Documente Academic

Documente Profesional

Documente Cultură

Ch14 Intro To Motor Controls

Încărcat de

s.b.v.seshagiri14070 evaluări0% au considerat acest document util (0 voturi)

55 vizualizări90 paginiThe document provides an overview of electric motors and motor control. It discusses the basic components and functions of electric motors, including the stator, rotor, electromagnets, and how reversing current direction reverses magnetic polarity. Common types of electric motors are described such as permanent magnet DC motors, stepper motors, and brushless DC motors. The document also explains what motor control is and how it is used to control speed, torque, position and other motor functions through electronics. An agenda outlines topics to be covered, including introductions to electromagnets, motors, motor control, and specific motor types.

Descriere originală:

Introduction to Motor controls

Titlu original

Ch14 Intro to Motor Controls

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThe document provides an overview of electric motors and motor control. It discusses the basic components and functions of electric motors, including the stator, rotor, electromagnets, and how reversing current direction reverses magnetic polarity. Common types of electric motors are described such as permanent magnet DC motors, stepper motors, and brushless DC motors. The document also explains what motor control is and how it is used to control speed, torque, position and other motor functions through electronics. An agenda outlines topics to be covered, including introductions to electromagnets, motors, motor control, and specific motor types.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

55 vizualizări90 paginiCh14 Intro To Motor Controls

Încărcat de

s.b.v.seshagiri1407The document provides an overview of electric motors and motor control. It discusses the basic components and functions of electric motors, including the stator, rotor, electromagnets, and how reversing current direction reverses magnetic polarity. Common types of electric motors are described such as permanent magnet DC motors, stepper motors, and brushless DC motors. The document also explains what motor control is and how it is used to control speed, torque, position and other motor functions through electronics. An agenda outlines topics to be covered, including introductions to electromagnets, motors, motor control, and specific motor types.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 90

Bridging Theory in Practice

Transferring Technical Knowledge

to Practical Applications

Introduction to Motor Control

Introduction to Motor Control

Intended Audience:

Individuals with an interest in learning about electric motors and how they are

controlled

A simple understanding of magnetics is assumed

Topics Covered:

What is an electric motor?

What are some common types of electric motors?

How do these electric motors work?

How these motors are controlled.

Expected Time:

Approximately 90 minutes

Introduction to Motor Control

Agenda

Introduction to Electromagnets and Electric

Motors

What Is Motor Control?

What Are Some Common Types of

Motors?

Permanent Magnet DC Motors

Stepper Motors

Brushless DC Motors

Summary of Motors and Motor Control

Circuits

Agenda

Introduction to Electromagnets and Electric

Motors

What Is Motor Control?

What Are Some Common Types of Motors?

Permanent Magnet DC Motors

Stepper Motors

Brushless DC Motors

Summary of Motors and Motor Control Circuits

What Is a Permanent Magnet?

A piece of iron or steel which produces a magnetic

field

Found in nature as magnetite (Fe

3

O

4

) lodestones

Magnetic field causes the permanent magnet to

attract iron and some other materials

Two ends of the permanent magnet are usually

designated North and South

Opposite magnet ends attract and like magnet ends

repel

What Is an Electromagnet?

Electromagnets behave like permanent

magnets

but their magnetic field is not

permanent

Magnetic field is temporarily induced by an

electric current

How Do You Make an

Electromagnet?

Start with an iron bar

How Do You Make an

Electromagnet?

Start with an iron bar

Wrap a wire around the iron bar

How Do You Make an

Electromagnet?

Start with an iron bar

Wrap a wire around the iron bar

Connecting a battery causes a current to flow

in the wire

Current

+

-

How Do You Make an

Electromagnet?

Start with an iron bar

Wrap a wire around the iron bar

Connecting a battery causes a current to flow in the wire

The current induces a magnetic field creating an

electromagnet

Current

SOUTH

NORTH

+

-

How Do You Make an

Electromagnet?

Reversing the current direction, reverses the

polarity

Current

+

-

NORTH

SOUTH

How Do You Make an

Electromagnet?

Reversing the current direction, reverses the

polarity

If the current is stopped, the induced magnetic field

decays to 0

Current

+

-

NORTH

SOUTH

Electromagnets and

Electric Motors

We can use electromagnets in electric motors to convert

electrical energy to mechanical work

+

Electric Motor

12V

-

Electric

Energy

Electric motors are used to

perform a mechanical task by

using electricity

Open a sunroof

Lift a power antenna

Control windshield wiper

What Is an Electric Motor?

STATOR

ROTOR

An electric motor has two basic parts:

The stationary part is called the stator.

The rotating part of the electric motor is called the

rotor.

What Is an Electric Motor?

STATOR

Electrical energy creates a rotating magnetic field

inside the motor causing the rotor to rotate,

creating mechanical motion

ROTOR

Where Are

Electric Motors Used?

Electric motors are used in many different automotive applications:

Power windows

Power seats

Power mirrors

Fans

Windshield wipers

Windshield washer pumps

Starter motor

Electric radio antennae

Door locks

Information gauges

Sunroof

Brakes

Power steering

Fuel pump

Water pump

Hybrid and electric vehicles

Cruise control

Throttle plate control

Air vents

Others

Agenda

Introduction to Electromagnets and Electric Motors

What Is Motor Control?

What Are Some Common Types of Motors?

Permanent Magnet DC Motors

Stepper Motors

Brushless DC Motors

Summary of Motors and Motor Control Circuits

The controlled application of electrical energy to a motor to

elicit a desired mechanical response

Start / Stop

Speed

Torque

Position

Significant amount of electronics may be required to

control the operation of some electric motors

What Is Motor Control ?

Control of Electromagnetics

Much of the physical design of an electric motor and its control

system are related to the switching of the electromagnetic field

There is a mechanical force which acts on a current carrying wire

within a magnetic field

The mechanical force is perpendicular to the wire and the magnetic

field

The relative magnetic fields between the rotor and stator are

arranged so that a torque is created, causing the rotor to rotate

about its axis

Agenda

Introduction to Electromagnets and Electric Motors

What Is Motor Control?

What Are Some Common Types of Motors?

Permanent Magnet DC Motors

Stepper Motors

Brushless DC Motors

Summary of Motors and Motor Control Circuits

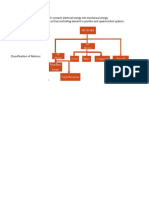

There are many different types and classifications of electric

motors:

Permanent magnet DC motor

Stepper motor

Brushless DC motor

Wound field motor

Universal motors

Three phase induction motor

Three-phase AC synchronous motors

Two-phase AC Servo motors

torque motors

Shaded-pole motor

split-phase induction motor

capacitor start motor

Permanent Split-Capacitor (PSC) motor

Repulsion-start induction-run (RS-IR) motor

Repulsion motor

Linear motor

Variable reluctance motor

Unipolar stepper motor

Bipolar stepper

Full step stepper motor

Half step stepper motor

Micro step stepper motor

Switched reluctance motor

Shaded-pole synchronous motor

Induction motor

Coreless DC motor

Others......

Types of Electric Motors

Permanent Magnet DC Motor

Similar in construction to the introductory example

Metallic contacts (brushes) are used to deliver electrical energy

Rotational speed proportional to the applied voltage

Torque proportional to the current flowing through the motor

Advantages:

+ Low cost (high volume demand)

+ Simple operation

Disadvantages:

Medium efficiency

Poor reliability (brush, commutator wear out)

Strong potential source of electromagnetic interference

Stepper Motor

Full rotation of electric motor divided into a number of "steps"

For example, 200 steps provides a 1.8

o

step angle

A stepper motor controller can move the electric motor one step (in

either direction) by applying a voltage pulse

Rotational speed is controlled by changing the frequency of the

voltage pulses

Advantages:

+ Low cost position control (instrument gauges)

+ Easy to hold position

Disadvantages:

Poor efficiency

Requires digital control interface

High motor cost

Brushless DC Motor

Similar to a permanent magnet DC motor

Rotor is always the permanent magnet (internal or external)

Design eliminates the need for brushes by using a more

complex drive circuit

Advantages:

+ High efficiency

+ High reliability

+ Low EMI

+ Good speed control

Disadvantages:

May be more expensive than "brushed" DC motors

More complex and expensive drive circuit than

"brushed" DC motors

Agenda

Introduction to Electromagnets and Electric Motors

What Is Motor Control?

What Are Some Common Types of Motors?

Permanent Magnet DC Motors

Stepper Motors

Brushless DC Motors

Summary of Motors and Motor Control Circuits

How Does a Permanent Magnet

DC Motor Work?

"DC Motors" use magnets to produce motion

Permanent magnets

NORTH SOUTH

"DC Motors" use magnets to produce motion

Permanent magnets

An electromagnet armature

How Does a Permanent Magnet

DC Motor Work?

NORTH SOUTH

NORTH SOUTH

Electromagnet armature is mounted on axle so that

it can rotate

Permanent Magnet DC Motor

Rotating Armature

NORTH SOUTH

Electromagnet armature is mounted on axle so that

it can rotate

A commutator makes an electrical contact with the

motor's brushes

Permanent Magnet DC Motor

Commutator and Brushes

Permanent Magnet DC Motor

Commutator Structure

Commutator is comprised of two "near-

halves" of a ring

Commutator is comprised of two "near-halves" of a ring

Mounted on the armature's axle to rotate with the rotor

Armature

Permanent Magnet DC Motor

Commutator Structure

Permanent Magnet DC Motor

Commutator Structure

Armature's windings are connected to the

commutator

Permanent Magnet DC Motor

Commutator and Brushes

Armature's windings are connected to the commutator

Brushes connect the commutator to the battery

NORTH SOUTH

Current flows through the armature's windings,

which polarizes the electromagnet

+

-

Permanent Magnet DC Motor

Electromagnet Polarization

NORTH SOUTH

The like magnets (NORTH-NORTH and SOUTH-SOUTH) repel

As the like magnets repel, the armature rotates, creating mechanical

motion

+

-

Permanent Magnet DC Motor

Rotation

NORTH SOUTH

What direction will the armature spin?

Clockwise? Counterclockwise?

Clockwise ?

Counterclockwise ?

Permanent Magnet DC Motor

Rotation Direction?

+

-

To determine the direction of the motor's rotation, we need

to use the "Left Hand Rule"

Permanent Magnet DC Motor

Rotation Direction?

Left Hand Rule

Start with two opposite

ends of a magnet

NORTH

SOUTH

Left Hand Rule:

Magnetic Field

NORTH

SOUTH

The magnetic field (B) is from

the NORTH pole to the

opposite SOUTH pole

The pointing finger

follows B into

screen

B

Left Hand Rule:

Current Flow

NORTH

SOUTH

Current flows in a wire through

the magnetic field from left to

right

The middle finger follows I

1

right, or I

2

left

I

1

I

2

Left Hand Rule:

Force

NORTH

SOUTH

The force, F, acting on each wire

is in the direction of the

thumb

The wire with I

1

is pushed up,

I

2

down

I

1

I

2

F

1

F

2

Left Hand Rule:

Force

NORTH

SOUTH

The magnitude of F is give by:

| F | = | I | * * | B |

where is the length of the

wire in B

I

1

I

2

F

1

F

2

Left Hand Rule:

Current Loop

NORTH

SOUTH

If the current flows in a loop,

the force(s) will cause the

loop to rotate

I

F

F

NORTH SOUTH

Magnetic field is from right to left

Imagine current flows out of the screen in this cross

section

+

-

Permanent Magnet DC Motor

Rotation

NORTH SOUTH

Magnetic field is from right to left

Imagine current flows out of the screen in this cross section

The force causes the armature to rotate clockwise

+

-

Permanent Magnet DC Motor

Rotation

NORTH SOUTH

+

-

Permanent Magnet DC Motor

Rotation

At some point, the commutator halves will rotate away

from the brushes

Momentum keeps the electromagnet and the commutator

ring rotating

NORTH SOUTH

+

-

Permanent Magnet DC Motor

Rotation

When the commutator halves reconnect with the

other brush, the current in the windings is reversed

NORTH SOUTH

+

-

Permanent Magnet DC Motor

Rotation

When the commutator halves reconnect with the

other brush, the current in the windings is reversed

The polarity is reversed and the armature continues

to rotate

+

-

NORTH SOUTH

Magnetic field is from right to left

Imagine current flows out of the screen in this cross section

The force causes the armature to rotate clockwise

+

-

Permanent Magnet DC Motor

Rotation

Controlling a Permanent Magnet

DC (PMDC) Motor

Bi-directional PM DC motors are controlled with an "H-Bridge"

circuit consisting of the motor and four power switches

Current

Turning On a PMDC Motor

One switch is closed in each leg of the "H"

One switch is open in each leg of the "H"

Current

One switch is closed in each leg of the "H"

One switch is open in each leg of the "H

Turning On a PMDC Motor

in the Other Direction

Current

Unidirectional motors are controlled by a half-H

bridge circuit

Controlling a Permanent Magnet

DC (PMDC) Motor

Controlling a PMDC Motor

Options

DC operation

Rotational speed of the DC motor is fixed at a given voltage

and load

PWM Operation

Average voltage (and rotational speed) can be controlled

by opening/closing the switches quickly

Braking

Shorting the terminals or momentarily reversing the drive

Others

Agenda

Introduction to Electromagnets and Electric Motors

What Is Motor Control?

What Are Some Common Types of Motors?

Permanent Magnet DC Motors

Stepper Motors

Brushless DC Motors

Summary of Motors and Motor Control Circuits

Why a Stepper Motor ?

Unlike the permanent magnet DC motor, stepper

motors move in discrete steps as commanded by the

stepper motor controller

Because of their discrete step operation, stepper

motors can easily be rotated a finite fraction of a

rotation

Another key feature of stepper motors is their ability

to hold their load steady once the require position is

achieved

An example application for stepper motors is for

implementing traditional "analog" instrumentation

gauges on a dashboard

How Does a

Stepper Motor Work ?

A stepper motor often has an internal rotor with a large number of

permanent magnet teeth

A large number of electromagnet "teeth" are mounted on an

external stator

Electromagnets are polarized and depolarized sequentially, causing

the rotor to spin one "step"

Full step motors spin 360

o

/(# of teeth) in each step

Half step motors spin 180

o

/(# of teeth) in each step

Microstep motors further decrease the rotation in each step

Full Step Motor Operation

`

Half Rotate

and Hold

`

Half Step Motor Operation

Half Rotate

and Hold

Stepper Motor Control

The stepper motor driver receives square wave pulse

train signals from a controller and converts the

signals into the electrical pulses to step the motor

This simple operation leads stepper motors to

sometimes be called "digital motors"

To achieve microstepping, however, the stepper

motor must be driven by a (quasi) sinusoidal current

that is expensive to implement

Agenda

Introduction to Electromagnets and Electric Motors

What Is Motor Control?

What Are Some Common Types of Motors?

Permanent Magnet DC Motors

Stepper Motors

Brushless DC Motors

Summary of Motors and Motor Control Circuits

Many of the limitations of the classic permanent magnet "brushed"

DC motor are caused by the brushes pressing against the rotating

commutator creating friction

As the motor speed is increased, brushes may not remain in

contact with the rotating commutator

At higher speeds, brushes have increasing difficulty in maintaining

contact

Sparks and electric noise may be created as the brushes

encounter flaws in the commutator surface or as the commutator

is moving away from the just energized rotor segment

Brushes eventually wear out and require replacement, and the

commutator itself is subject to wear and maintenance

Brushless DC motors avoid these problems with a modified design,

but require a more complex control system

Why a Brushless DC Motor ?

How Does a Brushless DC Motor

Work ?

A brushless DC motor uses electronic sensors to detect the

position of the rotor without using a metallic contact

Using the sensor's signals, the polarity of the electromagnets

is switched by the motor control drive circuitry

The motor can be easily synchronized to a clock signal,

providing precise speed control

Brushless DC motors may have:

An external PM rotor and internal electromagnet stator

An internal PM rotor and external electromagnet stator

This example brushless DC motor has:

An internal, permanent magnet rotor

Example Brushless DC Motor

Operation

This example brushless DC motor has:

An external, electromagnet stator

Example Brushless DC Motor

Operation

This example brushless DC motor has:

An external, electromagnet stator, with magnetic

field sensors

Example Brushless DC Motor

Operation

Brushless DC Motor

Construction

A

a

a

com

com

b

b

B

com

c

c

C

A

a

b

B

c

C

com

A

a

b

B

c

C

com

A

a

a

com

com

b

b

B

com

c

c

C

1

Brushless DC Motor Operation

A

a

b

B

c

C

com

A

a

a

com

com

b

b

B

com

c

c

C

2

Brushless DC Motor Operation

A

a

b

B

c

C

com

A

a

a

com

com

b

b

B

com

c

c

C

3

Brushless DC Motor Operation

A

a

b

B

c

C

com

A

a

a

com

com

b

b

B

com

c

c

C

4

Brushless DC Motor Operation

A

a

b

B

c

C

com

A

a

a

com

com

b

b

B

com

c

c

C

5

Brushless DC Motor Operation

A

a

b

B

c

C

com

A

a

a

com

com

b

b

B

com

c

c

C

6

Brushless DC Motor Operation

A

a

b

B

c

C

com

A

a

a

com

com

b

b

B

com

c

c

C

1

Brushless DC Motor Operation

A

a

b

B

c

C

com

A1 B1 C1

A2 B2 C2

Brushless DC Motor

Control Circuit

A

a

b

B

c

C

com

1

A1 B1 C1

A2 B2 C2

Brushless DC Motor

Control Circuit

A

a

b

B

c

C

com

2

A1 B1 C1

A2 B2 C2

Brushless DC Motor

Control Circuit

A

a

b

B

c

C

com

3

A1 B1 C1

A2 B2 C2

Brushless DC Motor

Control Circuit

A

a

b

B

c

C

com

4

A1 B1 C1

A2 B2 C2

Brushless DC Motor

Control Circuit

A

a

b

B

c

C

com

5

A1 B1 C1

A2 B2 C2

Brushless DC Motor

Control Circuit

A

a

b

B

c

C

com

6

A1 B1 C1

A2 B2 C2

Brushless DC Motor

Control Circuit

Brushless DC Motor

Control Circuit

A

a

b

B

c

C

com

1

A1 B1 C1

A2 B2 C2

Agenda

Introduction to Electromagnets and Electric Motors

What Is Motor Control?

What Are Some Common Types of Motors?

Permanent Magnet DC Motors

Stepper Motors

Brushless DC Motors

Summary of Motors and Motor Control Circuits

+

An electric motor converts electric energy into

mechanical motion

Electric Motor

12V

-

Electric

Energy

Electric motors are used to

perform a mechanical task by

using electricity

Open a sunroof

Lift a power antenna

Control windshield wiper

What Is an Electric Motor?

Permanent Magnet Stepper Brushless DC

DC Motor Motor Motor

Advantages: + Low cost + Position control + High efficiency

(high volume) (low cost + High reliability

+ Simple operation control circuits) + Low EMI

+ Speed control

Disadvantages: - Medium efficiency - Poor efficiency - Maybe higher cost

- Poor reliability - Digital interface - Complex control

- Bad EMI - High cost

Types of Electric Motors

Agenda

Introduction to Electromagnets and Electric Motors

What Is Motor Control?

What Are Some Common Types of Motors?

Permanent Magnet DC Motors

Stepper Motors

Brushless DC Motors

Summary of Motors and Motor Control Circuits

Introduction to Motor Control

Thank you!

www.btipnow.com

S-ar putea să vă placă și

- Bridging Theory in Practice: Transferring Technical Knowledge To Practical ApplicationsDocument90 paginiBridging Theory in Practice: Transferring Technical Knowledge To Practical Applicationskali_eee05100% (1)

- Electric MachineDocument45 paginiElectric MachineravihbtiÎncă nu există evaluări

- LEC - 05 (DC Machines)Document23 paginiLEC - 05 (DC Machines)zain malik100% (1)

- MotorDocument19 paginiMotorRabi khanÎncă nu există evaluări

- CNCDocument63 paginiCNCSahil Bangia100% (1)

- Mod5 - MECHATRONICS IN ROBOTICSDocument34 paginiMod5 - MECHATRONICS IN ROBOTICSDeepa Ragav RÎncă nu există evaluări

- Actuators: Department of E&E EngineeringDocument14 paginiActuators: Department of E&E Engineeringmanavi naikÎncă nu există evaluări

- Electric MotorsDocument20 paginiElectric MotorsJulie Ann CortezÎncă nu există evaluări

- Electrical Motors: ECE131 Basic Electrical & Electronics EnggDocument58 paginiElectrical Motors: ECE131 Basic Electrical & Electronics EnggVinamra MittalÎncă nu există evaluări

- MotorsDocument36 paginiMotorsscorpionarnold100% (1)

- MCT 5.1Document70 paginiMCT 5.1Alfred CheriyanÎncă nu există evaluări

- ActuatorsDocument88 paginiActuatorsMrs. Prabha Niranjan NMAMIT E & EÎncă nu există evaluări

- AGK - Electrics 16 DC Motors 16 S2Document16 paginiAGK - Electrics 16 DC Motors 16 S2Cemalettin öztoprakÎncă nu există evaluări

- 1 Fundamentals of Electric Motors v2Document21 pagini1 Fundamentals of Electric Motors v2Daejoong KimÎncă nu există evaluări

- On Ac MotorsDocument14 paginiOn Ac Motorspurna reddyÎncă nu există evaluări

- UNIT-3 Robot Drive MechanisamDocument82 paginiUNIT-3 Robot Drive MechanisamChetuÎncă nu există evaluări

- Sigma Institute of Engineering Department of Electrical Engineering Bakrol, VadodaraDocument52 paginiSigma Institute of Engineering Department of Electrical Engineering Bakrol, VadodaraBhavik PrajapatiÎncă nu există evaluări

- Induction Motors: Presentation by S.R.Paraskar Electrical Dept SSGMCEDocument22 paginiInduction Motors: Presentation by S.R.Paraskar Electrical Dept SSGMCEdoss mÎncă nu există evaluări

- Single Phase Induction MotorDocument24 paginiSingle Phase Induction MotorKh Muhammad MashoodÎncă nu există evaluări

- Unit 2: Electrical Actuation SystemsDocument47 paginiUnit 2: Electrical Actuation SystemsHariprasadÎncă nu există evaluări

- BLDC & PMDC MotorDocument29 paginiBLDC & PMDC MotorxfgngfbhsehÎncă nu există evaluări

- Single Phase Induction MotorDocument25 paginiSingle Phase Induction Motordumpy100% (1)

- Single Phase Induction MotorDocument25 paginiSingle Phase Induction MotorKh Muhammad Mashood0% (1)

- Electrical Motors EPDI2013Document51 paginiElectrical Motors EPDI2013neocentricgeniusÎncă nu există evaluări

- Week 14 - 1Document13 paginiWeek 14 - 1M. HamzaÎncă nu există evaluări

- Actuation SystemsDocument52 paginiActuation SystemsJkl MahanthÎncă nu există evaluări

- Module 5 Notes MTRDocument14 paginiModule 5 Notes MTRAbhijith JoseÎncă nu există evaluări

- Group 6 - DC Motors PDFDocument22 paginiGroup 6 - DC Motors PDFRashen DilÎncă nu există evaluări

- Lecture#5Document35 paginiLecture#520pwmct0739Încă nu există evaluări

- Working Principle of DC Motor & Back EMFDocument13 paginiWorking Principle of DC Motor & Back EMFsatyammishra1907Încă nu există evaluări

- Lec 18Document29 paginiLec 18Asher RizviÎncă nu există evaluări

- DC MotorDocument10 paginiDC MotorNagesh KolteÎncă nu există evaluări

- Electric Motors Year 8Document25 paginiElectric Motors Year 8M Rameez Ul HassanÎncă nu există evaluări

- AnimatedDocument18 paginiAnimatedfieraminaÎncă nu există evaluări

- Type of NC SystemDocument20 paginiType of NC Systemamit kumarÎncă nu există evaluări

- Chapter 1: Introduction To Electrical Machines Acm 03 - DC and Ac MachineryDocument14 paginiChapter 1: Introduction To Electrical Machines Acm 03 - DC and Ac MachineryGlaze GregorioÎncă nu există evaluări

- Single Phase Induction Motor and Special Electrical MachinesDocument22 paginiSingle Phase Induction Motor and Special Electrical MachinesRajesh Babu100% (2)

- DC MotorsDocument45 paginiDC Motorstristan jeff bautistaÎncă nu există evaluări

- Mechatronics MotorsDocument39 paginiMechatronics MotorsSanskar AgrawalÎncă nu există evaluări

- EM CH-4-5-6 Ac MachinesDocument80 paginiEM CH-4-5-6 Ac Machinesmuhammad.anas2007Încă nu există evaluări

- Beee-Unit 3Document54 paginiBeee-Unit 3Sano ManjiroÎncă nu există evaluări

- Induction MotorDocument15 paginiInduction MotorgireeshÎncă nu există evaluări

- DownloadfileDocument16 paginiDownloadfilemadanacharjya449Încă nu există evaluări

- Introduction To DC Machine: by Dr. Shubhobrata RudraDocument129 paginiIntroduction To DC Machine: by Dr. Shubhobrata RudraBhabani sankar KishanÎncă nu există evaluări

- Module 5 ElectricalDocument22 paginiModule 5 ElectricalSKANDAN BHARADWAJÎncă nu există evaluări

- Lab 3b PPT - Series MotorDocument23 paginiLab 3b PPT - Series MotorLiaqat AliÎncă nu există evaluări

- Simple Ac GeneratorDocument17 paginiSimple Ac GeneratorRishi singhÎncă nu există evaluări

- Introduction To DC Electric MotorsDocument31 paginiIntroduction To DC Electric MotorsJames Adrian Abalde SaboÎncă nu există evaluări

- AC and DC Electric MotorsDocument6 paginiAC and DC Electric Motorsroco_rasim100% (1)

- Induction MotorDocument29 paginiInduction Motordumpy100% (1)

- DC MotorDocument2 paginiDC MotorShailesh RanawareÎncă nu există evaluări

- AC Motors: AC Motors Convert AC Electrical Energy To Mechanical EnergyDocument18 paginiAC Motors: AC Motors Convert AC Electrical Energy To Mechanical EnergyIslam FouadÎncă nu există evaluări

- Bee Unit-4Document49 paginiBee Unit-4Aarush PitlaÎncă nu există evaluări

- Brushless DC MotorDocument19 paginiBrushless DC MotorAnonymous M8PzfJmÎncă nu există evaluări

- BEE (21EEE15A) Module 3BDocument49 paginiBEE (21EEE15A) Module 3BG46Anand P KÎncă nu există evaluări

- PMBLDC Motor DriveDocument55 paginiPMBLDC Motor DriveSushant SinghÎncă nu există evaluări

- G10 Science Q2-Week 9-ELECTRIC MOTORS - GENERATORSDocument29 paginiG10 Science Q2-Week 9-ELECTRIC MOTORS - GENERATORSKarina GentonÎncă nu există evaluări

- Basics and Working of AC Motors & Basics of Power GeneratorDocument37 paginiBasics and Working of AC Motors & Basics of Power GeneratorYasir ShaikhÎncă nu există evaluări

- Chapter 4Document37 paginiChapter 4Atul Jaysing PatilÎncă nu există evaluări

- Pmic Safety Detroit TechdayDocument61 paginiPmic Safety Detroit Techdays.b.v.seshagiri1407Încă nu există evaluări

- ZD 007 Sample Definition Project Management ENDocument1 paginăZD 007 Sample Definition Project Management ENs.b.v.seshagiri1407Încă nu există evaluări

- Gowda2019 ECU Inter - Processor Data CommunicationDocument11 paginiGowda2019 ECU Inter - Processor Data Communications.b.v.seshagiri1407Încă nu există evaluări

- QEP en Quality Requirements For SamplesDocument3 paginiQEP en Quality Requirements For Sampless.b.v.seshagiri1407Încă nu există evaluări

- AURIX MultiCore Lauterbach HandoutDocument56 paginiAURIX MultiCore Lauterbach Handouts.b.v.seshagiri1407Încă nu există evaluări

- Adc Student: Andrew Brown Jonathan Warner Laura StricklandDocument51 paginiAdc Student: Andrew Brown Jonathan Warner Laura Stricklands.b.v.seshagiri1407Încă nu există evaluări

- H Da Barth Functional Safety On MulticoreDocument23 paginiH Da Barth Functional Safety On Multicores.b.v.seshagiri1407Încă nu există evaluări

- Introduction To Electronic DesignDocument18 paginiIntroduction To Electronic Designs.b.v.seshagiri1407Încă nu există evaluări

- Analytical Study of Sense AmplifierDocument5 paginiAnalytical Study of Sense Amplifiers.b.v.seshagiri1407Încă nu există evaluări

- 07 DRITSANOS IoT-Conference Schneider-ElectricDocument13 pagini07 DRITSANOS IoT-Conference Schneider-Electrics.b.v.seshagiri1407Încă nu există evaluări

- L17 FET DC AnalysisDocument19 paginiL17 FET DC Analysiss.b.v.seshagiri1407Încă nu există evaluări

- Electronic Stability Control: NHTSA's Notice of Proposed RulemakingDocument18 paginiElectronic Stability Control: NHTSA's Notice of Proposed Rulemakings.b.v.seshagiri1407Încă nu există evaluări

- Introduction To Electronic DesignDocument18 paginiIntroduction To Electronic Designs.b.v.seshagiri1407Încă nu există evaluări

- Robot Chassis and Drivetrain FundamentalsDocument65 paginiRobot Chassis and Drivetrain Fundamentalss.b.v.seshagiri1407Încă nu există evaluări

- Software Testing and ReliabilityDocument77 paginiSoftware Testing and Reliabilitys.b.v.seshagiri1407Încă nu există evaluări

- Em1 2marksDocument9 paginiEm1 2marksSuryaÎncă nu există evaluări

- SEEA1601Document104 paginiSEEA1601skrtamilÎncă nu există evaluări

- BMW Starting SystemsDocument15 paginiBMW Starting Systemsgraig27Încă nu există evaluări

- 115826010Document166 pagini115826010ashvinÎncă nu există evaluări

- Section 16.5 Simple D.C. MotorDocument13 paginiSection 16.5 Simple D.C. Motortwy113Încă nu există evaluări

- Unit-2 - DC Machines PDFDocument123 paginiUnit-2 - DC Machines PDFsujithÎncă nu există evaluări

- CARBOTECH - Technical PresentationDocument37 paginiCARBOTECH - Technical PresentationpiojeziorÎncă nu există evaluări

- Electromechanical Systems CH 4Document64 paginiElectromechanical Systems CH 4fabrice mellantÎncă nu există evaluări

- 03 S Sankaran Energy Eff DesignDocument64 pagini03 S Sankaran Energy Eff DesignVignesh BalajiÎncă nu există evaluări

- Questions On Electrical Machine Applications Armature Reaction and CommutationDocument12 paginiQuestions On Electrical Machine Applications Armature Reaction and Commutationkibrom atsbhaÎncă nu există evaluări

- Working Principle of A DC Motor - Circuit GlobeDocument6 paginiWorking Principle of A DC Motor - Circuit GlobeHumair AhmedÎncă nu există evaluări

- MTS-231 Actuating Systems: Kanwal NaveedDocument21 paginiMTS-231 Actuating Systems: Kanwal NaveedARSLAN FALAKÎncă nu există evaluări

- IEEE STD ANSI-IEEE STD 116-1975Document12 paginiIEEE STD ANSI-IEEE STD 116-1975abdou samiÎncă nu există evaluări

- AN BLDC Sensorless Control ENG MCUMON-0 PDFDocument37 paginiAN BLDC Sensorless Control ENG MCUMON-0 PDFDoDuyBacÎncă nu există evaluări

- Summary of DC GeneratorDocument10 paginiSummary of DC GeneratorChristopher YsitÎncă nu există evaluări

- 3 CNC PPT Lecture 2 DoneDocument38 pagini3 CNC PPT Lecture 2 DoneSidhant AryaÎncă nu există evaluări

- Vapour Compression Refrigeration CycleDocument44 paginiVapour Compression Refrigeration CycleSayaliRewaleÎncă nu există evaluări

- Electrical Machines: DC GeneratorDocument34 paginiElectrical Machines: DC GeneratorMarc Joshua MACATANGAYÎncă nu există evaluări

- Answer For WorksheetDocument4 paginiAnswer For Worksheetabene danÎncă nu există evaluări

- (04-01) - StarterDocument3 pagini(04-01) - StartereduardoÎncă nu există evaluări

- ANSUMAN SHARMA 109ee0305 Department of ELECTRICAL Engineering, NIT RourkelaDocument1 paginăANSUMAN SHARMA 109ee0305 Department of ELECTRICAL Engineering, NIT RourkelaAnsuman Sharma100% (1)

- GEQParts CatalogDocument7 paginiGEQParts CatalogIRWIN_DSOUZAÎncă nu există evaluări

- 19 - Galvanometers & Electric MotorsDocument3 pagini19 - Galvanometers & Electric MotorsgavinilaaÎncă nu există evaluări

- Catalog Switchboard InstrumentsDocument42 paginiCatalog Switchboard InstrumentsFlo MircaÎncă nu există evaluări

- Group Number - 17: Prof. Saifullah PayamiDocument7 paginiGroup Number - 17: Prof. Saifullah PayamiMayank SinghÎncă nu există evaluări

- Pitanja Iz Engleskog-PrevodDocument1 paginăPitanja Iz Engleskog-PrevodZvonimirDelićÎncă nu există evaluări

- Salminen NikoDocument26 paginiSalminen Nikohashem AliÎncă nu există evaluări

- 45 16255 EE321 2015 1 1 1 Week 9 10Document22 pagini45 16255 EE321 2015 1 1 1 Week 9 10Zakaria MaazazÎncă nu există evaluări

- BTech EE 20211Document127 paginiBTech EE 20211Anurag DavesarÎncă nu există evaluări

- Chapter 3 ConceptsDocument5 paginiChapter 3 ConceptsEzequiel Posadas BocacaoÎncă nu există evaluări