Documente Academic

Documente Profesional

Documente Cultură

Operations Management: Supplement 6 - Statistical Process Control

Încărcat de

Shubham SharmaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Operations Management: Supplement 6 - Statistical Process Control

Încărcat de

Shubham SharmaDrepturi de autor:

Formate disponibile

2006 Prentice Hall, Inc.

S6 1

Operations

Management

Supplement 6

Statistical Process Control

2006 Prentice Hall, Inc.

PowerPoint presentation to accompany

Heizer/Render

Principles of Operations Management, 6e

Operations Management, 8e

2006 Prentice Hall, Inc. S6 2

Outline

Statistical Process Control (SPC)

Control Charts for Variables

The Central Limit Theorem

Setting Mean Chart Limits (x-Charts)

Setting Range Chart Limits (R-Charts)

Using Mean and Range Charts

Control Charts for Attributes

Managerial Issues and Control Charts

2006 Prentice Hall, Inc. S6 3

Outline Continued

Process Capability

Process Capability Ratio (C

p

)

Process Capability Index (C

pk

)

Acceptance Sampling

Operating Characteristic Curve

Average Outgoing Quality

2006 Prentice Hall, Inc. S6 4

Learning Objectives

When you complete this supplement,

you should be able to:

Identify or Define:

Natural and assignable causes of

variation

Central limit theorem

Attribute and variable inspection

Process control

x-charts and R-charts

2006 Prentice Hall, Inc. S6 5

Learning Objectives

When you complete this supplement,

you should be able to:

Identify or Define:

LCL and UCL

P-charts and c-charts

C

p

and C

pk

Acceptance sampling

OC curve

2006 Prentice Hall, Inc. S6 6

Learning Objectives

When you complete this supplement,

you should be able to:

Identify or Define:

AQL and LTPD

AOQ

Producers and consumers risk

2006 Prentice Hall, Inc. S6 7

Learning Objectives

When you complete this supplement,

you should be able to:

Describe or Explain:

The role of statistical quality control

2006 Prentice Hall, Inc. S6 8

Variability is inherent in every process

Natural or common causes

Special or assignable causes

Provides a statistical signal when

assignable causes are present

Detect and eliminate assignable

causes of variation

Statistical Process Control

(SPC)

2006 Prentice Hall, Inc. S6 9

Natural Variations

Also called common causes

Affect virtually all production processes

Expected amount of variation

Output measures follow a probability

distribution

For any distribution there is a measure

of central tendency and dispersion

If the distribution of outputs falls within

acceptable limits, the process is said to

be in control

2006 Prentice Hall, Inc. S6 10

Assignable Variations

Also called special causes of variation

Generally this is some change in the process

Variations that can be traced to a specific

reason

The objective is to discover when

assignable causes are present

Eliminate the bad causes

Incorporate the good causes

2006 Prentice Hall, Inc. S6 11

Samples

To measure the process, we take samples

and analyze the sample statistics following

these steps

(a) Samples of the

product, say five

boxes of cereal

taken off the filling

machine line, vary

from each other in

weight

F

r

e

q

u

e

n

c

y

Weight

#

# # #

# #

# #

#

# # # # # # #

# # # # # # # # # #

Each of these

represents one

sample of five

boxes of cereal

Figure S6.1

2006 Prentice Hall, Inc. S6 12

Samples

To measure the process, we take samples

and analyze the sample statistics following

these steps

(b) After enough

samples are

taken from a

stable process,

they form a

pattern called a

distribution

The solid line

represents the

distribution

F

r

e

q

u

e

n

c

y

Weight

Figure S6.1

2006 Prentice Hall, Inc. S6 13

Samples

To measure the process, we take samples

and analyze the sample statistics following

these steps

(c) There are many types of distributions, including

the normal (bell-shaped) distribution, but

distributions do differ in terms of central

tendency (mean), standard deviation or

variance, and shape

Weight

Central tendency

Weight

Variation

Weight

Shape

F

r

e

q

u

e

n

c

y

Figure S6.1

2006 Prentice Hall, Inc. S6 14

Samples

To measure the process, we take samples

and analyze the sample statistics following

these steps

(d) If only natural

causes of

variation are

present, the

output of a

process forms a

distribution that

is stable over

time and is

predictable

Weight

F

r

e

q

u

e

n

c

y

Prediction

Figure S6.1

2006 Prentice Hall, Inc. S6 15

Samples

To measure the process, we take samples

and analyze the sample statistics following

these steps

(e) If assignable

causes are

present, the

process output is

not stable over

time and is not

predicable

Weight

F

r

e

q

u

e

n

c

y

Prediction

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

?

Figure S6.1

2006 Prentice Hall, Inc. S6 16

Control Charts

Constructed from historical data, the

purpose of control charts is to help

distinguish between natural variations

and variations due to assignable

causes

2006 Prentice Hall, Inc. S6 17

Types of Data

Characteristics that

can take any real

value

May be in whole or

in fractional

numbers

Continuous random

variables

Variables Attributes

Defect-related

characteristics

Classify products

as either good or

bad or count

defects

Categorical or

discrete random

variables

2006 Prentice Hall, Inc. S6 18

Central Limit Theorem

Regardless of the distribution of the

population, the distribution of sample means

drawn from the population will tend to follow

a normal curve

1. The mean of the sampling

distribution (x) will be the same

as the population mean m

x = m

s

n

s

x

=

2. The standard deviation of the

sampling distribution (s

x

) will

equal the population standard

deviation (s) divided by the

square root of the sample size, n

2006 Prentice Hall, Inc. S6 19

Process Control

Figure S6.2

Frequency

(weight, length, speed, etc.)

Size

Lower control limit

Upper control limit

(a) In statistical

control and capable

of producing within

control limits

(b) In statistical

control but not

capable of producing

within control limits

(c) Out of control

2006 Prentice Hall, Inc. S6 20

Population and Sampling

Distributions

Three population

distributions

Beta

Normal

Uniform

Distribution of

sample means

Standard

deviation of

the sample

means

= s

x

=

s

n

Mean of sample means = x

| | | | | | |

-3s

x

-2s

x

-1s

x

x +1s

x

+2s

x

+3s

x

99.73% of all x

fall within 3s

x

95.45% fall within 2s

x

Figure S6.3

2006 Prentice Hall, Inc. S6 21

Sampling Distribution

x = m

(mean)

Sampling

distribution

of means

Process

distribution

of means

Figure S6.4

2006 Prentice Hall, Inc. S6 22

Steps In Creating Control

Charts

1. Take samples from the population and

compute the appropriate sample statistic

2. Use the sample statistic to calculate control

limits and draw the control chart

3. Plot sample results on the control chart and

determine the state of the process (in or out of

control)

4. Investigate possible assignable causes and

take any indicated actions

5. Continue sampling from the process and reset

the control limits when necessary

2006 Prentice Hall, Inc. S6 23

Control Charts for Variables

For variables that have continuous

dimensions

Weight, speed, length, strength, etc.

x-charts are to control the central

tendency of the process

R-charts are to control the dispersion of

the process

These two charts must be used together

2006 Prentice Hall, Inc. S6 24

Setting Chart Limits

For x-Charts when we know s

Upper control limit (UCL) = x + zs

x

Lower control limit (LCL) = x - zs

x

where x = mean of the sample means or a target

value set for the process

z = number of normal standard deviations

s

x

= standard deviation of the sample means

= s/ n

s = population standard deviation

n = sample size

2006 Prentice Hall, Inc. S6 25

Setting Control Limits

Hour 1

Sample Weight of

Number Oat Flakes

1 17

2 13

3 16

4 18

5 17

6 16

7 15

8 17

9 16

Mean 16.1

s = 1

Hour Mean Hour Mean

1 16.1 7 15.2

2 16.8 8 16.4

3 15.5 9 16.3

4 16.5 10 14.8

5 16.5 11 14.2

6 16.4 12 17.3

n = 9

LCL

x

= x - zs

x

= 16 - 3(1/3) = 15 ozs

For 99.73% control limits, z = 3

UCL

x

= x + zs

x

= 16 + 3(1/3) = 17 ozs

2006 Prentice Hall, Inc. S6 26

17 = UCL

15 = LCL

16 = Mean

Setting Control Limits

Control Chart

for sample of

9 boxes

Sample number

| | | | | | | | | | | |

1 2 3 4 5 6 7 8 9 10 11 12

Variation due

to assignable

causes

Variation due

to assignable

causes

Variation due to

natural causes

Out of

control

Out of

control

2006 Prentice Hall, Inc. S6 27

Setting Chart Limits

For x-Charts when we dont know s

Lower control limit (LCL) = x - A

2

R

Upper control limit (UCL) = x + A

2

R

where R = average range of the samples

A

2

= control chart factor found in Table S6.1

x = mean of the sample means

2006 Prentice Hall, Inc. S6 28

Control Chart Factors

Table S6.1

Sample Size Mean Factor

Upper Range

Lower Range

n A

2

D

4

D

3

2 1.880 3.268 0

3 1.023 2.574 0

4 .729 2.282 0

5 .577 2.115 0

6 .483 2.004 0

7 .419 1.924 0.076

8 .373 1.864 0.136

9 .337 1.816 0.184

10 .308 1.777 0.223

12 .266 1.716 0.284

2006 Prentice Hall, Inc. S6 29

Setting Control Limits

Process average x = 16.01 ounces

Average range R = .25

Sample size n = 5

2006 Prentice Hall, Inc. S6 30

Setting Control Limits

UCL

x

= x + A

2

R

= 16.01 + (.577)(.25)

= 16.01 + .144

= 16.154 ounces

Process average x = 16.01 ounces

Average range R = .25

Sample size n = 5

From

Table S6.1

2006 Prentice Hall, Inc. S6 31

Setting Control Limits

UCL

x

= x + A

2

R

= 16.01 + (.577)(.25)

= 16.01 + .144

= 16.154 ounces

LCL

x

= x - A

2

R

= 16.01 - .144

= 15.866 ounces

Process average x = 16.01 ounces

Average range R = .25

Sample size n = 5

UCL = 16.154

Mean = 16.01

LCL = 15.866

2006 Prentice Hall, Inc. S6 32

R Chart

Type of variables control chart

Shows sample ranges over time

Difference between smallest and

largest values in sample

Monitors process variability

Independent from process mean

2006 Prentice Hall, Inc. S6 33

Setting Chart Limits

For R-Charts

Lower control limit (LCL

R

) = D

3

R

Upper control limit (UCL

R

) = D

4

R

where

R = average range of the samples

D

3

and D

4

= control chart factors from Table S6.1

2006 Prentice Hall, Inc. S6 34

Setting Control Limits

UCL

R

= D

4

R

= (2.115)(5.3)

= 11.2 pounds

LCL

R

= D

3

R

= (0)(5.3)

= 0 pounds

Average range R = 5.3 pounds

Sample size n = 5

From Table S6.1 D

4

= 2.115, D

3

= 0

UCL = 11.2

Mean = 5.3

LCL = 0

2006 Prentice Hall, Inc. S6 35

Mean and Range Charts

(a)

These

sampling

distributions

result in the

charts below

(Sampling mean is

shifting upward but

range is consistent)

R-chart

(R-chart does not

detect change in

mean)

UCL

LCL

Figure S6.5

x-chart

(x-chart detects

shift in central

tendency)

UCL

LCL

2006 Prentice Hall, Inc. S6 36

Mean and Range Charts

R-chart

(R-chart detects

increase in

dispersion)

UCL

LCL

Figure S6.5

(b)

These

sampling

distributions

result in the

charts below

(Sampling mean

is constant but

dispersion is

increasing)

x-chart

(x-chart does not

detect the increase

in dispersion)

UCL

LCL

2006 Prentice Hall, Inc. S6 37

Automated Control Charts

2006 Prentice Hall, Inc. S6 38

Control Charts for Attributes

For variables that are categorical

Good/bad, yes/no,

acceptable/unacceptable

Measurement is typically counting

defectives

Charts may measure

Percent defective (p-chart)

Number of defects (c-chart)

2006 Prentice Hall, Inc. S6 39

Control Limits for p-Charts

Population will be a binomial distribution,

but applying the Central Limit Theorem

allows us to assume a normal distribution

for the sample statistics

UCL

p

= p + zs

p

^

LCL

p

= p - zs

p

^

where p = mean fraction defective in the sample

z = number of standard deviations

s

p

= standard deviation of the sampling distribution

n = sample size

^

p(1 - p)

n

s

p

=

^

2006 Prentice Hall, Inc. S6 40

p-Chart for Data Entry

Sample Number Fraction Sample Number Fraction

Number of Errors Defective Number of Errors Defective

1 6 .06 11 6 .06

2 5 .05 12 1 .01

3 0 .00 13 8 .08

4 1 .01 14 7 .07

5 4 .04 15 5 .05

6 2 .02 16 4 .04

7 5 .05 17 11 .11

8 3 .03 18 3 .03

9 3 .03 19 0 .00

10 2 .02 20 4 .04

Total = 80

(.04)(1 - .04)

100

s

p

= = .02

^

p = = .04

80

(100)(20)

2006 Prentice Hall, Inc. S6 41

.11

.10

.09

.08

.07

.06

.05

.04

.03

.02

.01

.00

Sample number

F

r

a

c

t

i

o

n

d

e

f

e

c

t

i

v

e

| | | | | | | | | |

2 4 6 8 10 12 14 16 18 20

p-Chart for Data Entry

UCL

p

= p + zs

p

= .04 + 3(.02) = .10

^

LCL

p

= p - zs

p

= .04 - 3(.02) = 0

^

UCL

p

= 0.10

LCL

p

= 0.00

p = 0.04

2006 Prentice Hall, Inc. S6 42

.11

.10

.09

.08

.07

.06

.05

.04

.03

.02

.01

.00

Sample number

F

r

a

c

t

i

o

n

d

e

f

e

c

t

i

v

e

| | | | | | | | | |

2 4 6 8 10 12 14 16 18 20

UCL

p

= p + zs

p

= .04 + 3(.02) = .10

^

LCL

p

= p - zs

p

= .04 - 3(.02) = 0

^

UCL

p

= 0.10

LCL

p

= 0.00

p = 0.04

p-Chart for Data Entry

Possible

assignable

causes present

2006 Prentice Hall, Inc. S6 43

Control Limits for c-Charts

Population will be a Poisson distribution,

but applying the Central Limit Theorem

allows us to assume a normal distribution

for the sample statistics

where c = mean number defective in the sample

UCL

c

= c + 3 c LCL

c

= c - 3 c

2006 Prentice Hall, Inc. S6 44

c-Chart for Cab Company

c = 54 complaints/9 days = 6 complaints/day

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

Day

N

u

m

b

e

r

d

e

f

e

c

t

i

v

e

14

12

10

8

6

4

2

0

UCL

c

= c + 3 c

= 6 + 3 6

= 13.35

LCL

c

= c - 3 c

= 3 - 3 6

= 0

UCL

c

= 13.35

LCL

c

= 0

c = 6

2006 Prentice Hall, Inc. S6 45

Patterns in Control Charts

Normal behavior.

Process is in control.

Upper control limit

Target

Lower control limit

Figure S6.7

2006 Prentice Hall, Inc. S6 46

Upper control limit

Target

Lower control limit

Patterns in Control Charts

One plot out above (or

below). Investigate for

cause. Process is out

of control.

Figure S6.7

2006 Prentice Hall, Inc. S6 47

Upper control limit

Target

Lower control limit

Patterns in Control Charts

Trends in either

direction, 5 plots.

Investigate for cause of

progressive change.

Figure S6.7

2006 Prentice Hall, Inc. S6 48

Upper control limit

Target

Lower control limit

Patterns in Control Charts

Two plots very near

lower (or upper)

control. Investigate for

cause.

Figure S6.7

2006 Prentice Hall, Inc. S6 49

Upper control limit

Target

Lower control limit

Patterns in Control Charts

Run of 5 above (or

below) central line.

Investigate for cause. Figure S6.7

2006 Prentice Hall, Inc. S6 50

Upper control limit

Target

Lower control limit

Patterns in Control Charts

Erratic behavior.

Investigate.

Figure S6.7

2006 Prentice Hall, Inc. S6 51

Which Control Chart to Use

Using an x-chart and R-chart:

Observations are variables

Collect 20 - 25 samples of n = 4, or n =

5, or more, each from a stable process

and compute the mean for the x-chart

and range for the R-chart

Track samples of n observations each

Variables Data

2006 Prentice Hall, Inc. S6 52

Which Control Chart to Use

Using the p-chart:

Observations are attributes that can

be categorized in two states

We deal with fraction, proportion, or

percent defectives

Have several samples, each with

many observations

Attribute Data

2006 Prentice Hall, Inc. S6 53

Which Control Chart to Use

Using a c-Chart:

Observations are attributes whose

defects per unit of output can be

counted

The number counted is often a small

part of the possible occurrences

Defects such as number of blemishes

on a desk, number of typos in a page

of text, flaws in a bolt of cloth

Attribute Data

2006 Prentice Hall, Inc. S6 54

Process Capability

The natural variation of a process

should be small enough to produce

products that meet the standards

required

A process in statistical control does not

necessarily meet the design

specifications

Process capability is a measure of the

relationship between the natural

variation of the process and the design

specifications

2006 Prentice Hall, Inc. S6 55

Process Capability Ratio

C

p

=

Upper Specification - Lower Specification

6s

A capable process must have a C

p

of at

least 1.0

Does not look at how well the process

is centered in the specification range

Often a target value of C

p

= 1.33 is used

to allow for off-center processes

Six Sigma quality requires a C

p

= 2.0

2006 Prentice Hall, Inc. S6 56

Process Capability Ratio

C

p

=

Upper Specification - Lower Specification

6s

Insurance claims process

Process mean x = 210.0 minutes

Process standard deviation s = .516 minutes

Design specification = 210 3 minutes

2006 Prentice Hall, Inc. S6 57

Process Capability Ratio

C

p

=

Upper Specification - Lower Specification

6s

Insurance claims process

Process mean x = 210.0 minutes

Process standard deviation s = .516 minutes

Design specification = 210 3 minutes

= = 1.938

213 - 207

6(.516)

2006 Prentice Hall, Inc. S6 58

Process Capability Ratio

C

p

=

Upper Specification - Lower Specification

6s

Insurance claims process

Process mean x = 210.0 minutes

Process standard deviation s = .516 minutes

Design specification = 210 3 minutes

= = 1.938

213 - 207

6(.516)

Process is

capable

2006 Prentice Hall, Inc. S6 59

Process Capability Index

A capable process must have a C

pk

of at

least 1.0

A capable process is not necessarily in the

center of the specification, but it falls within

the specification limit at both extremes

C

pk

= minimum of ,

Upper

Specification - x

Limit

3s

Lower

x - Specification

Limit

3s

2006 Prentice Hall, Inc. S6 60

Process Capability Index

New Cutting Machine

New process mean x = .250 inches

Process standard deviation s = .0005 inches

Upper Specification Limit = .251 inches

Lower Specification Limit = .249 inches

2006 Prentice Hall, Inc. S6 61

Process Capability Index

New Cutting Machine

New process mean x = .250 inches

Process standard deviation s = .0005 inches

Upper Specification Limit = .251 inches

Lower Specification Limit = .249 inches

C

pk

= minimum of ,

(.251) - .250

(3).0005

2006 Prentice Hall, Inc. S6 62

Process Capability Index

New Cutting Machine

New process mean x = .250 inches

Process standard deviation s = .0005 inches

Upper Specification Limit = .251 inches

Lower Specification Limit = .249 inches

C

pk

= = 0.67

.001

.0015

New machine is

NOT capable

C

pk

= minimum of ,

(.251) - .250

(3).0005

.250 - (.249)

(3).0005

Both calculations result in

2006 Prentice Hall, Inc. S6 63

Interpreting C

pk

C

pk

= negative number

C

pk

= zero

C

pk

= between 0 and 1

C

pk

= 1

C

pk

> 1

Figure S6.8

2006 Prentice Hall, Inc. S6 64

Acceptance Sampling

Form of quality testing used for

incoming materials or finished goods

Take samples at random from a lot

(shipment) of items

Inspect each of the items in the sample

Decide whether to reject the whole lot

based on the inspection results

Only screens lots; does not drive

quality improvement efforts

2006 Prentice Hall, Inc. S6 65

Operating Characteristic

Curve

Shows how well a sampling plan

discriminates between good and

bad lots (shipments)

Shows the relationship between

the probability of accepting a lot

and its quality level

2006 Prentice Hall, Inc. S6 66

Return whole

shipment

The Perfect OC Curve

% Defective in Lot

P

(

A

c

c

e

p

t

W

h

o

l

e

S

h

i

p

m

e

n

t

)

100

75

50

25

0

| | | | | | | | | | |

0 10 20 30 40 50 60 70 80 90 100

Cut-Off

Keep whole

shipment

2006 Prentice Hall, Inc. S6 67

AQL and LTPD

Acceptable Quality Level (AQL)

Poorest level of quality we are

willing to accept

Lot Tolerance Percent Defective

(LTPD)

Quality level we consider bad

Consumer (buyer) does not want to

accept lots with more defects than

LTPD

2006 Prentice Hall, Inc. S6 68

Producers and Consumers

Risks

Producer's risk ()

Probability of rejecting a good lot

Probability of rejecting a lot when the

fraction defective is at or above the

AQL

Consumer's risk (b)

Probability of accepting a bad lot

Probability of accepting a lot when

fraction defective is below the LTPD

2006 Prentice Hall, Inc. S6 69

An OC Curve

Probability

of

Acceptance

Percent

defective

| | | | | | | | |

0 1 2 3 4 5 6 7 8

100

95

75

50

25

10

0

= 0.05 producers risk for AQL

b = 0.10

Consumers

risk for LTPD

LTPD AQL

Bad lots

Indifference

zone

Good

lots

Figure S6.9

2006 Prentice Hall, Inc. S6 70

OC Curves for Different

Sampling Plans

n = 50, c = 1

n = 100, c = 2

2006 Prentice Hall, Inc. S6 71

Average Outgoing Quality

where

P

d

= true percent defective of the lot

P

a

= probability of accepting the lot

N = number of items in the lot

n = number of items in the sample

AOQ =

(P

d

)(P

a

)(N - n)

N

2006 Prentice Hall, Inc. S6 72

Average Outgoing Quality

1. If a sampling plan replaces all defectives

2. If we know the incoming percent

defective for the lot

We can compute the average outgoing

quality (AOQ) in percent defective

The maximum AOQ is the highest percent

defective or the lowest average quality

and is called the average outgoing quality

level (AOQL)

2006 Prentice Hall, Inc. S6 73

SPC and Process Variability

(a) Acceptance

sampling (Some

bad units accepted)

(b) Statistical process

control (Keep the

process in control)

(c) C

pk

>1 (Design

a process that

is in control)

Lower

specification

limit

Upper

specification

limit

Process mean, m

Figure S6.10

S-ar putea să vă placă și

- Supplement 6 Heizer Operations ManagementDocument74 paginiSupplement 6 Heizer Operations ManagementNadia NathaniaÎncă nu există evaluări

- Statistical Process Control: © 2014 Pearson Education, Inc. S6 - 1Document103 paginiStatistical Process Control: © 2014 Pearson Education, Inc. S6 - 1Nour LyÎncă nu există evaluări

- Chap 17 Statistical Quality ControlDocument37 paginiChap 17 Statistical Quality ControlAbhishek KesarwaniÎncă nu există evaluări

- Statistical Quality Control 2Document34 paginiStatistical Quality Control 2Tech_MXÎncă nu există evaluări

- Statistic ProcessDocument39 paginiStatistic ProcessxredjokerxÎncă nu există evaluări

- EafdvcdfvcDocument34 paginiEafdvcdfvcAmara UiÎncă nu există evaluări

- Variation: The Presence of VariationDocument17 paginiVariation: The Presence of VariationHarris ChackoÎncă nu există evaluări

- 5.2 Process Capability Analysis Rev2ADocument8 pagini5.2 Process Capability Analysis Rev2APollyÎncă nu există evaluări

- Which Control Charts To Use WhereDocument115 paginiWhich Control Charts To Use Whereanbarasuar1964Încă nu există evaluări

- Homework Solutions For Chapter 6Document8 paginiHomework Solutions For Chapter 6api-234237296Încă nu există evaluări

- Statistical Quality ControlDocument91 paginiStatistical Quality ControlJabir Aghadi100% (3)

- 4 SPCDocument53 pagini4 SPCShubham AggarwalÎncă nu există evaluări

- Chapter 3 Control Chart For VariablesDocument66 paginiChapter 3 Control Chart For VariablesRitam PalÎncă nu există evaluări

- Gsoe9810 Week 9Document30 paginiGsoe9810 Week 9Handy PratamaÎncă nu există evaluări

- Six Sigma BooK Part2Document83 paginiSix Sigma BooK Part2foofoolÎncă nu există evaluări

- Statistical Quality Control: by 4Th Edition © Wiley 2010 Powerpoint Presentation by R.B. Clough - Unh M. E. Henrie - UaaDocument40 paginiStatistical Quality Control: by 4Th Edition © Wiley 2010 Powerpoint Presentation by R.B. Clough - Unh M. E. Henrie - UaaInderpreet SinghÎncă nu există evaluări

- Class 3 NotesDocument209 paginiClass 3 NotesJason FischerÎncă nu există evaluări

- Process Capability and SPC : Operations ManagementDocument43 paginiProcess Capability and SPC : Operations ManagementRahul KhannaÎncă nu există evaluări

- Have You Ever : Shot A Rifle? Played Darts? Played Basketball?Document39 paginiHave You Ever : Shot A Rifle? Played Darts? Played Basketball?foofoolÎncă nu există evaluări

- X-Bar and S Charts: NCSS Statistical SoftwareDocument26 paginiX-Bar and S Charts: NCSS Statistical Softwareanon_123371106100% (1)

- Quality Metrics DraftDocument19 paginiQuality Metrics DraftAl RammohanÎncă nu există evaluări

- Quality Lecture NotesDocument23 paginiQuality Lecture NotesPrithiviraj RajasekarÎncă nu există evaluări

- Control ChartsDocument29 paginiControl Chartsmbstutextile100% (1)

- Chapter 2 of One - Theory of Control ChartDocument36 paginiChapter 2 of One - Theory of Control ChartAmsalu SeteyÎncă nu există evaluări

- SPC: Statistical Process ControlDocument53 paginiSPC: Statistical Process ControlSaoloan NaiborhuÎncă nu există evaluări

- Application of Statistical Quality Control On Production of Building MaterialsDocument14 paginiApplication of Statistical Quality Control On Production of Building MaterialsLokesh ReddyÎncă nu există evaluări

- Introduction To Samping DistributionsDocument33 paginiIntroduction To Samping DistributionsAmna AdnanÎncă nu există evaluări

- Introduction SPCDocument28 paginiIntroduction SPCmixarimÎncă nu există evaluări

- 06control Chart 1Document37 pagini06control Chart 1abishank09100% (1)

- Lecture On C - ChartDocument20 paginiLecture On C - Chart191329Încă nu există evaluări

- Operations Management: Statistical Process Control Supplement 6Document34 paginiOperations Management: Statistical Process Control Supplement 6Hafiz UmmarÎncă nu există evaluări

- 02 Peng Using Control Chart To Evaluate Process Variability FinalDocument21 pagini02 Peng Using Control Chart To Evaluate Process Variability FinalBhagyesh KulakrniÎncă nu există evaluări

- 06control Chart 1Document37 pagini06control Chart 1Ashok SubramaniamÎncă nu există evaluări

- Statistical Quality Control: Simple Applications of Statistics in TQMDocument57 paginiStatistical Quality Control: Simple Applications of Statistics in TQMHarpreet Singh PanesarÎncă nu există evaluări

- Control Chart TheoryDocument6 paginiControl Chart TheoryJorge BurgueteÎncă nu există evaluări

- Operations Management: Statistical Process Control Supplement 6Document34 paginiOperations Management: Statistical Process Control Supplement 6زهديابوانسÎncă nu există evaluări

- 7 QC Tools: Check-Sheet Cause and Effect Pareto Histogram Control Chart Scatter Plot StratificationDocument55 pagini7 QC Tools: Check-Sheet Cause and Effect Pareto Histogram Control Chart Scatter Plot StratificationNilesh RathoreÎncă nu există evaluări

- Statistical Quality Control (SQC) FinalDocument47 paginiStatistical Quality Control (SQC) FinalSagar DhageÎncă nu există evaluări

- Ch06ppln-Introduction To Distribution SamplingDocument33 paginiCh06ppln-Introduction To Distribution Sampling3rlangÎncă nu există evaluări

- Unit Iii - Statistical Process Control: TQM Tools (Seven Tools of Quality) 1. Pareto Diagram 2. Flow DiagramDocument11 paginiUnit Iii - Statistical Process Control: TQM Tools (Seven Tools of Quality) 1. Pareto Diagram 2. Flow DiagramKabilan KabilÎncă nu există evaluări

- Control Chart ExercisesDocument5 paginiControl Chart Exercisesmico.balinaÎncă nu există evaluări

- Statistics For Business and Economics: Bab 20Document43 paginiStatistics For Business and Economics: Bab 20balo100% (1)

- Technical Note 8: Process Capability and Statistical Quality ControlDocument46 paginiTechnical Note 8: Process Capability and Statistical Quality ControlVipin NairÎncă nu există evaluări

- Methods Philosophy of Statistical Process Control SPC 1233777331265093 2Document8 paginiMethods Philosophy of Statistical Process Control SPC 1233777331265093 2Ronaldo AmosÎncă nu există evaluări

- Elementary StatisticsDocument22 paginiElementary StatisticsRipkah Vyanee100% (1)

- Metrology Control ChartsDocument14 paginiMetrology Control ChartsRaghu KrishnanÎncă nu există evaluări

- Statistics and Quality (P Chart)Document21 paginiStatistics and Quality (P Chart)bernie_uyÎncă nu există evaluări

- 2 Mean Median Mode VarianceDocument29 pagini2 Mean Median Mode VarianceBonita Mdoda-ArmstrongÎncă nu există evaluări

- Statistical Process ControlDocument42 paginiStatistical Process ControlErick Bok Cang YeongÎncă nu există evaluări

- To Conduct Shewart's Experiments On Known Population by ABHISHEK SHARMADocument22 paginiTo Conduct Shewart's Experiments On Known Population by ABHISHEK SHARMAabhiÎncă nu există evaluări

- QualityDocument36 paginiQualityShobitha UchilÎncă nu există evaluări

- Chapter 4 Control Charts For VariablesDocument44 paginiChapter 4 Control Charts For Variablesgeletaw mitawÎncă nu există evaluări

- ASSIGNMENT ON STATISTICAL PROCESS CONTROL ProdDocument4 paginiASSIGNMENT ON STATISTICAL PROCESS CONTROL ProdsamanthaÎncă nu există evaluări

- Design of Experiments (SS)Document4 paginiDesign of Experiments (SS)Sudipta SarangiÎncă nu există evaluări

- Practical Design of Experiments (DOE): A Guide for Optimizing Designs and ProcessesDe la EverandPractical Design of Experiments (DOE): A Guide for Optimizing Designs and ProcessesÎncă nu există evaluări

- Six Sigma Green Belt, Round 2: Making Your Next Project Better than the Last OneDe la EverandSix Sigma Green Belt, Round 2: Making Your Next Project Better than the Last OneÎncă nu există evaluări

- The ASQ Pocket Guide to Statistics for Six Sigma Black BeltsDe la EverandThe ASQ Pocket Guide to Statistics for Six Sigma Black BeltsÎncă nu există evaluări

- Chapter-1 EntrepreneurDocument34 paginiChapter-1 EntrepreneurShubham SharmaÎncă nu există evaluări

- Entrepreneurship Development EOE 071 PDFDocument2 paginiEntrepreneurship Development EOE 071 PDFShubham SharmaÎncă nu există evaluări

- PtandoniiitjabalpurDocument16 paginiPtandoniiitjabalpurShubham SharmaÎncă nu există evaluări

- I C Engine TerminologyDocument47 paginiI C Engine TerminologyShubham SharmaÎncă nu există evaluări

- A Practical Solution To A Newspaper Distribution ProblemDocument9 paginiA Practical Solution To A Newspaper Distribution ProblemShubham SharmaÎncă nu există evaluări

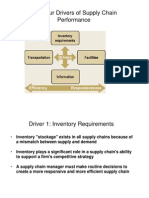

- Drivers of Supply Chain PerformanceDocument5 paginiDrivers of Supply Chain PerformanceShubham SharmaÎncă nu există evaluări

- Introduction To Quality: Assist. Prof. Dr. Özlem Türker Bayrak A 206-B Ozlemt@cankaya - Edu.trDocument60 paginiIntroduction To Quality: Assist. Prof. Dr. Özlem Türker Bayrak A 206-B Ozlemt@cankaya - Edu.trShubham SharmaÎncă nu există evaluări

- Similar TriangleDocument13 paginiSimilar TriangleShubham SharmaÎncă nu există evaluări

- CRA 2010-Poster-PresentationsDocument236 paginiCRA 2010-Poster-PresentationsJoe GassÎncă nu există evaluări

- Basic Strategies of Cognitive Behavioral Therapy-2017Document13 paginiBasic Strategies of Cognitive Behavioral Therapy-2017Juan ParedesÎncă nu există evaluări

- Wxyz Paper-I: Test Booklet No. Time: 1 Hours) (Maximum Marks: 100Document8 paginiWxyz Paper-I: Test Booklet No. Time: 1 Hours) (Maximum Marks: 100Ramanpreet KaurÎncă nu există evaluări

- Human Resource Management: Decenzo and RobbinsDocument17 paginiHuman Resource Management: Decenzo and RobbinsMae FloresÎncă nu există evaluări

- Pathik Desai Resume PDFDocument1 paginăPathik Desai Resume PDFpathik desaiÎncă nu există evaluări

- Chapter 1 - Introduction: 1.1 Research BackgroundDocument2 paginiChapter 1 - Introduction: 1.1 Research BackgroundNora PrueÎncă nu există evaluări

- Andragoske Studije 2010-2Document229 paginiAndragoske Studije 2010-2lazar_knezevic93Încă nu există evaluări

- Thesis About Teaching Strategies PhilippinesDocument6 paginiThesis About Teaching Strategies Philippinesgbvc57fd100% (2)

- Godisnjak Annual Review 2015 2016Document233 paginiGodisnjak Annual Review 2015 2016Beta ElizabetaÎncă nu există evaluări

- Research Plan For BCG Design Virtual InternshipDocument2 paginiResearch Plan For BCG Design Virtual InternshipTessyÎncă nu există evaluări

- Abrigo Funding Benchmark Data 2022Q3Document37 paginiAbrigo Funding Benchmark Data 2022Q3helmetheadbobÎncă nu există evaluări

- Career Planning and ExplorationDocument2 paginiCareer Planning and ExplorationCarla Rosa' TurnerÎncă nu există evaluări

- Reflection Exam Final 1Document5 paginiReflection Exam Final 1api-584147825Încă nu există evaluări

- Cognitive ObjectivesDocument9 paginiCognitive ObjectivesJennifer R. JuatcoÎncă nu există evaluări

- Summer Internship ProjectDocument70 paginiSummer Internship ProjectNitin SahniÎncă nu există evaluări

- pb4 Programme Coordinator Punjab KPK and Isb - RotaDocument6 paginipb4 Programme Coordinator Punjab KPK and Isb - RotaAar kyyÎncă nu există evaluări

- Solving High-Dimensional Partial Differential Equations Using Deep LearningDocument14 paginiSolving High-Dimensional Partial Differential Equations Using Deep LearningJames MattosÎncă nu există evaluări

- Generic Names of Plant Species Stored at Herbarium WanarisetDocument132 paginiGeneric Names of Plant Species Stored at Herbarium WanarisetKef AltikÎncă nu există evaluări

- CH 5Document57 paginiCH 5sÎncă nu există evaluări

- PLC Mathematics Year 2Document5 paginiPLC Mathematics Year 2AndyKongÎncă nu există evaluări

- Advanced MarketingDocument13 paginiAdvanced Marketingjme_pescasioÎncă nu există evaluări

- STAT8017 Assignment 1Document6 paginiSTAT8017 Assignment 1Thompson Daphnis LauÎncă nu există evaluări

- A Conservative Revolution in Publishing - BourdieuDocument32 paginiA Conservative Revolution in Publishing - BourdieuManuel González PosesÎncă nu există evaluări

- Halima Main Thesis PaperDocument17 paginiHalima Main Thesis PaperMd SarroarÎncă nu există evaluări

- Europeans and LanguagesDocument10 paginiEuropeans and Languages420Încă nu există evaluări

- The Scanlon Plan Involved Two SystemsDocument3 paginiThe Scanlon Plan Involved Two SystemsJehanzeb SiddiquiÎncă nu există evaluări

- Mixed and Hybrid MethodsDocument113 paginiMixed and Hybrid MethodsGabo FernándezÎncă nu există evaluări

- Internship Report On Digital Marketing and Telenor Health's Tonic: A Study On Jarvis Digital BangladeshDocument84 paginiInternship Report On Digital Marketing and Telenor Health's Tonic: A Study On Jarvis Digital BangladeshSultan-ul-Arefin SwapnilÎncă nu există evaluări

- O Level SociologyDocument6 paginiO Level SociologyJuniorÎncă nu există evaluări

- DR Rana Usmani KirkpatrickmodelDocument6 paginiDR Rana Usmani KirkpatrickmodelAgnes ManurungÎncă nu există evaluări