Documente Academic

Documente Profesional

Documente Cultură

Drilling Machines

Încărcat de

Qim SvDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Drilling Machines

Încărcat de

Qim SvDrepturi de autor:

Formate disponibile

Drill Presses

Drilling Machines

Probably first mechanical device developed

Principle of rotating tool to make hole

One of most common and useful machines in

industry

Come in several types and sizes

From hand-fed to computer-controlled

Drill Press

Drilling machine

Spindle

Turns drill to advance into work (hand or

automatically)

Work table

Holds workpiece rigidly in place as hole drilled

Used primarily to produce holes in metal

Other operations: tapping, reaming, boring,

counterboring, countersinking, spot-facing

Standard Operations

Drilling

Operation of producing hole by

removing metal from solid mass

using twist drill

Countersinking

Operation of producing tapered

or cone-shaped enlargement

to end of hole

Reaming

Operation of sizing and producing

smooth, round hole from previously drilled or

bored hole

Boring

Truing and enlarging hole by

means of single-point cutting tool

Tapping

Cutting internal threads in hole with

cutting tool called tap

Counterboring

Enlarging top of previously

drilled hole to given depth

to provide square shoulder for head of

bolt or capscrew

Spot-Facing

Smoothing and squaring surface

around hole to provide seat for head

of cap screw or nut

Boring bar fitted with

double-edged cutting

tool

Pilot section on end

to fit into existing hole

Principal Types of Drilling Machines

Wide variety of drill presses

Size of drill press may be designated in different

ways by different companies

Some state size as distance from center of spindle to column

of machine

Others state size by diameter of largest circular piece that

can be drilled in center

Sensitive Drill Press Parts

Hand feed lever

Controls downfeed

pressure

Feel the pressure

Manufactured in bench and

floor model

Four main parts

Base, column, table

and drilling head

Sensitive Drill Press Parts

Base

Provides stability for machine

Cast iron with holes to be bolted to table or bench

Slots or ribs in base allow work-holding device or work piece

to be fastened

Column

Accurate cylindrical post that fits in base

Table may be adjusted any point (base to head)

Drill press head mounted near top

Sensitive Drill Press Parts

Table

Round or rectangle shaped

Used to support workpiece to be machined

Surface 90 to column (move around)

Drilling Head

Mechanism used to revolve cutting tool

Spindle: round shaft holds cutting tool

Quill: houses spindle

Sensitive Drill

Sensitive Drill

Sensitive Drill

Upright Drilling Machine

Larger and heavier

Differences from sensitive-type drill

Equipped with gearbox for variety of speeds

Spindle may be advanced by: hand lever, hand wheel,

and automatically by feed mechanism

Table raised or lowered by mechanism

Some have reservoir in base for coolant storage

Upright Drill Press

Upright Drill Press

Radial Drill

Sometimes called radial-arm drill

Advantages of this machine

Larger and heavier work may be machined

Drilling head raised or lowered

Drilling head moves rapidly to any desired location

while workpiece remains clamped

More power

Head may swivel so holes can be drilled on angle

Radial Drill

Radial Drill

Radial Drill Parts

Base

Heavy, box-type, ribbed cast iron or welded steel

Used to bolt machine to floor and provide coolant

reservoir

Table may be bolted to base for small work

Column

Upright cylindrical member fitter to base

Supports radial arm at right angles

Radial Drill Parts

Radial arm

Attached to column

May be raised and lowered by means of power-driven

elevating screw

Supports drive motor and drilling head

Drilling head

Mounted on arm and moved along length of arm by

traverse handwheel

Drill spindle may be raised or lowered

Radial Drill

Radial Drill

Radial Drill

Radial Drill

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Inspection Technical Procedure I-115 STR STL Welding InspectionDocument20 paginiInspection Technical Procedure I-115 STR STL Welding InspectionELongLeeÎncă nu există evaluări

- Hidden Storage Coffee Table - RYOBI Nation Projects PDFDocument14 paginiHidden Storage Coffee Table - RYOBI Nation Projects PDFbwatkins6100% (1)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Power Transmission: Rotational PulleyDocument19 paginiPower Transmission: Rotational PulleyQim SvÎncă nu există evaluări

- EAT227-Lecture 2.1 - Metal CastingDocument42 paginiEAT227-Lecture 2.1 - Metal CastingQim SvÎncă nu există evaluări

- Thermofluids & Engine: Gas Power CyclesDocument29 paginiThermofluids & Engine: Gas Power CyclesQim SvÎncă nu există evaluări

- SunvoldddDocument6 paginiSunvoldddQim SvÎncă nu există evaluări

- Frozen BerriesDocument1 paginăFrozen BerriesQim SvÎncă nu există evaluări

- Deep Fried Packing RM/KG@P KT GS TDocument1 paginăDeep Fried Packing RM/KG@P KT GS TQim SvÎncă nu există evaluări

- Price List For JulyDocument5 paginiPrice List For JulyQim SvÎncă nu există evaluări

- Muthu Frozen Food SDN BHD: Chilled Beef RM/KG GST ZRL ZRL ZRLDocument1 paginăMuthu Frozen Food SDN BHD: Chilled Beef RM/KG GST ZRL ZRL ZRLQim SvÎncă nu există evaluări

- Australian Wagyu Beef RM/KG GST Australian Chilled Beef RM/KG GSTDocument1 paginăAustralian Wagyu Beef RM/KG GST Australian Chilled Beef RM/KG GSTQim SvÎncă nu există evaluări

- Frozen FishDocument1 paginăFrozen FishQim SvÎncă nu există evaluări

- Price List For 1 APRIL 2015 TO 30 APRIL 2015: ST THDocument22 paginiPrice List For 1 APRIL 2015 TO 30 APRIL 2015: ST THQim SvÎncă nu există evaluări

- Q3 September AnswerDocument1 paginăQ3 September AnswerQim SvÎncă nu există evaluări

- Hin Huat (Chuah) Wine Merchants Sdn. BHDDocument2 paginiHin Huat (Chuah) Wine Merchants Sdn. BHDQim SvÎncă nu există evaluări

- Air Consumption of Double-Acting Cylinders ChartDocument1 paginăAir Consumption of Double-Acting Cylinders ChartQim SvÎncă nu există evaluări

- Tutorial 7Document3 paginiTutorial 7Qim SvÎncă nu există evaluări

- Hydraulic Cylinders: Company QualityDocument2 paginiHydraulic Cylinders: Company QualityQim SvÎncă nu există evaluări

- StampingDocument1 paginăStampingQim SvÎncă nu există evaluări

- Vibrations 7Document6 paginiVibrations 7Egidius PutrandoÎncă nu există evaluări

- EAT227-Lecture 10 Non-Traditional ProcessesDocument16 paginiEAT227-Lecture 10 Non-Traditional ProcessesQim SvÎncă nu există evaluări

- AcademicWriting 1Document1 paginăAcademicWriting 1Qim SvÎncă nu există evaluări

- EAT227-Lecture 9 Composite Material and ProcessesDocument14 paginiEAT227-Lecture 9 Composite Material and ProcessesQim SvÎncă nu există evaluări

- PenangDocument12 paginiPenangQim SvÎncă nu există evaluări

- Fruitcakes Cookies: IngredientsDocument1 paginăFruitcakes Cookies: IngredientsQim SvÎncă nu există evaluări

- Shaping Processes for PolymersDocument18 paginiShaping Processes for PolymersQim SvÎncă nu există evaluări

- Causes For The OccurrenceDocument1 paginăCauses For The OccurrenceQim SvÎncă nu există evaluări

- Where Errors Happen in The ProcessDocument1 paginăWhere Errors Happen in The ProcessQim SvÎncă nu există evaluări

- Where Errors Happen in The ProcessDocument1 paginăWhere Errors Happen in The ProcessQim SvÎncă nu există evaluări

- Medtech Day 2012Document10 paginiMedtech Day 2012Qim SvÎncă nu există evaluări

- Pascal's LawDocument15 paginiPascal's LawQim SvÎncă nu există evaluări

- Final Presentation Thermal CoatingDocument16 paginiFinal Presentation Thermal CoatingKarimMattaÎncă nu există evaluări

- Senior Corrosion Technologist EPGDocument9 paginiSenior Corrosion Technologist EPGPravas PadhihariÎncă nu există evaluări

- Daylight Reflecting SystemDocument4 paginiDaylight Reflecting SystemSelva KumarÎncă nu există evaluări

- 8620 Steel DatasheetDocument1 pagină8620 Steel DatasheetLuis ReyesÎncă nu există evaluări

- Dealing With Corrosion - Kevin DaviesDocument44 paginiDealing With Corrosion - Kevin DaviesRyanÎncă nu există evaluări

- Chapter 1 Introduction To Mechanical WorkshopDocument10 paginiChapter 1 Introduction To Mechanical WorkshopDipayan DasÎncă nu există evaluări

- Sifat Fisika Dan Nilai Keteguhan Rekat Kayu KecapiDocument9 paginiSifat Fisika Dan Nilai Keteguhan Rekat Kayu KecapiKen GheaÎncă nu există evaluări

- Conbextra GP4Document4 paginiConbextra GP4Chukwuma OgbonnaÎncă nu există evaluări

- Foamers Solid CatDocument4 paginiFoamers Solid CatLuisAlbertoVazquezÎncă nu există evaluări

- 3000 LTR RO PLANT ISI PLANT R KDocument17 pagini3000 LTR RO PLANT ISI PLANT R KVidya SinghÎncă nu există evaluări

- CMT Braze+: James Evans Segment Manager Robotics Fronius UK LTDDocument11 paginiCMT Braze+: James Evans Segment Manager Robotics Fronius UK LTDJaviÎncă nu există evaluări

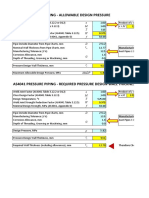

- As4041 Pressure Piping - Allowable Design Pressure: E M T W F D ExmDocument8 paginiAs4041 Pressure Piping - Allowable Design Pressure: E M T W F D ExmAkhil CÎncă nu există evaluări

- Questionnaires For Welding EngineerDocument7 paginiQuestionnaires For Welding EngineerCyril J PadiyathÎncă nu există evaluări

- Design and Fabrication of Single Cylinder Diesel Engine PDFDocument32 paginiDesign and Fabrication of Single Cylinder Diesel Engine PDFtadiwos100% (1)

- Steel Tube Sizing Chart Quick Reference Guide 4Document10 paginiSteel Tube Sizing Chart Quick Reference Guide 4ChetanÎncă nu există evaluări

- Printers' Marketplace Feb 9th 2010Document48 paginiPrinters' Marketplace Feb 9th 2010Christopher AllenÎncă nu există evaluări

- ASME B31.3-2016 Postweld Heat Treatment TableDocument1 paginăASME B31.3-2016 Postweld Heat Treatment TableSumner TingÎncă nu există evaluări

- DIY Dremel CNC Parts List PDFDocument1 paginăDIY Dremel CNC Parts List PDFServirol CiaÎncă nu există evaluări

- MEE 511 (Metallurgy)Document21 paginiMEE 511 (Metallurgy)Gabriel UdokangÎncă nu există evaluări

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument3 paginiInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiÎncă nu există evaluări

- Urespray S-004 enDocument4 paginiUrespray S-004 enAnonymous x7hm6CHDIÎncă nu există evaluări

- Lecture5 - Fludized Catalytic Cracking (FCC)Document3 paginiLecture5 - Fludized Catalytic Cracking (FCC)Bipradeep GhoshÎncă nu există evaluări

- Standard Normative ReferencesDocument2 paginiStandard Normative ReferencesAleksandar GochevskiÎncă nu există evaluări

- 5.1 Operating Conditions - Turning, Milling & DrillingDocument31 pagini5.1 Operating Conditions - Turning, Milling & DrillingjpmanikandanÎncă nu există evaluări

- Tds Uniqflow 488u enDocument1 paginăTds Uniqflow 488u enm daneshpourÎncă nu există evaluări

- Monthly Project Progress Report on MIG Welding OptimizationDocument1 paginăMonthly Project Progress Report on MIG Welding OptimizationHimanshu PawarÎncă nu există evaluări

- Session Plan - JLPBDocument7 paginiSession Plan - JLPBRose Ann MadenancilÎncă nu există evaluări

- Delta School of Trades Welding Handbook by Norman J. AshleyDocument164 paginiDelta School of Trades Welding Handbook by Norman J. Ashleyamin_corporationÎncă nu există evaluări