Documente Academic

Documente Profesional

Documente Cultură

Lancaster NAVAIR Cold Spray Status 2014 061814

Încărcat de

ycwbycwbDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lancaster NAVAIR Cold Spray Status 2014 061814

Încărcat de

ycwbycwbDrepturi de autor:

Formate disponibile

Presented to:

Presented by:

NAVAIR Cold Spray Initiative Update

CSAT 2014 TIM; Worcester Polytechnic Institute

Frederick A. Lancaster AIR 4.3.4 S&T Lead

Cold Spray Action TEAM

June 2014

1911-2011 100 Years of Naval Aviation

Objective

The US Navy has the need to perform dimensional restoration of metallic

components caused by corrosion, restoration of material due to wear or

damage, and the ability to easily and rapidly repair structures in place on

Naval Aircraft.

The objective is to develop a metallization process that can be used to

facilitate repairs on naval aviation assets at all levels of maintenance.

Naval S&T Focus Areas:

Affordability

Maintainability

Reliability

Naval S&T Objectives:

Platform Affordability

Availability

2

1911-2011 100 Years of Naval Aviation

NAVAIR Workforce Development

7/1/2014

3

Engineer 8,

Tech 1; Low Pressure unit

Engineer 4

Tech 1; Low Pressure

Engineer 3

Tech 1; Low Pressure, 2

Robotic High pressure units

Engineer 4

Tech 1; Low/High Pressure

units

Engineer 1 Ground

Support

1911-2011 100 Years of Naval Aviation

FY-05 FY-06 FY-07 FY-08 FY-09

FY-10 FY-11 FY-12+

FRC-East

Pax River

FRC-SE

FRC-SW

Part Repair Approval

MIL-STD-3021

Cold Spray

Spec

Specifications

MIL-PRF-XXXX

Aerospace Powder

Spec

8 F-18 parts back in service

3 H-1 parts back in service

2 approved repair processes

2 new process pending/local approval

5 parts OEM approved (SAC) for rework

4 Low pressure CS units Operational

All FRCs w/ full repair capability

Technical staff trained @ all sites

2 sites high pressure capable

Cold spray specifications for

process Approved

Aerospace Powder Spec

Developing

SME

SME

SME

SME Trai

ned

Trained

Trained

Trained

SME

SME

Modeling

Section 219 S&T Investment

Initiate

Army

Contact

Army Collaboration (Demval, Testing, Information Exchange, Project Teaming, DOD Vision)

3-------------------------4------------------5-------TRL Level--------------6--------7---------------------8--9

Gearbox CS Repaired

Pre-Section 219 Timeframe (5 Years)

NAVAIR Cold Spray Timeline

Current Navy Cold Spray Capabilities

NAVAIR Facilities

FRC-East. 2 high & 1 low pressure

Pax River, low pressure portable

FRC Southeast (Jax), low pressure portable

FRC Southwest (NI), low pressure portable, 2 high

pressure robotic units (fy 14)

NAVSEA

- NSWCCD Inovati since 2004

- Keyport?

NPS

- Low Pressure cabinet

Technology Assessment

Target Material Applications Air Vehicles

Aluminum alloys used for naval aviation applications

7075-T73651 Plate,

7075-T76511 Extruded,

7075-T6 sheet/clad skin,

2024-T3 sheet/cladskin,

A356-T61 Cast,

Steel alloys used for naval aviation applications

AISI 4130 & AISI 4340,

Stainless Steel PH13-8Mo,

High Strength Steels (landing gear, arresting hooks),

300M,

Aermet 100,

AF1410

Magnesium alloys (AZ-91, ZE41A)

Titanium (Ti6-4)

Partnerships / Collaborations

Direct collaboration with

AIR 4.4.2.3 Power & Propulsion

AIR 4.3.3.2 Structures

AIR 4.3.4.2 NDI (Pax & FRC-SW)

Penn State ARL (REPTECH)

PMA 265, PMA 299

FRC East, Southeast, Southwest

Sikorsky Aircraft, Boeing Aircraft

Australian DSTO

NSWC Carderock & US Naval Postgrad

Partnerships with

USMC Corrosion Program

NSWC Carderock Materials

Engineer/Scientist Rotation

NRL Code 35

US Naval Postgrad School, Monterey

Army Research Lab

AMRDEC

TIPS: H-1 Combining Gearbox Repair

DLA: IVD Aluminum Repair, Cad Alternative, Hard Chrome Alternative

SBIR: Low pressure repairs, two small businesses & academia

AERMIP: Low Pressure Portable Metallization FRC-SE, Hole restoration F-18

OSD Corrosion: Portable Robotic System

REPTECH- PSU ARL Portable Repair and Restoration of Aluminum and Magnesium

Components

OSD Mantech-2012 Cold Spray Repair & Rebuild Technology (automated)

ONR SBA (NSWC Carderock/NPS) Single Particle Impact Study

FY12 Progress

Key Milestones Achieved

All depots operational & workforce trained

DT/OT for AMAD Fretting Corrosion Repair

Parts released back into fleet

DT for AMAD internal damage rebuild repair

FRC-East System Upgrade

Auxiliary heater installed on CGT Unit.

FY13 Progress

Key Milestones Achieved

Continued flight time for AMAD repairs

Upgrade of CGT-4000 @ FRC-E w/ 47kW heater

OSD Corrosion Office sponsorship for continued

working relation with Australian DSTO.

(overall, slow due to sequestration)

FY14 Expectations

Future:

F-18

Radar Racks, AMAD Gear Hard Chrome Alt, Wing/spar fastener hole repair (ie

bushing repair)

20 F-18 Radar Racks est $220K each tot $4.4M

IVD Repair:

H-60

Canted bulkhead repair (bushing alternative)

Gearbox repair (SAC & Australian DSTO)

V-22

V-22 Sills est $80K+ each sending back to CP.

H-1

Cobox O-Level Repairs

FRC independent teams can now perform repairs

Continue S&T work at Pax River with FRCs to expand applications

Refine portable repair process (field and depot roll up to the airframe)

Further Navy & Marine Corps Collaborative projects

Collaborative engineer rotation set-up with NSWC Carderock

Change Authorizations to Date

Local Process Specifications: Authority granted by

the cognizant engineering authority at the Fleet

Readiness Center (With local Materials & involved

competencies concurrence)

Engineering Orders from Sikorsky (ORI/(MEO

Army)): OEM approval. For Cold Spray the parts to

date are for using cold spray aluminum as an

alternative to flame spray aluminum, mainly for

wear areas, 5 applications.

FRC-SW Cold Spray Apps & Repairs

1. F/A-18E/F AMAD Main Housing (hydraulic pad restoration) LPS

2. F/A-18E/F AMAD Main Housing (gear failure repair) LPS

3. F/A-18E/F AMAD Hydraulic Gearshaft (seal surface repair) LPS

4. F/A-18E/F Main Landing Gear Brake Carrier

5. F/A-18A-D AMAD Housing PTS Axis (fretting repair)

6. F/A-18E/F Radar Rack Assembly (dimensional restoration)

7. F/A-18A-D GCU Tube Flange (pitted repair)

8. F/A-18E/F GCU PMG Shaft (dimensional restoration)

9. F/A-18E/F Wing Panel Fastener Holes (dimensional restore)

10.F/A-18A-D Center Pylon (dimensional restoration)

10. F/A-18E/F Steering Collar Cover (HSS dimensional restore)

11. F/A-18E/F Arresting Hook Pivot (HSS dimensional restore)

AMAD = Aircraft Mounted Accessory Drive GCU = Generator Control Unit

PTS = Power Take-Off Shaft PMG = Permanent Magnet Group

HSS = High-Strength Steel LPS = Local Process Specification

M

a

t

u

r

e

I

n

-

P

r

o

c

e

s

s

R

e

c

e

n

t

l

y

I

d

e

n

t

i

f

i

e

d

FRC-E Cold Spray Apps & Repairs

1. H-60 Sump (wear restoration, dimensional repair) SAC ORI

2. H-53 Five SAC ORIs for various drivetrain parts. (detail coming)

3. H-1 Combining Gearbox Chafing repair (dimensional) LPS *

1. First Operational Level Repair

4. V-22 Window Sill Corrosion Repair (dimensional) LPS

5. H-60 Gearbox Pad Restoration;

1. Intermediate,

2. Tail,

3. Combining, &

4. Main

AMAD = Aircraft Mounted Accessory Drive

GCU = Generator Control Unit

PTS = Power Take-Off Shaft

PMG = Permanent Magnet Group

HSS = High-Strength Steel

LPS = Local Process Specification

M

a

t

u

r

e

I

n

-

P

r

o

c

e

s

s

FRC-SE Cold Spray Apps & Repairs

1. F-18 Bomb Rack Repair (coating repair) LPS

2. GSE Spotting Dolly Pin Coating Repair (coating repair)

Engineering Test

3. IVD Aluminum repair

AMAD = Aircraft Mounted Accessory Drive

GCU = Generator Control Unit

PTS = Power Take-Off Shaft

PMG = Permanent Magnet Group

HSS = High-Strength Steel\

GSE= Ground Support Equipment

LPS= Local Process Specification

M

a

t

u

r

e

I

n

-

P

r

o

c

e

s

s

14

Yr-13

Yr-10 Yr-11 Yr-12

Aircraft Component &Transition(s) Timeline

H-60 Gearbox

repairs

Australian

Navy/USN/US

Army/SAC

Repair of Cad & Al Coatings (OSD)

UH-1N/AH-1W COMBINING GEARBOX HOUSING REPAIR

PORTABLE (TIPS) FRC-E

Dimensional Repair/Aerospace Powder Spec(DLA)

UH-1N/AH-1W RING GEAR High Pressure (Section 219) FRC-E

F-18 EMI REPAIR PORTABLE (TBD)

UH-1N/AH-1W SUPPORT CASE PAD

MOUNT PORTABLE (TBD)

UH-1N/AH-1W CAD ALTERNATIVE

ELECTTRICAL CONNECTORS

PORTABLE (TBD)

F-18 E/F/G AMAD Transmission Housing High Pressure Fretting/Dim Rep(Section

219) FRC-SW

H-53 MGB

Pad

Mounts (

POM15)

Corrosion

Dimensional/No

n-structural

Structural (Repair

within struct

limits)

Key

PSU-ARL Repairability, F-18 (REPTECH)

F

u

t

u

r

e

Current & Future Projects

Repair of Cad Alt

to Brush Plate

(DLA)

Repair of IVD(DLA)

15

Yr-17

Yr-14 Yr-15 Yr-16

Aircraft Component &Transition(s) Timeline

Portable Robotic CS - H-60 Intermediate Gearbox repairs

Australian Navy DSTO/USN NAVAIR (OSD Corrosion)

UH-1N/AH-1W COMBINING GEARBOX HOUSING REPAIR

PORTABLE (TIPS) FRC-E (Deployment to O-Level)

Aerospace Powder Spec(DLA)

F-18 EMI REPAIR PORTABLE (TBD)

UH-1N/AH-1W CAD ALTERNATIVE

ELECTTRICAL CONNECTORS

PORTABLE (TBD)

Corrosion/Coat

Dimensional/Non-structural

Structural (Repair within struct limits)

Key

PSU-ARL Repairability, F-18

(REPTECH)

Current & Future Projects

Repair of Cad Alt to Brush Plate (DLA)

Repair of IVD(DLA)

Repair of Cad Alt to Brush Plate (DLA)

F-18 Wing Spar Fastener Hole Elongation Repair(AERMIP)

Portable Robotic Cold Spray Application

To Be Proposed (wish list)

Example: Australian DSTO

has adapted a robotic cold

spray metallization system

for Mobile Repair

Advantage: Ability to apply CS

portably at High Pressures for

structural applications or

precise repair.

Goal: A system that artisan

teams can deploy and repair

aircraft in the field, operational

level, or at the aircraft at the

Intermediate level.

Worked with RAN under a

Coalition Warfare project to

further develop this technology

for structural applications.

Currently awarded an OSD

Corrosion effort to further

collaboration & demonstration

of portable repairs.

*Rosebank Engineering presentation TSS Cold Spray Conference 2010-Cold Spray application in Australian

Aerospace Industries-Neil Matthews DSTO Project

Future: Field/FRC Deployable

Robotic Systems

S&T Analysis

Process parameters

Repair limitations

Coating optimization

Powder

Surface preparation

Spray parameters

Coating bond strength

Coating cohesion

Post-coating preparation

Sealing

Welding

Machining

Microstructural characterization

Metallurgical bond

Dislocation density

Coating formation

Mechanical properties

(comparison to existing

technology)

Residual stress

Fatigue

Corrosion

Evaluation/Development of NDT

Significance of Flaws

Specifications and Requirements

Fitness for service acceptance

criteria & logistics

In-service repair

Safety/Environmental concerns

Application based cost benefit

analysis

Modeling, process & materials

Logistics constraints

Material

Equipment

Issues for all materials of interest to the Navy/NAVAIR

Need to tie fundamental

understanding of process

parameters/operating envelope to

coating properties

Hierarchy of Cold Spray Application

Projects

Approach

Establish Procedure(s)

Develop Process(es) & Equipment

NRL, ARL, NSWC-Carderock, Industry, Academia

Certify Testing & Results (laboratory)

Physical Tests

Corrosion Tests

Non-destructive

Develop Process Certification

Procedures/Methods

System/Process Functional Tests

Apply to aircraft

Flight Test

Develop

Qualify

Check

Assure

Take-Aways

All Fleet Readiness Centers are capable of Cold Spray

repairs

Hardware in place

Personnel trained, SMEs in place

Active S&T portfolio to support new process

applications

Still a significant amount of applications & repairs to develop

New alloy development still an open technology area.

Continue process development, verification & validation,

and qualification of applications

Next Step: Portable Systems for Depot & Field Use

Develop portable repair processes for field and depot

roll up to the airframe in place.

Summary

Responsive to fleet needs with solutions

that keep fleet assets affordable &

maintainable

Establishing for NAVAIR a solid base to grow

from

Material & Process Protocols

Capabilities

Processes

Manpower

Logistics

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Model Boats - January 2018 PDFDocument84 paginiModel Boats - January 2018 PDFKamel Touati100% (1)

- Erosion of A Chromium-Plated Tank Gun Barrel PDFDocument16 paginiErosion of A Chromium-Plated Tank Gun Barrel PDFycwbycwbÎncă nu există evaluări

- Recent Findings and Developments in Chromium Plated Gun TubesDocument29 paginiRecent Findings and Developments in Chromium Plated Gun TubesycwbycwbÎncă nu există evaluări

- Additive Material Repairs: The Changing Nature of SustainmentDocument28 paginiAdditive Material Repairs: The Changing Nature of SustainmentycwbycwbÎncă nu există evaluări

- A Systems Engineering Modeling and Simulation Approach For Rotorcraft Drive System OptimizationDocument12 paginiA Systems Engineering Modeling and Simulation Approach For Rotorcraft Drive System OptimizationycwbycwbÎncă nu există evaluări

- 3di Workshop Presentations Public ReleaseDocument177 pagini3di Workshop Presentations Public ReleaseycwbycwbÎncă nu există evaluări

- Additive Manufacturing For Defense and Government (CTC)Document36 paginiAdditive Manufacturing For Defense and Government (CTC)ycwbycwbÎncă nu există evaluări

- Advanced Oilfield Metals - Better Outcomes PDFDocument19 paginiAdvanced Oilfield Metals - Better Outcomes PDFycwbycwbÎncă nu există evaluări

- Study of Materials Test Methods For Wear Resistance in Oil and Mining IndustryDocument2 paginiStudy of Materials Test Methods For Wear Resistance in Oil and Mining IndustryycwbycwbÎncă nu există evaluări

- Use of Electroplated Chromium in Gun BarrelsDocument41 paginiUse of Electroplated Chromium in Gun BarrelsycwbycwbÎncă nu există evaluări

- State-Of-The-Art Survey On Hot Corrosion in Marine Gas Turbine EnginesDocument11 paginiState-Of-The-Art Survey On Hot Corrosion in Marine Gas Turbine EnginesycwbycwbÎncă nu există evaluări

- Study of Materials Test Methods For Wear Resistance in Oil and Mining Industry PDFDocument11 paginiStudy of Materials Test Methods For Wear Resistance in Oil and Mining Industry PDFycwbycwbÎncă nu există evaluări

- Rev.I 112014 HTK Ultra Strip 100 EnglDocument1 paginăRev.I 112014 HTK Ultra Strip 100 EnglycwbycwbÎncă nu există evaluări

- Erosion of A Chromium-Plated Tank Gun BarrelDocument16 paginiErosion of A Chromium-Plated Tank Gun BarrelycwbycwbÎncă nu există evaluări

- Degradation of HVOF, Fe3Al Coatings in Simulated Coal AshDocument20 paginiDegradation of HVOF, Fe3Al Coatings in Simulated Coal AshycwbycwbÎncă nu există evaluări

- Honeywell CLEEN Projects Briefing 2011Document33 paginiHoneywell CLEEN Projects Briefing 2011ycwbycwbÎncă nu există evaluări

- Microstructure and Mechanical Properties of 18ni-300 Maraging Steel Fabricated by Selective Laser MeltingDocument7 paginiMicrostructure and Mechanical Properties of 18ni-300 Maraging Steel Fabricated by Selective Laser MeltingycwbycwbÎncă nu există evaluări

- Warm Spray Technology For Ti, Ti6Al4V and WC-CoDocument46 paginiWarm Spray Technology For Ti, Ti6Al4V and WC-CoycwbycwbÎncă nu există evaluări

- AMC Advanced Mould Coatings 2017Document4 paginiAMC Advanced Mould Coatings 2017ycwbycwbÎncă nu există evaluări

- Yttria-Stabilized Zirconia Thermal Barrier Coatings - A ReviewDocument10 paginiYttria-Stabilized Zirconia Thermal Barrier Coatings - A ReviewycwbycwbÎncă nu există evaluări

- Laser Surface Modification of HVOF Coatings For Improvement of Corrosion and Wear PerformanceDocument293 paginiLaser Surface Modification of HVOF Coatings For Improvement of Corrosion and Wear PerformanceycwbycwbÎncă nu există evaluări

- Advanced Low Conductivity Thermal Barrier Coatings PDFDocument39 paginiAdvanced Low Conductivity Thermal Barrier Coatings PDFycwbycwbÎncă nu există evaluări

- Abrasive Resistant Coatings-A ReviewDocument24 paginiAbrasive Resistant Coatings-A ReviewsumohiÎncă nu există evaluări

- Additive Manufacturing - Next Generation OEM & Sustainment SolutionsDocument15 paginiAdditive Manufacturing - Next Generation OEM & Sustainment SolutionsycwbycwbÎncă nu există evaluări

- CMAS Corrosion and Thermal Cycle of Al-Modified PS-PVD Environmental Barrier CoatingDocument19 paginiCMAS Corrosion and Thermal Cycle of Al-Modified PS-PVD Environmental Barrier CoatingycwbycwbÎncă nu există evaluări

- HVOF Thermal Spray TiC-TiB2 Coatings For AUSC Boiler-Turbine Components For Enhanced Corrosion Protection PDFDocument24 paginiHVOF Thermal Spray TiC-TiB2 Coatings For AUSC Boiler-Turbine Components For Enhanced Corrosion Protection PDFycwbycwbÎncă nu există evaluări

- Gas Turbine Coatings Eddy Current Quantitative and Qualitative EvaluationDocument10 paginiGas Turbine Coatings Eddy Current Quantitative and Qualitative EvaluationycwbycwbÎncă nu există evaluări

- Durability of Gadolinium Zirconate-YSZ Double-Layered Thermal Barrier Coatings Under Different Thermal Cyclic Test Conditions PDFDocument14 paginiDurability of Gadolinium Zirconate-YSZ Double-Layered Thermal Barrier Coatings Under Different Thermal Cyclic Test Conditions PDFycwbycwbÎncă nu există evaluări

- Applications of High Frequency Eddy Current Technology For Material Characterization of Thin CoatingsDocument7 paginiApplications of High Frequency Eddy Current Technology For Material Characterization of Thin CoatingsycwbycwbÎncă nu există evaluări

- Material Characterization of Thin Coatings Using High Frequency Eddy Current TechnologyDocument6 paginiMaterial Characterization of Thin Coatings Using High Frequency Eddy Current TechnologyycwbycwbÎncă nu există evaluări

- EP2511396 Guided Non-Line of Sight CoatingDocument13 paginiEP2511396 Guided Non-Line of Sight CoatingycwbycwbÎncă nu există evaluări

- PCGA Flotilla Handbook - Web VersionDocument10 paginiPCGA Flotilla Handbook - Web VersionLyel LimÎncă nu există evaluări

- loTHar WalTHer Gun Barrels and More - USDocument4 paginiloTHar WalTHer Gun Barrels and More - USPTCÎncă nu există evaluări

- ICSE - VII - Eng - King Porus - A Legend of Old (An Extract)Document9 paginiICSE - VII - Eng - King Porus - A Legend of Old (An Extract)9-VIIE Khushi B KoliÎncă nu există evaluări

- The Royal Occultist PrimerDocument82 paginiThe Royal Occultist Primerdkbradley100% (1)

- Spyder Victor 2012Document36 paginiSpyder Victor 2012William HernándezÎncă nu există evaluări

- T-64 - WikipediaDocument22 paginiT-64 - Wikipediadanko1du2458Încă nu există evaluări

- 06 - Handouts (Military History Evolution) 43 PagesDocument44 pagini06 - Handouts (Military History Evolution) 43 Pageseb cabiaÎncă nu există evaluări

- Uthariel "Uthar" Halfborn: If Someone Is in Trouble, I'm Always Ready To Lend HelpDocument1 paginăUthariel "Uthar" Halfborn: If Someone Is in Trouble, I'm Always Ready To Lend HelpOzrickdarcyÎncă nu există evaluări

- 201335698Document64 pagini201335698The Myanmar TimesÎncă nu există evaluări

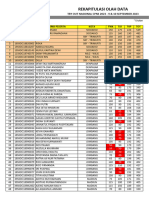

- Rekap To NasionalDocument52 paginiRekap To NasionalMelisawiÎncă nu există evaluări

- A2Z Telugu Boothu KathaluDocument82 paginiA2Z Telugu Boothu KathaluBommalu64% (11)

- District School ID SchoolDocument95 paginiDistrict School ID Schoolbrain john dizonÎncă nu există evaluări

- Ir. Sekarno Moh. Hatta Ahmad Yani Jendral Sudirman Pangeran AntasariDocument3 paginiIr. Sekarno Moh. Hatta Ahmad Yani Jendral Sudirman Pangeran AntasariIrman AminudinÎncă nu există evaluări

- Constanța: 1 HistoryDocument12 paginiConstanța: 1 HistoryMadalin StefanelÎncă nu există evaluări

- The Ming DynastyDocument29 paginiThe Ming DynastyNosiphoÎncă nu există evaluări

- Read TOEFL For Students Dec 15Document10 paginiRead TOEFL For Students Dec 15Robhy Alfarobi50% (2)

- 40K Horde Mode Rules v0.83Document30 pagini40K Horde Mode Rules v0.83Gilberto Sánchez VillegasÎncă nu există evaluări

- Top 10 Tips From MillionairesDocument11 paginiTop 10 Tips From Millionaireseventualmillion20Încă nu există evaluări

- 2019 Adac Performance Audit Final 2Document13 pagini2019 Adac Performance Audit Final 2Bienvenido TamondongÎncă nu există evaluări

- Cry of BalintawakDocument14 paginiCry of BalintawakPatrick LawagueÎncă nu există evaluări

- The One Ring Character SheetDocument2 paginiThe One Ring Character SheetRubens GolsmanÎncă nu există evaluări

- FITA Coach S Manual BarebowDocument12 paginiFITA Coach S Manual BarebowHolluxÎncă nu există evaluări

- President DuterteDocument10 paginiPresident DuterteaprilynÎncă nu există evaluări

- David Icke Haiti NewsletterDocument26 paginiDavid Icke Haiti NewsletterEnlightenedme100% (3)

- STARK InventionsDocument5 paginiSTARK InventionsUtkarsh BajpaiÎncă nu există evaluări

- Marine Corps Entertainment Liaison Office File On Hulk (2003)Document29 paginiMarine Corps Entertainment Liaison Office File On Hulk (2003)SpyCultureÎncă nu există evaluări

- PoochoottalDocument1 paginăPoochoottalNvsSrinivasanÎncă nu există evaluări

- Causes of The Great War DBQ Graphic OrganizerDocument4 paginiCauses of The Great War DBQ Graphic OrganizerMartin BotrosÎncă nu există evaluări

- 3BN - Unit - 274th - INFANTRYDocument74 pagini3BN - Unit - 274th - INFANTRYlanziÎncă nu există evaluări