Documente Academic

Documente Profesional

Documente Cultură

Chapter 13

Încărcat de

Chris SmithDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Chapter 13

Încărcat de

Chris SmithDrepturi de autor:

Formate disponibile

Chapter 13 - Elasticity

A PowerPoint Presentation by

Paul E. Tippens, Professor of Physics

Southern Polytechnic State University

2007

BUNGEE jumping

utilizes a long elastic

strap which stretches

until it reaches a

maximum length that

is proportional to the

weight of the jumper.

The elasticity of the

strap determines the

amplitude of the

resulting vibrations. If

the elastic limit for

the strap is exceeded,

the rope will break.

Chapter 13. Elasticity

Photo Vol. 10

PhotoDisk/Getty

Objectives: After completion of this

module, you should be able to:

Demonstrate your understanding of

elasticity, elastic limit, stress, strain, and

ultimate strength.

Write and apply formulas for calculating

Youngs modulus, shear modulus, and

bulk modulus.

Solve problems involving each of the

parameters in the above objectives.

Elastic Properties of Matter

An elastic body is one that returns to its original

shape after a deformation.

Golf Ball Soccer Ball Rubber Band

Elastic Properties of Matter

An inelastic body is one that does not return to its

original shape after a deformation.

Dough or Bread

Clay Inelastic Ball

Elastic or Inelastic?

An elastic collision loses

no energy. The deform-

ation on collision is fully

restored.

In an inelastic collision,

energy is lost and the

deformation may be

permanent. (Click it.)

An Elastic Spring

A spring is an example of an elastic body that

can be deformed by stretching.

A restoring force, F, acts

in the direction opposite

the displacement of the

oscillating body.

F = -kx

x

F

Hookes Law

When a spring is stretched, there is a restoring

force that is proportional to the displacement.

F = -kx

The spring constant

k is a property of the

spring given by:

F

x

m

F

k

x

The spring constant k is a measure

of the elasticity of the spring.

Stress and Strain

Stress refers to the cause of a deformation, and

strain refers to the effect of the deformation.

x

F

The downward force F

causes the displacement x.

Thus, the stress is the force;

the strain is the elongation.

Types of Stress

A tensile stress occurs when

equal and opposite forces are

directed away from each other.

A compressive stress occurs

when equal and opposite

forces are directed toward

each other.

F

W

Tension

F

W

Compression

Summary of Definitions

Stress is the ratio of an applied force F to the

area A over which it acts:

Strain is the relative change in the dimensions or

shape of a body as the result of an applied stress:

F

Stress

A

2 2

N lb

: Pa or

m in.

Units

Examples: Change in length per unit length;

change in volume per unit volume.

Longitudinal Stress and Strain

L

L

A

A

F

For wires, rods, and bars,

there is a longitudinal

stress F/A that produces a

change in length per unit

length. In such cases:

F

Stress

A

L

Strain

L

Example 1. A steel wire 10 m long and

2 mm in diameter is attached to the

ceiling and a 200-N weight is attached

to the end. What is the applied stress?

L

L

A

A

F

First find area of wire:

2 2

(0.002 m)

4 4

D

A

A = 3.14 x 10

-6

m

2

-6 2

200 N

3.14 x 10 m

F

Stress

A

Stress

6.37 x 10

7

Pa

Example 1 (Cont.) A 10 m steel wire

stretches 3.08 mm due to the 200 N

load. What is the longitudinal strain?

L

L

Given: L = 10 m; L = 3.08 mm

Longitudinal Strain

3.08 x 10

-4

0.00308 m

10 m

L

Srain

L

The Elastic Limit

The elastic limit is the maximum stress a body can

experience without becoming permanently deformed.

W

W

2 m

If the stress exceeds the elastic limit, the final

length will be longer than the original 2 m.

Okay

Beyond limit

F

W

2 m

F

Stress

A

The Ultimate Strength

The ultimate strength is the greatest stress a body can

experience without breaking or rupturing.

If the stress exceeds the ultimate strength,

the string breaks!

F

W

W

W

2 m

F

Stress

A

W

W

Example 2. The elastic limit for steel is

2.48 x 10

8

Pa. What is the maximum

weight that can be supported without

exceeding the elastic limit?

L

L

A

A

F

8

2.48 x 10 Pa

F

Stress

A

Recall: A = 3.14 x 10

-6

m

2

F = (2.48 x 10

8

Pa) A

F = (2.48 x 10

8

Pa)(3.14 x 10

-6

m

2

) F = 779 N

Example 2(Cont.) The ultimate strength

for steel is 4089 x 10

8

Pa. What is the

maxi- mum weight that can be

supported without breaking the wire?

L

L

A

A

F

8

4.89 x 10 Pa

F

Stress

A

Recall: A = 3.14 x 10

-6

m

2

F = (4.89 x 10

8

Pa) A

F = (4.89 x 10

8

Pa)(3.14 x 10

-6

m

2

) F = 1536 N

The Modulus of Elasticity

Provided that the elastic limit is not exceeded,

an elastic deformation (strain) is directly

proportional to the magnitude of the applied

force per unit area (stress).

stress

Modulus of Elasticity

strain

Example 3. In our previous example,

the stress applied to the steel wire was

6.37 x 10

7

Pa and the strain was 3.08 x 10

-4

.

Find the modulus of elasticity for steel.

L

L

7

-4

6.37 x 10 Pa

3.08 x 10

Stress

Modulus

Strain

Modulus = 207 x 10

9

Pa

This longitudinal modulus of elasticity is called

Youngs Modulus and is denoted by the symbol Y.

Youngs Modulus

For materials whose length is much greater than the

width or thickness, we are concerned with the

longitudinal modulus of elasticity, or Youngs

Modulus (Y).

'

longitudinal stress

Young s modulus

longitudinal strain

/

/

F A FL

Y

L L A L

2

lb

: Pa

in.

Units or

Example 4: Youngs modulus

for brass is 8.96 x 10

11

Pa. A

120-N weight is attached to an

8-m length of brass wire; find

the increase in length. The

diameter is 1.5 mm.

8 m

L

120 N

First find area of wire:

2 2

(0.0015 m)

4 4

D

A

A = 1.77 x 10

-6

m

2

or

FL FL

Y L

A L AY

Example 4: (Continued)

8 m

L

120 N

Y = 8.96 x 10

11

Pa; F = 120 N;

L = 8 m; A = 1.77 x 10

-6

m

2

F = 120 N; L = ?

or

FL FL

Y L

A L AY

-6 2 11

(120 N)(8.00 m)

(1.77 x 10 m )(8.96 x 10 Pa)

FL

L

AY

L = 0.605 mm Increase in length:

Shear Modulus

A

F

F

f l

d

A shearing stress alters only the shape of the body,

leaving the volume unchanged. For example,

consider equal and opposite shearing forces F

acting on the cube below:

The shearing force F produces a shearing

angle f. The angle f is the strain and the

stress is given by F/A as before.

Calculating Shear Modulus

F

Stress

A

d

Strain

l

f

F

F

f

l

d A

The strain is the angle

expressed in radians:

Stress is

force per

unit area:

The shear modulus S is defined as the ratio of the

shearing stress F/A to the shearing strain f:

The shear modulus:

Units are in Pascals.

F A

S

f

Example 5. A steel stud (S = 8.27 x 10

10

Pa)

1 cm in diameter projects 4 cm from the

wall. A 36,000 N shearing force is applied to

the end. What is the defection d of the stud?

d

l

F

2 2

(0.01 m)

4 4

D

A

Area: A = 7.85 x 10

-5

m

2

;

F A F A Fl Fl

S d

d l Ad AS f

-5 2 10

(36, 000 N)(0.04 m)

(7.85 x 10 m )(8.27 x 10 Pa)

d

d = 0.222 mm

Volume Elasticity

Not all deformations are linear. Sometimes an applied

stress F/A results in a decrease of volume. In such

cases, there is a bulk modulus B of elasticity.

Volume stress F A

B

Volume strain V V

The bulk modulus is negative

because of decrease in V.

The Bulk Modulus

Volume stress F A

B

Volume strain V V

Since F/A is generally pressure P, we may write:

/

P PV

B

V V V

Units remain in Pascals (Pa)

since the strain is unitless.

Example 7. A hydrostatic press contains 5

liters of oil. Find the decrease in volume of

the oil if it is subjected to a pressure of

3000 kPa. (Assume that B = 1700 MPa.)

/

P PV

B

V V V

6

9

(3 x 10 Pa)(5 L)

(1.70 x 10 Pa)

PV

V

B

V = -8.82 mL

Decrease in V;

milliliters (mL):

Summary: Elastic and Inelastic

An inelastic body is one that does not return to its

original shape after a deformation.

In an inelastic collision, energy is lost and the

deformation may be permanent.

An elastic collision loses no energy. The deform-

ation on collision is fully restored.

An elastic body is one that returns to its original

shape after a deformation.

A tensile stress occurs when

equal and opposite forces are

directed away from each other.

A compressive stress occurs

when equal and opposite

forces are directed toward

each other.

F

W

Tension

F

W

Compression

Summary

Types of Stress

Summary of Definitions

Stress is the ratio of an applied force F to the

area A over which it acts:

Strain is the relative change in the dimensions or

shape of a body as the result of an applied stress:

F

Stress

A

2 2

N lb

: Pa or

m in.

Units

Examples: Change in length per unit length;

change in volume per unit volume.

Longitudinal Stress and Strain

L

L

A

A

F

For wires, rods, and bars,

there is a longitudinal

stress F/A that produces a

change in length per unit

length. In such cases:

F

Stress

A

L

Strain

L

The Elastic Limit

The elastic limit is the maximum stress a body can

experience without becoming permanently deformed.

The ultimate strength is the greatest stress a body can

experience without breaking or rupturing.

The Ultimate Strength

Youngs Modulus

For materials whose length is much greater than the

width or thickness, we are concerned with the

longitudinal modulus of elasticity, or Youngs

Modulus Y.

'

longitudinal stress

Young s modulus

longitudinal strain

/

/

F A FL

Y

L L A L

2

lb

: Pa

in.

Units or

The Shear Modulus

F

Stress

A

d

Strain

l

f

F

F

f

l

d A

The strain is the angle

expressed in radians:

Stress is

force per

unit area:

The shear modulus S is defined as the ratio of the

shearing stress F/A to the shearing strain f:

The shear modulus:

Units are in Pascals.

F A

S

f

The Bulk Modulus

Volume stress F A

B

Volume strain V V

Since F/A is generally pressure P, we may write:

/

P PV

B

V V V

Units remain in Pascals (Pa)

since the strain is unitless.

CONCLUSION:

Chapter 13 - Elasticity

S-ar putea să vă placă și

- Jesus Christ Was A HinduDocument168 paginiJesus Christ Was A Hinduhbk22198783% (12)

- 05 ElasticityDocument29 pagini05 ElasticityJoyce CulloÎncă nu există evaluări

- Som 2013 - 001 PDFDocument431 paginiSom 2013 - 001 PDFKumar SamreshÎncă nu există evaluări

- Chapter - 1 - Basic Engineering ScienceDocument8 paginiChapter - 1 - Basic Engineering ScienceMathavaraja Jeyaraman100% (3)

- Habanera Botolena & Carinosa (Gas-A)Document8 paginiHabanera Botolena & Carinosa (Gas-A)christian100% (4)

- ElasticityDocument38 paginiElasticityIndra Dewa PutraÎncă nu există evaluări

- ElasticityDocument38 paginiElasticityPaul James ThadhaniÎncă nu există evaluări

- ElasticityDocument80 paginiElasticityRisa M. LimÎncă nu există evaluări

- Physics ElasticityDocument23 paginiPhysics ElasticityDaniel Danille KristianÎncă nu există evaluări

- Chapter 3 - Elastic Properties of MatterDocument32 paginiChapter 3 - Elastic Properties of MatterNour HakamÎncă nu există evaluări

- Elastisitas 2022Document40 paginiElastisitas 2022FIO IZZAFURRAHMANÎncă nu există evaluări

- Elasticity (Statics)Document25 paginiElasticity (Statics)Rizky PratamaÎncă nu există evaluări

- FSC115 Elasticity-1Document44 paginiFSC115 Elasticity-1RaphaelÎncă nu există evaluări

- Stress and StrainDocument13 paginiStress and StrainMuruganandam RamadassÎncă nu există evaluări

- Elasticity: L L, L LDocument8 paginiElasticity: L L, L LaassÎncă nu există evaluări

- Mechanical Principles HNC/D Preliminary Level Tutorial 1 Basic Studies of Stress and StrainDocument13 paginiMechanical Principles HNC/D Preliminary Level Tutorial 1 Basic Studies of Stress and StrainIzuchucku JohnÎncă nu există evaluări

- Mechanical Properties of SolidsDocument37 paginiMechanical Properties of SolidsRahul PugazhendiÎncă nu există evaluări

- Elastic Modulus: Proportionality Stress Strain Directly Proportional Depends Material Deformed Nature of The DeformationDocument21 paginiElastic Modulus: Proportionality Stress Strain Directly Proportional Depends Material Deformed Nature of The Deformationmahmoud munirÎncă nu există evaluări

- Elas%city: Elastic LimitDocument17 paginiElas%city: Elastic Limitmahmoud munirÎncă nu există evaluări

- FSC115 ElasticityDocument44 paginiFSC115 ElasticityFemi AdeosunÎncă nu există evaluări

- 10.mechanical Properties of SolidsDocument21 pagini10.mechanical Properties of SolidsSri DÎncă nu există evaluări

- Stress PDFDocument13 paginiStress PDF9966197483Încă nu există evaluări

- STR ModuleDocument10 paginiSTR ModuleViamae Avellana CabutajeÎncă nu există evaluări

- Mechanics: Module V: Concept of Stress and StrainDocument5 paginiMechanics: Module V: Concept of Stress and StrainVikas SrivastavaÎncă nu există evaluări

- Structural MembersDocument14 paginiStructural MemberscataiceÎncă nu există evaluări

- 2 T 2Document14 pagini2 T 2PuligalÎncă nu există evaluări

- Strength of Materials - PUPDocument60 paginiStrength of Materials - PUPshirelyna100% (1)

- Elasticity, Calorimetry & Thermal Expansion (Teaching Notes)Document21 paginiElasticity, Calorimetry & Thermal Expansion (Teaching Notes)Sankar KumarasamyÎncă nu există evaluări

- Som 2013Document151 paginiSom 2013Jaya NagarÎncă nu există evaluări

- Som ProjectDocument37 paginiSom ProjectVarun SinghÎncă nu există evaluări

- Som Unit I 2 & 16 MarksDocument7 paginiSom Unit I 2 & 16 MarksSurjith Bharathi SelvakumarÎncă nu există evaluări

- Engineering PhysicsDocument31 paginiEngineering PhysicsJoan VincentÎncă nu există evaluări

- Elasticity With Lecture 2020Document5 paginiElasticity With Lecture 2020mean comiaÎncă nu există evaluări

- g481 1 3 4 Springs and MaterialsDocument9 paginig481 1 3 4 Springs and Materialsapi-236179294Încă nu există evaluări

- Experiment No.: Name of The ExperimentDocument7 paginiExperiment No.: Name of The ExperimentMir Md. Mofachel HossainÎncă nu există evaluări

- Tutorial 1 - Basic Engineering Science: Instrumentation and ControlDocument6 paginiTutorial 1 - Basic Engineering Science: Instrumentation and ControlMohd A IshakÎncă nu există evaluări

- Tutorial 1 - Basic Engineering Science: Instrumentation and ControlDocument6 paginiTutorial 1 - Basic Engineering Science: Instrumentation and Controls_waqarÎncă nu există evaluări

- Tutorial 1 - Basic Engineering Science: Instrumentation and ControlDocument6 paginiTutorial 1 - Basic Engineering Science: Instrumentation and Control@@ngÎncă nu există evaluări

- Instrumentation Training Tutorial Part1Document6 paginiInstrumentation Training Tutorial Part1Gary8100% (1)

- Simple StrainDocument6 paginiSimple StrainKhan ToothÎncă nu există evaluări

- Gec224 - Lecture Note On Strength of MaterialsDocument54 paginiGec224 - Lecture Note On Strength of MaterialseltonmudzamiriÎncă nu există evaluări

- Stress and Stain DiagramDocument6 paginiStress and Stain DiagramArriane CausingÎncă nu există evaluări

- Ch1 Elasticity (1) UthmDocument34 paginiCh1 Elasticity (1) UthmNordiana IdrisÎncă nu există evaluări

- 24280Document24 pagini24280sarul_murugan2483Încă nu există evaluări

- Chapter 12 Static Equilibrium Elasticity: 12.1 The Rigid Object in EquilibriumDocument5 paginiChapter 12 Static Equilibrium Elasticity: 12.1 The Rigid Object in EquilibriumJhonny Zuasnabar PaucarÎncă nu există evaluări

- Elastic Properties of Materials: GoalsDocument12 paginiElastic Properties of Materials: GoalsKris OiraÎncă nu există evaluări

- Effect of Forces On Material Lec07Document19 paginiEffect of Forces On Material Lec07haseem hanaÎncă nu există evaluări

- Unit 1Document25 paginiUnit 1VENKATESHÎncă nu există evaluări

- 17 ElasticityDocument9 pagini17 ElasticityIsrael OlusegunÎncă nu există evaluări

- 11-15-14 Strength of MaterialsDocument60 pagini11-15-14 Strength of MaterialsJaypee CalambaÎncă nu există evaluări

- Geas FormulaDocument29 paginiGeas Formularoy016Încă nu există evaluări

- Unit - I - Stress and Strain SCIA1301: School of Building and Environment Department of Civil EngineeringDocument124 paginiUnit - I - Stress and Strain SCIA1301: School of Building and Environment Department of Civil EngineeringUllyses SebialÎncă nu există evaluări

- Mechanical Behavior of Materials: Tensile TestingDocument34 paginiMechanical Behavior of Materials: Tensile TestingSebut Saja IrwanÎncă nu există evaluări

- Physics NotesDocument18 paginiPhysics Notesthavaselvan50% (2)

- Ce6302 Notes Rejinpaul - 2 PDFDocument49 paginiCe6302 Notes Rejinpaul - 2 PDFSekar Dinesh50% (2)

- Lecture 5.1 - Design Mechanical PropertiesDocument30 paginiLecture 5.1 - Design Mechanical PropertiesFatimah Binti Abd RahmanÎncă nu există evaluări

- Deformation of SolidDocument37 paginiDeformation of SolidEllen Koh100% (1)

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresDe la EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresEvaluare: 4 din 5 stele4/5 (1)

- Strength of Materials: An Introduction to the Analysis of Stress and StrainDe la EverandStrength of Materials: An Introduction to the Analysis of Stress and StrainEvaluare: 5 din 5 stele5/5 (1)

- Stress, Strain and FOS3Document33 paginiStress, Strain and FOS3Chris SmithÎncă nu există evaluări

- Stress, Strain and FOSDocument10 paginiStress, Strain and FOSChris SmithÎncă nu există evaluări

- 5 Minute PlanDocument1 pagină5 Minute PlanChris SmithÎncă nu există evaluări

- En 10025Document4 paginiEn 10025Jayesh83% (6)

- s5 106901 2008 11 10 1Document12 paginis5 106901 2008 11 10 1Chris SmithÎncă nu există evaluări

- NorthStar 5th Edition Reading-Writing SKILLS 3-4Document265 paginiNorthStar 5th Edition Reading-Writing SKILLS 3-4Hassan JENZYÎncă nu există evaluări

- DLL Week 5Document3 paginiDLL Week 5Nen CampÎncă nu există evaluări

- Million-Day Gregorian-Julian Calendar - NotesDocument10 paginiMillion-Day Gregorian-Julian Calendar - Notesraywood100% (1)

- Southeast Asian Fabrics and AttireDocument5 paginiSoutheast Asian Fabrics and AttireShmaira Ghulam RejanoÎncă nu există evaluări

- Humanistic Developmental Physiological RationalDocument10 paginiHumanistic Developmental Physiological RationalJin TippittÎncă nu există evaluări

- PlayDocument121 paginiPlayellennelleÎncă nu există evaluări

- Entrepreneur: Job/Career InvolvementDocument5 paginiEntrepreneur: Job/Career InvolvementYlaissa GeronimoÎncă nu există evaluări

- Villegas vs. Subido - Case DigestDocument5 paginiVillegas vs. Subido - Case DigestLouvanne Jessa Orzales BesingaÎncă nu există evaluări

- Appellees Brief CIVILDocument7 paginiAppellees Brief CIVILBenBulacÎncă nu există evaluări

- Advantages and Disadvantages of Global WarmingDocument11 paginiAdvantages and Disadvantages of Global WarmingA Aldika Farlis50% (2)

- Nin/Pmjay Id Name of The Vaccination Site Category Type District BlockDocument2 paginiNin/Pmjay Id Name of The Vaccination Site Category Type District BlockNikunja PadhanÎncă nu există evaluări

- In Christ Alone My Hope Is FoundDocument9 paginiIn Christ Alone My Hope Is FoundJessie JessÎncă nu există evaluări

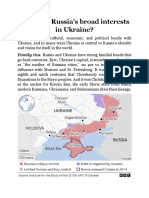

- What Are RussiaDocument3 paginiWhat Are RussiaMuhammad SufyanÎncă nu există evaluări

- Marketing Plan For Paraiso Islet ResortDocument25 paginiMarketing Plan For Paraiso Islet ResortEllaine Claire Lor100% (1)

- Unit 2-ED (Theory)Document13 paginiUnit 2-ED (Theory)chakramuÎncă nu există evaluări

- Improving Self-Esteem - 08 - Developing Balanced Core BeliefsDocument12 paginiImproving Self-Esteem - 08 - Developing Balanced Core BeliefsJag KaleyÎncă nu există evaluări

- Brain and LanguageDocument3 paginiBrain and LanguageJasper AngelesÎncă nu există evaluări

- In Partial Fulfillment of The Requirements in Care of Older Adult (NCM 114)Document2 paginiIn Partial Fulfillment of The Requirements in Care of Older Adult (NCM 114)Karen TangÎncă nu există evaluări

- Gothic Revival ArchitectureDocument19 paginiGothic Revival ArchitectureAlexandra Maria NeaguÎncă nu există evaluări

- Radiopharmaceutical Production: History of Cyclotrons The Early Years at BerkeleyDocument31 paginiRadiopharmaceutical Production: History of Cyclotrons The Early Years at BerkeleyNguyễnKhươngDuyÎncă nu există evaluări

- Water On Mars PDFDocument35 paginiWater On Mars PDFAlonso GarcíaÎncă nu există evaluări

- Biometric Security ConcernsDocument27 paginiBiometric Security ConcernsprinceuchenduÎncă nu există evaluări

- Introduction To Sociology ProjectDocument2 paginiIntroduction To Sociology Projectapi-590915498Încă nu există evaluări

- Task Basis JurisprudenceDocument10 paginiTask Basis JurisprudenceKerwin LeonidaÎncă nu există evaluări

- The ReformationDocument20 paginiThe ReformationIlyes FerenczÎncă nu există evaluări

- Bug Tracking System AbstractDocument3 paginiBug Tracking System AbstractTelika Ramu86% (7)

- Arsu and AzizoDocument123 paginiArsu and AzizoZebu BlackÎncă nu există evaluări

- Ernesto Sirolli - Eenterprise FacilitationDocument300 paginiErnesto Sirolli - Eenterprise FacilitationFrancis James Leite Marques PereiraÎncă nu există evaluări