Documente Academic

Documente Profesional

Documente Cultură

FSP Presentation

Încărcat de

Ashwani KumarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

FSP Presentation

Încărcat de

Ashwani KumarDrepturi de autor:

Formate disponibile

Filter Screw Press FSP

The New Separator by UTS Products GmbH Lippetal/Germany

Reliable Separation Technology

General Features

Filter Screw Press FSP

Developed by engineers with over ten years of experience with the FAN Press Screw Separator.

Modern manufacturing and quality control processes assure high precision and fitting accuracy.

Use of top quality materials and innovative technical solutions guarantee high reliability, easy operating, low maintenance and a long lifecycle.

Reliable Separation Technology

General Features

Filter Screw Press FSP

Compact filter screw press for separation of all kind of contaminated liquids containing fibers in suspension, e.g. slurry/liquid manure, digestate, distillers wash, vegetable peelings, waste from slaughterhouses, rejects, waste water.

Wide range of applications in agriculture and different industries, like meat processing industry, pulp and paper industry, plastic recycling, wood processing industry, food processing industry.

Filter Screw Press FSP can handle incoming mediums with a solid content of 0.5-15 % TS and achieves a dryness of 25-35 % (in some applications up to 50 % and more) in one step.

Reliable Separation Technology

Process Description

Filter Screw Press FSP

Reliable Separation Technology

Process Description

Filter Screw Press FSP

Material to be separated is fed via inlet pipe or inlet hopper to the inlet housing of the filter screw press by pump or gravity.

A rotating, dual-pitch press screw auger transports the material into the filter screen where free liquid drains through the screen slots and is discharged from the filter screen housing by pipe.

Solids captured by the screen build up a filter layer on the inner screen surface. The filter layer, which allows the filtering out of particles with a smaller dimension than the slot size of the screen, is constantly moved towards the press screen by the flights of the press screw.

Reliable Separation Technology

Process Description

Filter Screw Press FSP

A solid plug is continually formed, extruded and replaced at the end of the screw flights in the press screen area of the FSP.

Further moisture is removed from the solid plug as it is pressed against the spring-loaded door mechanism of the solid discharge regulator. Liquid drains out through the outlet pipe of the press housing.

Dry solids leave the FSP via the partially open doors of the discharge regulator. The solid plug is constantly renewed by fresh material conveyed by the press screw and the process continues.

Reliable Separation Technology

Advantages of FSP

Filter Screw Press FSP

Stainless Steel Construction Drive Adapter High Performance / Low Maintenance Easy Inspection and Repair

Reliable Separation Technology

Advantages of FSP Stainless Steel Construction

Filter Screw Press FSP

All parts of the machine are made out of Stainless Steel (with the exception of the gearbox and motor housing).

Ensures a long lifecycle of the entire unit even when using highly corrosive materials.

Reliable Separation Technology

Advantages of FSP Drive Adapter

Filter Screw Press FSP

Drive adapter connects the gearbox to the press screw.

Parallel shaft helical gear motor or parallel shaft helical gear with coupling and motor available.

Gearboxes with IEC or NEMA motor flange allow you to use motor manufacturer of your choice.

High grade and efficient bearing and seal system (incl. axial face seal and grease chamber) guarantees long life time and avoids leakage and water damage.

Reliable Separation Technology

High Performance / Low Maintenance FSP

Filter Screw Press

Strong Press Screw All press screws with strong flights (10mm) over the whole length of the screw auger increased pressing power and longer lifecycle! Press screw coated in special tungsten carbide hard coating for extra strength recoating possible. Screw press is supported at both ends by the drive adapter and shaft cone of the discharge regulator. Exact fitting into the screens and perfect cleaning of inner screen surface.

Reliable Separation Technology

High Performance / Low Maintenance Filter and Press Screen

Filter Screw Press FSP

Combination of filter screen and press screen adds100mm or 150mm (see model types) to the dewatering area allowing for greater separation.

Filter and press screen are separated from each other by a plastic ring so they do not wear at their faces.

Reliable Separation Technology

High Performance / Low Maintenance FSP Filter and Press Screen

Filter Screw Press

The flights of the press screw end

in this plastic ring, so the solid plug only builds up in the press screen, therefore no pressure in the filter screen. The very strong plug screen is fixed in the press body and resists high pressures. End of the flights not located in the screens, there can be no excessive wear at this position (as known from other separators), plastic ring takes all the wear.

Reliable Separation Technology

Easy Inspection and Repair Hinged Press Housing

Filter Screw Press FSP

Reliable Separation Technology

Easy Inspection and Repair Hinged Press Housing

Filter Screw Press FSP

Reliable Separation Technology

Easy Inspection and Repair Hinged Press Housing

Filter Screw Press FSP

Reliable Separation Technology

Easy Inspection and Repair Hinged Press Housing

Filter Screw Press FSP

Reliable Separation Technology

Easy Inspection and Repair Hinged Press Housing

Filter Screw Press FSP

Reliable Separation Technology

Easy Inspection and Repair Hinged Press Housing

Filter Screw Press FSP

Press housing including mounted press screen and discharge regulator with spring-loaded door mechanism can be quickly opened (4 bolts) and easily moved to the side.

Hence the filter screen and the press screw can be dismantled without removing the solid plug first.

Closing doors of the discharge regulator allow you to start the machine without forming a start-up plug first.

Minimal downtime during service and maintenance.

Reliable Separation Technology

Easy Inspection and Repair Revision Openings

Filter Screw Press FSP

Revision openings in inlet and screen housing, inlet housing with wear plates

Reliable Separation Technology

Easy Inspection and Repair Revision Openings

Filter Screw Press FSP

Opening(s) (DN 200) in the screen housing allow(s) access to outer screen surface (for reasons of monitoring and cleaning). Openings with quick release device.

Reliable Separation Technology

Easy Inspection and Repair Revision Openings

Filter Screw Press FSP

Lateral opening (DN 200) in the inlet housing gives access to the hub of the screw with no need for disconnecting inlet pipe (for reasons of maintenance and cleaning).

Exchangeable wear plates in the inlet housing provide a parallel intersection from inlet housing into the screen (no step).

Slotted holes in the wear plates prevents rotating of fibrous material with the auger.

Reliable Separation Technology

Fields of Application

Filter Screw Press FSP

Agriculture and Biogas Plants

The FSP can separate cattle, pig and poultry manure, as well as digestate from biogas plants.

The volume of manure is reduced by 10 30%, depending on the type and TS of manure.

The separated solids are produced at 25 30% dry matter and be easily stored and spread on the fields.

Reliable Separation Technology

Fields of Application Agriculture and Biogas Plants

Filter Screw Press FSP

The separated liquid is reduced in smell, the solid fraction has practically no smell.

The nutrient content of the liquid is reduced, with up to a 20% reduction in Phosphorus.

The separated liquid can be re-used in flushing systems.

The separated liquid does not need to be mixed before application to the fields and by be transported through standard irrigation systems.

Reliable Separation Technology

Fields of Application Meat Processing Industry

Filter Screw Press FSP

FSP can be used to separate raw waste water from slaughtering (red line) and washing water from the truck wash place (green line).

Dewatering of pig stomach contents, cattle paunch manure and gut contents (yellow line).

Separation of waste water from tanneries and products of coagulated blood.

Reliable Separation Technology

Fields of Application

Filter Screw Press FSP

Pulp, Paper and Wood Processing Industry

Filtering and pressing of cleaner and fine sorter rejects (final stages) in waste paper mills

Dewatering of pulp, flotation sludge and sedimentation sludge

Recovering of fibers from waste water flows

Treatment of chip washing water, circulation/washing water, sludge from waste water treatment and in particle and fiber board productions (e.g. MDF)

Reliable Separation Technology

Fields of Application Food Processing Industry

Filter Screw Press FSP

Separating and squeezing residues of fruits and vegetables from waste and washing waters.

Separated solid foodwaste can be used as feed for animals or biogas plants.

Separated liquids may be re-used in the processing system.

Dewatering of mash and draff from distilleries and breweries.

Reliable Separation Technology

Fields of Application Plastic Recycling

Filter Screw Press FSP

Waste and circulation waters containing plastic particles can be cleaned in recycling plants.

Wet rejects from sorters be dewatered.

Separation of paper labels from washing water in PE/PET bottle cleaning plants.

Reliable Separation Technology

Installation Examples Pump Feed System

Filter Screw Press FSP

pump and

Feeding with overflow T-pipe

Reliable Separation Technology

Installation Examples Pump Feed System

Filter Screw Press FSP

Reliable Separation Technology

Installation Examples Gravity Feed System

Filter Screw Press FSP

gravity, no needed

Feeding by overflow system

Reliable Separation Technology

Installation Examples Hopper Feed

Filter Screw Press FSP

gravity, no

Feeding by overflow system needed.

Flow into the hopper must be controlled.

Reliable Separation Technology

Installation Examples Hopper Feed

Filter Screw Press FSP

Reliable Separation Technology

Standard Scope of Supply

Filter Screw Press FSP

Filter Screw Press FSP A-52/10, Stainless Steel

- Solid discharge regulator with spring-flap mechanism. - Mounting frame 520 mm, pivoted. - Inlet body with inlet pipe NS 100 and revision opening NS 200. - Filter screen housing 520 mm with revision opening NS 200. - Filter screen basket F-52/xx, slot size xx selectable. - Press screen housing 100 mm. - Press screen basket P-10/xx, slot size xx selectable. - Press screw TC-900/848, tungsten carbide hard coating. - Drive adapter with axial face seal and grease chamber, shaft diameter 60 mm. - Parallel shaft helical gear motor 5.5 kW, 400/690 V-50 Hz-3 SK5282 phase, manufacturer: Nord, type:

All components Stainless Steel (with the exception of the gearbox and motor housing).

Reliable Separation Technology

Comparison Against Competitors

Filter Screw Press FSP

UTS FSP A-52/10

FAN PSS 3.2-520

24,950

20,900

- Inlet and screen body cast iron

- Inlet and screen body stainless steel

- Press screen 100mm - No press screen - Revision openings in inlet and screen body

- No revision openings

- Press screw with 10mm flights - Press screw with 5mm flights - Oscillator coming soon - Oscillator, inlet pipe size 225mm

Standard of all other components included are comparable

Reliable Separation Technology

Comparison Against Competitors

Filter Screw Press FSP

UTS FSP A-52/10

FAN PSS 5-520

24,950

39,900

- Inlet and screen body stainless steel

- Inlet and screen body stainless steel

- Press screen 100mm - No press screen - Revision openings in inlet and screen body

- No revision openings

- Press screw with 10mm flights - Press screw with 10mm flights - Oscillator coming soon - Oscillator, inlet pipe size 225mm

Standard of all other components included are comparable

Reliable Separation Technology

S-ar putea să vă placă și

- PFC-P102 Engl.1Document12 paginiPFC-P102 Engl.1keyur1109Încă nu există evaluări

- Bag DumpDocument2 paginiBag DumpalirizalÎncă nu există evaluări

- Hapman - Bulk Bag UnloaderDocument2 paginiHapman - Bulk Bag UnloaderangelsiddhartaÎncă nu există evaluări

- Operations Manual 2011Document18 paginiOperations Manual 2011Esteban VásquezÎncă nu există evaluări

- UM10705 01 00 Screw ConveyorDocument1 paginăUM10705 01 00 Screw ConveyorDADAIRESENDEÎncă nu există evaluări

- Oil Filter Unit, Type OLU, For On-Load Tap-Changers: ManualDocument40 paginiOil Filter Unit, Type OLU, For On-Load Tap-Changers: ManualViệt Hùng Nghiêm100% (1)

- JHF-Model Precision Filter Operational ManualDocument5 paginiJHF-Model Precision Filter Operational Manualkt34ttÎncă nu există evaluări

- Conveyor Assembly Manual PDFDocument68 paginiConveyor Assembly Manual PDFzaiayra71Încă nu există evaluări

- Scotchman Circular Cold Saw Operators Manual SUP-600-NFDocument36 paginiScotchman Circular Cold Saw Operators Manual SUP-600-NFJay100% (1)

- Filter Leaf Dimensions MedidasDocument2 paginiFilter Leaf Dimensions MedidasTalabarteria RaygozaÎncă nu există evaluări

- Cacao Coat Separator-PresentationDocument17 paginiCacao Coat Separator-PresentationChristopher OaresÎncă nu există evaluări

- Installation, Operation, & Maintenance Manual: Monorail Tarca SystemDocument32 paginiInstallation, Operation, & Maintenance Manual: Monorail Tarca SystemBosko Ginz JadibataÎncă nu există evaluări

- Vacuum Conveying: C Series Conveyor Troubleshooting GuideDocument60 paginiVacuum Conveying: C Series Conveyor Troubleshooting Guidesafe150_239331910Încă nu există evaluări

- Filtro Universal DomatDocument27 paginiFiltro Universal DomatAldair MezaÎncă nu există evaluări

- Filter Press Manual for Process & PackagingDocument70 paginiFilter Press Manual for Process & PackagingNicholas Suominen100% (1)

- Notch Filter Experimental Manual FDocument9 paginiNotch Filter Experimental Manual FShoaib PathanÎncă nu există evaluări

- CACF Filter Maintenance Manual en 2019Document36 paginiCACF Filter Maintenance Manual en 2019Anis GuebroudjÎncă nu există evaluări

- Decanter ANDRITZDocument3 paginiDecanter ANDRITZCesar LapaÎncă nu există evaluări

- RKES CONTROL SIFTER MANUALDocument61 paginiRKES CONTROL SIFTER MANUALAlejandro Gonzalez100% (1)

- Solid Gas Separation1Document48 paginiSolid Gas Separation1krizel100% (1)

- Screening SolutionsDocument32 paginiScreening SolutionsDarshan PatelÎncă nu există evaluări

- Bombas CR, Cri, CRNDocument88 paginiBombas CR, Cri, CRNOscar Ernesto RamírezÎncă nu există evaluări

- Niro Sanitary Code For Components DesignDocument10 paginiNiro Sanitary Code For Components DesignJignesh PandyaÎncă nu există evaluări

- Aeromatic Ltd. Fluid Bed DryerDocument13 paginiAeromatic Ltd. Fluid Bed DryerDitha ParamitaÎncă nu există evaluări

- LEEM Filtration Pneumatic Vibrator Kit Improves Cake ReleaseDocument1 paginăLEEM Filtration Pneumatic Vibrator Kit Improves Cake ReleaseArun GuptaÎncă nu există evaluări

- Potato Peeler Machine Instruction Manual GuideDocument14 paginiPotato Peeler Machine Instruction Manual GuideVasile SamoilaÎncă nu există evaluări

- en 3706Document22 paginien 3706Thanh XuanÎncă nu există evaluări

- Krones AirCo The Air Conveyor For PET BottlesDocument10 paginiKrones AirCo The Air Conveyor For PET BottlesfadyÎncă nu există evaluări

- Sulphur Remelters PDFDocument4 paginiSulphur Remelters PDFNenadÎncă nu există evaluări

- Desuperheater: Variable Nozzle Desuperheater - VND FeaturesDocument4 paginiDesuperheater: Variable Nozzle Desuperheater - VND FeaturesNutthakarn WisatsiriÎncă nu există evaluări

- Api 54Document1 paginăApi 54keyur1109Încă nu există evaluări

- JVK Filter Elements enDocument16 paginiJVK Filter Elements enArun GuptaÎncă nu există evaluări

- Asme b16.47 Cl.150 SR, B - Drilling STDDocument1 paginăAsme b16.47 Cl.150 SR, B - Drilling STDchannu rolliÎncă nu există evaluări

- Contherm® Core Scraped-Surface Heat ExchangerDocument2 paginiContherm® Core Scraped-Surface Heat ExchangerKhánh NgânÎncă nu există evaluări

- Screw ConveyorDocument37 paginiScrew ConveyorKamal Raju100% (1)

- GEA Niro WPN MethodDocument6 paginiGEA Niro WPN MethodDinesh Kumar BansalÎncă nu există evaluări

- ALPHA700 ManualDocument50 paginiALPHA700 ManualAlexialee83Încă nu există evaluări

- 3505-Factsheet Centrifugal SieveDocument2 pagini3505-Factsheet Centrifugal SieveAdzhar KhairulzaimÎncă nu există evaluări

- User's Manual: Purifier Vertical Clean BenchesDocument57 paginiUser's Manual: Purifier Vertical Clean BenchesNorbey Marin MorenoÎncă nu există evaluări

- Test Sieving ManualDocument52 paginiTest Sieving Manualoğuz kağan100% (1)

- Msds of Spraytech OilDocument4 paginiMsds of Spraytech OilNesscel Ann Piquero DonkDonkÎncă nu există evaluări

- Rotary Dryer HandbookDocument5 paginiRotary Dryer HandbookKevin Valle BendezuÎncă nu există evaluări

- Volkmann Weighing Dosing 2016 Final For Web 1Document4 paginiVolkmann Weighing Dosing 2016 Final For Web 1Suhas KODREÎncă nu există evaluări

- 01 Cleaning of Vibratory Sifter CL-01Document3 pagini01 Cleaning of Vibratory Sifter CL-01Ravi YadavÎncă nu există evaluări

- Sanitary PumpsDocument140 paginiSanitary PumpsMessouaf FouadÎncă nu există evaluări

- Abs Solutions For Mixing and AgitationDocument11 paginiAbs Solutions For Mixing and AgitationDipenÎncă nu există evaluări

- Falling Film Evap For DairyDocument8 paginiFalling Film Evap For DairysamirdudhandeÎncă nu există evaluări

- Improve Your Product Quality With Separation of Powder, Granules & Liquid Slurry by Sivtek Vibro SeparatorsDocument14 paginiImprove Your Product Quality With Separation of Powder, Granules & Liquid Slurry by Sivtek Vibro SeparatorsGalaxy SivtekÎncă nu există evaluări

- Process Filters EngDocument12 paginiProcess Filters Engmaurozuri100% (1)

- MDS Operation ManualDocument36 paginiMDS Operation ManualRinel DeTorres100% (1)

- CIP1Document7 paginiCIP1Rajendra Prasad100% (1)

- AMIAD Automatic Filters: "Ebs" FilterDocument21 paginiAMIAD Automatic Filters: "Ebs" FilterDENOUÎncă nu există evaluări

- Peeler CentrifugeDocument16 paginiPeeler CentrifugeSureshraaviÎncă nu există evaluări

- HH 1448HD BrakeSmart Centrifuge - Operations Manual - 2005Document120 paginiHH 1448HD BrakeSmart Centrifuge - Operations Manual - 2005Centrifugal SeparatorÎncă nu există evaluări

- GEA PHE Evaporation enDocument16 paginiGEA PHE Evaporation enGuerrero OmarÎncă nu există evaluări

- Bulk Bag UnloaderDocument8 paginiBulk Bag UnloadersandulupeniÎncă nu există evaluări

- Donaldson UK Manual TDS PDFDocument19 paginiDonaldson UK Manual TDS PDFPatricio TamayoÎncă nu există evaluări

- TEFSA - High Yield Filter PressesDocument8 paginiTEFSA - High Yield Filter PressesianphilanderÎncă nu există evaluări

- Continuous Sand Filter (CSFDocument2 paginiContinuous Sand Filter (CSFganeshÎncă nu există evaluări

- Hoho Map 2015Document1 paginăHoho Map 2015Anonymous uSezVd1LÎncă nu există evaluări

- Biogas HandbookDocument126 paginiBiogas HandbookmoemuneeÎncă nu există evaluări

- Msds 9149 Conc SdsDocument8 paginiMsds 9149 Conc SdsAshwani KumarÎncă nu există evaluări

- London Guidebook EN FR DE PDFDocument96 paginiLondon Guidebook EN FR DE PDFAshwani KumarÎncă nu există evaluări

- FCT h2 Fuelcell Factsheet PDFDocument2 paginiFCT h2 Fuelcell Factsheet PDFKristian PardedeÎncă nu există evaluări

- CH4 Recovery From Landfill - 01!11!08Document21 paginiCH4 Recovery From Landfill - 01!11!08Ashwani KumarÎncă nu există evaluări

- EPA's New RFS RuleDocument195 paginiEPA's New RFS RuleAshwani KumarÎncă nu există evaluări

- Explore iconic London landmarks with a London PassDocument1 paginăExplore iconic London landmarks with a London PassAmber RileyÎncă nu există evaluări

- Delivering Viable ProjectDocument24 paginiDelivering Viable ProjectAshwani KumarÎncă nu există evaluări

- Lystek Presentation Sep 27 2012Document18 paginiLystek Presentation Sep 27 2012Ashwani KumarÎncă nu există evaluări

- European Biogas Companies Catalogue PDFDocument29 paginiEuropean Biogas Companies Catalogue PDFAshwani KumarÎncă nu există evaluări

- Manufacturing Ammonium Sulphare From GypsumRich Flue GasesDocument7 paginiManufacturing Ammonium Sulphare From GypsumRich Flue GasesAshwani KumarÎncă nu există evaluări

- Biomethane by GreenlaneDocument3 paginiBiomethane by GreenlaneAshwani KumarÎncă nu există evaluări

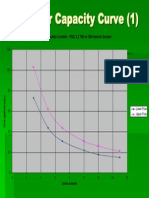

- Separator Capacity Curve Flow vs Solids Content PSS 3.2 780 500 micronDocument1 paginăSeparator Capacity Curve Flow vs Solids Content PSS 3.2 780 500 micronAshwani KumarÎncă nu există evaluări

- Ammonia RecoveryDocument2 paginiAmmonia RecoveryAshwani KumarÎncă nu există evaluări

- Manufacturing Ammonium Sulphare From GypsumRich Flue GasesDocument7 paginiManufacturing Ammonium Sulphare From GypsumRich Flue GasesAshwani KumarÎncă nu există evaluări

- AshwaniKumar B3C PresentationDocument38 paginiAshwaniKumar B3C PresentationAshwani KumarÎncă nu există evaluări

- HE AWN: RDP Technologies, IncDocument4 paginiHE AWN: RDP Technologies, IncAshwani KumarÎncă nu există evaluări

- Silvertrumpets2018 OnlineDocument12 paginiSilvertrumpets2018 OnlineYasm GnoÎncă nu există evaluări

- Smart City Development in Taiwan: The Trend and Strength of Smart City SolutionsDocument38 paginiSmart City Development in Taiwan: The Trend and Strength of Smart City SolutionssatyamÎncă nu există evaluări

- VtervrdvDocument3 paginiVtervrdvAdhit Mart DithaÎncă nu există evaluări

- Drilling Fluid Seminar Materials Loss ReductionDocument138 paginiDrilling Fluid Seminar Materials Loss Reductiongplese0Încă nu există evaluări

- Cybercrime and Environmental LawsDocument18 paginiCybercrime and Environmental LawsJENNIFER PADIERNOSÎncă nu există evaluări

- MSDS G Style E TDocument12 paginiMSDS G Style E TBudiJuwiÎncă nu există evaluări

- Safety Data Sheet for Acetylsalicylic AcidDocument7 paginiSafety Data Sheet for Acetylsalicylic AcidNyana ConstantinoÎncă nu există evaluări

- Technical Note Cgpeg Dilic Ibama 08 08Document21 paginiTechnical Note Cgpeg Dilic Ibama 08 08lulla_demolayÎncă nu există evaluări

- Samsung ML 1675Document70 paginiSamsung ML 1675DanielbudoÎncă nu există evaluări

- A4 Research Paper Complete ManuscriptDocument74 paginiA4 Research Paper Complete Manuscriptjessrelle.gumawaÎncă nu există evaluări

- Opinion WorksheetDocument4 paginiOpinion WorksheettridesÎncă nu există evaluări

- The Falling Lotus Blossoms - EON IT Park, PuneDocument10 paginiThe Falling Lotus Blossoms - EON IT Park, Puneprajakta vaidya50% (2)

- The Use of Lean Manufacturing Practices in Cleaner Production A Systematic ReviewDocument11 paginiThe Use of Lean Manufacturing Practices in Cleaner Production A Systematic ReviewJose Daniel Humanez LopezÎncă nu există evaluări

- Sand Replacement by Glass Powder in ConcreteDocument41 paginiSand Replacement by Glass Powder in Concretewaquar khan100% (2)

- đề ôn tập 03Document3 paginiđề ôn tập 03huongtrabsÎncă nu există evaluări

- Waukesha Digester GasDocument13 paginiWaukesha Digester GasA2 BhaskarÎncă nu există evaluări

- ISO 9001 Case StudyDocument16 paginiISO 9001 Case StudyAmmar AhmedÎncă nu există evaluări

- Ncom N102Document16 paginiNcom N102RixroxÎncă nu există evaluări

- Pollution /polushon: History /jistoriDocument3 paginiPollution /polushon: History /jistoriDiana Carolina Bustamante FloresÎncă nu există evaluări

- Laboratory Waste Disposal Management Guidelines CMLS. SL (Inal)Document19 paginiLaboratory Waste Disposal Management Guidelines CMLS. SL (Inal)Ravi Kumudesh100% (1)

- Aspect Impact Analysis QADocument1 paginăAspect Impact Analysis QAAtul SharmaÎncă nu există evaluări

- Eia ReportDocument185 paginiEia ReportClement Song Hua Ong100% (2)

- AAG Philippine Solid Wastes Nov2017Document4 paginiAAG Philippine Solid Wastes Nov2017Gherald EdañoÎncă nu există evaluări

- Understanding Municipal Solid Waste ManagementDocument55 paginiUnderstanding Municipal Solid Waste ManagementPatel TÎncă nu există evaluări

- SIAE - ALS PDH Radio Family - ManualDocument324 paginiSIAE - ALS PDH Radio Family - ManualBasriBerahimÎncă nu există evaluări

- Production of 10,000 Tonnes Per Year of Bioethanol From Empty Fruit BunchesDocument779 paginiProduction of 10,000 Tonnes Per Year of Bioethanol From Empty Fruit BunchesAinggararuban GaneshanÎncă nu există evaluări

- Fyp2 Technical PaperDocument7 paginiFyp2 Technical Paperselipar_ketok91Încă nu există evaluări

- ENS 522 MWF 10 11AM Solid Waste GROUP 3Document53 paginiENS 522 MWF 10 11AM Solid Waste GROUP 3Shariah MelonÎncă nu există evaluări

- Impacts of Single-Use Plastics on Environment, Wildlife & HumansDocument16 paginiImpacts of Single-Use Plastics on Environment, Wildlife & HumansMakilingE.CarlosÎncă nu există evaluări

- Waste Amount & Characterization Survey and Primary Collection & Transportation PlanDocument66 paginiWaste Amount & Characterization Survey and Primary Collection & Transportation PlanShahab KhanÎncă nu există evaluări