Documente Academic

Documente Profesional

Documente Cultură

FoamPro 2000 2001 Systems

Încărcat de

Simon BertoliDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

FoamPro 2000 2001 Systems

Încărcat de

Simon BertoliDrepturi de autor:

Formate disponibile

Class A Foam

FoamPro 2000/20001 Direct Injection

Proportioning Systems

Edition 1 May 2009

FOAMPRO 2001 / 2002 Pump Panel

Edition 1 May 2009

Slide 1

FOAMPRO 2001 / 2002 System Description

The FoamPro system 2001 / 2002 is an electric motor driven, flow based proportioning system. The system will accurately deliver foam concentrate to the injection point from 0.1 to 3.0%. A flow meter measures the water flow and sends a signal to the digital display control module.

Another sensor monitors the foam pump output.

Constant comparison of the two information signals ensures the selected proportioning ratio over flow rates of 20 2000 Lpm at all times.

Edition 1 May 2009

Slide 2

FOAMPRO 2001 / 2002 System Description

Foam is injected directly into the discharge side of the appliance pump, check valves are used to prevent contamination of the appliance pump and first aid tank. Control and monitoring are achieved by two visual display units mounted on the pump panel.

Edition 1 May 2009

Slide 3

Direct Injection Foam Proportioning System

Schematic Lay Out

Flow Meter Foam Injection Delivery Outlets

Pump Delivery Check Valve

Edition 1 May 2009

Slide 4

Reticulation System Type 3 Medium Pumper

Edition 1 May 2009

Slide 5

Class A and B Selection

FoamPro units fitted to Pumpers including

Type 4

Type 3 Heavy & Type 3 Medium are fitted with both A & B Class foam capability.

Edition 1 May 2009

Slide 6

Class A and B Selection and Flushing

A switch mounted in the centre of the pump panel facilitates selection between A & B class foam concentrate. Lights fitted to the panel indicate the type of foam that is in use.

When selecting between foam types, an eight second flush cycle is activated to prevent different concentrates mixing in the system.

Edition 1 May 2009

Slide 7

Control and Display

Multiflow Interface

Digital Display Control

Edition 1 May 2009

Slide 8

Multy Flow Interface

The Multiflow Interface allows a total of four flow meters to be used The display will show the discharge flow on the selected flow meter. Lights indicate which discharge is being monitored. Button A - onside front Button B - onside rear Button C - live hose reel Button D - not used (option roof monitors)

Edition 1 May 2009

Slide 9

Multy Flow Interface

A Flow

B Flow

Flowmeter Indicator

Flow Display

C Flow

D Flow

Edition 1 May 2009

Slide 10

Digital Display Control

FOAM

Turn FoamPro System On / Off

SELECT

Select Display Functions

DOWN ARROW

Decrease Value Shown

UP ARROW

Increase Value Shown

Edition 1 May 2009

Slide 11

Activating The System

To activate the system push the on button.

The on status lamp will indicate that system ready

Edition 1 May 2009

Slide 12

Selecting Between Functions

Indicator lamps will show current function selected

Use Select Button to change between functions

Edition 1 May 2009

Slide 13

Status Lamps

Status Lamps ON run stand by status Flow water flow rate Total Water total water flow % -- Foam Total Foam total concentrate flowed

Edition 1 May 2009

Slide 14

Foam Production

Activate system with on button

Select % function with select button

Select proportioning ratio required with buttons

The On light will flash to indicate that foam is being injected

Edition 1 May 2009

Slide 15

Default Settings

When foam % is initially selected the display will indicate the default setting for each type of foam: Class B Class A 3% = pb 3

pb

0.5% = pa 0.5

The default settings can be altered to the desired proportioning rate by pushing the buttons.

pa .5

Edition 1 May 2009

Slide 16

Foam Production

If your pumper has A / B foam capability through the FoamPro unit select the desired foam type.

Edition 1 May 2009

Slide 17

Restoring Settings

To restore settings to zero push both the buttons together.

Edition 1 May 2009

Slide 18

Safety Features

Several safety features are provided to protect the foam concentrate pump and electric motor.

A coded message will be displayed on the Digital Control unit to indicate the fault or problem.

Edition 1 May 2009

Slide 19

Low Foam Tank Level

If the foam concentrate tank is empty the pump will not run for more than two minutes.

A low foam concentrate tank level is denoted by LO CON blinking on the display.

LO CON

This code will alternate with the normal display value shown.

Edition 1 May 2009

Slide 20

Low Foam Tank Level

If two consecutive minutes of low concentrate level is detected the display will show NO CON the pump will stop and the system will go into Stand By until the foam level is restored and the on button is depressed

NO CON

Edition 1 May 2009

Slide 21

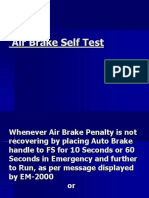

Pump Error

Motor stall protection In the event that the pump motor will not run or stalls for ten seconds the display will show ERR.EL.

ERR.EL

The system will return to off status to protect the electric motor and components

Edition 1 May 2009

Slide 22

High / Low Flow Condition

Whenever the foam pump cannot reach the selected level an indication of the status will blink in the background as

L0.Flo

Lo.Flo -- Foam delivery is below pump capability

Hi.Flo -- The water delivery rate is too high for the foam pumps capacity

Hi.Flo

Edition 1 May 2009

Slide 23

Practical Skills

Any further clarification required? Skills practice should be undertaken to ensure you are competent in the operation of this equipment Thank you

Edition 1 May 2009

Slide 24

S-ar putea să vă placă și

- The Complete Guide to Olympus' E-m1 - Firmware 2.0 ChangesDe la EverandThe Complete Guide to Olympus' E-m1 - Firmware 2.0 ChangesÎncă nu există evaluări

- FoamPro 1600 1601 Systems - 1Document11 paginiFoamPro 1600 1601 Systems - 1Simon BertoliÎncă nu există evaluări

- Quenchmaster Class A Foam System PPT - 1Document14 paginiQuenchmaster Class A Foam System PPT - 1Simon BertoliÎncă nu există evaluări

- FSG 880 FP Multiflo LRDocument20 paginiFSG 880 FP Multiflo LRzuhdisulaemanÎncă nu există evaluări

- PSI Manual v9Document12 paginiPSI Manual v9Dale BrierÎncă nu există evaluări

- POWERJET Setup Manual ENG 2011Document37 paginiPOWERJET Setup Manual ENG 2011Davis Anthony Atauqui Loa0% (1)

- Retro Fit TPMSDocument12 paginiRetro Fit TPMSSilmar da costa silvaÎncă nu există evaluări

- Project Manual: Sofcon India Pvt. Ltd. (Confidential-For Internal Use Only)Document7 paginiProject Manual: Sofcon India Pvt. Ltd. (Confidential-For Internal Use Only)Puspendra Singh YadavÎncă nu există evaluări

- IV Pump Flo-Gard 6301Document48 paginiIV Pump Flo-Gard 6301Dba BiomedtechÎncă nu există evaluări

- Vacon NX Quick Help Start-Up Wizard: Press EnterDocument6 paginiVacon NX Quick Help Start-Up Wizard: Press EntersilverrtfÎncă nu există evaluări

- Op3 Demo GuideDocument3 paginiOp3 Demo Guide4wocker4Încă nu există evaluări

- AirBAT Tractor Interface Module User Guide PDFDocument20 paginiAirBAT Tractor Interface Module User Guide PDFNeal BrattÎncă nu există evaluări

- Reset Limpieza Pcu mpc6502Document3 paginiReset Limpieza Pcu mpc6502Copycolor AdminstraciónÎncă nu există evaluări

- Manual Dosificadora Bubble Magus T01Document4 paginiManual Dosificadora Bubble Magus T01Jose Antonio Juarez100% (1)

- Ampero ControlDocument8 paginiAmpero ControlEdson LimaÎncă nu există evaluări

- Booster Service ManualDocument30 paginiBooster Service ManualALROTEK CRÎncă nu există evaluări

- 6-A) J-Air Brake Self TestDocument23 pagini6-A) J-Air Brake Self TestP. S. VENUGOPALÎncă nu există evaluări

- Man - Lem Itel PLC - en - 1.01Document18 paginiMan - Lem Itel PLC - en - 1.01Ihab Sadek FaekÎncă nu există evaluări

- Air Brake Self TestDocument24 paginiAir Brake Self TestAshoka SudharakaÎncă nu există evaluări

- Trip Computer A301Document29 paginiTrip Computer A301Mihut MoraruÎncă nu există evaluări

- Pumping Station-Slavoaca Florica AnaDocument3 paginiPumping Station-Slavoaca Florica AnaFlorica Ana SlavoacaÎncă nu există evaluări

- Pa1000 New Features v1.5.0 (English)Document14 paginiPa1000 New Features v1.5.0 (English)Holospin ConstantinÎncă nu există evaluări

- Aspen Plus Tutorial 2 Absorption Column SimulationDocument12 paginiAspen Plus Tutorial 2 Absorption Column Simulation82ghost82Încă nu există evaluări

- TP170A S7200 DemoGuideDocument3 paginiTP170A S7200 DemoGuide4wocker4Încă nu există evaluări

- BAM 1020 Training ManualDocument17 paginiBAM 1020 Training ManualkholisenangÎncă nu există evaluări

- Formation R984C enDocument120 paginiFormation R984C enSang Sang Barongan67% (3)

- LoopProTuner UserGuideDocument45 paginiLoopProTuner UserGuideHariajahÎncă nu există evaluări

- ATEM Operation ManualDocument85 paginiATEM Operation Manualcjfb30Încă nu există evaluări

- Digiflo OP91052CDocument25 paginiDigiflo OP91052Crichard_vannevelÎncă nu există evaluări

- FreePoint ServiceDocument7 paginiFreePoint Service087825550697Încă nu există evaluări

- User ManualDocument32 paginiUser ManualAljun LumbaoÎncă nu există evaluări

- Instruction Stag 200 Stag 300 ControllerDocument22 paginiInstruction Stag 200 Stag 300 ControllerionutsteÎncă nu există evaluări

- Bilgmon488 Instruction ManualDocument25 paginiBilgmon488 Instruction ManualÖzgürMetinÎncă nu există evaluări

- Topcon X20 Monitor Instructions 2013Document35 paginiTopcon X20 Monitor Instructions 2013Chan TkfcÎncă nu există evaluări

- HD785 7 OperationDocument51 paginiHD785 7 OperationSang Sang Barongan100% (10)

- User'S Guide: Installation & Operation Instructions Portable Doppler Flow Meter Model PDFM 5.1 Manual Series A.1.1Document31 paginiUser'S Guide: Installation & Operation Instructions Portable Doppler Flow Meter Model PDFM 5.1 Manual Series A.1.1engsergiomarquesÎncă nu există evaluări

- Renault ElectricDocument24 paginiRenault Electricjohn florosÎncă nu există evaluări

- Operation and Maintenance Manual: Panel Mount PRO/portionerDocument32 paginiOperation and Maintenance Manual: Panel Mount PRO/portionerAAR143Încă nu există evaluări

- Aop BopDocument8 paginiAop BopPassenger Medeam100% (1)

- Cnctrain Fanuc0M: CNC Simulation Systems 1995 2010Document51 paginiCnctrain Fanuc0M: CNC Simulation Systems 1995 2010Siti Idah TawhidÎncă nu există evaluări

- At-15 Series III 3B6 Operator ManualDocument39 paginiAt-15 Series III 3B6 Operator ManualFausto Herrera B100% (4)

- Yamaha: Digit Al Multi-Effe C T Pro C e SsorDocument31 paginiYamaha: Digit Al Multi-Effe C T Pro C e SsorshadesforgrayÎncă nu există evaluări

- PV380 Operations ManualDocument20 paginiPV380 Operations ManualCarlosÎncă nu există evaluări

- Peugeot Partner Owners Manual 2005Document73 paginiPeugeot Partner Owners Manual 2005grangreca100% (1)

- 1-22 PDF 20 NB Auto MPV ManualDocument22 pagini1-22 PDF 20 NB Auto MPV ManualRagu Venkat33% (3)

- Manual de Operación FOCUSDocument44 paginiManual de Operación FOCUSicki_twilight_6544900% (1)

- BAGkon 16 2.0 ManualDocument17 paginiBAGkon 16 2.0 ManualFahad MohamedÎncă nu există evaluări

- BAGkon 16 2.0 ManualDocument17 paginiBAGkon 16 2.0 ManualБорис Каптюг0% (1)

- DirectLink For Pro ToolsDocument16 paginiDirectLink For Pro ToolsKilano MaxÎncă nu există evaluări

- YUYANGKING Controller User Manual Bluetooth VersionDocument7 paginiYUYANGKING Controller User Manual Bluetooth VersionWendy EkoÎncă nu există evaluări

- Imed Gemini PC-1Document17 paginiImed Gemini PC-1Kim DionaldoÎncă nu există evaluări

- About Me-B - enDocument25 paginiAbout Me-B - enMannMannÎncă nu există evaluări

- Operation: Section IIIDocument9 paginiOperation: Section IIIAnonymous XbmoAFtIÎncă nu există evaluări

- Operation ManualDocument10 paginiOperation ManualBaeMoonSeobÎncă nu există evaluări

- Boiler Drum Level ControlDocument9 paginiBoiler Drum Level Controlsekhar_ntpcÎncă nu există evaluări

- Module Pool Programming NotesDocument7 paginiModule Pool Programming NotesNagesh reddyÎncă nu există evaluări

- IRB 6000 M93 Error ListDocument44 paginiIRB 6000 M93 Error Listairshow19100% (1)

- Rallye ComputerDocument12 paginiRallye ComputerMatt HinmanÎncă nu există evaluări

- Fujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsDe la EverandFujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsÎncă nu există evaluări

- Hale Class A Foam System - 1Document10 paginiHale Class A Foam System - 1Simon BertoliÎncă nu există evaluări

- Class A Foam Card Wildfire 1006Document2 paginiClass A Foam Card Wildfire 1006Simon BertoliÎncă nu există evaluări

- Class A Foam User CFA001 Edit4 Aug09 - 0Document66 paginiClass A Foam User CFA001 Edit4 Aug09 - 0Simon BertoliÎncă nu există evaluări

- Hale Class A Foam System - 1Document10 paginiHale Class A Foam System - 1Simon BertoliÎncă nu există evaluări

- Respond To Wildfire - Learning and Assessment StrategyDocument165 paginiRespond To Wildfire - Learning and Assessment StrategySimon BertoliÎncă nu există evaluări

- RM Bushfire Firefighter Edn1 Feb11Document248 paginiRM Bushfire Firefighter Edn1 Feb11Simon Bertoli100% (1)

- FoamPro 2000 2001 SystemsDocument25 paginiFoamPro 2000 2001 SystemsSimon BertoliÎncă nu există evaluări

- Class A Foam CFA001 Learning and Assessment StrategyDocument25 paginiClass A Foam CFA001 Learning and Assessment StrategySimon BertoliÎncă nu există evaluări

- RM Bushfire Firefighter Edn1 Feb11Document248 paginiRM Bushfire Firefighter Edn1 Feb11Simon Bertoli100% (1)

- Class A Foam Card Wildfire 1006Document2 paginiClass A Foam Card Wildfire 1006Simon BertoliÎncă nu există evaluări

- Safety On The Fire Ground - Learning and Assessment StrategyDocument51 paginiSafety On The Fire Ground - Learning and Assessment StrategySimon BertoliÎncă nu există evaluări

- Comms Systems Learning and Assessment StrategyDocument27 paginiComms Systems Learning and Assessment StrategySimon BertoliÎncă nu există evaluări

- Operate Communications Systems and Equipment - 0 - 0Document120 paginiOperate Communications Systems and Equipment - 0 - 0Simon BertoliÎncă nu există evaluări

- Respond To Wildfire - Learning and Assessment StrategyDocument165 paginiRespond To Wildfire - Learning and Assessment StrategySimon BertoliÎncă nu există evaluări

- Comms Systems Learning and Assessment StrategyDocument27 paginiComms Systems Learning and Assessment StrategySimon BertoliÎncă nu există evaluări

- Safety On The Fire Ground - Learning and Assessment StrategyDocument51 paginiSafety On The Fire Ground - Learning and Assessment StrategySimon BertoliÎncă nu există evaluări

- Safety On The Fire Ground - Learning and Assessment StrategyDocument51 paginiSafety On The Fire Ground - Learning and Assessment StrategySimon BertoliÎncă nu există evaluări

- Operate Communications Systems and Equipment - 0 - 0Document120 paginiOperate Communications Systems and Equipment - 0 - 0Simon BertoliÎncă nu există evaluări

- RM Bushfire Firefighter Edn1 Feb11Document248 paginiRM Bushfire Firefighter Edn1 Feb11Simon Bertoli100% (1)

- RM Bushfire Firefighter Edn1 Feb11Document248 paginiRM Bushfire Firefighter Edn1 Feb11Simon Bertoli100% (1)

- Marine Fire Responder Part 1 Safety Ed1.0 092010Document114 paginiMarine Fire Responder Part 1 Safety Ed1.0 092010Simon BertoliÎncă nu există evaluări

- Respond To Wildfire - Learning and Assessment StrategyDocument165 paginiRespond To Wildfire - Learning and Assessment StrategySimon BertoliÎncă nu există evaluări

- Operate Communications Systems and Equipment - 0 - 0Document120 paginiOperate Communications Systems and Equipment - 0 - 0Simon BertoliÎncă nu există evaluări

- Comms Systems Learning and Assessment StrategyDocument27 paginiComms Systems Learning and Assessment StrategySimon BertoliÎncă nu există evaluări

- LM Search and Rescue Edn1 Jun03Document60 paginiLM Search and Rescue Edn1 Jun03Simon BertoliÎncă nu există evaluări

- PublicationDocument234 paginiPublicationjitmarineÎncă nu există evaluări

- Manual Servicio WN 3503 PDFDocument196 paginiManual Servicio WN 3503 PDFFranklin Marcelo Alcantara TrinidadÎncă nu există evaluări

- Manual Del OperadorDocument146 paginiManual Del OperadorFernando NunezÎncă nu există evaluări

- TEPZZ 86Z 68A - T: European Patent ApplicationDocument13 paginiTEPZZ 86Z 68A - T: European Patent ApplicationNM GroupÎncă nu există evaluări

- Unit 2Document28 paginiUnit 2maniÎncă nu există evaluări

- 1997 3800 PCM Fiero WiringDocument3 pagini1997 3800 PCM Fiero WiringDamián Martínez SánchezÎncă nu există evaluări

- Byt BZB 1 8 Tsfi EngDocument51 paginiByt BZB 1 8 Tsfi EngΤασος ΑΜ100% (3)

- Automotive Technology 3 Ja301 Chapter 2 2Document19 paginiAutomotive Technology 3 Ja301 Chapter 2 2alllhass97Încă nu există evaluări

- Heat Engine DesignDocument25 paginiHeat Engine DesignEamonn McStravickÎncă nu există evaluări

- EH DX300LC DemolitioNDocument12 paginiEH DX300LC DemolitioNCopemaq CopemaqÎncă nu există evaluări

- Boeckhoff 2010-Operational Experience of The 51-60 DF From MANDocument11 paginiBoeckhoff 2010-Operational Experience of The 51-60 DF From MANsestoubosÎncă nu există evaluări

- Loco MechDocument29 paginiLoco MechAbhishek PandeyÎncă nu există evaluări

- SM 41Document46 paginiSM 41Daniel Muñoz SotomayorÎncă nu există evaluări

- Experimental Investigation of Injectors Nozzle Hole On CI Engine Using Jatropha Oil As Bio FuelDocument7 paginiExperimental Investigation of Injectors Nozzle Hole On CI Engine Using Jatropha Oil As Bio FuelSai KiranÎncă nu există evaluări

- AD45B Underground Articulated Truck - Service SheetDocument7 paginiAD45B Underground Articulated Truck - Service SheetaleciolyraÎncă nu există evaluări

- Safari ARMAX Z-Series ECU BrochureDocument8 paginiSafari ARMAX Z-Series ECU BrochureAlex TeixeiraÎncă nu există evaluări

- Injection Pump Specification ©Document4 paginiInjection Pump Specification ©Errol HuntÎncă nu există evaluări

- EMD, Special ToolsDocument116 paginiEMD, Special ToolsMaurice Connor81% (16)

- Ford EEC IV TesterDocument96 paginiFord EEC IV TesterTorney Benedict60% (10)

- 426C PDFDocument139 pagini426C PDFAlexander Chillitupa100% (6)

- ATA-100 JASC CodesDocument72 paginiATA-100 JASC CodesaerostressÎncă nu există evaluări

- Ec sr20 PDFDocument332 paginiEc sr20 PDFIshmael Wooloo100% (1)

- Maruti Suzuki AR FY11Document149 paginiMaruti Suzuki AR FY11Navneh100% (1)

- USCG ME Exam - Motor KnowledgeDocument486 paginiUSCG ME Exam - Motor KnowledgePagan jatarÎncă nu există evaluări

- Tractors: TsaidclDocument10 paginiTractors: TsaidclSamsher AliÎncă nu există evaluări

- Common RailDocument30 paginiCommon RailRowan CorneliusÎncă nu există evaluări

- The Case For Cavitation Induced HeatingDocument11 paginiThe Case For Cavitation Induced Heatingobe_nowÎncă nu există evaluări

- TechTool TerminologyDocument4 paginiTechTool TerminologyДрагиша Небитни ТрифуновићÎncă nu există evaluări

- Workshop Manual D16 Tai Lieu May Thuy Volvo PDFDocument228 paginiWorkshop Manual D16 Tai Lieu May Thuy Volvo PDFLonghuynh Lê100% (2)

- Delphi DP210 Rotary Mechanical Diesel Fuel Injection Pump: Powertrain SystemsDocument2 paginiDelphi DP210 Rotary Mechanical Diesel Fuel Injection Pump: Powertrain SystemsAmerican Bosch Diesel Olzam Sas0% (1)