Documente Academic

Documente Profesional

Documente Cultură

13 BShukla

Încărcat de

Jay KishanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

13 BShukla

Încărcat de

Jay KishanDrepturi de autor:

Formate disponibile

High Pressure and efficient Boilers for

Cogeneration applications

By

B. Shukla

MD and Chief Consultant,

WHITE POWERCON

#2082,1stmain 4

th

cross Judicial Layout,

GKVK Post

BANGALORE-560065

What is CO-GENERATION?

This is a combined / integrated System of

production of Electrical power and useful heat by

sequential use of energy from a common fuel source

generally bagasse).

To generate surplus power

For Best Utilization of resources

. To have Independency in power and steam

The Major advantage of Co- Gen

power is ;-

A-Most techno- commercial viable Projects with short pay back.

B-Cost of power production is very cheap compare to that of

purchase power.

C-Dependability and reliability with quality of power.

D-Quick return on investments.

E-Restore ecological imbalance.

F-Ability to use Bio-Mass and organic matters like wood, grass and

agro wastes and also municipal wastes.

G-Availability of power between Nov. to May when Hydel power availability

less.

H-provides ecmomical and timeluy solution of Power problems.

CO-GENERATION in SUGAR MILLS

How Cogeneration Saves Energy

BOILER

ALTERNATOR TURBINE

TO

PROCESS

TO PROCESS

Fuel

Air

TO

POWER

SUPPLY

CONDENSER

TO COOLING

TOWER

COGENERATION PLANT LAYOUT

Feed water

PRDS

Better Power Quality

Improved Reliability and run ability

Lower Energy Costs

Reduction CO2 in the environment

Conserve Natural Resources

Support Grid Infrastructure

Fewer T&D Constraints

Defer Costly Grid Upgrades

Price Stability

Benefits of cogeneration

Steps for conservation

1.Government of India enforced the

energy conservation act 2001 with effect

from 1.3.2002.

2.The initial phase of 5 years would be

implementation of the act .

3.The act provides mainly for efficient use

of energy and its conservation.

4.Industry using

Mandatory Requirement of Act

Those unit having connected load of 5000 KWh

are called as Designated Energy Consumer.

As per the act it is mandatory for all designated

Energy Consumers to get Energy Audit

conducted by an Accredited Energy Auditor. And

to designate or appoint an Energy Manager.

Energy Saving potential areas in sugar industries

1.Convertion from low Pressure to HP

Boilers

2.Steam Boilers (Reducing moisture percentage

in Bagasse)

3.Crushing section

4.Evaporator section

FEASIBILITY STUDY (TYPICAL STEPS)

Energy auditing

Technical Analysis

Inception

Implementation Planning

Financing

Operation and maintenance

CASE STUDIES

A-IMPROVEMENT PROJECT By

I-BY RETROFITTING

II- -RENOVATION &TECHNOLOGICAL

UPGRADATION

B-INITIATING NEW PROJECTS

RETROFITTING

Replacement of old 18/21Kgs/cm to HP >100bars

boilers

A-Provision of Better control system.

B-Efficiency improvement by Automation

C-Reduction of unaccountable losses by

providing dust extraction system

D-Reduction of Boiler & TG down time &

efficiency improvement by water & steam

quality control

Case Studies

Introducing New HP Boiler without affecting

Present Existing System

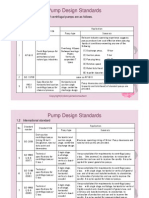

2002-03 2001-02 2000-01 1999-00 1998-99 Max Min Diff

%

Saving

scope

SL

NO

. PARTICULARS UOM Actual Actual Actual Actual Actual

1 Cane Crushed MT 729598 736838 646051 700916 736663

2 No. of Crop Days 173 191 159 165 188

3 Crushing Rate/22 hours MT 4162.95 3951 4194.98 4385.11 4230.29

4 Crushing Rate/24 hours MT 4541.39 4311.12 4576.34 4783.32 4614.77

5 Crop Day Average MT 4217.33 3857 4063.22 4247.98 3918.42

6 Recovery % 9.51 9.11 9.758 9.23 8.187

7 Bagasse Moisture % 50.66 50.56 50.11 50.4 51.3 51.3 50.11 1.19 2.32

8 Steam % Cane % 48.76 50.71 48.75 49.45 49.74

9 Power / Ton of Cane KWH 24.68 25.46 25.18 25.8 24.68 1.08 4.19

DOWN TIME ANALYSIS

Rs

51.57

lakhs

per

season

10 No Cane Hrs-Mts 6.-00 57-50 142-15 154-55 204-10

11 Mechanical Hrs-Mts 64-35 59-30 4.-30 24-55 180-45 181 4.5 176 97.5

12 Electrical Hrs-Mts 11.-10 53-55 4.-00 24-25 70-00 70 4 66 94.3

13 General Cleaning Hrs-Mts 97-10 97-15 109-25 110-25 51-05 110 51.08 59.3 53.7

14 Lost % on Available Hours % 7.06 10.3 11.23 8.96 11.9 11.9 7.06 4.84 40.7

Comparison of performance during various seasns from 1998 to 2002

SL

NO

PARTICULAR UOM 2002-03 2000-01 1994-95 Max Min %saving scope

Plant Sanctioned Capacity MT 5000 5000 2500

1 Cane Crushed MT 729598 646051.4 721475.5

2 No. of Crop Days 173 159 258

3 Crushing Rate / 22 hours MT 4162.9 4149.982 2819.806

4 Crushing Rate / 24 hours MT 4541.4 4576.344 3076.152

5 Crop Day Average MT 4217.3 4063.216 2796.416

6 Recovery % 9.51 9.758 9.357

7 Pol in Cane % 11.5 11.618 10.963

8 Total Losses % 2 1.871 1.617

a)Bagasse % 0.55 0.541 0.54

b)Filter Cake % 0.08 0.07 0.05

c)Final Molasses % 1.27 1.211 0.99

d)Unknown Loss % 0.1 0.049 0.037

9 Molasses % Cane % 4.52 4.449 4.415

10 Bagasse % Cane % 29.56 30.32 31.22

11 Cane Preparatory Index % 78.18

12 Bagasse Moisture % 50.66 50.11 50.52

13 Pol % Bagasse % 1.86 1.78 1.73

14 Sugar quality ICUMSA % 90to130 80-120

15 Total Available Hours HRS 4148-39 3816-33 6173-40

Coomparison of performance with best two seasons

16 Down Time Hours HRS 292-55 428-25 544-45

17 Imbibition% Fiber % 259.14 293.58 295.62

18 Milling Loss 4.12 3.78 3.69

19 Reduced Mill Extraction % 95.73 96.02 95.89

20 Reduced B.House Extraction % 91.27 91.66 93.43

21 Steam % Cane % 48.76 48.75 47.41 48.76 47.41 2.77

22 Power / Ton of Cane KWH 24.68 25.18

Rs 21.62

lakhs/seaso

n

23 Peak Period Recovery % 9.68 9.923 9.83

DOWN TIME ANALYSIS

24 No Cane HRS 6.-00 142-15 54-15

25 Mechanical HRS 64-35 4.-30 152-15 64.58 4.5 93

26 Electrical HRS 11.-10 4.-00 5.-30

27 General Cleaning HRS 97-10 109-25 164-00 109.416 97.16 11.2

28 Others HRS 112-10 167-50 168-45 167.83 112.166 33.17

29 Lost % on Avaible Hours % 7.06 11.23 8.82

30 Process Stock-Brown Sugar Qtls 2325 1477.49 694.65

341.8 213.8 128 hours

Remarks:Possible saving of running hours =128 hours

Possible increased in crushing of cane per season= 24220 MT/season

ANALYSIS OF PERFORMANCE FOR THE SEASON 2002-2003(MONTH WISE)

S

L

N

O PARTICULARS UOM DEC.02 JAN.03 FEB.03 MAR.03 APL.03 MAY.03 JUNE.03 TOTAL Max Min

%savi

ng

1 Cane Crushed MT 48558.3 128742 134980 140288 127097 128072.4 21860 729598

2 Recovery % 8.05 8.84 10.06 10.66 10.14 8.75 6.68 9.61

3 Sugar Production Qtls 3100 113875 13227.5 14747 13123.3 114975 25397 696220

4 Season Days-Crop Day Days 14 31 28 31 30 31 8 173

5 Season Days-Crushing Day Days 14 27 27 31 29 31 8 167

6 Total Available Hours HRs 332-36 744-00 672-00 744-00 720-00 744-00 192-03 4148-39

7 Total Working Hours HRs 330-51 641-40 636-35 705-45 676-15 692-10 172-28 3855-44

8 Stoppage Hours HRs 1.-45 102-20 35-25 38-15 43-45 51-50 19-35 292-55

a)Want of Cane HRs 0-00 6.-00 0-00 0-00 0-00 0-00 0-00 6.-00

b)Engineering(Mech&Elec) HRs 0-00 5.-00 5.-55 20-45 12.-40 21-35 10.-20 75-45

c)Proces

s HRs 0-00 0-50 0-00 0-30 0-00 0-00 0-00 1.-20

d)General Cleaning HRs 0-00 41-40 26-15 0-00 29-15 0-00 0-00 97-10

e)Others HRs 1.-45 48-50 3.-15 17-00 1.-50 30.15 9.-15 112-10

9 Down Time % Available % 0.53 13.75 5.27 5.14 6.08 6.97 10.-20 7.06

10 Crushing Rate / 22 hours MTs 3228.9 4414 4664.88 4373.12 4134.77 4617.712 2504.2 4162.95

11 Crushing Rate / 24 hours MTs 3522.43 4815.3 5088.96 4771 4510.66 5037.504 2731.8 4541.39

12 Crop Day Average MTs 3468.45 4153 4820.73 4525.41 4236.57 4131.368 2732.5 4217.33

13 Crushing Day Average MTs 3468.45 4768.2 4999.27 4525.41 4382.66 4131.368 2732.5 4368.85

14 Pol % Cane % 9.844 10.656 11.947 12.627 12.14 11.025 9.11 11.5

15 Total Losses % 1.8 1.828 1.898 1.993 2.01 2.284 2.443 2

a)Final Molasses % 1.13 1.143 1.218 1.306 1.31 1.369 1.45 1.27

b)Bagasse % 0.521 0.543 0.54 0.545 0.56 0.57 0.6 0.55

c)Filter Cake % 0.08 0.081 0.083 0.084 0.08 0.087 0.105 0.08

d)Unknown % 0.069 0.062 0.057 0.058 0.06 0.263 0.288 0.1

16 Reduced Mill Extraction % 94.79 95.31 95.88 96.12 96.02 95.64 94.48 95.73

17 Reduced BH. Extraction % 91.66 91.49 91.39 91.15 91.19 91.14 90.46 91.27

18 Pol % Bagasse % 1.89 1.88 1.86 1.85 1.84 1.84 1.9 1.86

19 Bagasse % Cane % 27.53 28.82 29.06 29.42 30.19 30.75 31.63 29.56

20 Final Molasses Purity % 29.6 30.45 30.99 31.71 31.51 31.55 34.15 31.35

21 Molasses % Cane % 4.26 4.17 4.37 4.61 4.66 4.85 4.93 4.52

22 Steam % Cane % 49.47 47.69 47.62 48.37 47.96 48.18 70.91 48.76

23 Power per Ton of Cane Units 23.61 23.61 23.27 24.69 25.13 25.57 34.3 24.63 34.3 23.27 32.2

Remarks: Saving of power in terms of money will be Rs 77.15 lakhs /month. @Rs 5.00/KWH

% Recovery during 2002-03

8.05

8.84

10.06

10.65

10.14

8.75

6.68

0

2

4

6

8

10

12

Dec Jan Feb Mar Apl May Jun

R

e

c

o

v

e

r

y

%bagasse moisture

27.53

28.82 29.06 29.42

30.19 30.75

31.63

0

5

10

15

20

25

30

35

Dec Jan Feb Mar Apl May Jun

Dec Jan Feb Mar Apl May Jun

%

b

a

g

a

s

s

e

m

o

i

s

t

u

r

e

Column 7

29

28.6

28.2

27.8

27.4

power consumption per ton of cane

crushed

23.61 23.61

23.27

24.69 25.13

25.57

34.3

0

5

10

15

20

25

30

35

40

Dec Jan Feb Mar Apl May Jun

p

o

w

e

r

c

o

n

s

u

m

e

d

p

e

r

t

o

n

o

f

c

a

n

e

BY Technological Up gradation

A-Replacement of old low pressure Boilers to

High pressure to get the benefits

improved cycle efficiency.

B-Providing Topping up TG Set to optimize

expenses on Electrical system.

C-Better environments by Providing

Emission monitoring.

Acquire Best Available Technology in

New Projects

A-Select Most modern and reliable

equipments

B-Design Tailor make System.

C-Select Flexible System for Better

utilization of resources and Better economy.

KCP Boiler

70 TPH, 43.4ata &

400C

TBW Boiler

70 TPH, 67ata & 485C

Comparison

Prevailing System Proposed System

Multi fuel Boiler

105ata, 525 C, 88%

GEC Turbine

SIEMENS Turbine

C

C

11 KV BUS

C

C

GEC Turbine

SIEMENS Turbine

Actual Thermal Efficiency of existing power plant

on date

Heat value of KPC boiler 767 Kcal/kg (from steam table)

(at 43.4 ata and 400C)

Then net heat value of KPC boiler 767 105 662 Kcal/kg.

Thermal efficiency of KPC boiler =

th

= (Net heat value * Total Steam generation) / (CV of

the bagasse * total bagasse consumption)

th

= (662 * 122759) / (2277 * 61672)

= 57.99% 58% ( against 69% of design)

Heat value of TBW boiler = 807.7 Kcal/kg (From steam table)

(at 67 ata and 485C)

Then net heat value of TBW boiler 807.7 105 702.7 Kcal/kg

GCV of coal = (CV of coal * total coal consumption) / Total fuel consumption

= (5500 * 4622) / 56213 = 452.22 Kcal/kg

GCV of Bagasse = (CV of bagasse * total bagasse consumption) / Total fuel consumption

= (2277 * 51591) / 56213 = 2089.77 Kcal/kg

Then net GCV = 452.22 + 2089.77 = 2542 Kcal/kg

Then net heat gain = heat gain * steam required for cane * efficiency of Topping TG set

= 13.8 * 125*10

3

* 0.9

= 1552.5 Kcal/kg

Total power generation = 1552.5/860 = 1.8 MW

Transfer rate = 1800 * 24 * 330 * 1.96 = 2.79 crore.

Thermal efficiency of TBW boiler =

th

= (Net heat value * Total Steam generation) /

(Net GCV * total fuel consumption)

= (702.7 * 129399) * 100 / (2542 * 56213)

th

= 63% (against 71.75% of design)

Average thermal efficiency of KPC & TBW boiler = (58+63) / 2 = 60.5%

Expected direct efficiency of multifuel boiler = 84%

Then fuel saving = 84 60.5 = 23.5%

Cost of fuel saving = Actual cane crushed * % of fuel caned * % fuel save

for 02-03 = 729598 * 0.3 * 0.235

= Rs. 51436.65

Then total saving of bagasse = 51437 * 500

= Rs. 2,57,815

= 2.57 crore

Net gain in power = 2.79 crore

Net gain in fuel save = 2.57 crore

Then total gain = 2.79+2.57 = 5.36 crore

Heat value of AFBC boiler = 821.5 Kcal/kg (from steam table)

(at 515 C and 105 kg/cm

2

)

Then net heat gain = 821.5 807.7

= 13.8 Kcal/kg

From data

Budgeted crane crushed/year = 775000 M.T

Actual crane crushed/year = 72598.401 M.T

No. of crop days = 170 days

% Steam required for crane = 48%

% of bagasse in cane = 30%

Then steam required for cane/hr. = (budgeted cane crushed * %steam reqd. for cane) /

(No. of days * 24)

= (775000 * 0.48) / (170*24)

= 91.176 tph

100 tph

For maximum efficiency

steam required for cane/hr = 100/0.80 = 125 tph

The Major advantage of Co- Gen

power is ;-

A-Most techno- commercial viable Projects with short pay back.

B-Cost of power production is very cheap compare to that of purchase

power.

C-Dependability and reliability with quality of power.

D-Quick return on investments.

E-Restore ecological imbalance.

F-Ability to use Bio-Mass and organic matters like wood, grass and agro

and

municipal wastes.

G-Availability of power between Nov. to May when Hydel power availability

less.

Continue---

H-provides ecmomical and timeluy solution of Power problems.

STEPS FOOR SAVINGS

!-Saving of Bagasse by adopting high technology HP Boilers

2-Reduction of moisture in bagasse 50 to 45% by improving Milling

Technique.

3-Reduction in Process steam consumptions in evaporator and Prime

movers

BLTFF evaporators

4- Reduction in live s team consumption by using multi stage reaction

Turbines.

5- Reduction in over consumptions of power TCH using new technique of

Variable drives and high efficient auxiliaries.

6-improve crushing rate by having quality power

S-ar putea să vă placă și

- Cea - Standard Technical Specification For Main Plant Package (2 500 MW)Document1.011 paginiCea - Standard Technical Specification For Main Plant Package (2 500 MW)vasudevapavanÎncă nu există evaluări

- Cea - Standard Technical Specification For Main Plant Package (2 500 MW)Document1.011 paginiCea - Standard Technical Specification For Main Plant Package (2 500 MW)vasudevapavanÎncă nu există evaluări

- Dial Gauge and Alignment: We Are Your Team MembersDocument11 paginiDial Gauge and Alignment: We Are Your Team MembersSIVAPATHASEKARAN100% (2)

- Gas Turbine PDFDocument747 paginiGas Turbine PDFrrcardoso230100% (1)

- Power Plant Equipment Operation and Maintenance Guide: Maximizing Efficiency and ProfitabilityDocument17 paginiPower Plant Equipment Operation and Maintenance Guide: Maximizing Efficiency and ProfitabilityMaterials Engineer100% (2)

- Test 896: Massey-Ferguson MF 165 (Diesel) (Also MF 165 8-Speed Diesel)Document2 paginiTest 896: Massey-Ferguson MF 165 (Diesel) (Also MF 165 8-Speed Diesel)Nour SkyperÎncă nu există evaluări

- Gas Insulated Transmission Line GILDocument3 paginiGas Insulated Transmission Line GILVENKATESAN RÎncă nu există evaluări

- Pump SelectionDocument112 paginiPump SelectionSIVAPATHASEKARAN100% (6)

- Perkins 404D-22G Model - DataDocument8 paginiPerkins 404D-22G Model - DataKrishÎncă nu există evaluări

- Visual Basic ProgrammingDocument117 paginiVisual Basic ProgrammingSIVAPATHASEKARAN100% (1)

- C12 ACERT 715 MHP SpecDocument6 paginiC12 ACERT 715 MHP SpecAl FbaÎncă nu există evaluări

- Best Practice Guide PumpDocument39 paginiBest Practice Guide PumpjavgeekÎncă nu există evaluări

- Introductory Chemistry B CH4751 Lecture Notes 11-20: Dr. Erzeng XueDocument81 paginiIntroductory Chemistry B CH4751 Lecture Notes 11-20: Dr. Erzeng XuethanhndbÎncă nu există evaluări

- Process STD 1001 Rev0 Utilities - Boiler FeedwaterDocument105 paginiProcess STD 1001 Rev0 Utilities - Boiler FeedwaterSteve WanÎncă nu există evaluări

- Pump Standards ComparisonDocument4 paginiPump Standards ComparisonAnish Dani50% (2)

- Pump Standards ComparisonDocument4 paginiPump Standards ComparisonAnish Dani50% (2)

- Understand The Basics of Centrifugal Pump Operations (CEP)Document5 paginiUnderstand The Basics of Centrifugal Pump Operations (CEP)Ari Firmansyah100% (1)

- Ac Loco ManualDocument103 paginiAc Loco ManualDeepak Gehlot100% (1)

- VCB SpecificationsDocument17 paginiVCB SpecificationsHarsh GuptaÎncă nu există evaluări

- CAT 3412C Brochure SpecificationsDocument6 paginiCAT 3412C Brochure Specificationsayman akrab100% (1)

- MCQ For Electrical EngDocument54 paginiMCQ For Electrical EngJayakrishnan Marangatt70% (10)

- Detailed Energy Audit of Thermal Power Plant EquipmentDocument22 paginiDetailed Energy Audit of Thermal Power Plant EquipmentPajooheshÎncă nu există evaluări

- C12 Acert: Marine PropulsionDocument6 paginiC12 Acert: Marine PropulsionAidel Mustafa100% (1)

- EE Benchmarking For Cement IndustrysDocument41 paginiEE Benchmarking For Cement Industrysshoaibhassan23100% (2)

- Sand2016 5977R PDFDocument108 paginiSand2016 5977R PDFmilloteÎncă nu există evaluări

- TM 5-1202 SCRAPER LeTOURNEAU MDL SUPER C TOURNAPULL WITH MDL LP CARRYALL LeTOURNEAU, 1944Document572 paginiTM 5-1202 SCRAPER LeTOURNEAU MDL SUPER C TOURNAPULL WITH MDL LP CARRYALL LeTOURNEAU, 1944Advocate100% (1)

- Fundamental of Steam TurbineDocument50 paginiFundamental of Steam TurbineImam Wahyudi100% (2)

- Drew Marine Tank Cleaning ManualDocument102 paginiDrew Marine Tank Cleaning ManualStasio8090% (10)

- SuperCritical Boiler-1Document45 paginiSuperCritical Boiler-1api-19986783100% (2)

- 30 MW Power PlantDocument151 pagini30 MW Power Plantsambhu0% (1)

- Dimpled Jacket 2Document4 paginiDimpled Jacket 2grincheu7050% (2)

- d7r II Vs D85ex-15 Perf Report (Texr0406)Document6 paginid7r II Vs D85ex-15 Perf Report (Texr0406)firman manaluÎncă nu există evaluări

- Attachment ReportDocument63 paginiAttachment ReportSajeed RahmanÎncă nu există evaluări

- Ford 5000Document2 paginiFord 5000Alvaro JavierÎncă nu există evaluări

- Test U445Document2 paginiTest U445DanyBobÎncă nu există evaluări

- 07.elec Weekly Report 12.06.2023 To 18.06.2023Document4 pagini07.elec Weekly Report 12.06.2023 To 18.06.2023Manohar Paul Praveen MÎncă nu există evaluări

- Industrial Attachment - 1701099Document63 paginiIndustrial Attachment - 1701099Omar Bin Harun TalhaÎncă nu există evaluări

- Product Specification Comparison: Cat 325D L Cat 325C L EngineDocument2 paginiProduct Specification Comparison: Cat 325D L Cat 325C L EngineDANIEL VARGAS RODRIGUEZÎncă nu există evaluări

- Name of The Document: Gujarat Water Supply & Sewerage Board, Gandhinagar Rajpipla, District: Narmada, GujaratDocument3 paginiName of The Document: Gujarat Water Supply & Sewerage Board, Gandhinagar Rajpipla, District: Narmada, Gujaratvikas maskeÎncă nu există evaluări

- 12 AirHeaterLeakage PDFDocument36 pagini12 AirHeaterLeakage PDFIfani DwiRamadhanÎncă nu există evaluări

- 324D Product SpecificationDocument2 pagini324D Product SpecificationDANIEL VARGAS RODRIGUEZÎncă nu există evaluări

- Seguimiento de Una Unidad FCCDocument24 paginiSeguimiento de Una Unidad FCCOswaldo FigueraÎncă nu există evaluări

- E.M AssignmentDocument2 paginiE.M Assignmentabdul qadeerÎncă nu există evaluări

- Attachment Report 72Document64 paginiAttachment Report 72Sajeed Rahman100% (1)

- Presentation For PresDocument11 paginiPresentation For PresMaverick P.Încă nu există evaluări

- 403D - 15 Industrial TPD1764E1Document8 pagini403D - 15 Industrial TPD1764E1Md ShÎncă nu există evaluări

- TMI Data 300311Document19 paginiTMI Data 300311Juan C Mendoza GonzalezÎncă nu există evaluări

- Technical Specifications Sheet 1 - : 10 To 185 BHPDocument1 paginăTechnical Specifications Sheet 1 - : 10 To 185 BHPwilsonÎncă nu există evaluări

- Lab 7 ArslanDocument4 paginiLab 7 ArslanMuhammad Arslan AfzalÎncă nu există evaluări

- Ruhaak SWRO Pecatu 04 DesignCalc 80068 01 8 PX Power Model SelectorDocument1 paginăRuhaak SWRO Pecatu 04 DesignCalc 80068 01 8 PX Power Model SelectorAyi JabarutiÎncă nu există evaluări

- TEJB9869-00. D10T2 X D375pdfDocument16 paginiTEJB9869-00. D10T2 X D375pdfluisÎncă nu există evaluări

- Enhancing Gas Turbine Performance by Correct Washing ProceduresDocument24 paginiEnhancing Gas Turbine Performance by Correct Washing ProceduresAbdulhameed HamadÎncă nu există evaluări

- Economics of Gas Gathering Cashflow of TechsimDocument77 paginiEconomics of Gas Gathering Cashflow of Techsimstructuredes.1Încă nu există evaluări

- Pump Power CalculatorDocument9 paginiPump Power CalculatorIrfanmaulana ardiansyahÎncă nu există evaluări

- 79 Stai Annual Convention: Innovative and Sustainable Options For Improving Juice Extraction EfficiencyDocument38 pagini79 Stai Annual Convention: Innovative and Sustainable Options For Improving Juice Extraction EfficiencyPrashantBudakeÎncă nu există evaluări

- RIPIDocument6 paginiRIPIOmar SaaedÎncă nu există evaluări

- AC Datasheet 582 65hpDocument2 paginiAC Datasheet 582 65hpArtur FrancoÎncă nu există evaluări

- Technical Data Sheet 50EPM, 60EPMDocument1 paginăTechnical Data Sheet 50EPM, 60EPMkwstdbjp5fÎncă nu există evaluări

- Datasheet Bomba 617-PcDocument6 paginiDatasheet Bomba 617-PcDiego Padilla100% (1)

- Power and EnergyDocument24 paginiPower and EnergySuman RegmiÎncă nu există evaluări

- 20150806-Modipalm Presentation v2 2010.3Document46 pagini20150806-Modipalm Presentation v2 2010.3David CS ChiangÎncă nu există evaluări

- Unit Status at 08:00 HRS: 105 MW Gazipur Power Plant Morning Meeting Discussion at 9:30 HrsDocument2 paginiUnit Status at 08:00 HRS: 105 MW Gazipur Power Plant Morning Meeting Discussion at 9:30 Hrsquazi mohiuddinÎncă nu există evaluări

- Stock Coal and Limestone Feed Systems: Powering Industry ForwardDocument12 paginiStock Coal and Limestone Feed Systems: Powering Industry ForwardNILESHÎncă nu există evaluări

- Balance Total RemoliendaDocument22 paginiBalance Total RemoliendaHQ MadelyÎncă nu există evaluări

- Feed Mill Energy ManagementDocument44 paginiFeed Mill Energy ManagementMinh PhamÎncă nu există evaluări

- Marine Generator Set: Standard Engine EquipmentDocument4 paginiMarine Generator Set: Standard Engine EquipmentJoko SusiloÎncă nu există evaluări

- Ce Series Filters & Moisture Separator: Compressed Air & Power SolutionsDocument4 paginiCe Series Filters & Moisture Separator: Compressed Air & Power SolutionsTim MitchellÎncă nu există evaluări

- E-Series Product Information Sheet 2018 1 2 PDFDocument4 paginiE-Series Product Information Sheet 2018 1 2 PDFgaineyskÎncă nu există evaluări

- PAT Target Achievement: Strategies and Practices: EEC Conference 31 August, 2015Document23 paginiPAT Target Achievement: Strategies and Practices: EEC Conference 31 August, 2015Gaurav SinghÎncă nu există evaluări

- Datasheet HCL Medium SystemsDocument4 paginiDatasheet HCL Medium SystemsLalit VashistaÎncă nu există evaluări

- Mtu538 120095 09092563Document2 paginiMtu538 120095 09092563Chaiwat PrssatpornÎncă nu există evaluări

- Genove Eduardo Cost Analysis of Combine Rice Harvester.Document7 paginiGenove Eduardo Cost Analysis of Combine Rice Harvester.Eduardo jr GenoveÎncă nu există evaluări

- Marketing Analysis and Sales PromotionDocument58 paginiMarketing Analysis and Sales PromotionSanjay SinghÎncă nu există evaluări

- Duratech Eco Pool Heat Pump ManualDocument16 paginiDuratech Eco Pool Heat Pump ManualNano SalamÎncă nu există evaluări

- Euroklimat Centrifugal Chiller Ekdc750b3Document3 paginiEuroklimat Centrifugal Chiller Ekdc750b3EddieÎncă nu există evaluări

- Cummins BT4.5-ME (40KW DEG) - DatasheetDocument3 paginiCummins BT4.5-ME (40KW DEG) - Datasheetazhan77Încă nu există evaluări

- DOP - OrgDocument12 paginiDOP - OrgAHMED HASSAN RAZAÎncă nu există evaluări

- Biomass GasificationDocument21 paginiBiomass GasificationLê Đức PhúÎncă nu există evaluări

- Submersible 150 MMDocument2 paginiSubmersible 150 MMSIVAPATHASEKARANÎncă nu există evaluări

- Solar EnergyDocument164 paginiSolar EnergykapenziaÎncă nu există evaluări

- Condensate Pumps - Vertical TurbineDocument12 paginiCondensate Pumps - Vertical TurbineSIVAPATHASEKARANÎncă nu există evaluări

- A Parabolic Trough Solar Power Plant Simulation ModelDocument12 paginiA Parabolic Trough Solar Power Plant Simulation ModelOrn-uma PimpochaÎncă nu există evaluări

- Drum Boiler DynamicsDocument16 paginiDrum Boiler DynamicsImran SiddiquiÎncă nu există evaluări

- Leakage Class of Control ValvesDocument4 paginiLeakage Class of Control Valvesg1232003gÎncă nu există evaluări

- Gas Turbine DescriptionDocument8 paginiGas Turbine DescriptionSIVAPATHASEKARANÎncă nu există evaluări

- ISO RatingDocument2 paginiISO RatingSIVAPATHASEKARANÎncă nu există evaluări

- Electircal Unit ConversionDocument8 paginiElectircal Unit ConversionSIVAPATHASEKARANÎncă nu există evaluări

- Specific SpeedDocument1 paginăSpecific SpeedSIVAPATHASEKARANÎncă nu există evaluări

- NPSH PumpsDocument3 paginiNPSH PumpsChem.EnggÎncă nu există evaluări

- Waste Heat Availability From Gas TurbineDocument7 paginiWaste Heat Availability From Gas TurbineSIVAPATHASEKARANÎncă nu există evaluări

- Fuel CellDocument21 paginiFuel CellSIVAPATHASEKARANÎncă nu există evaluări

- Table of Constants and ConversionDocument2 paginiTable of Constants and ConversionSIVAPATHASEKARANÎncă nu există evaluări

- Material Specifications: P-No. / Group No. Nominal Steel Designation Forgings Wrought Fittings Pipe Plate RemarksDocument1 paginăMaterial Specifications: P-No. / Group No. Nominal Steel Designation Forgings Wrought Fittings Pipe Plate RemarksSIVAPATHASEKARAN100% (2)

- Flange TypesDocument1 paginăFlange TypesHadi UtomoÎncă nu există evaluări

- Coagulants For Water Treatment: Application FeaturesDocument1 paginăCoagulants For Water Treatment: Application FeaturesSIVAPATHASEKARANÎncă nu există evaluări

- High Efficiency Poly Electrolytes For Solid-Liquid SeparationDocument1 paginăHigh Efficiency Poly Electrolytes For Solid-Liquid SeparationSIVAPATHASEKARANÎncă nu există evaluări

- Gauge Pole DesignDocument14 paginiGauge Pole DesignrichardchiamÎncă nu există evaluări

- Printed From Grundfos CAPSDocument7 paginiPrinted From Grundfos CAPSBambang Sigit PriyantoÎncă nu există evaluări

- Power Grid Failure: How Does It Happen?Document2 paginiPower Grid Failure: How Does It Happen?Swagat PradhanÎncă nu există evaluări

- Biofuels Persuasive EssayDocument5 paginiBiofuels Persuasive Essayapi-240645811Încă nu există evaluări

- FFA60UP30DN: 60 A, 300 V Ultrafast Dual DiodeDocument5 paginiFFA60UP30DN: 60 A, 300 V Ultrafast Dual DiodeselocaÎncă nu există evaluări

- Eed3001 Lab2 Single Phase Transformer Loading EM3000Document5 paginiEed3001 Lab2 Single Phase Transformer Loading EM3000Burak YılmazÎncă nu există evaluări

- Ent BlueprintDocument11 paginiEnt BlueprintKhairun NiesaÎncă nu există evaluări

- Gangadan Energy Company ProfileDocument4 paginiGangadan Energy Company ProfileAbhimanyu DethaÎncă nu există evaluări

- Class 8 Science Final Term Paper 2022-23Document5 paginiClass 8 Science Final Term Paper 2022-23Izyan AhmedÎncă nu există evaluări

- Thermo 1 - Mid TermDocument4 paginiThermo 1 - Mid TermMohammad Faiz AkbarÎncă nu există evaluări

- Canadian Solar Datasheet CS6K MDocument2 paginiCanadian Solar Datasheet CS6K MMostafaÎncă nu există evaluări

- Range of Wood Burning StovesDocument7 paginiRange of Wood Burning Stovesglynis100% (1)

- Danby DAC 5110M Air Conditioner ManualDocument16 paginiDanby DAC 5110M Air Conditioner ManualRJ BodenÎncă nu există evaluări

- How To Detect Electrostatic Discharges in OilDocument3 paginiHow To Detect Electrostatic Discharges in OilCalandrasReyCalandrasreyÎncă nu există evaluări

- Submitted in Partial Fulfillment of Requirements For The Award of The Degree ofDocument19 paginiSubmitted in Partial Fulfillment of Requirements For The Award of The Degree ofEarnest Joseph0% (1)

- U V Patel College of EngineeringDocument24 paginiU V Patel College of EngineeringRamnarayan MeenaÎncă nu există evaluări

- Sams IC2PF 111705Document113 paginiSams IC2PF 111705jisteeleÎncă nu există evaluări

- Dosaggio Additivo Deutz Tr019999012100 - enDocument6 paginiDosaggio Additivo Deutz Tr019999012100 - enLuca Butti S MÎncă nu există evaluări

- Chapter 2 Quiz - 231214 - 195227Document3 paginiChapter 2 Quiz - 231214 - 195227Munir IbrahimÎncă nu există evaluări

- Bibliography BooksDocument4 paginiBibliography BooksgustavopaloÎncă nu există evaluări

- Industrial Hemp (Cannabis Sativa L.)Document93 paginiIndustrial Hemp (Cannabis Sativa L.)Tturk87Încă nu există evaluări

- Thesis Valuation of Vestas Wind SystemsDocument55 paginiThesis Valuation of Vestas Wind SystemsgustavgothÎncă nu există evaluări