Documente Academic

Documente Profesional

Documente Cultură

Introduction To Onshore Drilling

Încărcat de

Su Chong GuangTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Introduction To Onshore Drilling

Încărcat de

Su Chong GuangDrepturi de autor:

Formate disponibile

1

references:

Bernt S. Aadnoy, Iain Cooper, Stefan Z. Miska, Robert F. Mitchell, Michael L. Payne:

Advanced Drilling and Well Technology. SPE 2009, ISBN: 978-1-55563-145-1.

Robello G. Samuel, Xiushan Liu: Advanced Drilling Engineering Principles and

Design. Gulf Publishing Company, Houston Texas, 2009,

ISBN: 978-1-933762-34-0.

World Oils Handbook of Horizontal Drilling and Completion Technology.

Gulf Publishing Company, Houston, Texas 1991, ISBN: 0-87201-361-8.

A Primer of Oilwell Drilling. Petroleum Extension Service, Houston, Texas 2001,

ISBN: 0-88698-194-8.

Robello, R. G.: Downhole Drilling Tools. Gulf Publishing Company, Houston, Texas

2007, ISBN: 978-1933762135.

Fundamentals of Onshore Drilling

Introduction to Onshore Drilling

presentation No. 1

2

objectives define hole/well construction

Fundamentals of Drilling

drilling means to make a hole in order

to get access to the earths subsurface

Objectives may be

gaining information about the subsurface

from sampling/testing/logging

=> hole discarded

production/injection of fluids/gases

(oil/gas/water)

=> hole completed into well

monitoring of subsurface properties

(aquifer preassure, stress state, etc.)

=> hole completed into well

3

Fields of Drilling Applications

Exploration/Production of Natural Resources

- Oil and Gas

- Water

- Geothermal Energy

Site Investigation

- Scientific

- Foundation/Construction

- Environmental

Mining Exploration

Blast Hole/Seismic

- Quarry

4

Drilling Techniques Classification by Hole Making Methods

5

Principles of Drilling Techniques Percussion Cabel Tool Drilling

very old drilling technique (applied

more than 2000 years ago by the

Chinese)

2 Phase Technique (discontinuous)

Phase 1: Rock Drilling

free falling bit strikes the bottom

with a heavy blow repeated lifting

and dropping makes the bit drill

Phase 2: Removal of Cuttings

interruption of drilling to remove

cuttings by bailing

suitable only for hard rock

total efficiency of drilling

process is fairly low

6

Principles of Drilling Techniques Percussion Cabel Tool Drilling

7

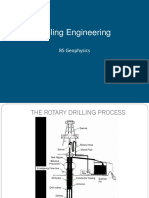

Principles of Drilling Techniques Rotary Drilling

Drilling Fluid is circulated by being

pumped down the drill string

The Drill String is rotated to turn

the bit; it is fed down as the bit

penetration

Bit is pushed into the bottom and

rotation makes it cut

Return circulation carries cuttings

up the annulus between the drill

string and the wall of the hole

Key Elements:

- Drill Bit

-Drill String

- Drilling Fluid

8

Types of Rotary Bits

Performance Parameters of Drill Bits: Penetration Rate (Drilling Speed: m/h)

Bit Life (Meters Drilled)

Rock Characterization

soft very hard medium hard soft

Roller Cone Bit

Milled Steel Tooth

Roller Cone Bit

Tungsten Carbide

(inserts)

Diamond Bit

Natural Diamonds

Diamond Bit

Polycrystalline

Diamond Compact

Cutters

9

Cutting Action of Rotary Drill Bits

10

Cutting Action of Rotary Drill Bits

Cones of Roller Bits do

only roll on the bottom

but always

Slide, Tear and Gouge

Offset of cones

increases

Sliding, Tearing,

Gouging action

11

Elements of Roller Cone Bits

Shape Types of Inserts

12

Bottom Hole Cleaning of Roller Cone Bits

Schematic of Nozzles Action Effect of Nozzle Velocity on Rate of Penetration

13

Typical Operating Parameters for Roller Cone Inserts Bits

14

Cutting Action of Diamond Bit

15

Cutting Action of Diamonds

16

Sizes and Texture of Hard Rock Cuttings Dependent on Bit Type

17

Operating Parameters of Diamond Bits

18

Typical Rotary Drill String Assembly

The drill string is the mechanical assemblage connection the

rotary drive on surface to the drilling bit on bottom of the hole

Functions of the Drillstring:

flow line for circulating drilling fluid

provides weight on bit

transmits rotation and torque to bit

guides and controls trajectory of the bit

Main Components:

Drill Collars: thick wall steel pipe with

Pin/Box threaded connection

Drill Pipe: steel pipe with Pin/Box

threaded toolioints

Ancillary Components:

crossover subs

stabilizers

reamers

19

Rotary Drillpipe Characteristics

18

Tooljoint Welded

Pin and Box Tooljoint

Rotary Drillpipes are standartized by API

Outer Diameter

of Pipe Body

5

5

4

4

3

2 7/8

2 3/8

1 = 2,54 cm

Steel Grades of

Pipe Body

E 75

X 95

G 105

S - 135

Nominal Weight

of Pipe Body

Tool Joints Steel Grade: 120 000 psi (827,4 Mpa)

Thread Type: NC 50, NC 38

Friction welded with upset pipe body annealed and machined

Wall Thickness

Pipe Lenght

Range 1: 18 22 ft

Range 2: 27 30 ft

Range 3: 38 45 ft

1 ft = 30,48 cm

20

Drill Pipe Problems

Drill pipe is the most stressed component of rotary equipment!!!

Tension Torque

Burst

(Inside Pressure)

Reversal Stresses

Fratigue

Bending

(While Rotation)

21

Putting Weight on Bit by Drill Collars

Buckling of Drillpipe under Compressional Load!

22

Typical Examples for Stabilized

Bottom Hole Assemblies (BHA)

23

Drilling Fluid Why its Called MUD

24

Drilling Mud A Multipurpose Fluid

Major Functions:

Bottomhole Cleaning

Cuttings Transport

Borehole Wall Support

Balancing Formation Pressure

Cooling the Bit

Hydraulic Power Transmission

Data transmission (MWD)

Reducing Friction

Corrosion Protection

Scientific Information Carrier

25

Drilling Fluid Circulating Pumps

Typical Operating Parameters:

max pressure: 35 Mpa

17 = 3 500 l/min

12 = 2 500 l/min

8 = 1 500 l/min

6 = 600 l/min

heavyweight rigs =>

2 pumps 1 200kW

lightweight rigs =>

2 pumps 600 kW

26

Principal Functions of a Rotary Drilling Rig

27

Main Components of the Hoisting System

28

Schematic of a Rotary Rigs Block and Tackle

29

Hoisting System of Drilling Rigs Hoisting Tower

Derrick

Structural tower assembled/

dismantled piece by piece

Assembling/

dismantling is time consuming

Used mainly offshore

Square shaped rig floor

30

Hoisting System of Drilling Rigs Hoisting Tower

Mast

A-shaped structure which can

be pulled or lowered to a

upright position by the

drawworks without completely

assembling or disassembling

Good mobility

Used mainly with onshore rigs

31

Rotary Rig Drawworks

Advantages of Gear Driven

Drawworks:

high performance

high availability

less noise

less vibration

increased safety

32

Rotating the Drillstring with a Rotary Table

33

Rotating the Drillstring with a Top Drive

TOP DRIVE means a Power Swivel which

directly turns the drillstring without need

for a kelly and rotary table

Advantages of a Top Drive Systm:

drill string can be pulled out while

rotating and circulating Back Reaming

can be reconnected to the drill string at

any mast height during tripping

drilling with 3-joint stands of drill pipe

is possible

with hydraulic driven power swivel

static torque can be applied for much

longer time

Save time!!!

Safer and easier operation!!!

34

Drilling Rig LOC 400

35

36

37

Classification of Drilling Rigs

Classification by Depth Rating:

lightweight rigs: 1 500 2 000 m

intermediate rigs: 3 500 m

heavyweight rigs: 6 000 m

ultraheavy rigs: 8 000 10 000 m

Classification by Horsepower:

Rule of Thumb:

every 100 ft (30,5 m) of borehole

requires 10 HP (7,5 kW) at

drawworks

lightweight rigs : 650 HP (484,7 kW)

intermediate rigs : 1 300 HP (969,4 kW)

heavyweight rigs : 2 000 HP (1491 kW)

ultraheavy rigs : 3 000 HP (2 237 kW)

38

Typical Rig Organization Scheme

39

Drilling Contracts

40

THE END!!!

41

S-ar putea să vă placă și

- Basic Drilling EngineeringDocument26 paginiBasic Drilling EngineeringbhuvanchaudhariÎncă nu există evaluări

- Working Guide to Drilling Equipment and OperationsDe la EverandWorking Guide to Drilling Equipment and OperationsEvaluare: 5 din 5 stele5/5 (9)

- Introduction To Drilling TechnologyDocument68 paginiIntroduction To Drilling TechnologyKrupal Patel100% (1)

- Fundamentals and Applications of Bionic Drilling FluidsDe la EverandFundamentals and Applications of Bionic Drilling FluidsÎncă nu există evaluări

- Lec 2 Intro To Drilling EngineeringDocument28 paginiLec 2 Intro To Drilling EngineeringRanaBarzamArshad100% (1)

- Measurement While Drilling: Signal Analysis, Optimization and DesignDe la EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignÎncă nu există evaluări

- 3 - Drilling EngineeringDocument118 pagini3 - Drilling EngineeringNelson Frendika Yudha100% (4)

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersDe la EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersÎncă nu există evaluări

- Rig ComponentsDocument59 paginiRig ComponentsMuhammad Nabil Ezra100% (3)

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsDe la EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsÎncă nu există evaluări

- Unit 1 4th Topic Oil Rig SystemDocument14 paginiUnit 1 4th Topic Oil Rig SystemUmaÎncă nu există evaluări

- Formulas and Calculations for Drilling OperationsDe la EverandFormulas and Calculations for Drilling OperationsÎncă nu există evaluări

- Hoisting SystemDocument42 paginiHoisting SystemBadut Sarkas100% (3)

- Offshore Drilling IntroductionDocument56 paginiOffshore Drilling IntroductionnaefmubarakÎncă nu există evaluări

- Applied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesDe la EverandApplied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesÎncă nu există evaluări

- Drilling Training ProgramDocument7 paginiDrilling Training Programbehnam197100% (1)

- Microbial Enhancement of Oil Recovery - Recent AdvancesDe la EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesÎncă nu există evaluări

- 3day Mud School Info6.24.07Document4 pagini3day Mud School Info6.24.07محمد سعيدÎncă nu există evaluări

- Shale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementDe la EverandShale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementEvaluare: 4.5 din 5 stele4.5/5 (2)

- Rotary Drilling Rig ComponentDocument130 paginiRotary Drilling Rig ComponentRamez Rimez0% (1)

- Bench Marking Drilling OpsDocument40 paginiBench Marking Drilling OpsSLACKENGINEERÎncă nu există evaluări

- Completion - Cementing and Perforating PDFDocument9 paginiCompletion - Cementing and Perforating PDFengineer1976Încă nu există evaluări

- 2.0 Components of Drilling RigDocument81 pagini2.0 Components of Drilling RigConnor Whiltshire100% (1)

- Analysis, Comparison and Application of CWD Against Conventional Drilling OperationsDocument104 paginiAnalysis, Comparison and Application of CWD Against Conventional Drilling Operationsprakharmathur14100% (1)

- Drill StringDocument25 paginiDrill StringsrikantaLeeÎncă nu există evaluări

- Structures and Land Rig Mobilization ST-1: IADC Drilling ManualDocument3 paginiStructures and Land Rig Mobilization ST-1: IADC Drilling ManualHussainÎncă nu există evaluări

- Summer Internship ON: Basics of Well Logging, Well Log Operations & Interpretation-Ongc Mehsana AssetDocument38 paginiSummer Internship ON: Basics of Well Logging, Well Log Operations & Interpretation-Ongc Mehsana AssetYaashpal Malik50% (2)

- Operation ProcedureDocument4 paginiOperation ProcedureEmad JamshidiÎncă nu există evaluări

- Running CasingDocument21 paginiRunning CasingSalem Halbaoui0% (1)

- End of Well ReportDocument21 paginiEnd of Well ReportmkwendeÎncă nu există evaluări

- Extended Reach Drilling1 PDFDocument18 paginiExtended Reach Drilling1 PDFMayra Betancourt Dominguez100% (1)

- Drilling and Well Operations - D-010r1Document39 paginiDrilling and Well Operations - D-010r1jorge_h_riveroÎncă nu există evaluări

- Rigs, Drilling A WellDocument50 paginiRigs, Drilling A Wellfrganga100% (1)

- Mwd-Manual PDFDocument151 paginiMwd-Manual PDFmanu pratap singhÎncă nu există evaluări

- Fishing in Drilling OperationsDocument19 paginiFishing in Drilling Operationsmts1234100% (1)

- Drilling Methods and Type of Rigs PDFDocument26 paginiDrilling Methods and Type of Rigs PDFnamdq-1Încă nu există evaluări

- Basic Course of Drilling ProcedureDocument4 paginiBasic Course of Drilling ProcedureAli Samani100% (2)

- Drilling Lectures BU 1Document32 paginiDrilling Lectures BU 1Talha Butt100% (1)

- Datalog Wellsite Procedures Manual 1999Document34 paginiDatalog Wellsite Procedures Manual 1999Muhammad HamdyÎncă nu există evaluări

- Well ControlDocument10 paginiWell ControlSamad Ali SiddiquiÎncă nu există evaluări

- Rig Selection 3Document59 paginiRig Selection 3okeynaijaÎncă nu există evaluări

- Deepwater Rig Selection: Well Engineering Services To The Oil & Gas IndustryDocument18 paginiDeepwater Rig Selection: Well Engineering Services To The Oil & Gas IndustryLuciano Fucello100% (1)

- Drilling Rig Components Illustration - Komponen Utama PemboranDocument86 paginiDrilling Rig Components Illustration - Komponen Utama PemboranPuji LestariÎncă nu există evaluări

- Fundamentals of Onshore DrillingDocument53 paginiFundamentals of Onshore DrillingshaileshNchaudharyÎncă nu există evaluări

- Basic Drilling EngineeringDocument26 paginiBasic Drilling EngineeringAhmedsharifMohammedÎncă nu există evaluări

- Basic Drilling EngineeringDocument26 paginiBasic Drilling Engineeringgfaux03Încă nu există evaluări

- PET 314 SlidesDocument126 paginiPET 314 SlidesBryan Israel100% (2)

- Lecture 3 - Drilling Methods and Process-1Document34 paginiLecture 3 - Drilling Methods and Process-1hasan sabah100% (2)

- Transocean REP Program - Stage 1 ReportDocument23 paginiTransocean REP Program - Stage 1 ReporttduyhaoÎncă nu există evaluări

- Basic Drilling EngineeringDocument26 paginiBasic Drilling EngineeringBinh ChuÎncă nu există evaluări

- Drill String Design BHA Design1Document97 paginiDrill String Design BHA Design1MohammadFaisalQureshi100% (1)

- Drill String Design BHA DesignDocument97 paginiDrill String Design BHA DesignAhmed SallamÎncă nu există evaluări

- Fundamentals of Petroleum Engineering. By: Bilal Shams MemonDocument26 paginiFundamentals of Petroleum Engineering. By: Bilal Shams MemonRaJaÎncă nu există evaluări

- Drill String Design BHA DesignDocument97 paginiDrill String Design BHA DesignAhmed SallamÎncă nu există evaluări

- Drilling PresentationDocument63 paginiDrilling PresentationRehan Mansoor100% (1)

- English I - Drilling Rig ClassificationDocument45 paginiEnglish I - Drilling Rig ClassificationCarlos Osorio VillabonaÎncă nu există evaluări

- Advances in Drilling TechnologyDocument46 paginiAdvances in Drilling TechnologySaurabh SinghÎncă nu există evaluări

- Basics of Rotary Drilling (1) Basics of Rotary DrillingDocument0 paginiBasics of Rotary Drilling (1) Basics of Rotary DrillingmvkellyÎncă nu există evaluări

- Karcher K - 791 - MDocument12 paginiKarcher K - 791 - MJoão Paulo FernandesÎncă nu există evaluări

- IA SeriesDocument20 paginiIA Seriessina20795Încă nu există evaluări

- All Over India Company DataDocument32 paginiAll Over India Company DataViren PatelÎncă nu există evaluări

- Ncomputing VSpace Server Management Console User ManualDocument34 paginiNcomputing VSpace Server Management Console User ManualJeff IvanÎncă nu există evaluări

- Education Abbreviation by AffairsCloudDocument6 paginiEducation Abbreviation by AffairsCloudgsaijanardhanÎncă nu există evaluări

- UAMDocument35 paginiUAMVishnu R PuthusseryÎncă nu există evaluări

- Calculation Rail Beam (Hoist Capacity 3 Ton)Document4 paginiCalculation Rail Beam (Hoist Capacity 3 Ton)Edo Faizal2Încă nu există evaluări

- ARO Pump ManualDocument8 paginiARO Pump Manualrazaq athabÎncă nu există evaluări

- Acidizing TreatmentsDocument93 paginiAcidizing TreatmentsPeña Lucia100% (2)

- Getting Started With Java: Atul PrakashDocument20 paginiGetting Started With Java: Atul PrakashOwsozeroÎncă nu există evaluări

- Control Unit ECUDocument2 paginiControl Unit ECUjag1961Încă nu există evaluări

- VocationalDocument2 paginiVocationalMegha RoyÎncă nu există evaluări

- Graco Pumps Catalog 300435EN MDocument76 paginiGraco Pumps Catalog 300435EN MAlbu MihaiÎncă nu există evaluări

- SIMODUAL2 Industrial Double Containment Piping System - Dual Pipes For Double The ProtectionDocument32 paginiSIMODUAL2 Industrial Double Containment Piping System - Dual Pipes For Double The Protectionrade.paripovicÎncă nu există evaluări

- Specific Gravity 20mmDocument4 paginiSpecific Gravity 20mmIsaiahogedaÎncă nu există evaluări

- BC 20s HandbuchDocument173 paginiBC 20s HandbuchmanoharÎncă nu există evaluări

- One Pipe Steam DesignDocument44 paginiOne Pipe Steam Designreyes hernandezÎncă nu există evaluări

- Supercontryx®: Innovative Glass For X - Ray ProtectionDocument2 paginiSupercontryx®: Innovative Glass For X - Ray ProtectionUsman AhmedÎncă nu există evaluări

- Grabi Al Jubail ProfileDocument130 paginiGrabi Al Jubail ProfileSlid ISO100% (1)

- The Family Handyman - October 2020 PDFDocument86 paginiThe Family Handyman - October 2020 PDFFabian MaunaÎncă nu există evaluări

- Method Statement of Pipeline WorksDocument13 paginiMethod Statement of Pipeline Worksमनिसभेटुवाल86% (21)

- Update Notifikasi Depkes FEB 18Document6 paginiUpdate Notifikasi Depkes FEB 18pratistanadia_912023Încă nu există evaluări

- Meinberg ManualDocument214 paginiMeinberg ManualLeonard NicolaeÎncă nu există evaluări

- D-Link DI-524 ManualDocument92 paginiD-Link DI-524 ManualhadzicinetÎncă nu există evaluări

- Ufgs 33 52 43.13Document40 paginiUfgs 33 52 43.13Tendai Felex MadukeÎncă nu există evaluări

- B747F 400Document2 paginiB747F 400Nadeem100% (1)

- Chapter - I: Hydro DriveDocument19 paginiChapter - I: Hydro Drivekuldeep ududholiraÎncă nu există evaluări

- US Hex Bolt SizesDocument2 paginiUS Hex Bolt SizesYana Jarang OlÎncă nu există evaluări

- Unit 5 GeosyntheticsDocument315 paginiUnit 5 Geosyntheticskowshik1737551Încă nu există evaluări

- Jura Subito Operating Instructions Automatic 2 Cup Espresso Coffee MachineDocument15 paginiJura Subito Operating Instructions Automatic 2 Cup Espresso Coffee MachineyangÎncă nu există evaluări