Documente Academic

Documente Profesional

Documente Cultură

Final PPT On Life Cycle Cost Analysis

Încărcat de

Bharath Kumar M100%(1)100% au considerat acest document util (1 vot)

354 vizualizări33 paginilife cycle cost analysis of flexible and regid pavement.

Titlu original

final ppt on life cycle cost analysis

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPTX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentlife cycle cost analysis of flexible and regid pavement.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

354 vizualizări33 paginiFinal PPT On Life Cycle Cost Analysis

Încărcat de

Bharath Kumar Mlife cycle cost analysis of flexible and regid pavement.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 33

UNDER THE GUIDENCE OF

Dr. P. NANJ UNDASWAMY

1

LIFE CYCLE COST ANALYSIS OF

FLEXIBLE AND RIGID PAVEMENT A CASE

STUDY

Presented by

Bharath Kumar. M

Hanumantha M

Mamatha S

Pooja S

Vijaya Kumar A C

Introduction

Objectives

RBI Grade 81

Laboratory studies

Pavement design

Life cycle cost analysis

Results and Discussion

2

Contents

3

Introduction

Project location

5

Objectives of the project

To identify the design requirements for

the proposed upgradation of project road.

To evaluate the effect of RBI grade 81

chemical on CBR property of subgrade

soil.

To develop electronic spread sheets for

designing flexible and rigid pavements for

high volume roads as per IRC guide lines

using Microsoft excel.

6

To design both flexible and rigid

pavement structure on treated and

untreated subgrade soil as per IRC

guidelines using the developed spread

sheet.

To perform the life cycle cost analysis

for economic evaluation of alternative

designs considered

Methodology

Collection of data with respect to present

and future traffic scenario on the project

road.

Collection of subgrade soil samples from

various locations and to evaluate the

basic properties needed for classification

on and design requirements.

Formulate the procedure for designing

flexible and rigid pavement as per the

present IRC guidelines and automate

the design process by implementing the

procedure in an electronic spread sheet

(Microsoft Excel).

Implement the process of life cycle cost

analysis in an electronic spread sheet for

choice of alternative pavement solutions

on the basis of economic consideration.

9

RBI Grade 81

10

Composition of RBI Grade 81

Contents Percentage

Ca 25-45

S 5-15

Si 5-20

K 0-5

Mg 0-10

Al 0-5

Fe 0-5

Zn 0-2

Cu 0-2

Mn 0-2

11

Laboratory Studies

Grain size distribution analysis as per IS 1498 :

1970

Atterberg

s limits as per IS 2720 (Part V ) 1985

Modified proctor compaction test as per IS 2720

(part Vlll)

California bearing test as per IS 2720 (Part XVl)

12

Tests conducted

Gradation results of untreated subgrade

soil

13

No. Chainage

Wet sieve analysis

%Gravel %Sand %Silt & clay

1 127-120 2 75.00 23.00

2 128-530 0.40 71.80 27.80

3 129-120 4.80 76.40 18.80

4 132-500 4.80 54.80 40.40

5 134-000 19 80.20 0.80

14

Atterbergs limits of untreated subgade soil

No Chainage LL(%) PL(%)

1 127-120 35.00 21.00

2 128-530 Non plastic soil Non plastic soil

3 129-120 27.50 19.00

4 132-500 33.00 18.00

5 134-000 46.50 23.00

Soil classification of untreated

subgrade soil

Chainage Type of soil

127-120

Clayey sand (SC)

128-120

Clayey sand (SC)

129-120

Clayey sand (SC)

132-500

Clayey sand (SC)

134-00

Well graded sand(SW)

16

Moisture density test results of untreated

subgrade soils

No. Chainage

Compaction Test

OMC (%) MDD (gm/cc)

1 127 - 120 12.50 2.085

2 128 - 530 08.30 2.265

3 128 - 120 09.33 2.060

4 132 - 500 11.30 2..230

5 134 - 000 10.50 2.240

17

CBR Test results of untreated subgrade

soils

No Chainage CBR(%)

1 127 - 120 4

2 128 - 530 14

3 128 - 120 13

4 132 - 500 7

5 134 - 000 5

CBR Test results of stabilized

subgrade soil using RBI grade 81

Chainage % of Stabilizer Curing period CBR (%)

127-120

4

3days

29

6 36

134-000

2

3days

20

4 28

DESIGN OF FLEXIBLE PAVEMENT AS PER

IRC 37-2011(DRAFT CODE)

Flexible pavement design thickness of

untreated subgrade soil

CHAINAGE 127-120 128-530 129-120 132-500 134-00

CBR(%) 4 14 13 7 5

TOTAL

THICKNESS

770 590 590 645 720

WEARING

COURSE(mm)

50 50 50 50 50

BINDER

COURSE(mm)

140 90 90 115 120

GRANULAR

BASE(mm)

250 250 250 250 250

GRANULAR

SUBBASE(mm)

330 200 200 230 300

Flexible pavement design thickness of

treated subgrade soil

CHAINAGE 127-120 134-000

% of stabilizer 4 6 2 4

Effective CBR (%) 13 16 14 15

TOTAL

THICKNESS

590 590 590 590

WEARING

COURSE(mm)

50 50 50 50

BINDER

COURSE(mm)

90 90 90 90

GRANULAR

BASE(mm)

250 250 250 250

GRANULAR

SUBBASE(mm)

200 200 200 200

Design of Rigid pavement as per

IRC 58-2010

Rigid pavement design thickness for untreated

sub grade soil

Chainage CBR (%) K(Mpa) Thickness(m)

127-120 4 35 0.3

128-120 14 60 0.29

129-120 13 59 0.29

132-500 7 48 0.3

134-00 5 42 0.3

Chainage

% of

Stabilizers

CBR(%)

Effective

CBR

K(Mpa)

Thickness

(m)

127-120

4 29 15 61 0.28

6 36 16 63 0.28

134-00

2 20 14 60 0.28

4 28 17 63 0.28

Pavement design thickness for

treated subgrade soil

LCCA OF FLEXIBLE AND RIGID PAVEMENT

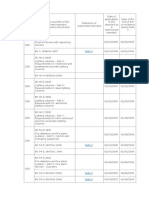

Rate adopted for LCCA

Pavement crust Rate /cu m (Rs)

BC 4762

DBM 4144

WMM 750

GSB1 720

Prime coat 16

Tack coat 10

PQC 3932

DLC 1563

RBI grade 81 30

Total life cycle Cost Estimate for

Rigid pavement

Life cycle cost cost (Lakhs)

Initial cost 11789750

Maintenance cost

Joint seal 682500

Concrete spalling 33600

Texturing 640000

Total 12505850

RESULTS

By addition RBI grade 81 to the untreated

subgrade soil at 2%, 4% & 6% increases the

CBR value by 300%, 600% & 800%

respectively.

In case of Flexible pavement due to increase in

the CBR value of subgrade soil the pavement

thickness decreases by 23% from 770mm to

590 mm.

In case of Rigid pavement due to increase in the

CBR value of subgrade soil the pavement

thickness decreases by 7% from 300mm to

280mm.

In LCCA the cost of Flexible pavement

is 46% more compare to rigid

pavement for untreated soil.

In LCCA the cost of rigid pavement

decreases 26% as compare to flexible

pavement for treated soil for treated

soil

CONCLUSSION

By using small dosage of RBI grade 81, there is

substantial increase in the CBR value of subgrades

soil and also there will be considerable amount of

reduction in pavement thickness, therefore usage

of chemical stabilizer, RBI 81 proves to be highly

cost effective.

For both the untreated and treated cases the total

life cycle cost of rigid pavement is less compared

to flexible pavement, so rigid pavement is more

economical.

Life cycle cost analysis is more scientific

approach for the economic evaluation of alternative

design solution and for choosing the best

alternative.

REFERENCES

IRC: 37-2011(draft), Indian road congress

methods of design for flexible pavement

Guidelines for the Design of flexible pavements.

IRC: 58 -2010, Indian road congress Guidelines

for the Design of Rigid pavements.

IS: 2720-Part5 (1980), Indian standard methods

of test for soils: Determination of Atterberg Limit,

Bureau of Indian Standards, New Delhi.

IS: 2720-Part4 (1980), Indian standard methods

of test for soils: Determination of Grain Size

Analysis, Bureau of Indian Standards, New Delhi.

IS: 2720-Part16 (1980), Indian standard methods

of test for soils: Determination of CBR values for 4

days soaked soil, Bureau of Indian Standards, New

Delhi.

IS: 1498(1970), Indian standard methods of test

for soils: Determination of Soil Classification,

Bureau of Indian Standards, New Delhi.

IS: 2720-Part8 (1970), Indian standard methods of

test for soils: Determination Dry density of Soil,

Bureau of Indian Standards, New Delhi.

Kadiyali L.R, (2011), Highway Engineering, 8

th

Edition, Inc. New Yark.

Khanna S.K., C.E.G.Justo (1971), Highway

Engineering, 9

th

Edition, Nem Chand & Bros, Civil

Lines, Roorkee 247 667 India.

Khanna S.K., C.E.G.Justo (1971), Highway

material testing, 9

th

Edition, Nem Chand & Bros,

Civil Lines, Roorkee 247 667 India.

Steven M.Waalkes, Life Cycle Cost Analysis: A

Guide for Comparing Alternate Pavement designs,

American Concrete pavement Association, Illinois

S-ar putea să vă placă și

- Life Cycle Cost AnalysisDocument36 paginiLife Cycle Cost AnalysisNIDHI JARIWALAÎncă nu există evaluări

- 44 CA Final Costing TheoryDocument38 pagini44 CA Final Costing TheoryJoydeep AdakÎncă nu există evaluări

- Volume 3 Part III Gravel Roads ManualDocument64 paginiVolume 3 Part III Gravel Roads ManualTracy KevinÎncă nu există evaluări

- Chapter 3 PDFDocument17 paginiChapter 3 PDF123Încă nu există evaluări

- Aor 41-82Document122 paginiAor 41-82Engr SwapanÎncă nu există evaluări

- 2 Replacement AnalysisDocument10 pagini2 Replacement AnalysisKrishna BirlaÎncă nu există evaluări

- BitumenDocument31 paginiBitumenPriyank Godhat100% (1)

- Lec 4 - Road MaterialsDocument51 paginiLec 4 - Road MaterialsRuel B. Ramos Jr.Încă nu există evaluări

- Study On Project Schedule and Cost OverrDocument162 paginiStudy On Project Schedule and Cost OverrWilliam Chipofya100% (1)

- Whole Life Costing of RoadsDocument105 paginiWhole Life Costing of RoadsZaheer DoomahÎncă nu există evaluări

- (26-33) Pavement Maintenance Management System - Revised-FormatDocument8 pagini(26-33) Pavement Maintenance Management System - Revised-FormatAmul ShresthaÎncă nu există evaluări

- Highway 1Document3 paginiHighway 1Cyrille CabungcalÎncă nu există evaluări

- Assignment 30% Construction Economics and Finance COTM 6021Document6 paginiAssignment 30% Construction Economics and Finance COTM 6021Mengstagegnew0% (1)

- 10 - Level of ServiceDocument24 pagini10 - Level of ServiceTrivesh MakenÎncă nu există evaluări

- Stabilization of Black Cotton Soil Using Fly AshDocument9 paginiStabilization of Black Cotton Soil Using Fly AshIJRASETPublicationsÎncă nu există evaluări

- Value EngineeringDocument10 paginiValue EngineeringSudeep D'SouzaÎncă nu există evaluări

- Building Economics Life Cycle Cost AnalysisDocument4 paginiBuilding Economics Life Cycle Cost AnalysisPrdeep SinghÎncă nu există evaluări

- Engineering Economics: ST ND RD TH THDocument4 paginiEngineering Economics: ST ND RD TH THniteshÎncă nu există evaluări

- Design Report of Sae Baja IndiaDocument9 paginiDesign Report of Sae Baja Indiagobajasaeindia67% (3)

- Analysis of Flexible Pavements Using IIT Pave: Harish G RDocument4 paginiAnalysis of Flexible Pavements Using IIT Pave: Harish G RArchan ChakrabortyÎncă nu există evaluări

- Chap 8Document61 paginiChap 8Mekdelawit TewodrosÎncă nu există evaluări

- Rigid Versus Flexible Pavement DesignDocument3 paginiRigid Versus Flexible Pavement DesignAlbertJnBaptisteÎncă nu există evaluări

- Highway & Railway Engineering: Dr. Siddharth S.M.P. Assistant Professor Thiagarajar College of EngineeringDocument38 paginiHighway & Railway Engineering: Dr. Siddharth S.M.P. Assistant Professor Thiagarajar College of EngineeringPraveen KumarÎncă nu există evaluări

- Comparative Highway Bridge Design LDA0802 PDFDocument236 paginiComparative Highway Bridge Design LDA0802 PDFanith kumar rÎncă nu există evaluări

- Transportation PlanningDocument20 paginiTransportation PlanningPenelope MalilweÎncă nu există evaluări

- Green Concrete: By: Abhinav Srivastava 3 B. Tech. Civil Engg. February 2011Document36 paginiGreen Concrete: By: Abhinav Srivastava 3 B. Tech. Civil Engg. February 2011Abhinav Srivastava85% (13)

- Developing A Computer-Aided Methodology For District Road Network Planning and Prioritization in NepalDocument31 paginiDeveloping A Computer-Aided Methodology For District Road Network Planning and Prioritization in NepalChandra Bahadur ShresthaÎncă nu există evaluări

- Chapter-3 Construction Equipment ManagementDocument92 paginiChapter-3 Construction Equipment ManagementDivya TadepalliÎncă nu există evaluări

- Textbook Scan0001Document17 paginiTextbook Scan0001MoNa MatoutÎncă nu există evaluări

- Irc Specification ListDocument16 paginiIrc Specification Listravikesh pathakÎncă nu există evaluări

- Benkelman BeamDocument28 paginiBenkelman BeamPandu PermanaÎncă nu există evaluări

- Flexible Pavement Overlay DesignDocument28 paginiFlexible Pavement Overlay Designgyan100% (1)

- Design and Cost Estimation of PavementsDocument1 paginăDesign and Cost Estimation of PavementsDharma banothuÎncă nu există evaluări

- Pavement DesignDocument10 paginiPavement DesignkevalÎncă nu există evaluări

- S CurveDocument3 paginiS Curveamal_millstone07@yahoo.comÎncă nu există evaluări

- Hybrid Annuity Model For Highway Projects: Ministry of Road Transport & Highways Government of IndiaDocument60 paginiHybrid Annuity Model For Highway Projects: Ministry of Road Transport & Highways Government of IndiaArunava Sengupta100% (1)

- Road Survey and Quantity CalculationDocument25 paginiRoad Survey and Quantity CalculationHarish joshiÎncă nu există evaluări

- Types of DrainageDocument2 paginiTypes of DrainageSandeep VaishnavÎncă nu există evaluări

- Prioritization of Accident Black Spots in KeralaDocument6 paginiPrioritization of Accident Black Spots in KeralaInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- 002 - Preliminary SectionsDocument17 pagini002 - Preliminary SectionssamÎncă nu există evaluări

- 6 Chapter Six-Equipment Life and Replacement AnalysisDocument24 pagini6 Chapter Six-Equipment Life and Replacement AnalysisFiraol TayeÎncă nu există evaluări

- Intro To Transportation Engineering & Typical Cross-Section Elements of HighwaysDocument77 paginiIntro To Transportation Engineering & Typical Cross-Section Elements of HighwaysMuhammad Faisal GauheerÎncă nu există evaluări

- Basic Highway Design Checklist PDFDocument13 paginiBasic Highway Design Checklist PDFirfan_960Încă nu există evaluări

- Chapter II The Transport Planning Process 15344Document26 paginiChapter II The Transport Planning Process 15344Izedin KindieÎncă nu există evaluări

- Pavement Design PhilosophyDocument35 paginiPavement Design PhilosophyMadhavpokale100% (2)

- 2 Text Book Project Risk Management Rev-3 (Final)Document14 pagini2 Text Book Project Risk Management Rev-3 (Final)Ajay MalikÎncă nu există evaluări

- Master Circular On Gati Shakti Cargo Terminals (GCT) 'Document21 paginiMaster Circular On Gati Shakti Cargo Terminals (GCT) 'gopi bhupathiÎncă nu există evaluări

- Economic Feasibility Analysis of Highway Project Using Highway Development and Management (HDM-4) ModelDocument4 paginiEconomic Feasibility Analysis of Highway Project Using Highway Development and Management (HDM-4) ModelSUMIT KUMARÎncă nu există evaluări

- 1.4 General Managment PrinciplesDocument25 pagini1.4 General Managment Principlesyodit.fekaduÎncă nu există evaluări

- VDFDocument1 paginăVDFNaqvi AÎncă nu există evaluări

- Major Construction Equipment Used inDocument2 paginiMajor Construction Equipment Used inAnzsherinah Sebastian Gumiho100% (1)

- Neilsoft A. Aptitude Test:: Technical Questions: Difference Between 1Document2 paginiNeilsoft A. Aptitude Test:: Technical Questions: Difference Between 1avinashbamneÎncă nu există evaluări

- Replacement of Cement Using Fly AshDocument22 paginiReplacement of Cement Using Fly Ashkaushal yadavÎncă nu există evaluări

- CHAPTER - 7 Structural DesignDocument32 paginiCHAPTER - 7 Structural Designzakaria100% (1)

- Types of Surface Dressing Note03 PDFDocument3 paginiTypes of Surface Dressing Note03 PDFVictorÎncă nu există evaluări

- RBI Grade 81Document67 paginiRBI Grade 81smkrishnan89100% (1)

- Flexible Pavement IITDocument39 paginiFlexible Pavement IITAmit Ruchi Yadav100% (1)

- Layers of Flexible PavementDocument52 paginiLayers of Flexible Pavementsavan chavanÎncă nu există evaluări

- Pavement Design Method NewDocument61 paginiPavement Design Method NewPrakash BhandariÎncă nu există evaluări

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeDe la EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeÎncă nu există evaluări

- Foundation SettlementDocument25 paginiFoundation SettlementBharath Kumar MÎncă nu există evaluări

- Poli and Its EffectDocument6 paginiPoli and Its EffectBharath Kumar MÎncă nu există evaluări

- Department of Backward Classes Welfare: Pending at Verification Officer For VerificationDocument1 paginăDepartment of Backward Classes Welfare: Pending at Verification Officer For VerificationBharath Kumar MÎncă nu există evaluări

- SR 2011-12 PWD Mys CircleDocument773 paginiSR 2011-12 PWD Mys CircleBharath Kumar MÎncă nu există evaluări

- Design of Flexible PavementDocument3 paginiDesign of Flexible PavementBharath Kumar MÎncă nu există evaluări

- R395k Seal Reseal Design Calculation Sheet 2Document17 paginiR395k Seal Reseal Design Calculation Sheet 2Mukhlis ChiefÎncă nu există evaluări

- Tatrapan 8x8 CCDocument6 paginiTatrapan 8x8 CCKonradK.Rybacki100% (1)

- Civil Engineer Resume - Sample 1Document4 paginiCivil Engineer Resume - Sample 1anandkumarrs6Încă nu există evaluări

- Engineering Impact Assessment of Asphalt PlantDocument26 paginiEngineering Impact Assessment of Asphalt PlantSaxum AquaSamuelÎncă nu există evaluări

- Module 3: Man, Machine & Environment ReviewDocument4 paginiModule 3: Man, Machine & Environment ReviewNelson PerezÎncă nu există evaluări

- Luganville Beautification Design BriefDocument26 paginiLuganville Beautification Design BriefJ Hunter SizemoreÎncă nu există evaluări

- DUPA PoW MASBATEDocument122 paginiDUPA PoW MASBATEIrene Ionie Rarangol - TengcoÎncă nu există evaluări

- American M35 Army TruckDocument4 paginiAmerican M35 Army TruckEnis LatićÎncă nu există evaluări

- OPSS 206 Nov09 (Nov10)Document19 paginiOPSS 206 Nov09 (Nov10)Haley ThompsonÎncă nu există evaluări

- En Standards For Construction MaterialsDocument50 paginiEn Standards For Construction MaterialsAnonymous xqokgZ3GÎncă nu există evaluări

- Traffic Violation Detection System Based On RFIDDocument5 paginiTraffic Violation Detection System Based On RFIDInternational Journal of Science and Engineering InvestigationsÎncă nu există evaluări

- L&T-built Iconic Durgam Cheruvu Cable Stay Bridge Dedicated To The People of HyderbadDocument2 paginiL&T-built Iconic Durgam Cheruvu Cable Stay Bridge Dedicated To The People of HyderbadIndra MishraÎncă nu există evaluări

- Amberg Engineering Ag: Trockenloostrasse, Postfach 27 CH-8105 Regensdorf-WattDocument1 paginăAmberg Engineering Ag: Trockenloostrasse, Postfach 27 CH-8105 Regensdorf-WattDebasis BarmanÎncă nu există evaluări

- HHS Musical Sets Sail This Week: Planting A New Seed: Humboldt Business ExpandsDocument24 paginiHHS Musical Sets Sail This Week: Planting A New Seed: Humboldt Business ExpandshumboldtnewsÎncă nu există evaluări

- Icao Standards & Recommended PracticesDocument24 paginiIcao Standards & Recommended PracticesrmaffireschoolÎncă nu există evaluări

- Report On Pushrod SuspensionDocument33 paginiReport On Pushrod SuspensionAshish Rawat100% (4)

- MS 825-4 2012 - Code of Practice For The Design of Road Lighting - Performance RequirementsDocument20 paginiMS 825-4 2012 - Code of Practice For The Design of Road Lighting - Performance RequirementsCharles Wong50% (2)

- Western Star 6900 - Xd40 Offroad Tractor: Smithco Dt-150 150-Ton Double Tip Side Dump TrailerDocument9 paginiWestern Star 6900 - Xd40 Offroad Tractor: Smithco Dt-150 150-Ton Double Tip Side Dump TrailerСергейÎncă nu există evaluări

- Report On The Dangers of Cellphone Use While DrivingDocument6 paginiReport On The Dangers of Cellphone Use While DrivingMitchell JacksonÎncă nu există evaluări

- DMRC NotificationDocument4 paginiDMRC NotificationMalhotraSoniaÎncă nu există evaluări

- Sport Aviation Dec-1975Document92 paginiSport Aviation Dec-1975laerciofilho100% (1)

- RPF RoadDocument56 paginiRPF Roadpawan chauhanÎncă nu există evaluări

- Development Authority: Bhubaneswar Development Authority RFP Document For EPC contractor-ISBT Baramunda, BhubaneshwarDocument8 paginiDevelopment Authority: Bhubaneswar Development Authority RFP Document For EPC contractor-ISBT Baramunda, BhubaneshwarSARIT SEKHAR MUKHERJEEÎncă nu există evaluări

- Wheel Stiffness TestDocument13 paginiWheel Stiffness TestGeoffrey ArmstrongÎncă nu există evaluări

- UttarakhandDocument2 paginiUttarakhandfaisal begÎncă nu există evaluări

- Traffic Engineering: University of Duhok College of Engineering Civil Department Fourth Year Students 2020-2021Document14 paginiTraffic Engineering: University of Duhok College of Engineering Civil Department Fourth Year Students 2020-2021Ahmad SalihÎncă nu există evaluări

- Vic Rider HandbookDocument96 paginiVic Rider HandbookTom GiulyanÎncă nu există evaluări

- 200 Seated Hostels (Recovered) (Recovered)Document124 pagini200 Seated Hostels (Recovered) (Recovered)Mohammed ShahbazÎncă nu există evaluări

- LetterHead 2012 (2) Partiipations Invitation.Document1 paginăLetterHead 2012 (2) Partiipations Invitation.Mohammad Musthak AhmedÎncă nu există evaluări

- Seat BacksDocument65 paginiSeat BacksEngineerÎncă nu există evaluări