Documente Academic

Documente Profesional

Documente Cultură

Chapter 9

Încărcat de

Mimi Rose VauseDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Chapter 9

Încărcat de

Mimi Rose VauseDrepturi de autor:

Formate disponibile

Hanyang Univ.

Spring 2008

Chap 9. Chain-growth Polymerization

Chain-Growth Polymerization (Addition) Processes

1. Free radical Initiation Processes

2. Cationically Initiated Processes

3. Anionically Initiated Processes

4. Group Transfer Polymerization

5. Coordination Polymerization

Hanyang Univ.

Spring 2008

Chain-Growth Polymerization

Step-Growth Polymerization

1. Molecular weight increases steadily.

2. High molecular weight polymers are found at the end.

3. Long reaction time needs to synthesize high conversion and high molecular weight.

1. Only growth reaction adds repeating units one at a time to the chain

2. Monomer concentration decreases steadily throughout the reaction

3. High Molecular weight polymer is formed at once; polymer molecular

weight changes little throughout the reaction.

4. Long reaction times give high yields but affect molecular weight little.

5. Reaction mixture contains only monomer, high polymer, and about 10

-8

part of growing chains.

Hanyang Univ.

Spring 2008

(1) I nitiation

k

d

: Initiator decomposition rate constant

: 10

-4

~ 10

-6

L/mole sec

Unstable radical

Chain Growth Polymerization

Heat (60C)

UV k

d

Primary radical

AIBN

Bond Energy = 46 kcal/mole

| || | = I M k R

i i

Hanyang Univ.

Spring 2008

(2) Propagation

k

p

: 10

2

~ 10

4

L/mole sec (much faster than step-growth polymerization)

(Repetition of similar reaction)

Chain Growth Polymerization

| || | = M M k R

p p

Hanyang Univ.

Spring 2008

(3) Termination

(a) Coupling or combination

Chain Growth Polymerization

Hanyang Univ.

Spring 2008

(b) Disproportionation

k

t

=k

tc

+k

td

10

6

~ 10

8

L/mole sec

(3) Termination

Chain Growth Polymerization

| || | | |

2

= = M R M M k R

t k t

td

k

td

k

Hanyang Univ.

Spring 2008

(4) Chain Transfer

Kinetic chain length

Monomer, Polymer, Solvent or Chain transfer agent

Physical chain length

Chain Growth Polymerization

Hanyang Univ.

Spring 2008

Chain Growth Polymerization

Kinetic Chain Length :

kinetic chain length of a radical chain polymerization is defined as the

average number of monomer molecules consumed (polymerized) per

each radical, which initiates a polymer chain.

ex) Monomer # 4000 Disproportionation

=4,000/4 =1,000

Determined by steps 1, 2, 3. (Initiation, propagation, and termination)

(No chain transfer)

Physical Chain Length :

This condition contains Step 1, 2, 3, 4.

Radical

1,2,3,4

Hanyang Univ.

Spring 2008

Non-Polymerization Reaction

Peroxide induced Bromination of Toluene

1) Initiation

Two types of reaction

- R-O-O-R 2RO (1)

- R-O + Br

2

ROBr + Br (2)

- R-O + CH

3

ROH + CH

2

(3)

Two radicals and two kinetic chains are formed by decomposition of

each ROOR molecules

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

2) Propagation

- Br + CH

3

HBr + CH

2

(4)

- CH

2

+ Br

2

CH

2

Br + Br (5)

Two special features

The number of active species is fixed.

Same reactions are repeated during the kinetic chain reaction.

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

3) Termination

- 2 Br Br

2

- 2CH

2

CH

2

CH

2

- CH

2

+ Br CH

2

Br + Br

Net Effect of Kinetic Chain Reaction:

One ROOR molecule can cause formation of Br2, |CH2CH2|, |CH2Br,HBr, .

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

Time

R

e

a

c

t

i

o

n

R

a

t

e

Induction period

Steady state

Chain reaction R

i

= R

t

In proportion to the O

2

concentration

Comparison between Chain Polymerization & Chain Reaction

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

In the case of Chain reaction, there are induction periods, due to the

existence of inhibitor.

When an active center is formed, the reaction rate would be faster and

then go to steady state.

The whole reaction rate is reaching a plateau region.

After that, reaction rate decreases due to a loss of monomers or initiators.

Linear Chain-Growth:

Polymer of high DP

n

found easily in early reaction

Linear Step-Growth:

high extent of reaction value required to obtain high DP

n

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

Comparison Free Radical Reaction & Ionic Reaction

- Ionic Initiation multiple bond addition, ring opening polymerization

- Radical Initiation Ring-opening polymerization is not initiated.

CH

3

CH

3

CH

2

R

CH

3

C H

3

CH

2

H

CH

2

C H

3

CH

2

C H

2

C H

3

CH

2

+

+

For the cationic initiation, it will not be free radical.

Ex)

Because of resonance stability

Kinetic Chain Reaction

isobutylene

Hanyang Univ.

Spring 2008

Ionic Free Radical

Anionic Cationic

Ring opening + - -

End-groups Generally, combine with counter-ion or gegenion

E.g. R

+

AlCl4

Degree of association depends on below

Solvent-system polarity

Stability of end group

Type & size of scounter-ion

Temp.

Degree of association influences:

Reaction rates

Termination rate

Stereospecificity

Truly Free Radical

(no association)

Termination Depend on monomer

consumption, Living polymer or

Block copolymer

unimolecular Combination or

disproportionation reaction

Bimolecular

combination or

disproportionation

Comparison between Free Radical Reaction & Ionic Reaction

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

A) Free Radical Termination

CH

2

CH

X

CHCH

2

X

CH

2

CH CH CH

2

X X

CH CH

X

CH

CH

2

X

CH CH

X

CHCH

2

X

H

H

unsaturated group.

.

.

.

.

..

k

tc

(coupling

or combination)

k

td

(disproportionation)

+

Comparison between Free Radical Reaction & Termination Step of Ionic Reaction

Two molecules involved

= bimolecular reaction

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

B) Cationic Termination

Anionic capture is similar to combination of free radical reaction.

But, this reaction cant include increasing of MW because of unimolecular reaction

CH

2

CH

R

CH

2

CH

R

X

AlCl

4

AlCl

3

[XY]

+

Y

EX)

X= Cl Y=

+

-

-

-

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

C) Anionic Termination

Termination is rare but can occur by loss of a hydride ion

Unimolecular type termination occurs

CH

2

CH

R

M

-

-H

-

+

CH CH

R

+ HM

CH

R

H

R

[XY]

+

-

proton release

+

..

+

HY

+

Y

The proton release is similar to disproportination of free radical..

But, one chain joins in the reaction unimolecular reaction

C) Anionic Termination

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

Anionic Cationic

Termination Termination

Free Radical

Termination

Reaction rate Unimolecular

High concentration of growing

chains 10

-2

~10

-3

molar Rates 10

4

~10

5

times higher than free radical

Bimolecular

Relativity low

concentration 10

-8

~10

-9

molar occurs at high

Rates

AE

Activation Energies Similar

Chain Transfer Negligible + +

Disadvantage Rigorous Purity or precautions

Polymer System Solution or Bulk Wide variety of

polymer systems,

Gas, Solid, Solution,

Bulk, Precipitation,

Suspension, Emulsion

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

Free Radical Initiated Polymerization of Unsaturated monomers

Kinetic Scheme

Initiation

Two step sequence-Both enter into overall rate

1. Initiator decomposition

I

2

2I-

2. Addition of Initiator fragment to the monomer, Initiation of Chain growth.

I-+M IM-

The efficiency of Initiator - Determined by competition of desired reaction and side reaction

Primary radical species

Generally, 0.5 << f << 1

k

d

k

i

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

A.Cage Effect primary recombination

Initiator fragments surrounded by restricting cage of solvent

Ex)

(acetyl peroxide)

CH

3

C O O C CH

3

O

O

Kinetic Chain Reaction

O

O

C H

3

CH

3

O

O

Hanyang Univ.

Spring 2008

I) Recombination possible I

2

2I-

II) If elimination reaction occurs while the free radical in-cage,

Formation of stable molecules due to Radical combination.

And formation of Inactive Species.

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

B. Induced Decomposition Secondary combination

I) Through Radical attack on peroxide molecules

-R + R'-O-O-R' RH + -R'OOR' R'=O + R'O-

Finally, R- + R'OOR' ROR'+ R'O-

Total number of radical does not change, but among them half molecules were wasted.

II) Chain Transfer to Solvent

(In this case, since just one radical was obtained half molecules were wasted.)

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

III) Reaction with Chain Radical

Since not all Molecules participate in the initiation Efficiency factor

f: Initiator Efficiency

= mole fraction of initiator fragments that actually initiate polymer chains.

0.5 < f < 1.0

Kinetic Chain Reaction

I + M

.

I M n

.

I M n

. + I

2

I M n I

+

I

.

Hanyang Univ.

Spring 2008

C. Reaction Rate

If [M-] is representative for the concentration of chain radical,

That is , M- = IM-

or = I [M-]

f ~ 1 R

i

is unrelated with [M]

f=|[M]

f < 1 R

i

is related with [M]

[M] , f

[I

2

] , f due to induced decomposition

by convention, two radical formation.

] [ 2

] ][ [

] [

2

I fk

M I k

dt

M d

R

d

i

i

=

=

=

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

D. Initiator

- containing compounds.

O O S S N N

O O

O

C

CH

3

O

CH

3

C

O O

O

C

O

C

O O C

CH

3

CH

3

C

CH

3

CH

3

Kinetic Chain Reaction

Acetyl peroxide 80~100C

Benzoyl peroxide 80~100C

Cumyl peroxide 120~140C

Hanyang Univ.

Spring 2008

N N C

CH

3

CN

C

CN

CH

3

CH

3

CH

3

C

CH

3

CN

CH

3

.

+ N

2

2

50~70C

AIBN 2,2' azobisisobutyronitrile

Kinetic Chain Reaction

C H

3

O O CH

3

CH

3

CH

3

CH

3

CH

3

C H

3

O OH

CH

3

CH

3

Hydroperoxides, cumyl or t-butyl

80~100C

t-butyl peroxide

Hanyang Univ.

Spring 2008

Propagation

Termination

+

= =

n

k

k

p p

IM

IM M I

M M k

dt

M d

R

p

p

2

] ][ [

] [

By convention

Since 2 radical elimination

2

] )[ ( 2

] [

- + =

-

= M k k

dt

M d

R

td tc t

M

.

M

.

k tc

k td

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

Overall Rate of Polymerzation

Radical concentration

Difficulty of measurement, low concentration. (~10

-8

molar)

Thus, it is impractical using this therm.

[M-] elimination is desirable.

] ][ [ ~

] ][ [ ] ][ [

- =

- + - =

M M k R R

M M k M I k R

p p o

p i o

(# of propagation step >>> # of initiation step)

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

[M-] elimination methods

Steady-State Assumption

Radical concentration increases at the start, comes to steady state simultaneously

and then reaction rate change becomes 0. (active centers created and destroyed at the same time)

R

i

= R

t

2

1

2

1

2

2

1

2

2

]

2

[

] [ ) ( ] [

] )[ ( 2 ] [ 2

t

i

td tc

d

td tc d

R

R

or

I

k k

fk

M

M k k I fk

=

+

= -

- + =

2

1

2

1

2

) ( ] ][ [

] ][ [

] [

td tc

d

k k

fk

I M k

M M k

dt

M d

R

+

=

= =

Kinetic Chain Reaction

Hanyang Univ.

Spring 2008

Mostly in case of f<1 system [I

2

]

1/2

(Square Root Dependence of [I

2

])

Odian Fig. 3-4

MMA using BPO

Vinyl Acetate

using AIBN

R

p

[I

2

]

1/2

O O

O

C

O

C

O

C O

N N C

CH

3

CN

C

CN

CH

3

CH

3 CH

3

C

CH

3

CN

CH

3

.

2

BPO

-CO

2

2

30

0

C

+ N

2

Azobisisobutyronitrile

Kinetic Chain Reaction

H

.

Hanyang Univ.

Spring 2008

+ BPO +

system

In case f < 1, but SRD is not applicable,

] [ ] [

2

1

2

M I R

p

2

3

2

1

2

] [ ] [ M I R

p

Because f is dependent on [M]

Why?

Due to induced decomposition of toluene + [I

2

]

Kinetic Chain Reaction

+ BPO + C H

3

Hanyang Univ.

Spring 2008

At S-S assumption

(1) Disproportionation

Knowing that

Kinetic Chain Length (KCL)

) (

chain) polymer a initiates ( radical each

ed) (polymeriz consumed molecules monomer of number average the

i t

p

R R

R

KCL

=

=

=

dt

M d

R R R

tc td t

] [ -

= + =

(2) Coupling or combination

term

tc

tc

dt

M d

R

k

] [

chains) polymer 2 from product polymer 1 (

2

1

const. rate the

-

=

=

Hanyang Univ.

Spring 2008

(3) Both (1)+(2)

Kinetic Chain Length (KCL)

) 1 (

2 2

2

1

t

td

t

p

td tc td

p

tc td

p

t

p

R

R

R

R

R R R

R

R R

R

R

R

KCL

+

=

+ +

=

+

= =

) 1 (

2

case, in this

:

y R

R

KCL

ionation disproport by caused n terminatio of f raction

R

R

y def ine

t

p

t

td

+

=

=

Hanyang Univ.

Spring 2008

The more concentration of monomer,

The less concentration of initiator,

(1) Dispropotionation

(2) Coupling

Degree of Polymerization

Kinetic Chain Length (KCL)

v =

n

DP

v = 2

n

DP

dt Polymer d

dt M d

DP

n

/ ] [

/ ] [

= =

Monomer consumption rate

polymer formation rate

n

DP

n

DP

Hanyang Univ.

Spring 2008

) 3 ( ] [ 2

) 2 ( ] [ ] [

1

2

) 1 (

) 1 (

2

2

1

2

1

2

2

1

2

I fk R R

M I f

k

k

k R that knowing

y

DP

R

R

y where

y R

R

R R

R

DP

R

R R Polymer

d i t

t

d

p p

n

t

td

t

p

tc td

p

n

p

tc td

= =

)

`

=

+

v

=

=

+

=

+

=

=

+ =

(3) Dispropotionation & Coupling

Polymer formation rate

Monomer consumption rate

Kinetic Chain Length (KCL)

Hanyang Univ.

Spring 2008

From (1),(2),(3)

In case of no Chain transfer, and valid S-S assumption

) 4 (

] [ ) 1 (

] [

2

1

2

)

`

+

=

I f

k

k

k y

M k

DP

t

d

t

p

n

) 5 (

) 1 (

] [

2 2

p t

p

n

R k y

M k

DP or

+

=

Kinetic Chain Length (KCL)

Hanyang Univ.

Spring 2008

M- + XY MX + Y-

Chain transfer agent

If Chain transfer occurs R

p

is unchangable but has an effect on DP

n

( Since [Y-] instead of R

p

=k

p

[M][M-] )

ex)

(1) Chain transfer occurs by solvents or additives

In this case, High chain transfer coefficient.

(2) Transfer occurs by monomer or polymer

Chain Transfer

C C

H

X

H

H

R

.

+ C C l

4

C C

H

X

H

H

R

C l

+ C C l

3

.

Hanyang Univ.

Spring 2008

Inhibitor

When Y take part in chain opening reaction, polymer moves from one site to another.

In this case, hydroquinone etc. are used as inhibitor.

Retarder

When the reactivity of Y is low, controlling the MW of the monomer including

these two materials, Mercaptan etc. are used as Retarder.

Chain Transfer

Inhibitor and Retarder

2

1

2

2

]} [ { ] [

] [ ) 1 ]( [

] [

] ][ [ 2 ) 1 ( ] [ 2

] ][ [ 2

2 ) 1 (

2

] [

2

1 ] [

I

k

f k

M that Knowing

XY k y M k

M k

XY M k y M k

M M k

R y R

R

dt

Polymer d

R

DP

R R R

dt

Polymer d

t

d

tr t

p

tr t

p

tr t

p p

n

tr tc td

= -

+ + -

=

- + + -

-

=

+ +

= =

+ + =

Like this, when chain transfer condition arises

Hanyang Univ.

Spring 2008

+ + + =

+ + + =

+

)

`

+

=

+

)

`

+

=

] [

] [

] [

] [ 1 1

] [

] [

] [

] [

1 1

] [

] [

] [

] [

) 1 ( 1

] [ ] [ ) 1 (

] [

0 ,

, ,

0 ,

2

1

2

2

1

2

M

T

C

M

S

C

DP DP

M k

T k

M k

S k

DP DP

M k

XY k

I f

k

k

M k

y k

DP

XY k I f

k

k

y k

M k

DP

T S

n n

p

t tr

p

s tr

n n

p

tr

t

d

p

t

n

tr

t

d

t

p

n

From the slope of a graph

Chain transfer coefficient Cs

See Odian

P.235

1

[5]/[M]

DP

n

Chain Transfer

Hanyang Univ.

Spring 2008

Assume : no chain transfer

Temperature Dependence of R

p

and DP

n

mole kcal E e k k

mole kcal E e k k

mole kcal E e k k

(1) I f

k

k

k M R

M I f

k

k

k R

t

RT E

t

t

d

RT E

d

d

p

RT E

p

p

t

d

p p

t

d

p p

t

d

/ 5 ~ 2

/ 30

/ 8 ~ 5

]] [ ln[ ln ] ln[ ln

] [ ] [

/

/

/

2

1

2

2

1

2

1

2

=

=

=

+

(

(

(

|

|

.

|

\

|

+ =

|

|

.

|

\

|

=

Hanyang Univ.

Spring 2008

slope of lnR

p

/T is ( + )

as T | lnR

p

|

but Rate of Increase + as d lnR

p

/dT +

Temperature Dependence of R

p

and DP

n

0

15 2 7

2 2

] ln[

ln

. , ] [ ], [ ), 1 (

2 2

2

1

2

>

+

=

+

=

|

|

.

|

\

|

=

=

RT RT

E E

E

dT

k

k

k d

dT

R d

T of t independen f const M I assume and Eq From

d t

p

t

d

p

p

Hanyang Univ.

Spring 2008

Temperature Dependence of R

p

and DP

n

+ + v |

+ | |

+ + v |

<

=

=

v

= = v

+

=

n

n p

n

d t

p

i

p

t

p

t

p

n

DP T

DP but R I

DP T as

RT RT

E E

E

dT

d

R

R

R

R

y R

R

DP

] [

ln ,

0

15 2 7

2 2

ln

,

) 1 (

2

2 2

Hanyang Univ.

Spring 2008

Ceiling Temperature

Polymerization and Depolymerization are in equilibrium

G

p

= H

p

TS

p

H

p

: Heat of polymerization

S

p

: Molecular arrangement changes between monomer and polymer

At eq. State G

p

=0

Monomers can no longer be persuaded to form polymers by chain

polymerization above a certain temperature. ceiling Temperature(T

c

)

Ceiling Temperature Polymer-Depolymerization Equilibria

Hanyang Univ.

Spring 2008

Rate Eq. of Polymerization Reactions

at Depolymerization prominent Temperature

If,

M T

c

Hanyang Univ.

Spring 2008

k

sec

-1

k

dp

k

p

[M]

k

p

[M]- k

dp

300 400 500 Tc

T

c

: No reaction above T

c

Stable blow T

c

Ceiling Temperature Polymer-Depolymerization Equilibria

Hanyang Univ.

Spring 2008

Monomer -AH

kcal/g mole T

c

C (bulk)

St 16 235

MMA 13 164

Ethylene 26 407

Propylene 21 300

o-methyl St. 7 6

Odian Fig 3-18

Entropy changes for all polymers are not so different.

AS

p

= S

p

- S

m

() value of S

p

is higher

AH

p

= H

p

- H

m

if () , exothermic.

Ceiling Temperature Polymer-Depolymerization Equilibria

Hanyang Univ.

Spring 2008

Trommsdorff Effect or Gel Effect

restricted mobility of polymer radical

k

p

( relative to [M] )

( k

p

const. in reaction progress, k

t

drop off in reaction progress )

Autoaccerelation effect

The increasing viscosity limits the rate of termination because of

diffusional limitations

Hanyang Univ.

Spring 2008

t

80%

60%

40%

10%

autoacceleratioan

as [M

0

] drastic in .

Trommsdorff Effect or Gel Effect

kt

e

= 1 one would expect + as t | But | as [[M

0

] |

S-ar putea să vă placă și

- Polymer Science: Varsha AwasarkarDocument38 paginiPolymer Science: Varsha AwasarkarAnugraha GarmentsÎncă nu există evaluări

- Polymerization Reactions ExplainedDocument111 paginiPolymerization Reactions ExplainedHamsiah Sayah100% (1)

- Living PolymerizationDocument58 paginiLiving PolymerizationdohuucauÎncă nu există evaluări

- Basic Principal of Organic ChemistryDocument69 paginiBasic Principal of Organic Chemistry1MS19CH049100% (1)

- Handbook of Polymer Reaction EngineeringDocument1.131 paginiHandbook of Polymer Reaction Engineeringtflmckenna100% (10)

- Polymer Synthesis by Metal CatalystsDocument58 paginiPolymer Synthesis by Metal CatalystsCuddle- Guess Whoz BacÎncă nu există evaluări

- Research ProjectDocument38 paginiResearch ProjectKarena NguyenÎncă nu există evaluări

- Unsaturated PolyestersDocument56 paginiUnsaturated PolyestersSaba SohailÎncă nu există evaluări

- Multi-Block Copolymers and Living PolymerisationDocument2 paginiMulti-Block Copolymers and Living PolymerisationAde AndriansyahÎncă nu există evaluări

- Objective Qus WD AnswerDocument98 paginiObjective Qus WD Answeradhitya100% (2)

- PhotocatalysisDocument57 paginiPhotocatalysisdrndryl92% (13)

- Chain Growth Polymerization GuideDocument49 paginiChain Growth Polymerization GuideFAIQÎncă nu există evaluări

- Chain GrowthDocument62 paginiChain Growthtemesgen abebeÎncă nu există evaluări

- Chain GRWTH PolymerizatinDocument63 paginiChain GRWTH PolymerizatinSundas FatimaÎncă nu există evaluări

- Kinetics of Step-Growth PolymerizationDocument28 paginiKinetics of Step-Growth PolymerizationMahmutTaşÎncă nu există evaluări

- Chapter 3. Chain-Growth (Addition) PolymerizationDocument28 paginiChapter 3. Chain-Growth (Addition) Polymerizationafic219473Încă nu există evaluări

- Polymer Synthesis and Characterization: Basic Laboratory Course For Polymer Science M. Sc. ProgramDocument58 paginiPolymer Synthesis and Characterization: Basic Laboratory Course For Polymer Science M. Sc. ProgramNiranjan Narayan GoriwaleÎncă nu există evaluări

- Step Growth PolymersizationDocument40 paginiStep Growth PolymersizationSayantan Roy ChoudhuryÎncă nu există evaluări

- Chemical Kinetics: 2011 by Nob Hill Publishing, LLCDocument99 paginiChemical Kinetics: 2011 by Nob Hill Publishing, LLCLemepcÎncă nu există evaluări

- Lecture CHAP 3 Part 3Document31 paginiLecture CHAP 3 Part 3Lee Shin LeongÎncă nu există evaluări

- Kuliah 2. Dynamic Reaction NewDocument22 paginiKuliah 2. Dynamic Reaction NewCindy OctavianiÎncă nu există evaluări

- Polymer Synthesis and Technology: Key ProcessesDocument52 paginiPolymer Synthesis and Technology: Key ProcessesmengsteabÎncă nu există evaluări

- Chapter 20 FDocument21 paginiChapter 20 FBerru VardarÎncă nu există evaluări

- PolymersDocument38 paginiPolymersPurna BhavnariÎncă nu există evaluări

- 00 Cavin PolymerDocument11 pagini00 Cavin PolymeraminÎncă nu există evaluări

- Chain Growth PolymerizationDocument17 paginiChain Growth PolymerizationDurjoy SahaÎncă nu există evaluări

- LECTURE - 03 - CDB 3044 - Conceptual Process Design - Synthesis of Reaction System (I)Document29 paginiLECTURE - 03 - CDB 3044 - Conceptual Process Design - Synthesis of Reaction System (I)Ong Jia YeeÎncă nu există evaluări

- The Fundamental of Polymers (MSE3209) : Chapter Four Controlled PolymerizationDocument42 paginiThe Fundamental of Polymers (MSE3209) : Chapter Four Controlled PolymerizationFayisaa LamessaÎncă nu există evaluări

- Week6 - Polymers, Carbon Based MaterialsDocument50 paginiWeek6 - Polymers, Carbon Based MaterialstuanaÎncă nu există evaluări

- Polymer Engineering Chapter 4 PDFDocument71 paginiPolymer Engineering Chapter 4 PDFLuis PerezÎncă nu există evaluări

- Step Growth PolymerizationDocument50 paginiStep Growth Polymerizationtemesgen abebeÎncă nu există evaluări

- Module 3 Organic Reaction MechanismsDocument7 paginiModule 3 Organic Reaction Mechanismsycca galianÎncă nu există evaluări

- BMS College Engineering, Bengaluru 560 019Document6 paginiBMS College Engineering, Bengaluru 560 019Akarsh AkuÎncă nu există evaluări

- CHP 1Document23 paginiCHP 1Kerem Cengiz KılıçÎncă nu există evaluări

- Spring 2015 OMET Practice Problem Set KEYDocument12 paginiSpring 2015 OMET Practice Problem Set KEYSay sayÎncă nu există evaluări

- Polymerisation and KineticsDocument20 paginiPolymerisation and KineticsMaulik KotadiyaÎncă nu există evaluări

- Polymerization Reactions: - Step-Growth Polymerization (Old Condensation Polym.)Document20 paginiPolymerization Reactions: - Step-Growth Polymerization (Old Condensation Polym.)Sheiren Itu SarahÎncă nu există evaluări

- Inorganic Reaction Mechanism oral questionsDocument11 paginiInorganic Reaction Mechanism oral questionsYoussef AliÎncă nu există evaluări

- 2 Chain-Growth Polymerization (201052)Document43 pagini2 Chain-Growth Polymerization (201052)Said Al-shukailiÎncă nu există evaluări

- 1586283952Document17 pagini1586283952Youssef AliÎncă nu există evaluări

- Lecture 1Document15 paginiLecture 1Kaushik. RajÎncă nu există evaluări

- Elimination Reactions 20172178Document14 paginiElimination Reactions 20172178Mahmoud AhmedÎncă nu există evaluări

- Assignment For Chemical Kinetics: Submitted To: Dr. Erum JabeenDocument11 paginiAssignment For Chemical Kinetics: Submitted To: Dr. Erum JabeenIsrar KhanÎncă nu există evaluări

- Reaction Mechanism, Molecularity of A ReactionDocument4 paginiReaction Mechanism, Molecularity of A ReactionBenjaminÎncă nu există evaluări

- PLX KineticsDocument8 paginiPLX KineticsDucbinh NghiemÎncă nu există evaluări

- Conformational Energy From The Oxidation Kinetics of Poly (3,4-Ethylenedioxythiophene) FilmsDocument8 paginiConformational Energy From The Oxidation Kinetics of Poly (3,4-Ethylenedioxythiophene) FilmsaneicouboiÎncă nu există evaluări

- Condensation Reactions ADocument28 paginiCondensation Reactions ANino FelicesÎncă nu există evaluări

- Organic Concepts Jeemain - GuruDocument83 paginiOrganic Concepts Jeemain - Guruchaewon10271Încă nu există evaluări

- Plasma Reactor Waste ManagementDocument4 paginiPlasma Reactor Waste ManagementOrlando BarriosÎncă nu există evaluări

- Chemistry Paper VI SyllabusDocument7 paginiChemistry Paper VI SyllabusPrudhvi Raghu TejaÎncă nu există evaluări

- Jurnal KimfisDocument8 paginiJurnal KimfisAiiu RahayuÎncă nu există evaluări

- Moad RAFT PDFDocument32 paginiMoad RAFT PDFEdin SljivoÎncă nu există evaluări

- PolymerizationDocument7 paginiPolymerizationrehrifat2000Încă nu există evaluări

- Che 2Document32 paginiChe 2dineshsilambam2305Încă nu există evaluări

- AP Lab Manual 18 - Kinetics of A ReactionDocument13 paginiAP Lab Manual 18 - Kinetics of A ReactionRodrigo GarciaÎncă nu există evaluări

- Gen Chem PhotoDocument6 paginiGen Chem PhotoKim NaÎncă nu există evaluări

- Zaky Al-FatonyDocument16 paginiZaky Al-FatonyZakyAlFatonyÎncă nu există evaluări

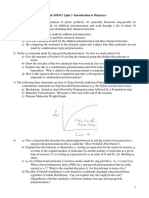

- (051013 Quiz 3 Introduction To Polymers)Document10 pagini(051013 Quiz 3 Introduction To Polymers)Vivian Angarita VillamizarÎncă nu există evaluări

- Studies On Manganese (Ii) Catalyzed Oxidation of N-Methylaniline by Periodate IonDocument10 paginiStudies On Manganese (Ii) Catalyzed Oxidation of N-Methylaniline by Periodate IonYuda AryokoÎncă nu există evaluări

- SAMPLE PAPER-04 (Solved) Class - XII Answers: NO Fe H NO Fe HO Feho NO Feho NO HODocument8 paginiSAMPLE PAPER-04 (Solved) Class - XII Answers: NO Fe H NO Fe HO Feho NO Feho NO HOShivam KumarÎncă nu există evaluări

- Chap 7 Ionic and Living PolymerizationsDocument57 paginiChap 7 Ionic and Living PolymerizationsSyuan CÎncă nu există evaluări

- Reaction Mechanism Key ConceptsDocument13 paginiReaction Mechanism Key ConceptsGauri ThakurÎncă nu există evaluări

- Lecture Note - Che 332-2Document56 paginiLecture Note - Che 332-2NestorÎncă nu există evaluări

- InterviewDocument8 paginiInterviewMD. SOHANUR RAHMANÎncă nu există evaluări

- Inorganic Reactions and Methods, Oligomerization and Polymerization Formation of Intercalation CompoundsDe la EverandInorganic Reactions and Methods, Oligomerization and Polymerization Formation of Intercalation CompoundsA. P. HagenÎncă nu există evaluări

- 58 PolymerDocument33 pagini58 Polymermuhammad rizky fitraÎncă nu există evaluări

- Chain Growth Polymerization: A Living Polymerization: C C H H H (H C-C) H NDocument2 paginiChain Growth Polymerization: A Living Polymerization: C C H H H (H C-C) H NTanmay RayÎncă nu există evaluări

- Entalpia de Fofmacion Del PoliisoprenoDocument36 paginiEntalpia de Fofmacion Del PoliisoprenoNena Jessi LoveÎncă nu există evaluări

- Controlled Polymerization in Flow Microreactor SystemsDocument56 paginiControlled Polymerization in Flow Microreactor SystemsLuis DiazÎncă nu există evaluări

- Living Polymerization Techniques ExplainedDocument20 paginiLiving Polymerization Techniques ExplainedsamiÎncă nu există evaluări

- Chem. Rev. 2009, 109, 5069-5119Document51 paginiChem. Rev. 2009, 109, 5069-5119dhuglÎncă nu există evaluări

- Monomers Oligomers Polymers MacromoleculesDocument6 paginiMonomers Oligomers Polymers MacromoleculesQuar Tul AinÎncă nu există evaluări

- Advances in Polymer ScienceDocument250 paginiAdvances in Polymer ScienceswasÎncă nu există evaluări

- Journal of The Taiwan Institute of Chemical Engineers Volume 45 Issue 6 2014 (Doi 10.1016/j.jtice.2014.05.012) Ameduri, Bruno - Recent Advances in The Controlled Radical (Co) Polymerization of FluoDocument10 paginiJournal of The Taiwan Institute of Chemical Engineers Volume 45 Issue 6 2014 (Doi 10.1016/j.jtice.2014.05.012) Ameduri, Bruno - Recent Advances in The Controlled Radical (Co) Polymerization of FluoRyan Eka JuniawanÎncă nu există evaluări

- Topics in Organometallic ChemistryDocument259 paginiTopics in Organometallic ChemistrytomÎncă nu există evaluări

- Polymer Grafting and Applications in Pharmaceutical Drug Delivery Systems - A Brief ReviewDocument5 paginiPolymer Grafting and Applications in Pharmaceutical Drug Delivery Systems - A Brief ReviewRasidah AmirÎncă nu există evaluări

- Living PolymerizationDocument2 paginiLiving PolymerizationAhmad KusumaatmajaÎncă nu există evaluări

- Dissertation PolymereDocument8 paginiDissertation PolymerePaperWritingHelpOnlineCanada100% (1)

- Determination of The Intrinsic Viscosity and Molecular Weight of Poly (Methyl Methacrylate) Blends (#648289) - 903143Document6 paginiDetermination of The Intrinsic Viscosity and Molecular Weight of Poly (Methyl Methacrylate) Blends (#648289) - 903143Özlem YılmazÎncă nu există evaluări

- Group Transfer PolymerizationDocument22 paginiGroup Transfer Polymerizationcuongtran_siegenÎncă nu există evaluări

- ASC Symposium. Vol. 768. ControlledLivingDocument483 paginiASC Symposium. Vol. 768. ControlledLivingUriel PeñaÎncă nu există evaluări

- Review SawamotoDocument88 paginiReview SawamotoMiriam GarciaÎncă nu există evaluări

- Anionic and Coordination PolymerizationDocument32 paginiAnionic and Coordination PolymerizationPathik ShahÎncă nu există evaluări

- Types of PolymerizationDocument98 paginiTypes of PolymerizationFJNovaes454Încă nu există evaluări

- The Fundamental of Polymers (MSE3209) : Chapter Four Controlled PolymerizationDocument42 paginiThe Fundamental of Polymers (MSE3209) : Chapter Four Controlled PolymerizationFayisaa LamessaÎncă nu există evaluări

- Ionic Chain Polymerization MechanismsDocument23 paginiIonic Chain Polymerization MechanismsAman PotdarÎncă nu există evaluări

- Chap 7 Ionic and Living PolymerizationsDocument57 paginiChap 7 Ionic and Living PolymerizationsSyuan CÎncă nu există evaluări