Documente Academic

Documente Profesional

Documente Cultură

VGRS

Încărcat de

Boy DolandDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

VGRS

Încărcat de

Boy DolandDrepturi de autor:

Formate disponibile

Chassis

-A -W -Q

-V

VGRS (Variable Gear Ratio Steering) System General The steering gear ratio will be changed in accordance with the vehicle speed

a

Vehicle speed low

a+

Vehicle speed high

a

Low Ratio (Quick)

High Ratio (Slow)

Chassis

-A -W -Q

-V

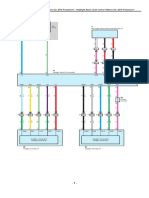

VGRS System System Diagram (Main Signal)

Engine ECU (ECM)

Engine Speed

Steering Angle Sensor

Steering Angle

Control Signal

VGRS Actuator

Lock Mechanism Rotational Angle Sensor

Steering Wheel Neutral Position Vehicle Speed Engine Speed Etc.

Skid Control ECU

VGRS Actuator Operating Angle

VGRS ECU

VGRS Actuator Actual Operating Angle

Control ECU

Wheel Angle (Steering Angle + VGRS Suspension Actuator Operating Angle)

Temp. Sensor

VGRS Warning Light DLC3

Chassis

-A -W -Q

Combination Meter

-V

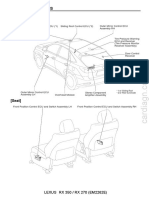

VGRS System Component Location

VGRS Warning Light Steering Angle Sensor

VGRS Actuator

VGRS ECU

Chassis

-A -W -Q

-V

VGRS System Steering Gear Ratio

Comparison of the gear ratio

Steering Gear Ratio

Slow

Gear Ratio : 19.8 Lock to Lock : 3.8

VGRS system not operates

Gear Ratio : 17.3 Lock to Lock : 3.3

Quick

Gear Ratio : 18.0 Lock to Lock : 3.5

: 03 Model with VGRS System : 02 Model

Gear Ratio : 12.4 Lock to Lock : 2.4

Vehicle Speed

Chassis

-A -W -Q

-V

VGRS System Normal Operation

Steering Angle Sensor

VGRS Actuator Motor Gear

Control Signal (Target Operating Angle) Actuator Operating Angle

VGRS ECU

Map Calculate actuator target operating angle

Steering Angle Skid Control ECU Vehicle Speed

Vehicle Speed

Chassis

-A -W -Q

-V

VGRS System Cooperative Control of Brake Control System For example, in order to enable quicker steering when braking suddenly (VSC active)

Drives steering effort

Effectiveness of Cooperative Control of Brake Control System Slippery Surface

Braking

Chassis

-A -W -Q

-V

VGRS System VGRS Actuator

Steering Wheel

Rubber Coupling

VGRS Actuator

Spiral Cable Lock Mechanism DC Motor Reduction Mechanism

Rack & Pinion

Chassis

-A -W -Q

-V

VGRS System Spiral Cable Flexible flat cable is used

Control Signal

VGRS ECU

Power Source Motor

Rotational angle and rotational direction of the DC motor

Chassis

-A -W -Q

-V

VGRS System Lock Mechanism This mechanism locks the motor shaft if the system fails

A A Cross Section

Lock Holder (Motor Shaft) Solenoid

A

Motor Shaft Lock Lever (Housing)

Return Spring

Chassis

-A -W -Q

-V

VGRS System Lock Mechanism

Solenoid ON Solenoid OFF

Unlock

System is Normal

Lock

Engine is stopped System inoperative (Fail Safe)

Chassis

-A -W -Q

-V

VGRS System Motor A compact high-output low-noise DC brush-less stepper motor

Motor Shaft DC Motor

Magnet

Coil

Reduction Mechanism

Rotational Angle sensor (Three Hole ICs) is included in the motor

Chassis

-A -W -Q

-V

VGRS System Reduction Mechanism The strain wave gearing type reduction mechanism is used

Steering Wheel Motor

Stator Gear Wave Generator

Stator Gear

Flexible Gear

Flexible Gear Driven Gear

Driven Gear Output Shaft

Wave Generator

Chassis

-A -W -Q

-V

VGRS System Reduction Mechanism Components

Stator Gear (input) Flexible Gear Driven Gear (output) Wave Generator (input)

Steering Wheel

Rack & Pinion

Chassis

-A -W -Q

-V

VGRS System Reduction Mechanism Components

Stator Gear (input ) Flexible Gear Driven Gear (output) Wave Generator (input)

Teeth Coupled to the housing of the VGRS actuator (Steering wheel input) Number of teeth: 102

Teeth Flexible metal body Gear teeth are meshed with the inside of both stator gear and driven gear Number of teeth: 100

Teeth Coupled to the output shaft of the VGRS actuator (Steering gear output) Number of teeth: 100 Consists an ovalshaped cam and bearing rotated by the DC motor -

The difference of number of teeth

Chassis

-A -W -Q

-V

VGRS System Reduction Mechanism Construction

Stator Gear Flexible Gear Wave Generator

Meshing

Not meshing View from stator gear side (Steering wheel side)

Ball Bearing is between flexible gear and wave generator

Chassis

-A -W -Q

-V

VGRS System Reduction Mechanism Operation of strain wave gearing

The flexible gear is flexed into an oval shape by wave generator The teeth of flexible gear meshes with the teeth of stator gear and driven gear

The wave generator rotates

The meshed area of the flexible gear and stator gear and driven gear moves in sequence

The wave generator makes one turn

View from stator gear side The driven gear and flexible gear have the same (stator gear fixed) number of teeth, so their rotational movements are

identical

The flexible gear moves by 2 teeth because the flexible gear has 2 fewer teeth than the stator gear

The driven gear moves by 2 teeth (=Actuator output)

Reference

-A -W -Q

-V

VGRS System Reduction Mechanism

Motor Shaft

Flexible Gear

Wave Generator

Stator Gear

View from stator gear side

Ball Bearing (Between flexible gear and wave generator)

Chassis

-A -W -Q

-V

VGRS System Reduction Mechanism Operation of strain wave gearing

102 teeth The wave generator makes one turn

Moves 2 teeth

Click Picture

100 teeth

Every time motor rotates, flexible gear and stator gear shifts by two teeth

The shift is used as actuator output

Chassis

-A -W -Q

-V

VGRS System Reduction Mechanism Gear ratio

102 teeth Wave generator (motor) rotates 50 times

Flexible gear rotates one time

100 teeth

Gear Ratio

50

Motor

1

Flexible Gear

Chassis

-A -W -Q

-V

VGRS System Operation (Left turn when the vehicle speed is low) The motor rotates the clockwise and adds steering angle

Steering wheel 1 rev.

Chassis

-A -W -Q

-V

VGRS System Operation (Left turn when the vehicle speed is mid.) The motor does not operate and no assist

Motor 0 rev. / Steering wheel 1 rev.

Click Picture

Chassis

-A -W -Q

-V

VGRS System Operation (Left turn when the vehicle speed is high) The motor rotates the counterclockwise and reduces steering angle

Steering wheel 1 rev.

Chassis

-A -W -Q

-V

VGRS System VGRS Warning Light VGRS warning light comes ON when the system has a malfunction

Chassis

-A -W -Q

-V

VGRS System VGRS ECU (Fail-safe 1)

Malfunction Parts Fail-safe Operation VGRS Warning Light DTC Memory Condition

Steering Angle Sensor Malfunction DC Motor Malfunction VGRS ECU Malfunction DC Motor Circuit Malfunction Lock Mechanism Circuit Malfunction Vehicle Speed Signal Malfunction Skid Control ECU Communication Signal Malfunction System stop (Lock mechanism)

Chassis

-A -W -Q

-V

VGRS System VGRS ECU (Fail-safe 2)

Malfunction Parts Fail-safe Operation

VGRS Warning Light DTC Memory Condition

DC Motor Overheat (approx. 100C *1) VGRS ECU Overheat (approx. 100C) PIG Power Source Drop Voltage Malfunction VGRS Actuator Malfunction *2

First, the control is stopped; then, the control resume after the system resumes its normal operation

*1: The temperature presumed from the motor drive current *2: Specific examples 1) When the steering operated while the output of the power steering pump is unstable, immediately after starting a cold engine 2) If the driver attempts to operate the steering wheel further after is has been steered entirely to the rock end

Chassis

-A -W -Q

-V

VGRS System Diagnosis DTCs 1/3

DTCs C1511 / 11 C1515 / 15 C1516 / 16 C1521 / 21 C1522 / 22 C1527 / 27 C1528 / 28 C1531 / 31 C1532 / 32 C1533 / 33 VGRS ECU Malfunction VGRS Actuator Malfunction Detection item Steering Angle Sensor Malfunction VGRS Actuator Neutral Position undone

Chassis

-A -W -Q

-V

VGRS System Diagnosis DTCs 2/3

DTCs C1541 / 41 C1549 / 49 C1551 / 51 C1552 / 52 C1554 / 54 C1555 / 55 Detection item Skid Control System Malfunction Skid Control System Communication Malfunction IG Power Source Voltage Malfunction DC Motor Power Source Voltage Malfunction Power Source Relay failure Predriver Source Relay Failure

Chassis

-A -W -Q

-V

VGRS System Diagnosis DTCs 3/3

DTCs C1561 / 61 C1567 / 67 C1568 / 68 C1569 / 69 Detection item Lock Mechanism Malfunction Lock Mechanism Insertion Malfunction Lock Holder Deviation Detection Lock Mechanism Release Incomplete

Test Mode

C1571

C1572 C1575 C1576

Vehicle Speed Sensor Malfunction (FLO)

Vehicle Speed Sensor Malfunction (FRO) Steering Angle Sensor Malfunction DC Motor Revolution Angle Sensor Malfunction

Chassis

-A -W -Q

-V

VGRS System Initialize Initialize VGRS ECU, after exchange VGRS ECU or VGRS actuator

Remove Install

Remove Install

Initialize VGRS ECU

When the VGRS ECU initialize is undone, the DTC (C1515 or C1516) is memorized

S-ar putea să vă placă și

- CVT Mitsubishi 1Document12 paginiCVT Mitsubishi 1Humberto Lojan50% (2)

- En Tech E4wdDocument1 paginăEn Tech E4wdwirelesssoulÎncă nu există evaluări

- Diagnosis and Testing: Automatic Transmission (Automatic Shifting Manual Transmission/Transaxle)Document60 paginiDiagnosis and Testing: Automatic Transmission (Automatic Shifting Manual Transmission/Transaxle)GabrielÎncă nu există evaluări

- Mazda l3 With TC Engine Workshop Manual PDFDocument70 paginiMazda l3 With TC Engine Workshop Manual PDFJuan Idrovo100% (1)

- Driver Assistance System: SectionDocument357 paginiDriver Assistance System: SectionАндрей НадточийÎncă nu există evaluări

- Engine Control System (HR) : SectionDocument322 paginiEngine Control System (HR) : SectionSergey KosulinÎncă nu există evaluări

- Turbine Speed Sensor Removal (TB-50LS) : 1. Preliminary and Post Procedures 1. Preliminary ProceduresDocument17 paginiTurbine Speed Sensor Removal (TB-50LS) : 1. Preliminary and Post Procedures 1. Preliminary ProceduresPatricio ValenciaÎncă nu există evaluări

- Hyundai Chassis EPS - MDPS-Power SteeringDocument99 paginiHyundai Chassis EPS - MDPS-Power SteeringDedi Suwasono100% (2)

- Actyon A0 A06005Document10 paginiActyon A0 A06005Arimbi GembiekÎncă nu există evaluări

- Nissan Patrol Y61 Series 1 Brake SystemDocument10 paginiNissan Patrol Y61 Series 1 Brake SystemKofetoÎncă nu există evaluări

- Suzuki PresentationDocument30 paginiSuzuki PresentationGaurav KhandelwalÎncă nu există evaluări

- 2tz Fze 2Document22 pagini2tz Fze 2che-ahmad-majdi-7191Încă nu există evaluări

- El PDFDocument782 paginiEl PDFRoberto Bravo100% (1)

- Terra CanDocument530 paginiTerra CanEduardo FloresÎncă nu există evaluări

- 2AZ-FE FuelDocument43 pagini2AZ-FE FuelAdedeji OluwatobilobaÎncă nu există evaluări

- Montero ABSDocument136 paginiMontero ABSBer HonzaÎncă nu există evaluări

- Engine Mechanical: Precautions and Preparations Timing ChainDocument88 paginiEngine Mechanical: Precautions and Preparations Timing ChainJames HavocÎncă nu există evaluări

- DTC P0335 Crankshaft Position Sensor "A" CircuitDocument3 paginiDTC P0335 Crankshaft Position Sensor "A" CircuitErln LimaÎncă nu există evaluări

- Prado Manual SM - 2Document104 paginiPrado Manual SM - 2jeddo2005100% (1)

- Ignition CoilDocument41 paginiIgnition Coilwaterlife70100% (1)

- 120a PDFDocument2 pagini120a PDFNilson MaldonadoÎncă nu există evaluări

- YD25 Manual DieselDocument42 paginiYD25 Manual Dieselalexsandro91537Încă nu există evaluări

- TRANSMISSION/TRANSAXLE TROUBLESHOOTING GUIDEDocument611 paginiTRANSMISSION/TRANSAXLE TROUBLESHOOTING GUIDEanmec20Încă nu există evaluări

- General: Click On The Applicable Bookmark To Selected The Required Model YearDocument54 paginiGeneral: Click On The Applicable Bookmark To Selected The Required Model YearRogério MorenoÎncă nu există evaluări

- Control System 1Document34 paginiControl System 1Shrinivas Prabhu100% (4)

- Caja Automatica Suzuki Sidekick 1995Document15 paginiCaja Automatica Suzuki Sidekick 1995Glenn50% (2)

- GR00007800 23a PDFDocument160 paginiGR00007800 23a PDFToponari MedveÎncă nu există evaluări

- Patrol Y61 2.8 TD Ecu System Operation DiagramDocument9 paginiPatrol Y61 2.8 TD Ecu System Operation Diagramvali_nedelea100% (1)

- Air Suspension System Parts List and Electrical ConnectionsDocument2 paginiAir Suspension System Parts List and Electrical ConnectionsBelchior CostaÎncă nu există evaluări

- Technical Service Bulletin: - DescriptionDocument4 paginiTechnical Service Bulletin: - Description08088338Încă nu există evaluări

- 1 ZzfeDocument8 pagini1 ZzfeScuderia Redin100% (1)

- 3grfse 2 PDFDocument20 pagini3grfse 2 PDFMarranÎncă nu există evaluări

- Em PDFDocument188 paginiEm PDFRoberto BravoÎncă nu există evaluări

- Technical data on the Hyundai H1 2.5 TCI vehicleDocument22 paginiTechnical data on the Hyundai H1 2.5 TCI vehicleJesús AraizaÎncă nu există evaluări

- Auto Trans Overview Cooper SDocument25 paginiAuto Trans Overview Cooper SDiego Fuertes Forero100% (1)

- 10-Automatic Transmission PDFDocument192 pagini10-Automatic Transmission PDFLakzana Budhy100% (2)

- Diesel Fuel System GuideDocument553 paginiDiesel Fuel System GuideObrocea Nelu100% (5)

- F Relay Locations: LEXUS RX 350 / RX 270 (EM2262E)Document23 paginiF Relay Locations: LEXUS RX 350 / RX 270 (EM2262E)Echa DudoÎncă nu există evaluări

- Rear Axle & Suspension NVH TroubleshootingDocument26 paginiRear Axle & Suspension NVH TroubleshootingblumngÎncă nu există evaluări

- Harness & Circuit DiagramDocument71 paginiHarness & Circuit DiagramTomyÎncă nu există evaluări

- DTC C1267/67 Brake Pedal Load Sensing Switch: DescriptionDocument4 paginiDTC C1267/67 Brake Pedal Load Sensing Switch: DescriptionbakriramziÎncă nu există evaluări

- Mitsubishi Engine 6G7 E W Series Workshop ManualDocument68 paginiMitsubishi Engine 6G7 E W Series Workshop ManualJimmy Brian Kaifiti0% (1)

- Nissan PDFDocument312 paginiNissan PDFardyanmustsuccess100% (2)

- Wiring Diagrams PDFDocument35 paginiWiring Diagrams PDFTessa HernandezÎncă nu există evaluări

- Adaptive headlight system controlsDocument15 paginiAdaptive headlight system controlsMaiChiVuÎncă nu există evaluări

- Advanced Chassis and Body Control Systems-Part2Document60 paginiAdvanced Chassis and Body Control Systems-Part2aliÎncă nu există evaluări

- T1 Cam Trigger Instructions 1Document10 paginiT1 Cam Trigger Instructions 1Initial_BG100% (1)

- EC System sr20Document332 paginiEC System sr20Gabriel BalcazarÎncă nu există evaluări

- 13 Re Russia-Kd 6B3 WM PDFDocument636 pagini13 Re Russia-Kd 6B3 WM PDFIgor LukÎncă nu există evaluări

- Navara qr25deBCSDocument20 paginiNavara qr25deBCSAhmedÎncă nu există evaluări

- Toyota Camry 2017 Electric Wiring DiagramDocument1.583 paginiToyota Camry 2017 Electric Wiring DiagramIvan Pevnitsky100% (2)

- DTC P0700 and U0073Document3 paginiDTC P0700 and U0073fulltransmission100% (1)

- Mazda 6 2014 OBD2 PinDocument2 paginiMazda 6 2014 OBD2 Pinoak2147Încă nu există evaluări

- RE4R03ADocument2 paginiRE4R03AAbbode HoraniÎncă nu există evaluări

- Mitsubishi PajeroDocument18 paginiMitsubishi PajeroWilliam Nteja0% (2)

- Toyota 140l 140e Transmission Repair Manual Atsg Automatic Transmission Service GroupDocument102 paginiToyota 140l 140e Transmission Repair Manual Atsg Automatic Transmission Service Grouptoan100% (2)

- Hybrid Electric Vehicles: Principles and Applications with Practical PerspectivesDe la EverandHybrid Electric Vehicles: Principles and Applications with Practical PerspectivesÎncă nu există evaluări

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003De la EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Evaluare: 5 din 5 stele5/5 (1)

- The Electro-Mechanical Power Steering System: Self-Study Programme 225Document24 paginiThe Electro-Mechanical Power Steering System: Self-Study Programme 225Gregg MedinaÎncă nu există evaluări

- New Text DocumentDocument5 paginiNew Text DocumentBoy DolandÎncă nu există evaluări

- Paguyubanet The Internet of Indonesia 1994Document34 paginiPaguyubanet The Internet of Indonesia 1994Boy DolandÎncă nu există evaluări

- NX8 Sketching HelpDocument242 paginiNX8 Sketching HelpBoy Doland75% (4)

- UTS Faculty of Engineering DC Machines GuideDocument8 paginiUTS Faculty of Engineering DC Machines GuideBoy DolandÎncă nu există evaluări

- Jumpa HariDocument2 paginiJumpa HariBoy DolandÎncă nu există evaluări

- UTS Faculty of Engineering DC Machines GuideDocument8 paginiUTS Faculty of Engineering DC Machines GuideBoy DolandÎncă nu există evaluări

- 20 Minute Countdown Timer: The Next Session Will Start inDocument24 pagini20 Minute Countdown Timer: The Next Session Will Start inBoy DolandÎncă nu există evaluări

- Read MeDocument2 paginiRead MetrieuchinhÎncă nu există evaluări

- Unigraphics NX8 - Mesh SurfaceDocument71 paginiUnigraphics NX8 - Mesh SurfaceBoy Doland75% (4)

- NX8 Sketching HelpDocument242 paginiNX8 Sketching HelpBoy Doland75% (4)

- Win 8 Prox 86Document1 paginăWin 8 Prox 86Boy DolandÎncă nu există evaluări

- Virtual Access Point 3.3Document1 paginăVirtual Access Point 3.3Boy DolandÎncă nu există evaluări

- Ano Ang Structural Mitigation at Non Structural Mitigatio1Document4 paginiAno Ang Structural Mitigation at Non Structural Mitigatio1sean ollerÎncă nu există evaluări

- Buddhist Foundation of EconomicsDocument21 paginiBuddhist Foundation of Economicsbyangchubsems100% (1)

- Experimental Psychology Its Scope and Method Volume V-Motivation, Emotion and PersonalityDocument300 paginiExperimental Psychology Its Scope and Method Volume V-Motivation, Emotion and PersonalityJuan PérezÎncă nu există evaluări

- Assignment 3 PDFDocument15 paginiAssignment 3 PDFPArk100100% (1)

- Release 2: May 2001 J. Ronald EastmanDocument16 paginiRelease 2: May 2001 J. Ronald EastmanbrayanalarconÎncă nu există evaluări

- Hazard Identification - OSH AnswersDocument5 paginiHazard Identification - OSH Answersanil73Încă nu există evaluări

- ICap Manual - Oct 2012Document20 paginiICap Manual - Oct 2012ecocadecÎncă nu există evaluări

- Level I Radiography TestDocument33 paginiLevel I Radiography Testndi101100% (1)

- Pre Implementation StepsDocument2 paginiPre Implementation Stepshoney0% (1)

- Biology of Halobates (Heteroptera: Gerridae)Document25 paginiBiology of Halobates (Heteroptera: Gerridae)anubiz2450Încă nu există evaluări

- Sterling StrategiesDocument4 paginiSterling Strategiesapi-361348967Încă nu există evaluări

- Resume Final 1Document1 paginăResume Final 1api-462298018Încă nu există evaluări

- Virtualbox Star VMDocument10 paginiVirtualbox Star VMcoolporroÎncă nu există evaluări

- Syllabus HRM, Jan-May 2012Document12 paginiSyllabus HRM, Jan-May 2012alejandro_garcia_240Încă nu există evaluări

- CE 27 11617 Practice Problems For Second LEDocument2 paginiCE 27 11617 Practice Problems For Second LECJÎncă nu există evaluări

- How Centrifuges Separate MixturesDocument13 paginiHow Centrifuges Separate MixturesNuril Liana YasinÎncă nu există evaluări

- Design and Fabrication of Project On Water Bodies Cleaning RobotDocument3 paginiDesign and Fabrication of Project On Water Bodies Cleaning RobotgksahaÎncă nu există evaluări

- DTCWTDocument60 paginiDTCWTRoot TempÎncă nu există evaluări

- Product Prices BitumenDocument55 paginiProduct Prices BitumenSatish Kumar Prajapati92% (12)

- Basic Project Management Module 3Document14 paginiBasic Project Management Module 3Ajaya KumarÎncă nu există evaluări

- Concept Rationale PaperDocument2 paginiConcept Rationale Paperjason_277624092Încă nu există evaluări

- Caracterización Y Zonificación Edáfica Y Climática de La Región de Coquimbo, ChileDocument23 paginiCaracterización Y Zonificación Edáfica Y Climática de La Región de Coquimbo, ChileSantos DamasÎncă nu există evaluări

- MS Mphil PHD Prospectus Spring 2020 Revised 21 - 01 - 20 PDFDocument82 paginiMS Mphil PHD Prospectus Spring 2020 Revised 21 - 01 - 20 PDFAmir RehmanÎncă nu există evaluări

- Week 01 - Introduction To Project ManagementDocument82 paginiWeek 01 - Introduction To Project ManagementtaribÎncă nu există evaluări

- Human Relations & YouDocument27 paginiHuman Relations & YouDhea Rizky Amelia SatoÎncă nu există evaluări

- Infinity Optional Mathematics Book 9 Final For CTP 2077Document352 paginiInfinity Optional Mathematics Book 9 Final For CTP 2077Aakriti PoudelÎncă nu există evaluări

- Important Valeo QsDocument7 paginiImportant Valeo QsMarwan Ahmed100% (1)

- Michael D. Cohen, James G. March and Johan P. Olsen - Garbage Model PDFDocument26 paginiMichael D. Cohen, James G. March and Johan P. Olsen - Garbage Model PDFJack000123Încă nu există evaluări

- RPH Module 3Document37 paginiRPH Module 3Ninia Crishelle A. ManzanoÎncă nu există evaluări