nu există evaluări

- ORIG - Oxygen Cylinder Checks and StorageDocument8 paginiORIG - Oxygen Cylinder Checks and StorageImnot Realanymore ImanillusionÎncă nu există evaluări

- 04 Technical PDFDocument64 pagini04 Technical PDFRashel HasanÎncă nu există evaluări

- Model O2 CalibrationDocument2 paginiModel O2 CalibrationAhmed HummerÎncă nu există evaluări

- 13X DatasheetDocument3 pagini13X Datasheetdrizzt299Încă nu există evaluări

- Pressure Gauge and Transmitter GuideDocument35 paginiPressure Gauge and Transmitter GuideTHEOPHILUS ATO FLETCHERÎncă nu există evaluări

- MN150 3 B PDFDocument157 paginiMN150 3 B PDFamanuel waleluÎncă nu există evaluări

- Checking The EquipmentDocument6 paginiChecking The Equipmentapi-142637023100% (1)

- Portable Oxygen Cylinders Training and Safety Guidelines (Homecare Series)Document4 paginiPortable Oxygen Cylinders Training and Safety Guidelines (Homecare Series)Haruna.2008 Ghareeb2003Încă nu există evaluări

- Compressed Air PreparationDocument3 paginiCompressed Air PreparationNatsuko KayamaÎncă nu există evaluări

- Gas Equipment SolutionsDocument19 paginiGas Equipment SolutionsKuntari Tri SulistyawardaniÎncă nu există evaluări

- Medical Gas Alarm PointsDocument4 paginiMedical Gas Alarm PointsMesiah MaphakelaÎncă nu există evaluări

- Everdry Int 2015 08Document8 paginiEverdry Int 2015 08Rain KongÎncă nu există evaluări

- Burkert - Solenoid Valve For Gas Applications PDFDocument27 paginiBurkert - Solenoid Valve For Gas Applications PDFBurkert IndiaÎncă nu există evaluări

- GDS Catalog PDFDocument72 paginiGDS Catalog PDFkuraimundÎncă nu există evaluări

- Gardner Denver - ESM30Document8 paginiGardner Denver - ESM30namnt11100% (1)

- Health Technical Memorandum 08-03 - Bed Head UnitDocument58 paginiHealth Technical Memorandum 08-03 - Bed Head UnitRagline SerranoÎncă nu există evaluări

- Microplasma Water Purification TechnologyDocument16 paginiMicroplasma Water Purification Technologyanurag jhaÎncă nu există evaluări

- Infant Incubator Maintenance and Troubleshooting GuideDocument18 paginiInfant Incubator Maintenance and Troubleshooting GuideFaqih AuliyaÎncă nu există evaluări

- Waste Incineration Processs39Document9 paginiWaste Incineration Processs39hilalpunooÎncă nu există evaluări

- Halliburton Membrane Nitrogen Equipment Presentation April 10, 2014Document14 paginiHalliburton Membrane Nitrogen Equipment Presentation April 10, 2014Beatriz Velásquez LeónÎncă nu există evaluări

- Energy Scenario AnalysisDocument98 paginiEnergy Scenario AnalysisAvinash Rai100% (1)

- Operating Instructions and PARTS LIST For: Rix Industries Gas CompressorDocument65 paginiOperating Instructions and PARTS LIST For: Rix Industries Gas CompressorDomingoscarlos RubbenÎncă nu există evaluări

- Addis Ababa Institute of Technology: Center of Biomedical EngineeringDocument6 paginiAddis Ababa Institute of Technology: Center of Biomedical EngineeringYabÎncă nu există evaluări

- Trimethylolpropane Msds enDocument12 paginiTrimethylolpropane Msds enronnyprbÎncă nu există evaluări

- Agss Plant IomDocument31 paginiAgss Plant Iomwaleed.murad@gmail.comÎncă nu există evaluări

- Emergency Alternative Mode of Oxygen Generation: Confidential 1Document37 paginiEmergency Alternative Mode of Oxygen Generation: Confidential 1Nipun Jain0% (1)

- DENAIR Oxygen Generator and Nitrogen Generator CatalogueDocument8 paginiDENAIR Oxygen Generator and Nitrogen Generator CatalogueIngeniería AplicacionesÎncă nu există evaluări

- ISO 8573 Purity Classes PDFDocument1 paginăISO 8573 Purity Classes PDFOky Andytya PratamaÎncă nu există evaluări

- Centrifugal Damper CatDocument8 paginiCentrifugal Damper CatAdil Shahzad100% (2)

- CFPP 01-01 Part C Steam SterilizationDocument31 paginiCFPP 01-01 Part C Steam Sterilizationsbalu12674Încă nu există evaluări

- 05 V PattabathulaDocument16 pagini05 V Pattabathulapcorreia_81Încă nu există evaluări

- Bmo Beaconmedaes Psa Medical Oxygen Concentrator Plant SpecificationDocument13 paginiBmo Beaconmedaes Psa Medical Oxygen Concentrator Plant Specificationdiah131Încă nu există evaluări

- Ozone PDFDocument4 paginiOzone PDFShesharam ChouhanÎncă nu există evaluări

- Medical Equipment Catalog For WebDocument16 paginiMedical Equipment Catalog For WebPhạm Quốc AnhÎncă nu există evaluări

- The Energy Costs Associated With Nitrogen Specifications: Sustainable Manufacturing FeaturesDocument8 paginiThe Energy Costs Associated With Nitrogen Specifications: Sustainable Manufacturing FeaturesJaime Andres Pardo QuinteroÎncă nu există evaluări

- PSA Oxymat Servicio de MantenimientoDocument28 paginiPSA Oxymat Servicio de Mantenimientovictor hugo valqui lopezÎncă nu există evaluări

- FM Global Property Loss Prevention Data Sheets: Ignitable Liquid OperationsDocument60 paginiFM Global Property Loss Prevention Data Sheets: Ignitable Liquid OperationsElbechir SenkezÎncă nu există evaluări

- Compressed Gases Inspection Checklist: Yes No N/A CommentsDocument2 paginiCompressed Gases Inspection Checklist: Yes No N/A CommentsikponmwonsaÎncă nu există evaluări

- Medical and Laboratory Gas Pipeline Design Part 1Document3 paginiMedical and Laboratory Gas Pipeline Design Part 1karunaÎncă nu există evaluări

- 2.2 - Pamphlet 6 Chlorine InstituteDocument16 pagini2.2 - Pamphlet 6 Chlorine InstituteAdemilson Junior100% (1)

- PSA medical oxygen generators presentation for COVID-19 hospitalsDocument10 paginiPSA medical oxygen generators presentation for COVID-19 hospitalsrutujaÎncă nu există evaluări

- N-Propanol - CAS # 71-23-8: Product Handling GuideDocument2 paginiN-Propanol - CAS # 71-23-8: Product Handling Guidesharmi2011Încă nu există evaluări

- Anesthesiamachine 180201123347Document22 paginiAnesthesiamachine 180201123347Abdelrahman B Abu AmroÎncă nu există evaluări

- PHOSGENE Incident Management v2Document10 paginiPHOSGENE Incident Management v2djsp5009Încă nu există evaluări

- Catalogue Nitrogen GeneratorsDocument5 paginiCatalogue Nitrogen GeneratorsMilos BajicÎncă nu există evaluări

- Oil Gas Boilers and Hot Water Boilers PDFDocument60 paginiOil Gas Boilers and Hot Water Boilers PDFanon_411130333Încă nu există evaluări

- Notification Order Equipment DescriptionDocument18 paginiNotification Order Equipment Descriptionઅનુરુપ સોનીÎncă nu există evaluări

- 05 - 2 Heat Balance - Practice Problem - InstructorDocument31 pagini05 - 2 Heat Balance - Practice Problem - Instructorsawitri diah ayu komala100% (2)

- 200TR Modern Air ChillerDocument14 pagini200TR Modern Air ChillerJhon LewisÎncă nu există evaluări

- Combined Cycle Gas-TurbinesDocument5 paginiCombined Cycle Gas-TurbineswarshipvnÎncă nu există evaluări

- Public 866 PDFDocument4 paginiPublic 866 PDFJOSE GARCIAÎncă nu există evaluări

- Capacity factor explained: the ratio of actual output to potential outputDocument5 paginiCapacity factor explained: the ratio of actual output to potential outputCh Srikanth ReddyÎncă nu există evaluări

- GTG-1 GTG-2: A-Shift B-Shift C-Shift A-Shift B-Shift C-ShiftDocument3 paginiGTG-1 GTG-2: A-Shift B-Shift C-Shift A-Shift B-Shift C-Shiftcksharma68Încă nu există evaluări

- Specification & Drawings: EH-500F, 750F, 1000FDocument6 paginiSpecification & Drawings: EH-500F, 750F, 1000FIPSRS TEKNISIÎncă nu există evaluări

- Final - Paj 062617-070217Document11 paginiFinal - Paj 062617-070217モーラーリー いたちÎncă nu există evaluări

- Saline Water Conversion Corporation Strategic Reservoirs at Makkah Phase Ii & Taif Phase IDocument2 paginiSaline Water Conversion Corporation Strategic Reservoirs at Makkah Phase Ii & Taif Phase IAnonymous uLAATWpfÎncă nu există evaluări

- Thermal Design of A Fluidized Bed Steam Boiler Using Refuse Derived Fuel (RDF) in Organic Rankine Cycle (#487643) - 612964 PDFDocument17 paginiThermal Design of A Fluidized Bed Steam Boiler Using Refuse Derived Fuel (RDF) in Organic Rankine Cycle (#487643) - 612964 PDFnemochuÎncă nu există evaluări

- Experimental Performance Evaluation of A Centrifugal PumpDocument6 paginiExperimental Performance Evaluation of A Centrifugal PumpShashank ChoudharyÎncă nu există evaluări

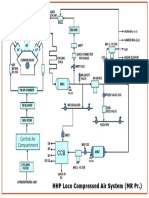

- HHP Compressed Air DrawingDocument1 paginăHHP Compressed Air Drawingdhaneesh22Încă nu există evaluări

- Data Sheet Ejector PDFDocument2 paginiData Sheet Ejector PDFSuryaprakashÎncă nu există evaluări

- Nash TC Data SheetDocument2 paginiNash TC Data SheetAnthonyÎncă nu există evaluări

- Company Catalogue HAUG enDocument14 paginiCompany Catalogue HAUG enjshdlhÎncă nu există evaluări

- Process Control Philosophy for Gas Pipeline StationsDocument30 paginiProcess Control Philosophy for Gas Pipeline Stationsahmad santoso100% (2)

- EverExceed Hybrid Solar SystemDocument0 paginiEverExceed Hybrid Solar Systemasr2972Încă nu există evaluări

- How piping systems are classified by stressDocument1 paginăHow piping systems are classified by stresstibor121774_66173108Încă nu există evaluări

- Topic: Reheat, Regenerative & Other Steam Power CycleDocument17 paginiTopic: Reheat, Regenerative & Other Steam Power CycleMurvin VillarosaÎncă nu există evaluări

- A1F8D3 - Appendix ICES-APL-003 (D) - Main Maintenance Tasks PDFDocument23 paginiA1F8D3 - Appendix ICES-APL-003 (D) - Main Maintenance Tasks PDFdj.amin07Încă nu există evaluări

- Bunsen Burner LabDocument2 paginiBunsen Burner LabFarikha UlyÎncă nu există evaluări

- Chapter - 6Document10 paginiChapter - 6BennyÎncă nu există evaluări

- Internal: Confidentiality Class Acc. To 1102 KDocument1 paginăInternal: Confidentiality Class Acc. To 1102 KGuiver Santisteban IbañezÎncă nu există evaluări

- 4BTA3.9-GM Genset SpecificationDocument1 pagină4BTA3.9-GM Genset SpecificationnarisÎncă nu există evaluări

- Problem On Steam Nozzle 01 - Mollier ChartDocument7 paginiProblem On Steam Nozzle 01 - Mollier ChartDr. BIBIN CHIDAMBARANATHANÎncă nu există evaluări

- Conventional Power GenerationDocument74 paginiConventional Power GenerationAlexandru DobosÎncă nu există evaluări

- Smart automatic irrigation with soil moisture sensorsDocument15 paginiSmart automatic irrigation with soil moisture sensorsDebashishParidaÎncă nu există evaluări

- 7 Fluid Dynamics Tutorial SolutionDocument25 pagini7 Fluid Dynamics Tutorial SolutionAldhaAhmadyaningratÎncă nu există evaluări

- Boiler ChecklistDocument3 paginiBoiler ChecklistSegamaha Palm Oil Mill0% (2)