Documente Academic

Documente Profesional

Documente Cultură

Chapter 7

Încărcat de

lockas222Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Chapter 7

Încărcat de

lockas222Drepturi de autor:

Formate disponibile

Chapter 6:

PUMPS

1

The Goals

Describe how centrifugal and positive-displacement pumps

operate and common applications.

Calculate system head requirements.

Determine head, pump efficiency, and pump. horsepower

from a typical centrifugal pump curve.

Define net positive suction head (NPSH) and understand

how it relates to cavitation.

Compute NPSH required by a pump.

Determine an appropriate pump (impeller diameter,

efficiency, etc.) for a given required head.

Describe how to modify system to operate on the

appropriate pump curve.

Background

Fluid Moving Equipment

Fluids are moved through flow systems using pumps, fans,

blowers, and compressors. Such devices increase the

mechanical energy of the fluid. The additional energy can

be used to increase

Velocity (flow rate)

Pressure

Elevation

Background

pumps move liquids while compressors add

energy to gasses.

Pump is a device which converts mechanical power

into fluid power, while turbine converts fluid

power into mechanical power. Mechanical

power is usually obtained by shaft rotation

Pumps and fans do not appreciably affect the density

of the fluids that they move and thus incompressible

flow theory is applicable.

There are two basic types of pumps: positive-

displacement and dynamic or momentum change

pumps. There are several billion of each type in use

in the world today.

(PDPs) force the displacement pumps - Positive - 1

fluid along by volume changes. A cavity opens, and

the fluid is admitted through an inlet. The cavity then

closes, and the fluid is squeezed through an outlet.

Classification of Pumps

A. Reciprocating

1. Piston or plunger

2. Diaphragm

B. Rotary

1. Single rotor

a. Sliding vane

b. Flexible tube or lining

c. Screw

d. Peristaltic (wave contraction)

2. Multiple rotors

a. Gear

b. Lobe

c. Screw

d. Circumferential piston

A brief classification of PDP designs is as follows:

(a) reciprocating

piston or plunger,

(b) external

gear pump,

(c) double-screw

pump,

(d) sliding vane,

(e) three-lobe pump,

(f) double

circumferential

piston,

(g) flexible-tube

squeegee.

A Schematic design of positive-displacement pumps:

2- Dynamic pumps

simply add momentum to the fluid by means of fast-moving blades

or vanes or certain special designs. There is no closed volume:

The fluid increases momentum while moving through open

passages and then converts its high velocity to a pressure

increase by exiting into a diffuser section.

Dynamic pumps can be classified as follows:

A. Rotary

1. Centrifugal or radial exit flow

2. Axial flow

3. Mixed flow (between radial and axial)

B. Special designs

1. Jet pump or ejector

2. Electromagnetic pumps for liquid metals

3. Fluid-actuated: gas-lift or hydraulic-ram

Dynamic pumps generally provide a higher flow rate than PDPs and

a much steadier discharge but are ineffective in handling high-

viscosity liquids.

Dynamic pumps, also generally need priming; i.e., if they are filled

with gas, they cannot suck up a liquid from below into their inlet.

The PDP, on the other hand, is self-priming for most applications.

A dynamic pump can provide very high flow rates (up to 300,000

gal/min) but usually with moderate pressure rises (a few atmospheres).

In contrast, a PDP can operate up to very high pressures (300 atm) but

typically produces low flow rates (100gal/min).

The relative performance (p versus Q) is quite different for the two types

At constant shaft rotation speed, the PDP produces nearly constant flow rate

and virtually unlimited pressure rise, with little effect of viscosity.

The flow rate of a PDP cannot be varied except by changing the displacement

or the speed

The dynamic pump, provides a continuous constant-speed variation of

performance, from near-maximum p at zero flow (shutoff conditions) to

zero p at maximum flow rate. High-viscosity fluids sharply degrade the

performance of a dynamic pump.

Comparisons Between the Two types

Comparison of performance curves of typical dynamic

and positive-displacement pumps at constant speed.

Positive Displacement Pumps

To move fluids positive displacement pumps admit a

fixed volume of liquid from the inlet into a chamber

and eject it into the discharge.

Positive displacement pumps are used when higher

head increases are required. Generally they do not

increase velocity.

Positive Displacement Pump

Works on the principle of

letting fluid flow into a cavity

from a low-pressure source,

trapping the fluid, and forcing

it out to a high-pressure

receiver by decreasing the

volume of the cavity

Simplest pump that can be

found anywhere from liquid

soap dispensers, to

automobile fuel injectors, to

the human heart.

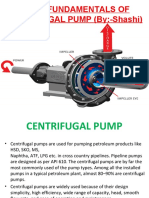

Centrifugal Pumps

Most common type of pumping machinery. There are many

types, sizes, and designs from various manufacturers who

also publish operating characteristics of each pump in the

form of performance (pump) curves.

Pump curves describe head delivered, pump efficiency, and

net positive suction head (NPSH) for a properly operating

specific model pump.

Centrifugal pumps are generally used where high flow rates

and moderate head increases are required.

Centrifugal Pump

Based on the concept of raising the pressure of a liquid

indirectly by increasing the kinetic energy via the centrifugal

action of the impeller and converting this kinetic energy to fluid

work

Used predominantly for high-flow applications, less expensive,

and less complex thereby minimizing maintenance

Must be pre-charged with liquid or else it wont pump at start-

up. Positive displacement pumps dont have this

limitation.

Cavitation

A centrifugal pump increases the fluid pressure by first imparting angular

momentum (or kinetic energy) to the fluid, which is converted to

pressure in the diffuser section. Hence, the fluid velocity in and around

the impeller is much higher than that either entering or leaving the

pump, and the pressure is the lowest where the velocity is highest.

The minimum pressure at which a pump will operate properly must be

of the fluid; otherwise the fluid will vaporize above the vapor pressure

(or boil), a condition known as cavitation.

Obviously, the higher the temperature the higher the vapor pressure

and the more likely that this condition will occur. When a centrifugal

pump contains a gas or vapor it will still develop the same head

Centrifugal Pump

Centrifugal Pumps

Impeller

Pump Curves

Pumps from manufacturers are

typically rated by how much fluid

work that can be achieved as a

function of fluid flow

Fluid work in the pump curves are

typically expressed in head form

Potential work decreases with

increasing flow due to increased

losses incurred at higher flow

velocities

g

P P

h

inlet outlet

=

h is the pump head that equal to the

change in pressure head flow between

point 1, the eye, and point 2, the exit,

as Z

1

=Z

2

=0 & V

1

=V

2

around pump

Pump Efficiency

The power delivered to the fluid simply equals the specific weight times the

discharge times the net head change Pw=ghQ (hp)

This is traditionally called the water horsepower.

The power required to drive the pump is the brake horsepower

bhp=T (hp)

where is the shaft angular velocity and T the shaft torque. If there were no

losses, P

w

and brake horsepower would be equal, but of course P

w

is

actually less, and the efficiency of the pump is defined as

The chief aim of the pump designer is to make as high as possible over as

broad a range of discharge Q as possible.

The volumetric efficiency is

where Q

L

is the loss of fluid due to leakage in the impeller-casing clearances.

(1 hp 550 ft lbf/s = 746 W)

A pump delivers gasoline at 20C and 12 m

3

/h. At the inlet,

p

1

= 100 kPa, z

1

= 1 m, and V

1

= 2 m/s. At the exit p

2

= 500 kPa,

z

2

= 4 m, and V

2

= 3 m/s. How much power is required if the

motor efficiency is 75% ?

Example

Centrifugal Pump Performance 1/2

The operating characteristics of a

pump are shown by plotting the total

pump head ( h), pump power (P),

pump efficiency () and the (NPSH)

R

versus the flow rate (Q), any rpm,

impeller diameter and liquid viscosity.

[Net Positive Suction Head ] Required

to avoid cavitation

BEP is the best effective point which

led to design flow rate (Q)

In a particular system, a

centrifugal pump can only

operate at one point on the h

against Q curve and that is the

point where the pump h

against Q curve intersects with

the system h against Q curve

as shown. The intersection

point should be near to the

best efficiency point of the

pump. The point of intersection

is called duty point. the system

total head at a particular liquid flow

rate.

Centrifugal Pump Performance 2/2

duty point

Where s for suction side & d for

discharge side

Pump Map

For a given flow rate and pump head, the manufacturers pump map would

indicate the operation of the pump at the physically available sizes

Impeller size

Pump power

Pump efficiency

NPSH

R

NPSH : is the difference between the absolute pressure head at the pump inlet

and the absolute vapor pressure head of the liquid being pumped

suction discharge side

side P

a

P

vap

|

|

.

|

\

|

=

g

P P

NPSH

vap a

Net Positive Suction Head

(NPSH), which is the head required at the pump inlet to keep the

liquid from cavitating or boiling. The pump inlet or suction side is the

low-pressure point where cavitation will first occur.

NPSH Net Positive Suction Head

In centrifugal pumps, the fluid must be brought up to the rotational speed of

the impeller blades.

Increasing the fluid velocity would result in a decrease in pressure

This can cause boiling of the fluid or cavitation around the eye of the

impeller. To prevent this, there must be elevation of the fluid before the

pump.

This height is known as the net positive suction head (NPSH).

P

a

Z

a

h

fs

Net Positive Suction Head

If the pump inlet is placed at a height Z

i

above a reservoir whose free

surface is at pressure pa, we can use Bernoullis equation to rewrite

NPSH as

where h

f i

is the friction-

head loss between the

reservoir and the pump

inlet. Knowing p

a

and h

f i

,

we can set the pump at a

height Z

i

which will keep the

right-hand side greater than

the required NPSH plotted

in Figure of pump map

NPSH must be positive

and larger than [NPSH]

R

The 32-in pump of Figure below is to pump 24,000 gal/min of water at 1170

r/min from a reservoir whose surface is at 14.7 lbf/in

2

absolute. If head loss

from reservoir to pump inlet is 6 ft, where should the pump inlet be placed to

avoid cavitation for water at

(a) 60F, P

v

= 0.26 lbf/in2 absolute, SG 1.0 and

(b) 200F, P

v

= 11.52 lbf/in2 absolute, SG 0.9635?

Example

S-ar putea să vă placă și

- Volvo EC160Document25 paginiVolvo EC160superbludnik100% (3)

- Supply Chain QuestionDocument22 paginiSupply Chain Questionlockas22280% (5)

- AS/NZS 3008.1.1 Amendment 1 Aug 2011 Cable Selection StandardsDocument7 paginiAS/NZS 3008.1.1 Amendment 1 Aug 2011 Cable Selection Standardslastwest1Încă nu există evaluări

- CHP SopDocument26 paginiCHP Sopkalyanm20351550% (2)

- Brief History of Safety ValvesDocument21 paginiBrief History of Safety ValvesUdhayakumar VenkataramanÎncă nu există evaluări

- FeyzinDocument38 paginiFeyzinAkmael Al-hajjÎncă nu există evaluări

- Ammonia Plant DesignDocument75 paginiAmmonia Plant Designlockas22288% (16)

- Design of Acetone HYSYSDocument6 paginiDesign of Acetone HYSYSlockas222100% (1)

- Acetone BDocument9 paginiAcetone BIrdani IdrisÎncă nu există evaluări

- Delta Industrial Knife Gate ValvesDocument28 paginiDelta Industrial Knife Gate ValvesAlin AllinÎncă nu există evaluări

- TACO Hydronics Step by StepDocument45 paginiTACO Hydronics Step by Stepminiongsky100% (4)

- Tutorial 7 - Kinetics - SOLUTIONSDocument5 paginiTutorial 7 - Kinetics - SOLUTIONSJustin Chuong NguyenÎncă nu există evaluări

- Pumps - Centrifugal vs. Positive Displacement: Instructor: Edward P. Brunet, JR., PEDocument11 paginiPumps - Centrifugal vs. Positive Displacement: Instructor: Edward P. Brunet, JR., PEyogachemÎncă nu există evaluări

- Air Cooled Heat ExchangersDocument2 paginiAir Cooled Heat ExchangersMohamad Arif IbrahimÎncă nu există evaluări

- Separator ComponentsDocument16 paginiSeparator ComponentsvsroilgasÎncă nu există evaluări

- Design and Use of Check ValvesDocument10 paginiDesign and Use of Check Valvesjenshid0% (1)

- Assignment: Name Muhammad ArsalanDocument8 paginiAssignment: Name Muhammad ArsalanMuhammad Arsalan TariqÎncă nu există evaluări

- 329 Cryogenic Valves September 2016Document8 pagini329 Cryogenic Valves September 2016TututSlengeanTapiSopanÎncă nu există evaluări

- Level GaugeDocument3 paginiLevel Gaugemerijan10Încă nu există evaluări

- Experiment No. 1 CompressorsDocument9 paginiExperiment No. 1 CompressorsgmÎncă nu există evaluări

- Pleated Filter Pressure Drop PDFDocument12 paginiPleated Filter Pressure Drop PDFAmbrish SinghÎncă nu există evaluări

- Butterfly Valve Info PDFDocument14 paginiButterfly Valve Info PDFCS100% (1)

- Prince Rupert Natural Gas Transmission Compressor Station Basics Factsheet TranscanadaDocument2 paginiPrince Rupert Natural Gas Transmission Compressor Station Basics Factsheet TranscanadaShaho Abdulqader MohamedaliÎncă nu există evaluări

- Ese652 - Process Control Ii Chapter 5.2 - Distillation ColumnDocument5 paginiEse652 - Process Control Ii Chapter 5.2 - Distillation ColumnJennifer HughesÎncă nu există evaluări

- Everything You Need to Know About BoilersDocument9 paginiEverything You Need to Know About BoilersSunny Engineers & AssociatesÎncă nu există evaluări

- Erosion Due To FlowDocument3 paginiErosion Due To FlownguyenÎncă nu există evaluări

- Positive Displacement: Reciprocating CompressorDocument54 paginiPositive Displacement: Reciprocating CompressorJordan MosesÎncă nu există evaluări

- PumpsDocument115 paginiPumpsMehmet Yılmaz100% (1)

- Principal Types of Atmospheric Storage TanksDocument9 paginiPrincipal Types of Atmospheric Storage Tanksmohsen ranjbarÎncă nu există evaluări

- Review of Adsorption Refrigeration Technologies PDFDocument5 paginiReview of Adsorption Refrigeration Technologies PDFVerma AbhiÎncă nu există evaluări

- Principles of Steam Trap ApplicationDocument14 paginiPrinciples of Steam Trap ApplicationemailÎncă nu există evaluări

- Compressor Equipment in Oil and Gas IndustryDocument4 paginiCompressor Equipment in Oil and Gas IndustryHamid HameedÎncă nu există evaluări

- Reciprocating Compressor Tutorial SolutionsDocument12 paginiReciprocating Compressor Tutorial SolutionsArif SabainÎncă nu există evaluări

- Pressure VesselDocument9 paginiPressure VesselbekkuÎncă nu există evaluări

- Heat ExchangersDocument7 paginiHeat ExchangersAgustin Gago LopezÎncă nu există evaluări

- Piping Plans Pocket Guide HorizontalDocument49 paginiPiping Plans Pocket Guide Horizontalmuho1Încă nu există evaluări

- Motor Torque and Load Torque SelectionDocument22 paginiMotor Torque and Load Torque Selectionrobertovm2002Încă nu există evaluări

- Level Measurement Using Gauge Glass TechniqueDocument3 paginiLevel Measurement Using Gauge Glass TechniqueYeabsira WorkagegnehuÎncă nu există evaluări

- ThermalDocument48 paginiThermalChris RosarioÎncă nu există evaluări

- PMC 02 Process Control Fundamentals Control Loop PDFDocument29 paginiPMC 02 Process Control Fundamentals Control Loop PDFPrince PrashanthÎncă nu există evaluări

- Cooler CatalogueDocument53 paginiCooler CatalogueCărunta-Crista CristinaÎncă nu există evaluări

- Condensate ReturnDocument24 paginiCondensate Returnwaheed2286Încă nu există evaluări

- Compressors: Basic Classification and Design OverviewDocument35 paginiCompressors: Basic Classification and Design Overviewfilmon abebe100% (1)

- Solid, Liquids, and GasesDocument27 paginiSolid, Liquids, and GasesHamass D MajdiÎncă nu există evaluări

- Understanding Check Valves: Sizing For The Application, Not The Line SizeDocument5 paginiUnderstanding Check Valves: Sizing For The Application, Not The Line SizeSCR_010101Încă nu există evaluări

- Gas Loads in Vacuum SystemsDocument7 paginiGas Loads in Vacuum SystemsEduardo LopesÎncă nu există evaluări

- Relief Valves - NCCDocument26 paginiRelief Valves - NCCNour HÎncă nu există evaluări

- Design Gas LiftDocument5 paginiDesign Gas LiftRima Apriani JamilahÎncă nu există evaluări

- ATEX Certified Enardo Detonation Flame Arrestor ModelDocument2 paginiATEX Certified Enardo Detonation Flame Arrestor Modelali kararÎncă nu există evaluări

- VALVES - NotesDocument17 paginiVALVES - NotesPortifer Harrison Ray Mubanga100% (1)

- Slides - Compressors Pumps Turbines 3+2 SlidesDocument177 paginiSlides - Compressors Pumps Turbines 3+2 SlidestomryanÎncă nu există evaluări

- Design and Fabrication of Direct Evaporative Modified CoolerDocument14 paginiDesign and Fabrication of Direct Evaporative Modified CoolerPraful RajputÎncă nu există evaluări

- Atmospheric Relief Valve ManualDocument12 paginiAtmospheric Relief Valve ManualTarun ChandraÎncă nu există evaluări

- Cleaning of Pipes by Gas Discharge Back PuffingDocument1 paginăCleaning of Pipes by Gas Discharge Back PuffingVamsi MahantiÎncă nu există evaluări

- 5 Industrial Noise and Vibrations ControlDocument81 pagini5 Industrial Noise and Vibrations ControlSreetheja NarlaÎncă nu există evaluări

- Bladder Accumulator Olaer EHV EHVF 1425384043 PDFDocument16 paginiBladder Accumulator Olaer EHV EHVF 1425384043 PDFJas SumÎncă nu există evaluări

- Cryogenic Service Ball ValveDocument2 paginiCryogenic Service Ball ValvesaminasritnÎncă nu există evaluări

- Technical Requirements For Plumbing Works in BuildingsDocument38 paginiTechnical Requirements For Plumbing Works in BuildingsWai Ling WongÎncă nu există evaluări

- SeparatorDocument8 paginiSeparatorIra Purnama SariÎncă nu există evaluări

- Compressors TeoriDocument41 paginiCompressors TeoriMarcel MrcÎncă nu există evaluări

- Types of PumpsDocument7 paginiTypes of PumpspakÎncă nu există evaluări

- Steam Traps: Used As A Energy SaverDocument47 paginiSteam Traps: Used As A Energy SaverAnonymous w6TIxI0G8lÎncă nu există evaluări

- What Is A ThermocoupleDocument13 paginiWhat Is A ThermocoupleMuhammad Wasiq TanveerÎncă nu există evaluări

- TEMPERATURE MEASUREMENT INSTRUMENTATIONDocument42 paginiTEMPERATURE MEASUREMENT INSTRUMENTATIONjimsistiÎncă nu există evaluări

- Pumps and Compressors: Essential Guide to Energy Transfer DevicesDocument48 paginiPumps and Compressors: Essential Guide to Energy Transfer DevicesIndiran SelvanÎncă nu există evaluări

- Industrial Pumps: Types, Applications & PerformanceDocument19 paginiIndustrial Pumps: Types, Applications & Performancedevasree reddyÎncă nu există evaluări

- Pumps and CompressorsDocument16 paginiPumps and CompressorsAbc AbcÎncă nu există evaluări

- Basic Fundamentals of CENTRIFUGAL PUMP (By:-Shashi)Document42 paginiBasic Fundamentals of CENTRIFUGAL PUMP (By:-Shashi)RaduIon100% (1)

- Germany Guideline SBDocument123 paginiGermany Guideline SBlockas222Încă nu există evaluări

- Historic DeLand Building Earns LEED CertificationDocument30 paginiHistoric DeLand Building Earns LEED Certificationlockas222Încă nu există evaluări

- 04 - AbsorbersDocument11 pagini04 - AbsorbersRafael ReyesÎncă nu există evaluări

- MVC Desalination Process Modeling and AnalysisDocument44 paginiMVC Desalination Process Modeling and Analysislockas222Încă nu există evaluări

- PDC Chapter 10.1Document16 paginiPDC Chapter 10.1lockas222Încă nu există evaluări

- Green Building RevolutionDocument229 paginiGreen Building Revolutionlockas222Încă nu există evaluări

- 04 - AbsorbersDocument11 pagini04 - AbsorbersRafael ReyesÎncă nu există evaluări

- Chapter 4 Shell and Tube Heat ExchangersDocument45 paginiChapter 4 Shell and Tube Heat Exchangerslockas222Încă nu există evaluări

- PDC CH 10.3 (Problems)Document6 paginiPDC CH 10.3 (Problems)lockas222Încă nu există evaluări

- Tech - 16a2d0707412ca70pct 100 071Document2 paginiTech - 16a2d0707412ca70pct 100 071lockas222Încă nu există evaluări

- Manufacturing Process FertilizerDocument14 paginiManufacturing Process FertilizermoentaseerÎncă nu există evaluări

- PCT100Document2 paginiPCT100lockas222Încă nu există evaluări

- Manufacturing Process FertilizerDocument14 paginiManufacturing Process FertilizermoentaseerÎncă nu există evaluări

- Chapter 4Document106 paginiChapter 4lockas222Încă nu există evaluări

- Fluid Mechanics IntroductionDocument49 paginiFluid Mechanics IntroductionIastraÎncă nu există evaluări

- Start AgainDocument1 paginăStart Againlockas222Încă nu există evaluări

- BackgroundDocument9 paginiBackgroundlockas222Încă nu există evaluări

- Start AgainDocument1 paginăStart Againlockas222Încă nu există evaluări

- BackgroundDocument9 paginiBackgroundlockas222Încă nu există evaluări

- Material BalanceDocument42 paginiMaterial Balancealireza_e_20% (1)

- A Summary of Thermodynamic FundamentalsDocument11 paginiA Summary of Thermodynamic Fundamentalslockas222Încă nu există evaluări

- Neraca Massa ATKDocument49 paginiNeraca Massa ATKMuhammad KholidinÎncă nu există evaluări

- Neraca Massa ATKDocument49 paginiNeraca Massa ATKMuhammad KholidinÎncă nu există evaluări

- Adeka Introduction Portfolio GeneralDocument19 paginiAdeka Introduction Portfolio Generalladislav_hipolÎncă nu există evaluări

- JKR Mech DRWG PDFDocument117 paginiJKR Mech DRWG PDFFelix Semion100% (1)

- Warning: Keystart 9620/9621Document4 paginiWarning: Keystart 9620/9621John GarnetÎncă nu există evaluări

- Battery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsDocument146 paginiBattery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsLo Siento de VerdadÎncă nu există evaluări

- AMMIE 2023 Conference on Advanced Materials and ManufacturingDocument9 paginiAMMIE 2023 Conference on Advanced Materials and ManufacturingrjÎncă nu există evaluări

- Full Scale Test FacilitiesDocument2 paginiFull Scale Test FacilitiesChangjiang DuÎncă nu există evaluări

- AURORA KN95 Face Mask Introduction 2020Document23 paginiAURORA KN95 Face Mask Introduction 2020victorcamposÎncă nu există evaluări

- Steam Turbine Solutions Steam Turbine SolutionsDocument8 paginiSteam Turbine Solutions Steam Turbine SolutionsramakantinamdarÎncă nu există evaluări

- 5E Series Tractors from John Deere: 55-75hp Reliable Performance for Small Farms and Specialty TasksDocument4 pagini5E Series Tractors from John Deere: 55-75hp Reliable Performance for Small Farms and Specialty Tasksbrujula24100% (1)

- Week 2 Module - CHEMDocument13 paginiWeek 2 Module - CHEMMichael AustriaÎncă nu există evaluări

- Explanation of NSK life calculation factors and reliability in bearing selectionDocument5 paginiExplanation of NSK life calculation factors and reliability in bearing selectionAndiniPermanaÎncă nu există evaluări

- DIY Knifemaker's Info Center - Heat Treatment Oven ProjectDocument34 paginiDIY Knifemaker's Info Center - Heat Treatment Oven ProjectRicardo VelozÎncă nu există evaluări

- NETZSCH Progressing Cavity Pumps 04 16aDocument28 paginiNETZSCH Progressing Cavity Pumps 04 16aCarlos TomeyÎncă nu există evaluări

- Calculating Expansion TanksDocument4 paginiCalculating Expansion TanksanescuveronicaÎncă nu există evaluări

- Xypec Catalog B UVC A MS 9106 R0 DraftDocument94 paginiXypec Catalog B UVC A MS 9106 R0 DraftJusron MasjhudaÎncă nu există evaluări

- Impulse Steam Turbines Explained in 40 CharactersDocument5 paginiImpulse Steam Turbines Explained in 40 CharactersBharani100% (1)

- Almex Light Weight BrochureDocument16 paginiAlmex Light Weight BrochureGijoÎncă nu există evaluări

- Internship Report CRDocument22 paginiInternship Report CRRockyXYZÎncă nu există evaluări

- Lyophilic and Lyophobic SolsDocument7 paginiLyophilic and Lyophobic Solssatvik guptaÎncă nu există evaluări

- ProductSpec HS2.4S HS3.75S HSZ2.4S HSZ3.75S HSD2.55S1Document1 paginăProductSpec HS2.4S HS3.75S HSZ2.4S HSZ3.75S HSD2.55S1Araujo Felipe AndrésÎncă nu există evaluări

- 2013 Marine Air PricebookDocument111 pagini2013 Marine Air Pricebooknwmarineair2869Încă nu există evaluări

- 423-Renolin CLP-1Document1 pagină423-Renolin CLP-1Moutaz IsmailÎncă nu există evaluări

- Evaluating Strength of Brazed JointsDocument7 paginiEvaluating Strength of Brazed JointssutrimoÎncă nu există evaluări

- Adokapı Technical PresentationDocument32 paginiAdokapı Technical PresentationHussain BagasrawalaÎncă nu există evaluări