Documente Academic

Documente Profesional

Documente Cultură

Lec-25 - Analysis and Design of Slabs

Încărcat de

Mian M KhurramTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lec-25 - Analysis and Design of Slabs

Încărcat de

Mian M KhurramDrepturi de autor:

Formate disponibile

Plain & Reinforced

Concrete-1

CE-313

Lecture # 25

16

th

May 2006

Analysis and Design

of Slabs

By Engr. Azhar

Sixth Term

Civil Engineering

Plain & Reinforced Concrete-1

Example: Design a cantilever projecting out from a room

slab extending 1.0m and to be used as balcony (LL = 300

kg/m

2

). A brick wall of 250 mm thickness including plaster

of 1m height is provided at the end of cantilever.

f

c

= 17.25 MPa f

y

= 300 MPa

Slab thickness of room = 125 mm. Slab bottom steel 1in the

direction of cantilever is # 13 @ 190 mm c/c.

Plain & Reinforced Concrete-1

Solution:

1m

125 mm

cantilever

2

h

1000 L + =

mm 1063

2

125

1000 L = + =

Plain & Reinforced Concrete-1

Solution: (contd)

mm 89

12

1063

12

h

h

min

= = =

Let we use the same thickness as of the room

min

h mm 125 h > =

d

mm 98 7 20 125 d = =

Main steel in cantilever is

at the top

Plain & Reinforced Concrete-1

Solution: (contd)

Slab Load

2

m / kg 300 2400

1000

125

= = Self weight of slab

75 mm brick ballast/ screed

2

m / kg 135 1800

1000

75

= =

60 mm floor finishes

2

m / kg 138 2300

1000

60

= =

Total dead load

2

m / kg 573 138 135 300 = + + =

Plain & Reinforced Concrete-1

Solution: (contd)

Slab Load

2

m / kg 300 = Live Load

( )

1000

81 . 9

300 6 . 1 573 2 . 1

u

+ =

2

u

m / kN 46 . 11 =

m / kN 46 . 11

u

= For a unit strip

( )

1000

81 . 9

1930 1 1 25 . 0 2 . 1 P

u

=

kN 65 . 5 P

u

=

Plain & Reinforced Concrete-1

Solution: (contd)

2

L

L P M

2

u

u u

+ =

kN 65 . 5 P

u

=

1.063m

m / kN 46 . 11

u

=

2

063 . 1 11.46

063 . 1 65 . 5 M

2

u

+ =

m kN 48 . 12 M

u

=

Per meter width

3 . 1

98 1000

10 48 . 12

bd

M

2

6

2

u

=

=

0488 . 0

f

' f

85 . 0

y

c

= =

0.0052 =

Plain & Reinforced Concrete-1

Solution: (contd)

2

s

510mm 98 1000 0.0052 A = =

d

# 13 @ 380 mm c/c already

available in the form half the

bent up bar from the room slab

2

s

mm 342 A c / c 380 @ 13 # =

Plain & Reinforced Concrete-1

Solution: (contd)

2

168mm 342 - 510 = =

Remaining steel required at the top

c / c 400 @ 10 #

Use

c / c 380 @ 10 #

Distribution steel

2

mm 250 125 1000 002 . 0 = =

c / c 280 @ 10 #

Plain & Reinforced Concrete-1

Solution:

#13 @ 380 c/c

#10 @ 380 c/c

#10 @ 280 c/c

1500 mm

Slab bottom steel

Plain & Reinforced Concrete-1

Two-Way Edge

Supported Slabs

Plain & Reinforced Concrete-1

Two-Way Slabs

Slab resting on walls or sufficiently deep and rigid beams on all

sides. Other options are column supported slab e.g. Flat slab,

waffle slab.

5 . 0

L

L

m

y

x

> =

Two-way slabs have two way bending unlike one-way slab.

Plain & Reinforced Concrete-1

Design Methods

1. ACI co-efficient method

2. Direct design method

3. Equivalent frame method

4. Finite element method

Notes

1. In two-way slabs shorter direction strip carry greater

%age of load.

2. Steel will be more in shorter direction.

3. Shorter direction steel will be placed near the outer edge

to get more d means more lever arm to get more

flexural capacity.

L

x

L

y

Plain & Reinforced Concrete-1

ACI Co-efficient Method

Unit width strip is taken in both directions. The strip is

designed separately for +ve and ve moment.

2

n u u

L C M =

C = ACI co-efficient

u

= Slab load

C depends upon the end conditions of slab and the

aspect ratio.

Three tables are available for C

Dead load positive moment

Live load positive moment

-ve moment

M+ coefficients are increased

by 25 % and M- coefficients

are reduced by 10 % to get

the result more closer to

accurate solution.

Plain & Reinforced Concrete-1

Minimum Depth of 2-Way Slab for Deflection

Control

According to ACI-318-1963

h

min

= (inner perimeter of slab panel)/180

90 mm

For f

y

= 300 MPa

( )

180

L L 2

h

y x

min

+

=

For f

y

= 420 MPa

( )

165

L L 2

h

y x

min

+

=

According to ACI-318-2005

( )

( ) 9 m 36

1500 f 8 . 0 L

h

y n

min

+

+

=

y

x

L

L

m =

L

n

= clear span in short direction

Plain & Reinforced Concrete-1

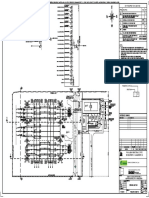

Example: Design the 4 marked slab panels of an ordinary

house. Use US customary bars. f

c

= 17.25 MPa f

y

= 300 MPa

4500

x

7000

6000

x

7000

3500

x

6000

6000

x

6000

1 2

3 4

Wall thickness = 228 mm

Plain & Reinforced Concrete-1

Solution: Panel Edge Conditions

Panel # 1

L

x

= 4.5m , L

y

= 7.0m

m = 0.64 > 0.5, 2-way slab

Panel # 2

L

x

= 6.0m , L

y

= 7.0m

m = 0.86> 0.5, 2-way slab

Panel # 3

L

x

= 3.5m , L

y

= 6.0m

m = 0.58 > 0.5, 2-way slab

Panel # 4

L

x

= 6.0m , L

y

= 6.0m

m = 1 > 0.5, 2-way slab

Plain & Reinforced Concrete-1

Solution: (contd)

Slab Thickness

Generally same depth is preferred for one monolith slab.

Calculate h

min

for all the panels and select the largest value.

( )

9 m 36

1500 f 8 . 0 L

h

y n

min

+

+

=

Panel # 1

( )

mm 140

9 64 . 0 36

1500 300 8 . 0 4500

h

min

~

+

+

=

Panel # 2

( )

mm 150

9 86 . 0 36

1500 300 8 . 0 6000

h

min

~

+

+

=

Plain & Reinforced Concrete-1

Solution: (contd)

Panel # 3

( )

mm 117

9 58 . 0 36

1500 300 8 . 0 3500

h

min

~

+

+

=

Panel # 4

( )

mm 133

9 1 36

1500 300 8 . 0 6000

h

min

~

+

+

=

mm 150 h =

Plain & Reinforced Concrete-1

Solution: (contd)

Effective depth

mm 123 27 h d

1

= =

For longer direction steel

d

2 d

1

Long direction steel

Short direction steel

mm 112 2 10 13 20 h d

2

= =

For short direction steel

Plain & Reinforced Concrete-1

Solution: (contd)

Slab Load

2

m / kg 360 2400

1000

150

= = Self weight of slab

75 mm brick ballast/ screed

2

m / kg 135 1800

1000

75

= =

60 mm floor finishes

2

m / kg 138 2300

1000

60

= =

Total dead load

2

m / kg 633 138 135 360 = + + =

Plain & Reinforced Concrete-1

Solution: (contd)

Slab Load

2

m / kg 200 = Live Load

( )

1000

81 . 9

633 2 . 1 1.2

d

=

2

d

m / kN 45 . 7 1.2 =

( )

2

L

m / kg 14 . 3

1000

81 . 9

200 6 . 1 1.2 = =

2

u

m / kN 59 . 10 14 . 3 45 . 7 = + =

Plain & Reinforced Concrete-1

Solution: (contd)

Minimum Steel

bh 002 . 0 A

min

s

=

150 1000 002 . 0 A

min

s

=

2

min

s

mm 300 A = For a unit strip

Concluded

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Bangalore Company List With ContactsDocument3 paginiBangalore Company List With Contactskiransunsmart67% (15)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Collapse of Flats at Ronan Point, Canning TownDocument83 paginiCollapse of Flats at Ronan Point, Canning TownAman 'kebe' KebedeÎncă nu există evaluări

- Account Opening Letter AsifDocument1 paginăAccount Opening Letter AsifMian M KhurramÎncă nu există evaluări

- Rate AnalysisDocument4 paginiRate AnalysisMian M KhurramÎncă nu există evaluări

- Key of Equipment 132Kv Substation Description Symbol Qty MakeDocument1 paginăKey of Equipment 132Kv Substation Description Symbol Qty MakeMian M KhurramÎncă nu există evaluări

- 21.stone Pitching & Boundary FenceDocument1 pagină21.stone Pitching & Boundary FenceMian M KhurramÎncă nu există evaluări

- 132KV GIS Grid Station DHA Karachi Distribution Board DetailDocument1 pagină132KV GIS Grid Station DHA Karachi Distribution Board DetailMian M KhurramÎncă nu există evaluări

- Loading OutputDocument6 paginiLoading OutputMian M KhurramÎncă nu există evaluări

- G.F PlanDocument1 paginăG.F PlanMian M KhurramÎncă nu există evaluări

- Guard Tower Plan Base Beam Layout Plan Roof R.C.C Slab 100Mm ThickDocument1 paginăGuard Tower Plan Base Beam Layout Plan Roof R.C.C Slab 100Mm ThickMian M KhurramÎncă nu există evaluări

- Soil Stabilization With Slope (3 of 3)Document1 paginăSoil Stabilization With Slope (3 of 3)Mian M KhurramÎncă nu există evaluări

- Control Room - Updated 18th May PDFDocument1 paginăControl Room - Updated 18th May PDFMian M KhurramÎncă nu există evaluări

- Tower Drawing 100 FeetDocument3 paginiTower Drawing 100 FeetMian M Khurram100% (3)

- Replacement of 02 Nos. 100mva Transformers (At03 & At04) With 01 No. 200mva Transformer (At06)Document1 paginăReplacement of 02 Nos. 100mva Transformers (At03 & At04) With 01 No. 200mva Transformer (At06)Mian M KhurramÎncă nu există evaluări

- Typical Lap Detail Option-2 PDFDocument1 paginăTypical Lap Detail Option-2 PDFMian M KhurramÎncă nu există evaluări

- AIIC AdvertisementDocument1 paginăAIIC AdvertisementMian M KhurramÎncă nu există evaluări

- Ref. DRGS: AH/09/18/ST-: Main Building 2200X 2200X 400 F1 FootingDocument14 paginiRef. DRGS: AH/09/18/ST-: Main Building 2200X 2200X 400 F1 FootingMian M KhurramÎncă nu există evaluări

- Control Room - Updated 18th May PDFDocument1 paginăControl Room - Updated 18th May PDFMian M KhurramÎncă nu există evaluări

- Grid Connectivity Standards, Grid Standards: Alka Npti, Psti BangaloreDocument54 paginiGrid Connectivity Standards, Grid Standards: Alka Npti, Psti BangaloreRkantvyasÎncă nu există evaluări

- DORDocument3 paginiDORMian M KhurramÎncă nu există evaluări

- Scope of WorkDocument2 paginiScope of WorkMian M KhurramÎncă nu există evaluări

- Grid Connectivity Standards, Grid Standards: Alka Npti, Psti BangaloreDocument54 paginiGrid Connectivity Standards, Grid Standards: Alka Npti, Psti BangaloreRkantvyasÎncă nu există evaluări

- Sheet-09 (Rev-01)Document1 paginăSheet-09 (Rev-01)Mian M KhurramÎncă nu există evaluări

- Ismc Isma: Input Running Meter To Obtain Output in KilogramDocument2 paginiIsmc Isma: Input Running Meter To Obtain Output in KilogramMian M KhurramÎncă nu există evaluări

- National Transmission & Despatch Company Limited - NTDCL: Plan & ProfileDocument1 paginăNational Transmission & Despatch Company Limited - NTDCL: Plan & ProfileMian M KhurramÎncă nu există evaluări

- Offer For Cable Tray / Ladder With AccessoriesDocument2 paginiOffer For Cable Tray / Ladder With AccessoriesMian M KhurramÎncă nu există evaluări

- Concrete Design and Construction Details For Tank Farms.Document23 paginiConcrete Design and Construction Details For Tank Farms.António FontesÎncă nu există evaluări

- Types of BricksDocument5 paginiTypes of BricksMian M Khurram100% (1)

- Detailed Quantity CalculationDocument24 paginiDetailed Quantity CalculationMian M KhurramÎncă nu există evaluări

- ReadmeDocument1 paginăReadmetb ahmad gumilarÎncă nu există evaluări

- Brick PropertiesDocument6 paginiBrick Propertiesswathia09Încă nu există evaluări

- Teng Curve For Negative PressureDocument6 paginiTeng Curve For Negative PressureMian M KhurramÎncă nu există evaluări

- Regatta Boutique Apartments Brochure PDFDocument7 paginiRegatta Boutique Apartments Brochure PDFyilikal addisuÎncă nu există evaluări

- Arch Prasan SukanDocument14 paginiArch Prasan SukanINTAN FARHANA MOHD ROSLANÎncă nu există evaluări

- Amended BOQ (Vol.3)Document103 paginiAmended BOQ (Vol.3)Herman NdauÎncă nu există evaluări

- 1373A Basic Engineer: Combat OperationsDocument775 pagini1373A Basic Engineer: Combat OperationsAlbertWillis100% (1)

- Weissenhofsiedlung Progressive Architecture 10-1988Document12 paginiWeissenhofsiedlung Progressive Architecture 10-1988RominaVillegasÎncă nu există evaluări

- How To Read Architect DrawingDocument32 paginiHow To Read Architect DrawingKutty Mansoor50% (2)

- Limited Asbestos Survey (8!19!13)Document22 paginiLimited Asbestos Survey (8!19!13)TOTA OWASSOÎncă nu există evaluări

- 7300 QH Stationary Gothic High-Tunnel Bender Instruction ManualDocument43 pagini7300 QH Stationary Gothic High-Tunnel Bender Instruction ManualZlatko JusupovicÎncă nu există evaluări

- Number and Spacing of Piles in A GroupDocument7 paginiNumber and Spacing of Piles in A GroupmadaraÎncă nu există evaluări

- Apartment Literature StudyDocument60 paginiApartment Literature Studylakshmi akshaya maddi100% (8)

- Warranty Book FullDocument28 paginiWarranty Book Fullrajanikant_singhÎncă nu există evaluări

- As3740-2004 Bsa GuideDocument5 paginiAs3740-2004 Bsa GuideOwen Perrin100% (1)

- Conipur BrochureDocument8 paginiConipur Brochuredox4printÎncă nu există evaluări

- NTCC FinalDocument43 paginiNTCC FinalNihar NanyamÎncă nu există evaluări

- Item/ Element Number Building Law Source Statement of The Law RemarksDocument4 paginiItem/ Element Number Building Law Source Statement of The Law Remarksmiriam martinezÎncă nu există evaluări

- Brickhouse Torlift PPFdataDocument2 paginiBrickhouse Torlift PPFdataLaura EddowesÎncă nu există evaluări

- Parts of A House: Mevin Varughese (B130027CE) & Mohammed Al Sabah (B130220CE)Document6 paginiParts of A House: Mevin Varughese (B130027CE) & Mohammed Al Sabah (B130220CE)Mohammed Al SabahÎncă nu există evaluări

- Carpentry Skill StandardsDocument52 paginiCarpentry Skill StandardsYang LiuÎncă nu există evaluări

- Bosch - Power Tools For DIYDocument164 paginiBosch - Power Tools For DIYjo_rz_57Încă nu există evaluări

- Annex 1-2Document198 paginiAnnex 1-2Edin UgarakÎncă nu există evaluări

- Domestic Building Surveys PDFDocument280 paginiDomestic Building Surveys PDFJamie BÎncă nu există evaluări

- Grand Bazaar: Cultural Heritage in IstanbulDocument27 paginiGrand Bazaar: Cultural Heritage in IstanbulZey Kar0% (1)

- Hara Vijaya Heights E-BrocheureDocument13 paginiHara Vijaya Heights E-BrocheureSiddarth P RajÎncă nu există evaluări

- Electrical Specification Kim ProjectDocument14 paginiElectrical Specification Kim Projectsooppasek katruksaÎncă nu există evaluări

- Lego SummaryDocument3 paginiLego Summaryapi-274095338Încă nu există evaluări

- Painiter QuotationDocument2 paginiPainiter QuotationSaravanan RajendranÎncă nu există evaluări

- Real Estate PresentationDocument3 paginiReal Estate PresentationRaj VoraÎncă nu există evaluări

- Fire Resistance Assessment of Concrete StructuresDocument81 paginiFire Resistance Assessment of Concrete StructuresJevgenijsKolupajevsÎncă nu există evaluări