Documente Academic

Documente Profesional

Documente Cultură

Clad Restoration

Încărcat de

viswamanoj100%(1)100% au considerat acest document util (1 vot)

932 vizualizări42 paginiMaintenance

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentMaintenance

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

932 vizualizări42 paginiClad Restoration

Încărcat de

viswamanojMaintenance

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 42

1

Weld Joints Of Clad Material

By L D Poyyara

POYYARA CONSULTANTS 2

Clad Material

What Is Clad Material / Clad Plate?

Non Corrosive SS / NFS Clad

CS / LAS Base Material

Any ferrous (CS / LAS) base plate which is integrally

bonded with a thin sheet / layer of non corrosive (SS

/ non ferrous) material on one side.

Clad Plate

POYYARA CONSULTANTS 3

Clad Plates

Bonding Process

Non Corrosive SS / NFS Clad

CS / LAS Base Material

Clad Bonding by Explosion / Hot Rolling /

Fusion Welding.

Clad Plate

POYYARA CONSULTANTS 4

Clad Plates

Non Corrosive SS / NFS Clad CS / LAS Base Material

Base Material: CS / LAS

Clad Material:

SS -304, 304 L, 316, 316 L,317, 317 L, 318, 321, 347

NFM / NFA Copper, Aluminium, Titanium, Monel, Inconel,

Cupronickel

Clad Plate

POYYARA CONSULTANTS 5

Clad Plates

Where Clad Plates are In Use?

For Fabricating Pressure Vessels & Pipe

Lines which are subjected to high

pressure & corrosion from inside surface

Corrosion Resistant Part

3 to 5 mm thick

Corrosive

Media

Pressure Resistant Part

Weld Joint

Clad Restoration

POYYARA CONSULTANTS 6

Clad Plates

What is the advantage of using Clad Plates in

Pressure Vessel Fabrication?

Saving in Material Cost. Allows to use low cost CS /

LAS corrosive base material as pressure retaining pats for highly

corrosive fluid. An inside thin layer of non corrosive clad prevents

internal corrosion

Corrosion Resistant Part

2 to 5 mm thick

Corrosive

Media

Pressure Resistant Part

Weld Joint

Clad Restoration

POYYARA CONSULTANTS 7

Clad Plates

What is the disadvantage of using Clad Plates in

Pressure Vessel Fabrication?

Additional Precautions in Fabrication.

Cutting, WEP, Rolling, Handling, Set up, Welding, PWHT

Corrosion Resistant Part

2 to 5 mm thick

Weld Joint

Clad Restoration

Corrosive

Media

Pressure Resistant Part

POYYARA CONSULTANTS 8

Cladding By Weld Overlay

What is weld Overlay Clad?

One or more layers of corrosion resistant

weld metal is deposited on CS / LAS base

material

Dilution :- 5 to 8%

ESSC

Final Layer E 308L First Layer - E309

POYYARA CONSULTANTS 9

Cladding By Weld Overlay

Weld Cladding Process:

ESSC Electro Slag Strip Cladding. Applicable to large

inside area of Shell, D/E, Cone, & TS

SASC Submerged Arc Strip Cladding Applicable to large

inside area of Shell, D/E, Cone, TS

FCAW Flux Cored Arc Welding. Applicable to Flange face,

Small size TS, Pipes of smaller diameter,

MIG Metal Inert Gas Welding. Applicable to Flange face,

Small size TS, Pipes of smaller diameter,

SMAW Shielded Metal Arc Welding. Applicable to small

components and repairs of clad

POYYARA CONSULTANTS 10

Cladding By Weld Overlay

Typical Section Of Weld Overlay

SASC

Dilution :- 10 to 15%

Final Layer E 308L

Final Layer E 308L First Layer - E309

First Layer E 309

Dilution :- 5 to 8%

ESSC

POYYARA CONSULTANTS 11

Cladding By Weld Overlay

Dilution :- 15 to 20%

FCAW / MIG

Typical Section Of Weld Overlay

SMAW

Dilution :- 20 to 25%

Final Layer

Final Layer First Layer

First Layer

E308L

E309

E308L

E309

POYYARA CONSULTANTS 12

What Is Overlap In Weld Overlay?

The extent of covering or over lapping on

previous weld bead by the adjacent bead.

40 to 50 % Over Lap

Less Dilution More Dilution

10 to 15 % Over Lap

More Thickness

Less Thickness

POYYARA CONSULTANTS 13

What Is Significant Of Overlap In

Weld Overlay?

Overlap of 40 to 50% in SMAW & FCAW results

in Less Dilution & more weld overlay

Thickness per layer

Less dilution results weld metal chemistry

more towards filler metal chemistry

40 to 50 % Over Lap 10 to 15 % Over Lap

Less Dilution More Dilution

More Thickness

Less Thickness

POYYARA CONSULTANTS 14

Overlap In ESSC & SASC

The extent of covering or over lapping on

previous weld bead by the adjacent bead.

4 to 5 mm Over Lap

Dilution

Minimum Overlay Thickness

POYYARA CONSULTANTS 15

Weld Joints In Clad Plates

Normally Only Base Metal Thickness Is Considered For

Design Calculations

Base Metal to be welded with qualified WPS

NDT (RT, UT, MT, PT) of weld joint on base metal to be

cleared prior to clad restoration

Clad to be restored by welding (SMAW, FCAW, SAW,

SASC, ESSC) with qualified WPS

Base Metal Joint

Clad Restoration Clad Base Metal

POYYARA CONSULTANTS 16

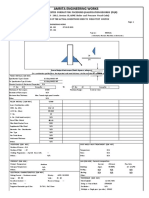

Typical Butt Weld In Clad Plate

Base Metal Weld Joint

Clad Stripping Clad Base Metal

Base Metal Butt Weld

Final Weld

Base Metal Joint

Clad Base Metal

Clad Restoration Final Layer

Base Metal Joint

Barrier Layer Clad Base Metal

Clad Restoration Barrier Layer

1

2

3

POYYARA CONSULTANTS 17

Typical Fillet Weld In Clad Plates

3

2

1

SS 304L Clad

SS 304L Clad

SS 304L Clad

SS 304L Support

SS 304L Support

SS 304L Support

Clad Stripping

CS

CS

CS

E309

E308L

18

Liner Attachment

By L D Poyyara

POYYARA CONSULTANTS 19

What Is Liner Attachment?

A thin sheet / Strip / Pipe of corrosion resistant

material (SS / non ferrous) is attached on corrosive

metal surface by welding along the outer edges.

Unlike clad, Liner is not an integral part of base

material

It is a substitute for Clad

CS / LAS Base Material

Vent

Attachment Weld Liner

Liner Attachment

POYYARA CONSULTANTS 20

Advantages

- Easy to attach

- Cheaper than integral clad / weld overlay

Disadvantages

- Less durable compared to integral clad

- More chances for leakage through liner in service

- Frequent repair / replacement of liner in service

- Needs vent holes below each liner

CS / LAS Base Material

Vent

Attachment Weld Liner

Liner Attachment

POYYARA CONSULTANTS 21

Typical Liner Attachment Weld

CS / LAS Base Material

Vent

Attachment Weld Liner

Liner

Liner Final Layer

1

St

Fillet 2

nd

Fillet

1 2

3

22

Qualification Requirements For

Weld Joints In Clad Material

By L D Poyyara

POYYARA CONSULTANTS 23

Welding Qualification For Clad

Material

Generally Qualifications Separately Done For

1) Weld Joints On Base Material

2) Restoration Of Clad On Weld Joints In Base Metal

Base Metal Weld Joint

Clad Stripping Clad Base Metal

Base Metal Butt Weld

Final Weld

Base Metal Joint

Clad Base Metal

Clad Restoration Final Layer

1

2

POYYARA CONSULTANTS 24

Welding Qualification For Clad

Material

Qualifications For Welding Of Base Material

1) Procedure As Per QW 200 & QW 451

2) Performance As Per QW 300 & 452

Test Coupon May Be With or Without Clad

Base Metal Weld Joint

Clad Stripping Clad Base Metal

Base Metal Weld Joint

OR

POYYARA CONSULTANTS 25

Qualification For Weld Overlay / Clad

Restoration

Qualifications For Restoring Clad By Weld Overlay

1) Procedure & Performance As Per QW 217(b), QW 451.4 &

QW 453

Test Coupon may be with or without clad

Clad Stripping Clad Base Metal

Base Metal Without Cladding

Base Metal For Welding Qualification Weld

Overlay / Clad Restoration

OR

Base Metal With Cladding

POYYARA CONSULTANTS 26

Qualification For Weld Overlay / Clad

Restoration

How to qualify procedure?

1 Prepare WPS Format available in ASME Sec. IX

2 Prepare a test coupon of P number in WPS

3 Coupon may be with or without clad

4 Coupon size minimum 150 mm X 150 mm

5 Coupon thickness minimum equal to production weld,

maximum need not be more than 25 mm

POYYARA CONSULTANTS 27

Qualification For Weld Overlay / Clad

Restoration

Test Coupon For Qualification of Weld

Overlay / Clad Restoration

OR

Base Metal Without Cladding

Clad Stripping

Clad

Base Metal With Cladding

37 mm min

37 mm min

POYYARA CONSULTANTS 28

Qualification For Weld Overlay / Clad

Restoration

Welding Of procedure Test Coupon

1. Clean the surface

2. Weld barrier layer as per WPS

3. Width minimum 37 mm and length minimum 150 mm

4. PT examine the barrier layer (optional) Acceptance as

per QW 195

5. Weld subsequent layers as per WPS

6. PT examine the final layer Acceptance as per QW

195

7. Each bead shall have uniform width and height

POYYARA CONSULTANTS 29

Qualification For Weld Overlay / Clad

Restoration

Procedure / Performance Qualification Test Coupon

OR

Base Metal Without Cladding

Clad Stripping Clad

Base Metal With Cladding

37 mm min

37 mm min

Min Job Size need not > 25 mm

Barrier Layer

Final Layer

Weld Area 37 X 150 mm Min

POYYARA CONSULTANTS 30

Procedure Qualification For Weld

Overlay / Clad Restoration

Physical Tests , QW 453

1. Side Bends - Transverse to welding direction - 4

No, WQ 161

(Location of bend specimens as per QW 462.5)

Acceptance Standard, QW - 163

1. No open discontinuity more than 1.5 mm in any

direction within the weld overlay cladding.

2. No open discontinuity more than 3 mm along the

weld interface.

POYYARA CONSULTANTS 31

Procedure Qualification For Weld

Overlay / Clad Restoration

Chemical Analysis. QW 462.5 (a)

Requires only when WPS / Spec. Calls for

All elements specified in WPS / Spec. are to be

analyzed.

Location of chips based on minimum thickness

of clad / overlay envisaged on production

welds.

Acceptance Limit

Within the WPS / Spec / Clad Chemistry.

POYYARA CONSULTANTS 32

Procedure Qualification For Weld Overlay / Clad Restoration

Location Of Chemical Analysis & Minimum Thickness Qualified

1

st

2

nd

3

rd

X

Weld inter Face

Base metal

Fusion Face

1

st

2

nd

3

rd

Weld inter Face

Base metal

Fusion Face

Location of Chips for Chemical Analysis Depth Minimum Possible

X

X

X = Min. Overlay Thickness Qualified

POYYARA CONSULTANTS 33

Procedure Qualification For Weld

Overlay / Clad Restoration

Special Process Essential Variables. QW 251.4

Welding in each position requires separate

qualification

Welding in vertical up hill position qualifies all

position ( SMAW, GMAW, GTAW).

Welding with single layer and multilayer needs

separate qualification

POYYARA CONSULTANTS 34

Procedure Qualification For Weld

Overlay / Clad Restoration

Procedure Qualification Thickness range Base

metal & Overlay

Thickness Of Test

Coupon

Base metal thickness

Qualified

Weld Overlay

Thickness

Min Max Min Max

Less Than 25 mm

Test

Coupon

Thickness

Any

Minimum

thickness

where

chemical

analysis

found

within limit

Any

Above 25 mm 25 mm Any

POYYARA CONSULTANTS 35

Performance Qualification For Weld

Overlay / Clad Restoration

How to qualify Welders Performance? QW-381

1 Prepare WPS & Qualify the procedure

2 Prepare a test coupon of P number in WPS

3 Coupon may be with or without clad

4 Coupon size minimum 150 mm X 150 mm

5 Coupon thickness minimum equal to production weld,

maximum need not be more than 25 mm

POYYARA CONSULTANTS 36

Qualification For Weld Overlay / Clad

Restoration

Welding Of Performance Test Coupon

1. Clean the surface

2. Weld barrier layer as per WPS

3. Minimum three beads in first layer

4. Width minimum 37 mm and length minimum 150 mm

5. PT examine the barrier layer (optional) Acceptance as

per QW 195

6. Weld subsequent layers as per WPS

7. PT examine the final layer Acceptance as per QW

195

8. Each bead shall have uniform width and height

POYYARA CONSULTANTS 37

Procedure Qualification For Weld

Overlay / Clad Restoration

Physical Tests , QW 453

Side Bends - Transverse to welding direction - 4

No, WQ 161

(Location of bend specimens as per QW 462.5)

Acceptance Standard, QW - 163

No open discontinuity more than 1.5 mm in any

direction within the weld overlay cladding.

No open discontinuity more than 3 mm along the

weld interface.

POYYARA CONSULTANTS 38

Applicable Essential variables QW 350 & 360

No upper limit for thickness of overlay qualified

Welders qualified on Clad restoration or liner

attachment are also qualified in weld overlays

QW 381 (d)

No limits in pipe diameters, if welded in

longitudinal direction QW 381 (c)

Performance Qualification For Weld

Overlay / Clad Restoration

POYYARA CONSULTANTS 39

Performance Qualification For Weld

Overlay / Clad Restoration

Performance Qualification Thickness range Base

metal & Overlay

Thickness Of Test

Coupon

Base metal thickness

Qualified

Weld Overlay

Thickness

Min Max Min Max

Less Than 25 mm

Test

Coupon

Thickness

Any

Procedure

Qualified

Any

Above 25 mm 25 mm Any

POYYARA CONSULTANTS 40

Qualification Requirements for Liner Attachment

procedure :- WPS qualified on Groove / Fillet as

per QW 202.2 (a), (b) or (c) also

qualifies for liner attachments within

the essential variables, If chemical

analysis is not a requirement

Performance:- Welders those who are qualified for

groove / fillet welds as per QW 301 are

also qualified for liner attachments

within the essential variables

CS / LAS Base Material

Vent

Attachment Weld Liner

Liner Attachment

POYYARA CONSULTANTS 41

Alternate Qualification. QW 218.2, QW - 383.2 (b)

procedure & Performance

- Weld a liner attachment assembly as shown below as per

the WPS.

- Base plate thickness min. job size max. need not be more

than 25 mm

- One Cross Section from each position for macro exam

- Chemical analysis if required as per WPS only for

procedure

- Each position needs separate qualification

- Procedure in vertical up qualifies all position

Liner Attachment

Liner Final Layer

S-ar putea să vă placă și

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsDe la EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsÎncă nu există evaluări

- SS Weld SpecificationDocument39 paginiSS Weld SpecificationmurugesanÎncă nu există evaluări

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsDocument6 paginiOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketÎncă nu există evaluări

- Metrode Welding Duplex & Superduplex Stainless SteelsDocument18 paginiMetrode Welding Duplex & Superduplex Stainless SteelsClaudia Mms50% (2)

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationDocument8 paginiQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীÎncă nu există evaluări

- EG 19-2-1.1 Strip Lining of Pressure Vessels: ScopeDocument6 paginiEG 19-2-1.1 Strip Lining of Pressure Vessels: ScopeaminÎncă nu există evaluări

- PDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-TemplateDocument1 paginăPDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-Templateيوسف عادل حسانينÎncă nu există evaluări

- How To Specify and Predict Ferrite Number in Stainless Steel WeldsDocument11 paginiHow To Specify and Predict Ferrite Number in Stainless Steel WeldsWeldPulseÎncă nu există evaluări

- Welding Duplex Stainless SteelDocument44 paginiWelding Duplex Stainless SteelTran Thanh HaoÎncă nu există evaluări

- Impact Test ASME IXDocument13 paginiImpact Test ASME IXbounatiro Hatem0% (1)

- 254smo (Uns 31254)Document8 pagini254smo (Uns 31254)Yang Gul LeeÎncă nu există evaluări

- ASME 9 Multi Process Welding Procedures QW200Document2 paginiASME 9 Multi Process Welding Procedures QW200Teodor EzaruÎncă nu există evaluări

- IIW Document No. IX-2165-05: Dnolan@uow - Edu.au Zoran@uow - Edu.auDocument28 paginiIIW Document No. IX-2165-05: Dnolan@uow - Edu.au Zoran@uow - Edu.aukatfy1Încă nu există evaluări

- GIS 36-107 Integral Cladding Weld Overlay and Limited LooseDocument17 paginiGIS 36-107 Integral Cladding Weld Overlay and Limited LooseMarkoJovicin100% (5)

- Saudi Aramco Inspection ChecklistDocument5 paginiSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- 1015 To Hastelloy VickoDocument14 pagini1015 To Hastelloy Vickovgestantyo100% (1)

- Auditing Oof Welding Under ASME Section IXDocument21 paginiAuditing Oof Welding Under ASME Section IXsabahiraqÎncă nu există evaluări

- SP-1096 Specification For Welding of Duplex Stainless Steel Pipelines Amendments Suppliments ASME B31.3Document47 paginiSP-1096 Specification For Welding of Duplex Stainless Steel Pipelines Amendments Suppliments ASME B31.3kart_rl100% (2)

- (1-VI) - Rules For Welding - 2013 PDFDocument302 pagini(1-VI) - Rules For Welding - 2013 PDFKhoirulRamadhanÎncă nu există evaluări

- Material Ferrite DeterminationDocument5 paginiMaterial Ferrite DeterminationPemburu Jablay100% (1)

- Wis5 WPS 05Document22 paginiWis5 WPS 05Gibson FisherÎncă nu există evaluări

- Hydrogen Bake-Out During In-Service Pressure Vessel Welding - Arun K Soman - Pulse - LinkedInDocument5 paginiHydrogen Bake-Out During In-Service Pressure Vessel Welding - Arun K Soman - Pulse - LinkedInAravindRajendranÎncă nu există evaluări

- Butt JointsDocument21 paginiButt JointsRaj1-23Încă nu există evaluări

- ASME PCC-1 - 2013 Guidelines For Pressure Boundary Bolted Flange Joint AssemblyDocument4 paginiASME PCC-1 - 2013 Guidelines For Pressure Boundary Bolted Flange Joint AssemblyIrshad AhmadÎncă nu există evaluări

- Saudi Aramco Standards: WeldingDocument12 paginiSaudi Aramco Standards: WeldingGEORGE IVANÎncă nu există evaluări

- Weld Fit Up Inspection Employee TrainingDocument10 paginiWeld Fit Up Inspection Employee TrainingBadiuzzama Azmi100% (1)

- Technical Handbook of CladdingDocument20 paginiTechnical Handbook of Claddingkaruma100% (1)

- Post Weld Heat TreatmentDocument10 paginiPost Weld Heat Treatmentcristian291011Încă nu există evaluări

- Api 571 PDFDocument3 paginiApi 571 PDFumnartkhÎncă nu există evaluări

- ASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesDocument9 paginiASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesAnnamalai Ram JGC100% (2)

- WPS 316 L PDFDocument4 paginiWPS 316 L PDFIrinaÎncă nu există evaluări

- SAIC-W-2006 Rev 8Document4 paginiSAIC-W-2006 Rev 8saravananmenmathiÎncă nu există evaluări

- Welding Procedure Specification: Page 1 of 1Document2 paginiWelding Procedure Specification: Page 1 of 1Harshad100% (1)

- Welding of CS Materials For Use in Sour ServiceDocument8 paginiWelding of CS Materials For Use in Sour ServicetrpacÎncă nu există evaluări

- Temper Bead Welding WPS and PQRDocument27 paginiTemper Bead Welding WPS and PQRSandeep Parmar100% (3)

- Asme QCMDocument84 paginiAsme QCMCaptainTonies100% (2)

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 paginiAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyÎncă nu există evaluări

- Duplex Ss WPSDocument8 paginiDuplex Ss WPSVinu Raveendran100% (1)

- 6GR RequirementsDocument1 pagină6GR Requirementswalitedison100% (1)

- Austenitic Stainless Steels, Problems-Failures-DifficultiesDocument69 paginiAustenitic Stainless Steels, Problems-Failures-DifficultiesAnnamalai Ram JGC100% (2)

- T-MCE-STD-001 Rev 0 - Welding and Inspection of Process and Utility Pipework Vessels and EquipmentDocument59 paginiT-MCE-STD-001 Rev 0 - Welding and Inspection of Process and Utility Pipework Vessels and EquipmentMichael CovillÎncă nu există evaluări

- Essential and Non-Essential Variables For WPS - PQRDocument4 paginiEssential and Non-Essential Variables For WPS - PQRNatarajan MurugesanÎncă nu există evaluări

- Weld Cladding Overlay - Topics by ScienceDocument73 paginiWeld Cladding Overlay - Topics by ScienceMichael TayactacÎncă nu există evaluări

- De-119951 Monel Sheathing InstallationDocument8 paginiDe-119951 Monel Sheathing InstallationJithuJohn100% (1)

- Radiography Cheat SheetDocument1 paginăRadiography Cheat SheetbplturnerÎncă nu există evaluări

- Cladded & Weld Overlayed Components For Oil & Gas, Refinery and Petrochemical IndustryDocument8 paginiCladded & Weld Overlayed Components For Oil & Gas, Refinery and Petrochemical Industrykatchani50% (2)

- Welder Performance Qualification (WPQ)Document2 paginiWelder Performance Qualification (WPQ)alokbdasÎncă nu există evaluări

- Technical Handbook Stainless Steel WeldingDocument92 paginiTechnical Handbook Stainless Steel WeldingRamesh sivanÎncă nu există evaluări

- 32 Samss 031 PDFDocument9 pagini32 Samss 031 PDFFlorin Daniel AnghelÎncă nu există evaluări

- Petronas Technical Standards: Shop and Field Fabrication of Steel PipingDocument30 paginiPetronas Technical Standards: Shop and Field Fabrication of Steel PipingAli YarahmadiÎncă nu există evaluări

- Method Statement For Titanium PipeworkDocument3 paginiMethod Statement For Titanium Pipeworkprem nautiyalÎncă nu există evaluări

- 02 Samss 012Document9 pagini02 Samss 012slan79bisÎncă nu există evaluări

- Cladding Clad RestorationDocument41 paginiCladding Clad RestorationBaveenaDinesh100% (2)

- Clad RestorationDocument48 paginiClad RestorationsalunkheclÎncă nu există evaluări

- Asme Section IX Educational SeriesDocument144 paginiAsme Section IX Educational Seriesglazetm100% (6)

- Vasanth W 012Document12 paginiVasanth W 012mohamedqcÎncă nu există evaluări

- S-0000-1360-0005 - TECHNICAL SPECIFICATION FOR PipesDocument22 paginiS-0000-1360-0005 - TECHNICAL SPECIFICATION FOR PipesPaul NieÎncă nu există evaluări

- API 570 Part 1 - Pipe ComponentsDocument41 paginiAPI 570 Part 1 - Pipe Componentspeach5100% (18)

- Welding Qualification SeminarDocument66 paginiWelding Qualification SeminarsoparlÎncă nu există evaluări

- Installing The Scribd App - Scribd Help CenterDocument3 paginiInstalling The Scribd App - Scribd Help Centerviswamanoj50% (4)

- Key Personnel ListDocument1 paginăKey Personnel ListviswamanojÎncă nu există evaluări

- How To Download A Book From Scribd - QuoraDocument2 paginiHow To Download A Book From Scribd - Quoraviswamanoj71% (7)

- Pressure Relief SAES A 004Document1 paginăPressure Relief SAES A 004viswamanojÎncă nu există evaluări

- Piping SupervisorDocument4 paginiPiping Supervisorviswamanoj100% (1)

- CRR No KKS Code: LFN WD: R01.KK.1UMA - LFN.TM - OK.WD001 Rev. 06 As Built DRG No:AB.R01.KK.1UMA - LFN.TM - OK.WD001 SH.8/16 - 12/16Document8 paginiCRR No KKS Code: LFN WD: R01.KK.1UMA - LFN.TM - OK.WD001 Rev. 06 As Built DRG No:AB.R01.KK.1UMA - LFN.TM - OK.WD001 SH.8/16 - 12/16viswamanojÎncă nu există evaluări

- Weld Fit Up Inspection Employee TrainingDocument10 paginiWeld Fit Up Inspection Employee TrainingviswamanojÎncă nu există evaluări

- Pipe BendsDocument23 paginiPipe BendsabhisheknharanghatÎncă nu există evaluări

- 24 Loomis Welding Procedures 9.10.14Document22 pagini24 Loomis Welding Procedures 9.10.14viswamanojÎncă nu există evaluări

- Saudi Aramco Approval PDFDocument1 paginăSaudi Aramco Approval PDFviswamanojÎncă nu există evaluări

- Safety Policy StatementDocument8 paginiSafety Policy StatementviswamanojÎncă nu există evaluări

- CWI Training API 1104 20th 2008 TrainingDocument11 paginiCWI Training API 1104 20th 2008 TrainingviswamanojÎncă nu există evaluări

- Weld ChartDocument3 paginiWeld ChartviswamanojÎncă nu există evaluări

- Safety in Gas Welding & Cutting Process PDFDocument11 paginiSafety in Gas Welding & Cutting Process PDFviswamanojÎncă nu există evaluări

- Independent Laboratories S Materials TesllngDocument1 paginăIndependent Laboratories S Materials TesllngviswamanojÎncă nu există evaluări

- TG144 Nov2012Document58 paginiTG144 Nov2012viswamanojÎncă nu există evaluări

- Form Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 paginăForm Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)viswamanojÎncă nu există evaluări

- Scaffolding Control & MeasuresDocument3 paginiScaffolding Control & Measuresviswamanoj100% (1)

- SECTION 12490 Window Treatments Rev 0Document29 paginiSECTION 12490 Window Treatments Rev 0viswamanojÎncă nu există evaluări

- Practical Lab Report Typed Burning Fuels Fill inDocument6 paginiPractical Lab Report Typed Burning Fuels Fill inAh Yeong LeeÎncă nu există evaluări

- Names and Formulas of InorganicDocument24 paginiNames and Formulas of InorganicMae SocialÎncă nu există evaluări

- CP-29 Carbopol Aqua SF-1 Product SummaryDocument2 paginiCP-29 Carbopol Aqua SF-1 Product SummaryadrianaÎncă nu există evaluări

- Catalogo SurvavierDocument24 paginiCatalogo SurvavierPhanor ReveloÎncă nu există evaluări

- Property Evaluation of Magnesium Phosphate Cement MortarDocument6 paginiProperty Evaluation of Magnesium Phosphate Cement MortarUfuk AKKAŞOĞLUÎncă nu există evaluări

- Kerosine: Standard Specification ForDocument3 paginiKerosine: Standard Specification ForDavid CazorlaÎncă nu există evaluări

- KAU Curriculum of ChemistryDocument47 paginiKAU Curriculum of ChemistrygogookÎncă nu există evaluări

- Basf Aditivo PinturasDocument34 paginiBasf Aditivo Pinturasv0% (1)

- Laboratory Manual (Inorganic and Organic Chem)Document89 paginiLaboratory Manual (Inorganic and Organic Chem)renÎncă nu există evaluări

- HI-PM31: High Wear Resistance GradeDocument6 paginiHI-PM31: High Wear Resistance GradetaknevÎncă nu există evaluări

- Mark Scheme Synthesis and Analytical TechniquesDocument37 paginiMark Scheme Synthesis and Analytical TechniquesAddan AddanÎncă nu există evaluări

- Sika® Rustop: Product Data SheetDocument2 paginiSika® Rustop: Product Data SheetAbhishekÎncă nu există evaluări

- Visco-Elastic CoatingsDocument7 paginiVisco-Elastic CoatingsXiaohua ChenÎncă nu există evaluări

- Bellwork-Ionic & Metallic Venn DiagramDocument32 paginiBellwork-Ionic & Metallic Venn Diagramarissa noorÎncă nu există evaluări

- HetshortDocument4 paginiHetshortSallyCroyÎncă nu există evaluări

- Petrovietnam University: Viet Nam Oil and Gas GroupDocument21 paginiPetrovietnam University: Viet Nam Oil and Gas GroupHoang BuiÎncă nu există evaluări

- Karty CharakterystykDocument6 paginiKarty CharakterystykekoherwantoroÎncă nu există evaluări

- CaseinDocument11 paginiCaseinsudhuÎncă nu există evaluări

- Boya, Vernik, Cila Katkı MaddeleriDocument27 paginiBoya, Vernik, Cila Katkı MaddeleriYusuf ErtürkÎncă nu există evaluări

- Chloride SCC of 316 SST PDFDocument5 paginiChloride SCC of 316 SST PDFSH1961Încă nu există evaluări

- Periodic Table of Elements - Sorted by 1st Ionization Potential (EV) (EnvironmentalChemistryDocument2 paginiPeriodic Table of Elements - Sorted by 1st Ionization Potential (EV) (EnvironmentalChemistryTrushar ParmarÎncă nu există evaluări

- Day 1 AnswersDocument31 paginiDay 1 Answershaoues23100% (2)

- January 2016 - InternationalDocument72 paginiJanuary 2016 - InternationalAlis Pastrana100% (1)

- 1 Sodium ChlorideDocument2 pagini1 Sodium ChlorideManit ShahÎncă nu există evaluări

- Page 0014Document1 paginăPage 0014has sasÎncă nu există evaluări

- JSPL Hard PlateDocument3 paginiJSPL Hard PlateKrishna KumarÎncă nu există evaluări

- Work FilesDocument36 paginiWork FilesAhmed AbdullahÎncă nu există evaluări

- For Teachers Only P .S.-CH: Physical Setting/ChemistryDocument10 paginiFor Teachers Only P .S.-CH: Physical Setting/ChemistryAAVANIÎncă nu există evaluări

- Chem Qs MolesDocument7 paginiChem Qs MolesWinson LauÎncă nu există evaluări

- Iso TC 238 WG 2 N 57Document11 paginiIso TC 238 WG 2 N 57Piyush AgarwalÎncă nu există evaluări