Documente Academic

Documente Profesional

Documente Cultură

Weld Joint Fatigue

Încărcat de

Logeswaran RajiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Weld Joint Fatigue

Încărcat de

Logeswaran RajiDrepturi de autor:

Formate disponibile

Fatigue Assessment of

**

Weld Joints Using ANSYS,

Verity & FE-Safe

Zhichao Wang

Aditya Sakhalkar

5/8/2007

** Verity is a weld fatigue assessment software

developed by Battelle based on Structural

Stress & Fracture Mechanics theory proposed

by Dr. Dong et al, Battelle

Part I: Key Points on Equivalent SS Method

Part II: Example Application

ECT_wht_templ 2/28/2013 11:09 AM 2

Part I: Key Points on SS & Weld Assessments

Zhichao Wang

Sr. Lead Engineer

Emerson Climate Technology Inc.

Background

Why The Battelles Structure Stress Is Not Sensitive To FE Mesh

Size?

How Could Multiple Joint S~N Curves Be Reduced to A Single S~N

Curve, the Master S~N Curve?

Example Application (Part ii, Aditya)

ECT_wht_templ 2/28/2013 11:09 AM 3

Background

Fatigue Assessment Unwelded Structures

ECT_wht_templ 2/28/2013 11:09 AM 4

Fatigue Assessment Welded Structures

Its been commonly recognized that the fatigue life of the polished

specimen is dominated by fatigue crack initiation, whereas that of

welded structures is dominated by small crack propagation from some

pre-existing discontinuity.

ECT_wht_templ 2/28/2013 11:09 AM 5

(i). Nominal Stress Method (BS,IIW)

The nominal stress range is used to develop the S~N curves using

samples with actual weld joint geometry. The life curves refer to

particular weld details, there is no need for the user to attempt to quantify

the local stress concentration effect of the weld detail itself.

(ii). Hotspot Stress Approach (structural stress, geometric stress,

BS, IIW, CEN,DNV)

This procedure uses hot-spot stress range as a parameter. The SN

curves are obtained from tests of actual welded joints based on the hot-

spot stress range rather than the nominal stress range.

(iii). Local Notch Stress Method (ASME, BS, IIW).

The notch stress approach attempts to include all sources of stress

concentration in the stress used with the design SN curve. Thus a single

SN curve may be sufficient for a given type of material. The problem is

that the local geometry of the toe or root of a weld is highly variable. It

may be hard to achieve consistent results.

Fatigue Assessment Welded Structures

ECT_wht_templ 2/28/2013 11:09 AM 6

Fatigue Assessment Welded Structures

(iv). The Fracture Mechanics Approach (For crack propagation life)

The parameter widely used is SIF, K. The fatigue resistance is represented by

fatigue crack growth rate da/dN. Many crack propagation laws are available. The

simplest one is Paris Law in which the crack growth law approximates to a linear

relationship:

For a flaw size starts from a

0

to a critical fatigue crack size a

f

, the remaining

fatigue life N under stress range S is obtained by integrating Eq (1):

(v) Verity Equivalent Structural Stress Method (Battelle)

Equivalent Structural Stress + Single Master S~N Curve

n

da

C ( K) (1)

dN

= A

f

0

a

n

a

da

C N (2)

( K)

=

A

}

ECT_wht_templ 2/28/2013 11:09 AM 7

Structural Stress & Mesh Sensitivity

(b) Comparison of SCF predicted by various modeling

procedures and extrapolation based HSS at the weld toe [12].

(b) Comparison of SCF predicted by various modeling

procedures and extrapolation based HSS at the weld toe [12].

(c) Structural Stress Using Verity Method (c) Structural Stress Using Verity Method

Hot Spot Nomina

Nominal

l

FE

(Human Factor)

~

0

o

o

< o <

o

x

o

X

~0.4 t

Hot Spot

o

FE

o

Nominal

o

(a) Normal Stress at the sharp corner

(Structural Stress)

t

x

s

p

A

A

P

Y

X

0.4 t

A

A

t

Hot Spot Nomina

Nominal

l

FE

(Human Factor)

~

0

o

o

< o <

o

x

o

X

~0.4 t

Hot Spot

o

FE

o

Nominal

o

(a) Normal Stress at the sharp corner

x

o

X

~0.4 t

Hot Spot

o

FE

o

Nominal

o

(a) Normal Stress at the sharp corner

(Structural Stress)

t

x

s

p

A

A

(Structural Stress)

t

x

s

p

(Structural Stress)

t

x

s

p

A

A

P

Y

X

0.4 t

A

A

t

P

Y

X

0.4 t

A

A

A

A

t

ECT_wht_templ 2/28/2013 11:09 AM 8

Why Structure Stress

Is Not Sensitive To FE Mesh?

(a)

(b)

(c) Structural Stress Using Verity Method (c) Structural Stress Using Verity Method

N

P

1

P

2

Q

m

P

1

P

2

P

1

P

2

N

/

Q

/

m

/

P

1

P

2

t

X

Y

F

x

P

1

P

2

F

y

Neutral axis

t

t

m

t

b

)'

t

(

)'

t

m

( )'

t

b

(

N

P

1

P

2

Q

m

N

P

1

P

2

Q

m

P

1

P

2

P

1

P

2

P

1

P

2

N

/

Q

/

m

/

P

1

P

2

N

/

Q

/

m

/

P

1

P

2

t

X

Y

P

1

P

2

P

1

P

2

t

X

Y

F

x

P

1

P

2

F

y

Neutral axis

F

x

P

1

P

2

F

y

F

x

P

1

P

2

F

y

Neutral axis

t

t

m

t

b

t

m

t

b

)'

t

(

)'

t

m

( )'

t

b

(

)'

t

(

)'

t

m

( )'

t

b

(

Calculation of Structure Stress

3-D Solid Element:

i. Calculate nodal force

ii. Transformation of nodal force to neutral

axis to obtain resultant forces (N, m).

iii.Calculation of structural stress

Shell Element:

i. Calculate nodal force ( N

/

, m

/,

Q

/

)

ii. Calculation of structural stress

Because equilibrium has to be satisfied

Thus: m

/

=m

Q

/

=Q And

N

/

=N

t

m

N

( )=

A

t

b

m

()=

W

( ) ( )

,

/ /

t t t t

m m b b

= =

The equations in the calculation of

structural stress are the same. Hence, the

structural stress is mesh independent

Calculation of Structure Stress

3-D Solid Element:

i. Calculate nodal force

ii. Transformation of nodal force to neutral

axis to obtain resultant forces (N, m).

iii.Calculation of structural stress

Shell Element:

i. Calculate nodal force ( N

/

, m

/,

Q

/

)

ii. Calculation of structural stress

Because equilibrium has to be satisfied

Thus: m

/

=m

Q

/

=Q And

N

/

=N

t

m

N

( )=

A

t

b

m

()=

W

( ) ( )

,

/ /

t t t t

m m b b

= =

The equations in the calculation of

structural stress are the same. Hence, the

structural stress is mesh independent

ECT_wht_templ 2/28/2013 11:09 AM 9

Master S~N Curve

Most codes divide weld joints into different types

Categorization of Weld Joints (BS 7608) Weld Joints (IIW)

Weld Joint Categorization

ECT_wht_templ 2/28/2013 11:09 AM 10

Multiple S~N Curves Due to Weld Joint Categorization

Example Design S~N curves for

welded joints: (a) Steel weld joint S~N

curves (BS 7608); (b) Weld joint type

and S~N curves (IIW

recommendations); (c) Aluminum weld

joint S~N curves (IIW

recommendations)

(a)

(b)

(c)

Multiple S~N curves provide flexibility

for the selection of life curves and

increase difficulty to select the proper

one due to the variation of actual

joints

ECT_wht_templ 2/28/2013 11:09 AM 11

How Could multiple joint S~N curves be

merged into one - Master S~N curve?

Nominal Stress Method (BS) Hot Spot Stress Method (IIW)

Equivalent SS Method

Weld Joints (IIW)

ECT_wht_templ 2/28/2013 11:09 AM 12

Small Crack Propagation Behavior

The data does not fall into one curve for the same specimen;

Multiple da/dN curves obtained for the same or different

specimens, which tells that the Paris Law does not hold for

small crack growth. This is called anomalous crack growth

behavior.

(g) AK-correlated small

crack vs. large crack

growth, 7075-T6 AI [13]

The curves show that

small crack growth faster

than corresponding large

cracks at the same value

of the driving force AK.

Specimens for notch induced short crack growth test. (a)

Compact tension (CT) with keyhole by Ramulu; (b) single edged

notched (SEN) by Shin and Smith; (c) double edged notched

(DEN) by Shin and Smith; (d) center notched (CB) by Tanaka and

Nakai; (e) for CT specimen; (f) for three different

specimens

da

K

dN

A

da

K

dN

A

Specimens for notch induced short crack growth test. (a)

Compact tension (CT) with keyhole by Ramulu; (b) single edged

notched (SEN) by Shin and Smith; (c) double edged notched

(DEN) by Shin and Smith; (d) center notched (CB) by Tanaka and

Nakai; (e) for CT specimen; (f) for three different

specimens

da

K

dN

A

da

K

dN

A

Different factors may attribute to short crack anomalous growth such as the effect of crack

closure, micro structure interaction and that of notch details.

A unified SIF formulation for both short and long crack and a two stage crack propagation model

were proposed by Dr. Dong & his coworkers, Battelle, to use Equivalent Structural Stress as a

parameter for weldments fatigue life assessment.

ECT_wht_templ 2/28/2013 11:09 AM 13

A Unified Stress Intensity Factor (SIF) Formulation

(a) Weld geometry with a hypothetical crack l ; (b) Actual normal stress distribution; (c)

Simplification; (d) Decomposition; (e) Equilibrium-equivalent structural stress or far-field

stress; (f) Self-equilibrating stress (notch stress) with respect to a reference depth t

1

.

( b )

t

A

A

x

l 0

( b )

t

A

A

x

l 0

( a )

A

A

t

l

( a )

A

A

t

l

( c )

t

1

t

1

2

3

1

A

A

R

1

R

2

'

x

( c )

t

1

t

1

2

3

1

1

2

3

1

A

A

R

1

R

2

'

x

t

1

t

1

2

3

A

A

A

t

A

A

t

t

1

t

1

2

3

A

A

A

( d )

( e )

( f )

t

1

t

1

2

3

A

A

A

t

t

1

t

1

2

3

A

A

A

t

A

A

t

A

A

t

A

A

t

t

1

t

1

2

3

A

A

A

t

1

t

1

2

3

A

A

A

( d )

( e )

( f )

/ t

x

= - o A o o

/ t

x

= o o + Ao

/ t

x

= - o A o o

/ t

x

= o o + Ao

t

1

/t=0.1

ECT_wht_templ 2/28/2013 11:09 AM 14

A Unified Stress Intensity Factor

t

( ) ( ) (0 l t) A o + < < o

s n

K K = K

Notch Stress

Structural Stress, Far field stress

Notch Stress

Structural Stress, Far field stress

The drive force for crack to start and grow is the crack tip stress, introduce crack

surface traction p

s

called self equilibrating surface traction due to Ao (notch effect)

x

t /

s

( ) (p , (0 l t ) ) ( ) Ao ~ = o o < <

s s s

K K K

t

l

t

l

( a ) ( b )

A

A

t

A

A

t

A

A

t

t

1

t

1

2

3

A

A

A

t

1

t

1

2

3

A

A

A

( c )

t

s

p

l

( d )

t

s

p

l

tt

s

p

l

( d )

'

x

t

1

t

3

A

A

l

/

s x

t

p = f( )= f( , )

( e )

'

x

t

1

t

3

A

A

l

/

s x

t

p = f( )= f( , )

( e )

ECT_wht_templ 2/28/2013 11:09 AM 15

A Unified Stress Intensity Factor

t

s

(p ( ) (0 l t ) ) o + < <

n s

K = K K

Notch Effect

Structural Stress, Far field stress

t

s

(p ( ) (0 l t ) ) o + < <

n s

K = K K

Notch Effect

Structural Stress, Far field stress

Notch Effect

Structural Stress, Far field stress

t

l

( d )

( e )

A

A

t

( f )

t

s

p

l

t

l

( d )

t

l

( d )

( e )

A

A

t

( e )

A

A

t

A

A

t

A

A

t

( f )

t

s

p

l

( f )

t

s

p

l

tt

s

p

l

Notch Effect

Notch Effect

Far Field SIF

Far Field SIF

Notch Effect

Notch Effect

Far Field SIF

Far Field SIF

Stress intensity solutions

using published weight

function results: (a) remote

tension; (b) remote

bending.

ECT_wht_templ 2/28/2013 11:09 AM 16

SIF Magnification Factor M

kn

t

s

(p ( ) (0 l t ) ) o + < <

n s

K = K K

Introduction of notch induced SIF magnification factor M

kn

:

t

t

s

(p ) ( )

1.0 (0 l t)

( )

o +

> < <

o

kn

s n

n

K

M =

K

K

t

( ) (0 l t) o < <

kn n

K = M K

a/t a/t a/t a/t

Comparisons of stress intensity magnification factor M

kn

at 135 sharp V notch for various

specimen geometries and loading conditions: (a) Edge crack solutions; (b) Elliptical crack

solutions for a/c = 0.4

ECT_wht_templ 2/28/2013 11:09 AM 17

M

kn

for 135

0

V Notch Specimen

a/t

a/t

Conclusions:

M

kn

approaches unity as crack size a/t approaches 0.1 i.e., a/t=0.1 (short

crack correction factor) Thus a/t=0.1 can be taken as a characteristic

parameter beyond which the notch effect is negligible

The difference between edge crack and elliptical crack solutions are not

significant.

ECT_wht_templ 2/28/2013 11:09 AM 18

Modified Paris Law

m

n

n m

kn n

Paris Law :

da

C K (a)

dN

Introduce t

da

CM K

dN

heUnified SIF:

(b) = A

= A

Figures showed the

significant improvement

for the application of

Paris Law and its

application

More important the

crack starts from zero

that covers crack

initiation life

ECT_wht_templ 2/28/2013 11:09 AM 19

Master S~N Curve

=

=

=

=

=

=

}

-m

s

f

m

1

n m

2

n

kn

kn n

a a

n m

a 0

m b

n

m

kn

Using the Unified Paris Law,

da

N (b)

CM K

Introduction of

S ~ N curve can be obtained

1

N t I(r) (c)

C

d(a/ t)

Where,

generallized SIF ra

da

C

I(r)

M {f (a

M K (a)

dN

nge

/ t) r [f (a/ t) f

, leads

(a

to,

/ t)]

=

=

}

a / t 1

m

a / t 0

(d)

}

1

2 m 1 1

m

2m m m

2 m 1

2

1

1

m

m m

m

Then

C t I(r) N (e)

Introduce Equivalent Structrual Stress Range,

t I(r)

C N (f )

=

=

=

s

s

s s

S

S

ECT_wht_templ 2/28/2013 11:09 AM 20

Master S~N Curve

Nominal Stress Method Hot Spot Stress Method

Equivalent SS Method

Weld Joints (IIW)

ECT_wht_templ 2/28/2013 11:09 AM 21

Summary

The Structural Stress Method developed at Battelle is

mesh insensitive that removes the uncertainty in the

calculation of structural stress for weld joint fatigue

assessment

The nature of weld joint fatigue is considered through the

introduction of Equivalent Structural Stress based on

fracture mechanics, which enable most fatigue curves of

weld joints merged into a narrow band, the Master S~N

curve. Thus one S~N curve can be used for majority of

weld joints

Note: I believe that the weld joints have to be stress

concentration dominant to achieve consistent

results with test data.

ECT_wht_templ 2/28/2013 11:09 AM 22

References

[1]. BS PD 5500: , BSI Standards, London, 2000.

[2]. European Standard for Unfired Pressure Vessels, EN 13445: 2002, BS EN 13445:2002, BSI, London, 2002

[3]. ASME Boiler and Pressure Vessel Code, Section VIII, Rules for construction of pressure vessels, Division 2-

Alternative rules, ASME, 2003.

[4]. Carl E. Jaske, FSRF for WPVP, Journal of Pressure Vessel Technology, AUGUST 2000, Vol. 122, 297-304

[5]. S.J.Maddox, Review of fatigue assessment procedures, Int. J. of Fatigue, Vol. 25, 12, 2003, 1359-1378.

[6]. Maddox S J: 'Fatigue aspects of pressure vessel design, Spence J and Tooth A S, E & F N Spon, London, 1994.

[7]. Harrison J D and Maddox S J: 'A critical examination of rules for the design of pressure vessels subject to fatigue

loading' in Proc. 4th Int. Conf. on 'Pressure Vessel Technology', Mech E, London, 1980.

[8]. Taylor N (Ed): 'Current practices for design against fatigue in pressure equipment', EPERC Bulletin No.6, European

Commission, NL-1755ZG, Petten, The Netherlands, 2001.

[9]. Dong, P., 2005, A Robust Structural Stress Method for Fatigue Analysis of Offshore/Marine Structures, Journal of

Offshore Mechanics and Arctic Engineering , Vol. 127, pp. 68-74.

[10]. Dong, P., 2001, A Structural Stress Definition and Numerical Implementation for Fatigue Evaluation of Welded

Joints, Int. J. Fatigue, 23/10, pp. 865876.

[11]. Dong, P., Hong, J. K, Osage, D., and Prager, M., Assessment of ASMEs FSRF Rules for Pipe and Vessel Welds

Using A New Structural Stress Method, Welding In the World, Vol. 47, No. 1/2, 2003, pp. 3143.

[12] Dong, P., Hong, J. K., Osage, D., Prager, M., 2002, Master S-N Curve Method for Fatigue Evaluation of Welded

Components, WRC Bulletin, No. 474, August.

[13]. Lankford, J. , Fatigue of Eng Mater and Structures 5 (1982), pp233-248

[14]. R. Craig McClung, et al, Behavior of Small Fatigue Cracks, ASME, Vol. 19, Fatigue & Fracture, P153

[15]. Fricke W., 2001, Recommended Hot-Spot Analysis Procedure for Structural Details of FPSOs and Ships Based on

Round-Robin FE Analysis, ISOPE Proceedings, Stavanger, Norway, June.

ECT_wht_templ 2/28/2013 11:09 AM 23

Part II: Example Application

Aditya Sakhalkar

Sr. Applied Mechanics Engineer

Emerson Climate Technology Inc.

Background

ANSYS, Verity, Fe-Safe Weld Assessment Procedure

ANSYS Preprocessing

Verity Analysis

Fe-Safe Analysis

ANSYS Results

Comparison of Analysis Results with the Test Results

Conclusions

ECT_wht_templ 2/28/2013 11:09 AM 24

Resistance welded suction fitting

Three failures in the suction fitting weld

during reliability testing

Crack initiated at the weld toe (9 o clock)

and propagated through the shell.

Failure due to reverse bending fatigue.

Background

ECT_wht_templ 2/28/2013 11:09 AM 25

ANSYS, Verity, Fe-Safe Weld Analysis Procedure

Verity, Fe-Safe Weld analysis

Ansys Preprocessing

Ansys Post processing

- Meshing per Verity requirements

- Linear material properties

- Apply load

- Solution

Verity Analysis (Eq. Structural Stress

calculations along the weld line)

- Fe-Safe analysis (Weld life calculations

using Master S-N curve)

- Import .rst file

- Post processing

Verity result validation

and comparison

Reliability Testing

Calibration

Quantify loading

relative to the test

for FEA

ECT_wht_templ 2/28/2013 11:09 AM 26

Suction Fitting

Shell

Weld Line

Element Type: Solid 186

Ansys Preprocessing- FE Model

Mesh Requirements

Shell Elements:

3D mid-surface element with no through-

thickness dimension

Solid Element:

Rectangular faces required along the through-

thickness cut from the weld line

Regular mesh along the through thickness cut

from weld line

Recommended elements: Hexahedral (brick) and

Pentahedral (wedge)

Tetrahedral elements can be used. Requires

special handling.

Hex elements along weld line

Linear material properties

(E = 29,000 Ksi, = 0.29)

Symmetry BC

On sides

Top & Bottom

fixed

ECT_wht_templ 2/28/2013 11:09 AM 27

ANSYS Results

o

eq

o

1

Maximum Stress

Equivalent Stress

ECT_wht_templ 2/28/2013 11:09 AM 28

Verity Procedures

Structural Stresses calculated along the

weld line at each node

Fe-Safe builds a connectivity table and

maps the stresses to elemental stresses.

These stresses are inserted into the

stress matrix to be used for fatigue

evaluation

ECT_wht_templ 2/28/2013 11:09 AM 29

Fe-Safe Analysis Weld life predictions

using Master SN Curve

Fully reverse loading defined

Fe-Safe calculates weld fatigue life

based on the Battelles Master SN

curve

The weld life (log N) data at each

node is written in the ANSYS .rst

format

ECT_wht_templ 2/28/2013 11:09 AM 30

ANSYS Post processing Weld Life Results

Minimum life at element # 4436, node # 4212

ECT_wht_templ 2/28/2013 11:09 AM 31

Comparison of Verity Predictions

with Reliability Test Results

Conservative life estimate!

Predicted Failure Location correlated well with the test failures!!

ECT_wht_templ 2/28/2013 11:09 AM 32

ANSYS could be used for the fatigue assessment of welded

joints in conjunction with Verity & Fe-Safe

Verity provides conservative estimate of the weld life

Good correlation with the predicted and test failure locations

Verity & Fe-Safe provides a excellent weld design tool in

conjunction with ANSYS

Conclusions

S-ar putea să vă placă și

- 2008 Int ANSYS Conf Weld Joint AssessmentDocument27 pagini2008 Int ANSYS Conf Weld Joint AssessmentRajesh KachrooÎncă nu există evaluări

- Fatigue Analysis of Welded Components: Designer’s Guide to the Structural Hot-Spot Stress ApproachDe la EverandFatigue Analysis of Welded Components: Designer’s Guide to the Structural Hot-Spot Stress ApproachEvaluare: 5 din 5 stele5/5 (1)

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceDe la EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceÎncă nu există evaluări

- Comparison of Different Calculation Methods For Structural Stresses at Welded JointsDocument11 paginiComparison of Different Calculation Methods For Structural Stresses at Welded JointsBob LoblawÎncă nu există evaluări

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityDe la EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityÎncă nu există evaluări

- Fatigue AnalysisDocument23 paginiFatigue AnalysisarnoldmarshalÎncă nu există evaluări

- A Structural Stress Definition and Numerical Implementation For Fatigue Analysis of Welded JointsDocument12 paginiA Structural Stress Definition and Numerical Implementation For Fatigue Analysis of Welded Jointsjoshua6Încă nu există evaluări

- STRESS ANALYSIS and FATIGUE of Welded StructuresDocument20 paginiSTRESS ANALYSIS and FATIGUE of Welded Structuresmatteo_1234100% (1)

- Neuber's Rule Accuracy in Predicting Notch Stress-StrainDocument10 paginiNeuber's Rule Accuracy in Predicting Notch Stress-StrainbatmanbittuÎncă nu există evaluări

- Downing Simple Rainflow Counting AlgorithmsDocument10 paginiDowning Simple Rainflow Counting Algorithmsridzim4638Încă nu există evaluări

- DNV FatigueDocument115 paginiDNV FatigueImran Siddiqui100% (1)

- Multiaxial Fatigue Simulation Using Ansys PDFDocument100 paginiMultiaxial Fatigue Simulation Using Ansys PDFjohn_max03Încă nu există evaluări

- Fracture Mechanics CharacterizationDocument124 paginiFracture Mechanics CharacterizationJose Luis GrajedaÎncă nu există evaluări

- The Rainflow Method in Fatigue: The Tatsuo Endo Memorial VolumeDe la EverandThe Rainflow Method in Fatigue: The Tatsuo Endo Memorial VolumeÎncă nu există evaluări

- A. Hobbacher-Fatigue Design of Welded Joints and Components, Recommendations of IIW Joint Working Group XIII - XV - Woodhead Publishing (1996) PDFDocument130 paginiA. Hobbacher-Fatigue Design of Welded Joints and Components, Recommendations of IIW Joint Working Group XIII - XV - Woodhead Publishing (1996) PDFMatteoMelaiÎncă nu există evaluări

- Effect of Frequency On FatigueDocument10 paginiEffect of Frequency On FatigueMahadevan RÎncă nu există evaluări

- Comparison of Hot Spot Stress Evaluation Methods For Welded Structures PDFDocument11 paginiComparison of Hot Spot Stress Evaluation Methods For Welded Structures PDFhbsheenÎncă nu există evaluări

- NI 611 - Guidelines For Fatigue Assessment of Offshore Units PDFDocument172 paginiNI 611 - Guidelines For Fatigue Assessment of Offshore Units PDFKirti BairathiÎncă nu există evaluări

- Tutorial 15b CT XFEMDocument19 paginiTutorial 15b CT XFEMVarghese MathewÎncă nu există evaluări

- Fatigue Life Calculation of WeldDocument15 paginiFatigue Life Calculation of WeldSaut Maruli Tua SamosirÎncă nu există evaluări

- Perhitungan Untuk Mencari Alat Bantu AngkatDocument6 paginiPerhitungan Untuk Mencari Alat Bantu AngkatGame Just forÎncă nu există evaluări

- Fatigue Ocean StructuresDocument65 paginiFatigue Ocean StructureslukmantralalaÎncă nu există evaluări

- Weld CalcDocument8 paginiWeld CalcOmil RastogiÎncă nu există evaluări

- Explosion Analysis of PiperackDocument146 paginiExplosion Analysis of PiperackSun Rui0% (1)

- BS 7910: The UK Guide On Methods For Assessing The Acceptability of Flaws in Metallic StructuresDocument32 paginiBS 7910: The UK Guide On Methods For Assessing The Acceptability of Flaws in Metallic Structuresgeraldo gilÎncă nu există evaluări

- Adiabatic Shear Localization: Frontiers and AdvancesDe la EverandAdiabatic Shear Localization: Frontiers and AdvancesBradley DoddÎncă nu există evaluări

- Estimation Methods For Fatigue Properties of Steels Under Axial and Torsional LoadingDocument11 paginiEstimation Methods For Fatigue Properties of Steels Under Axial and Torsional Loadingrobinisc100% (1)

- Full-Range Stress-Strain Curves For Stainless SteelDocument15 paginiFull-Range Stress-Strain Curves For Stainless SteelNurul HudaÎncă nu există evaluări

- VDI2230 Review Design GuidelineDocument15 paginiVDI2230 Review Design GuidelinebreeeeezzzzzeÎncă nu există evaluări

- Master Thesis Residual Stresses in Welds of Supersize Monopiles For Offshore Wind Substructures PDFDocument246 paginiMaster Thesis Residual Stresses in Welds of Supersize Monopiles For Offshore Wind Substructures PDFChristian Ammitzbøll100% (1)

- Fe-Safe Ansys WorkbenchDocument36 paginiFe-Safe Ansys WorkbenchSrashmi100% (1)

- Local Buckling Analysis Based On DNV-OS-F101 2000Document4 paginiLocal Buckling Analysis Based On DNV-OS-F101 2000shervinyÎncă nu există evaluări

- Hot Spot StressDocument11 paginiHot Spot Stressevo2005_2006Încă nu există evaluări

- DNV CN30 7 - 2014Document151 paginiDNV CN30 7 - 2014hendry_hdwÎncă nu există evaluări

- What Is Verification and Validation, NAFEMSDocument4 paginiWhat Is Verification and Validation, NAFEMSgulilero_yoÎncă nu există evaluări

- IMP-Crack Fracture Mechanics#KEC Plant Pressure Vessel Training Manual 5 of 5 PDFDocument228 paginiIMP-Crack Fracture Mechanics#KEC Plant Pressure Vessel Training Manual 5 of 5 PDFbomikaÎncă nu există evaluări

- A Code of Practice For The Determination of Cyclic Stress-StrainDocument22 paginiA Code of Practice For The Determination of Cyclic Stress-StrainDeivyson AugustoÎncă nu există evaluări

- Simulation of Low Cycle Fatigue With AbaqusFEA 376-383Document8 paginiSimulation of Low Cycle Fatigue With AbaqusFEA 376-383Dmitry GrenishenÎncă nu există evaluări

- ANSYS Offshore Products 14-0 Update - SchofieldDocument44 paginiANSYS Offshore Products 14-0 Update - SchofieldZhiqiang GuÎncă nu există evaluări

- Fatigue Design of Plated Structures Using Finite Element AnalysisDocument11 paginiFatigue Design of Plated Structures Using Finite Element AnalysisAan YudiantoÎncă nu există evaluări

- Elastic Foundation StiffnessDocument6 paginiElastic Foundation StiffnesstigerpumaÎncă nu există evaluări

- Lecture Weld Highlighted PDFDocument12 paginiLecture Weld Highlighted PDFHerschell Vergel de DiosÎncă nu există evaluări

- ANODE SLED Padeye CalculationDocument5 paginiANODE SLED Padeye Calculationejim2Încă nu există evaluări

- Discussion - Stress Strain CurveDocument3 paginiDiscussion - Stress Strain CurveAnonymous UoHUagÎncă nu există evaluări

- DS63 - (1985) References and Conference Proceedings Towards The Understanding of Fracture MechanicsDocument58 paginiDS63 - (1985) References and Conference Proceedings Towards The Understanding of Fracture MechanicsJacques Strappe100% (1)

- Fatigue SN CurveDocument19 paginiFatigue SN CurveSelva100% (2)

- (A. Hobbacher) Fatigue Design of Welded JointsDocument130 pagini(A. Hobbacher) Fatigue Design of Welded JointsandypcÎncă nu există evaluări

- FEM of Welded JointDocument34 paginiFEM of Welded JointbysktyvktoÎncă nu există evaluări

- Explain ANSYS NcodeDocument34 paginiExplain ANSYS Ncodemarcorreo_pe100% (1)

- Bolt Calculation Method AgatonovicAdvancBalkenModelDocument19 paginiBolt Calculation Method AgatonovicAdvancBalkenModeljvalverdegarciaÎncă nu există evaluări

- 3D Fracture Mechanics in ANSYSDocument20 pagini3D Fracture Mechanics in ANSYSFadillah Nur RahmanÎncă nu există evaluări

- Fatigue Analysis of Welded JointsDocument16 paginiFatigue Analysis of Welded Jointsangelobuijtels100% (1)

- The Wind-Induced Vibration Response For Tower Crane BasedDocument5 paginiThe Wind-Induced Vibration Response For Tower Crane BasedGogyÎncă nu există evaluări

- HSE Report - Fatigue Provisions Comparison ReportDocument70 paginiHSE Report - Fatigue Provisions Comparison Reportmehdi64090% (1)

- Buckling Strength of Plated Structures: Recommended Practice DNV-RP-C201Document32 paginiBuckling Strength of Plated Structures: Recommended Practice DNV-RP-C201aace3422Încă nu există evaluări

- ElementTech (EDI SACS Guide)Document69 paginiElementTech (EDI SACS Guide)kleidi85Încă nu există evaluări

- Analysis of Bolted Joints SAMPE2011 Collier Automated Space VesselDocument13 paginiAnalysis of Bolted Joints SAMPE2011 Collier Automated Space Vesselmatteo_1234Încă nu există evaluări

- Linear Elastic Theory of Thin Shells: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionDe la EverandLinear Elastic Theory of Thin Shells: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionEvaluare: 5 din 5 stele5/5 (2)

- Fatigue Design: International Series on the Strength and Fracture of Materials and StructuresDe la EverandFatigue Design: International Series on the Strength and Fracture of Materials and StructuresÎncă nu există evaluări

- Xoom Page Jassim Rahma: Powered By: Developed byDocument1 paginăXoom Page Jassim Rahma: Powered By: Developed byLogeswaran RajiÎncă nu există evaluări

- BaseDocument1 paginăBaseLogeswaran RajiÎncă nu există evaluări

- Base 5Document1 paginăBase 5Logeswaran RajiÎncă nu există evaluări

- Base 4Document1 paginăBase 4Logeswaran RajiÎncă nu există evaluări

- Base 1Document1 paginăBase 1Logeswaran RajiÎncă nu există evaluări

- Simple Column Base Plates How ToDocument6 paginiSimple Column Base Plates How ToLogeswaran RajiÎncă nu există evaluări

- Base 3Document1 paginăBase 3Logeswaran RajiÎncă nu există evaluări

- Base 2Document1 paginăBase 2Logeswaran RajiÎncă nu există evaluări

- Response SpectraDocument1 paginăResponse SpectraLogeswaran RajiÎncă nu există evaluări

- Response Spectra1Document1 paginăResponse Spectra1Logeswaran RajiÎncă nu există evaluări

- Base PlateDocument1 paginăBase PlateLogeswaran RajiÎncă nu există evaluări

- Base Plate 01Document1 paginăBase Plate 01Logeswaran RajiÎncă nu există evaluări

- PipeDocument1 paginăPipeLogeswaran RajiÎncă nu există evaluări

- Pipe 1Document1 paginăPipe 1Logeswaran RajiÎncă nu există evaluări

- DX X D X X) Y, Z: Torsion in Structural Design - Notes 11/30/01Document1 paginăDX X D X X) Y, Z: Torsion in Structural Design - Notes 11/30/01Logeswaran RajiÎncă nu există evaluări

- Limit StaDocument1 paginăLimit StaLogeswaran RajiÎncă nu există evaluări

- NotationDocument1 paginăNotationLogeswaran RajiÎncă nu există evaluări

- Latest 2Document1 paginăLatest 2Logeswaran RajiÎncă nu există evaluări

- Iso Information On Technical Standardisation - Changeover To IsoDocument7 paginiIso Information On Technical Standardisation - Changeover To IsoLogeswaran RajiÎncă nu există evaluări

- 10 16Document1 pagină10 16Logeswaran RajiÎncă nu există evaluări

- Base Plate and Anchor Bolt DesignDocument30 paginiBase Plate and Anchor Bolt DesignShaikh Muhammad Ateeq100% (1)

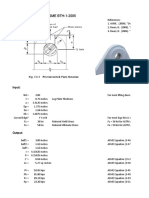

- Lug Design (FML-1) : Connection Design As Per Bs 5950-1:2000 Design Loads: (For Max. Major Moment)Document1 paginăLug Design (FML-1) : Connection Design As Per Bs 5950-1:2000 Design Loads: (For Max. Major Moment)Logeswaran RajiÎncă nu există evaluări

- ForewordDocument1 paginăForewordLogeswaran RajiÎncă nu există evaluări

- Bad GameDocument1 paginăBad GameLogeswaran RajiÎncă nu există evaluări

- Brochure Shading Tension System 440 Horiso 2012Document4 paginiBrochure Shading Tension System 440 Horiso 2012Logeswaran RajiÎncă nu există evaluări

- Embedded PlateDocument1 paginăEmbedded PlateLogeswaran RajiÎncă nu există evaluări

- Ground ScrewDocument1 paginăGround ScrewLogeswaran RajiÎncă nu există evaluări

- Using Bookmarks and Cross-References in WordDocument4 paginiUsing Bookmarks and Cross-References in WordcivilidÎncă nu există evaluări

- Bachelor of Interior Design) : Accredited by NAACDocument25 paginiBachelor of Interior Design) : Accredited by NAACLogeswaran RajiÎncă nu există evaluări

- Full Page PhotoDocument1 paginăFull Page PhotoLogeswaran RajiÎncă nu există evaluări

- Ijpret - Mech 102Document8 paginiIjpret - Mech 102chotichanduÎncă nu există evaluări

- Name: Robbie Jane S. de Guzman: Answer The Following ProblemsDocument5 paginiName: Robbie Jane S. de Guzman: Answer The Following ProblemsAkirajane De GuzmanÎncă nu există evaluări

- OIML R 61-1: Nternational EcommendationDocument48 paginiOIML R 61-1: Nternational Ecommendationdavid dcÎncă nu există evaluări

- Nature Milestone Complete EbookDocument145 paginiNature Milestone Complete Ebookvishal040393_9824775Încă nu există evaluări

- Nuclear Stability Radioactivity and Half LifeDocument20 paginiNuclear Stability Radioactivity and Half LifeKris Carl QuirapasÎncă nu există evaluări

- Materials Characterization: Lab ReportDocument9 paginiMaterials Characterization: Lab ReportGM MalikÎncă nu există evaluări

- Matter Waves and Davisson-Germer ExperimentDocument2 paginiMatter Waves and Davisson-Germer ExperimentNatheesh TpÎncă nu există evaluări

- Engineering Survey 1Document27 paginiEngineering Survey 1Ralph MarronÎncă nu există evaluări

- Tugas PPT Gas Well TestingDocument31 paginiTugas PPT Gas Well TestingRahman Sudrajat PamungkasÎncă nu există evaluări

- Newton-Cartan Theory and Teleparallel Gravity: The Force of A FormulationDocument12 paginiNewton-Cartan Theory and Teleparallel Gravity: The Force of A FormulationInês AlmeidaÎncă nu există evaluări

- MECH 211 Module 9 Distributed Loads and Hydrostatic Forces CablesDocument18 paginiMECH 211 Module 9 Distributed Loads and Hydrostatic Forces CablesFirst name Last nameÎncă nu există evaluări

- Maths Lab SyntaxDocument12 paginiMaths Lab SyntaxFS-33-Aryan KulharÎncă nu există evaluări

- Soil Satbilization Using Plastic WasteDocument5 paginiSoil Satbilization Using Plastic WasteSabbir NadimÎncă nu există evaluări

- Ammann Asphalt Mixing-Plant Brochure enDocument90 paginiAmmann Asphalt Mixing-Plant Brochure enMihai Popescu100% (4)

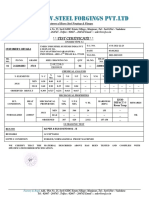

- A.V.Steel Forgings PVT - LTD: Test CertificateDocument1 paginăA.V.Steel Forgings PVT - LTD: Test CertificateNirmit GandhiÎncă nu există evaluări

- Topic 1quantitative ChemistryDocument8 paginiTopic 1quantitative Chemistrylobna masadehÎncă nu există evaluări

- Republic of The Philippines: ISUI-EDU-PRF-012 Effectivity: January 3, 2017 Revision: 1Document2 paginiRepublic of The Philippines: ISUI-EDU-PRF-012 Effectivity: January 3, 2017 Revision: 1Kristelle V. TorrealbaÎncă nu există evaluări

- Engineering Mechanics Unit 3Document102 paginiEngineering Mechanics Unit 3SundraÎncă nu există evaluări

- Student-5.1 PHET LAB - Friction LabDocument3 paginiStudent-5.1 PHET LAB - Friction Labisaacrose876Încă nu există evaluări

- Summative Test No.1 Grade 7Document4 paginiSummative Test No.1 Grade 7LENETTE ALAGON100% (1)

- Log 92 Tip Conductivity SalinityDocument1 paginăLog 92 Tip Conductivity SalinityJUAN RAMIREZ MARTINEZÎncă nu există evaluări

- Chapter 2Document70 paginiChapter 2Trần QuangÎncă nu există evaluări

- Veb1043 Geomatics January 2020 Lab Report: Experiment: Group: Group MembersDocument8 paginiVeb1043 Geomatics January 2020 Lab Report: Experiment: Group: Group MembersAdam Kamaruzaman50% (2)

- Plotting Pressure Coefficient Distribution For Airfoils: Calculation of CDocument19 paginiPlotting Pressure Coefficient Distribution For Airfoils: Calculation of CMarisha BhattiÎncă nu există evaluări

- Design Strength of Screw AAMA TIR-A9Document1 paginăDesign Strength of Screw AAMA TIR-A9Giri DharanÎncă nu există evaluări

- Nuclear PhysicsDocument21 paginiNuclear PhysicsAbdur RehmanÎncă nu există evaluări

- SEMINAR PRESENTATION: Forced Vibration Due To Excitation of The SupportDocument8 paginiSEMINAR PRESENTATION: Forced Vibration Due To Excitation of The SupportKriti GuptaÎncă nu există evaluări

- Some Effects of Wind On Ship's ManoeuvrabilityDocument4 paginiSome Effects of Wind On Ship's ManoeuvrabilityCOSTAÎncă nu există evaluări

- Asymptotic Expansion of Integrals: Chee Han Tan Last Modified: April 16, 2017Document19 paginiAsymptotic Expansion of Integrals: Chee Han Tan Last Modified: April 16, 2017audaciousribbonÎncă nu există evaluări

- KrishnaDocument9 paginiKrishnaKrishna KashyapÎncă nu există evaluări