Documente Academic

Documente Profesional

Documente Cultură

Drive Failure and Interruption in SCP Machines of Battery 567, Coke Plant

Încărcat de

narendramaharana39Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Drive Failure and Interruption in SCP Machines of Battery 567, Coke Plant

Încărcat de

narendramaharana39Drepturi de autor:

Formate disponibile

PROJECT REPORT

ON

TO STUDY DRIVE FAILURE AND

INTERRUPTION IN SCP MACHINES OF

BATTERY 567,COKE PLANT AND SUGGEST

PRACTICES TO REDUCE INTERRUPTION.

CONTENT

TATA STEEL A BRIF INTRODUCTION

INTRODUCTION TO COKE PLANT

COAL CARBONIAZATION OR COKEING

CONVERSION OF COAL TO COKE

SCHEMATIC DIAGRAM OF COKE PLANT

IMPORTANT DIMENSION @ PARAMETERS

BATTERY 8@9

INTRODUCTION TO DRIVE

DRIVE

COMPONENT OF DRIVE

COMPARISON BETWEEN DC & AC DRIVE

SIEMENS MASTERDRIVE

CONCLUSION

TATA STEEL: A Brief Introduction

Established in 1907, Tata Steel is the worlds 6

th

largest steel company

with an existing annual crude steel capacity of 30 million tonnes. Asias

first integrated steel plant and Indias largest integrated private sector

steel company is now the worlds second most geographically diversified

steel producer, with operations in 26 countries and commercial presence

in over 50 countries.

Tata Steel completed 100 glorious years of existence on august 26, 2007

following the ideals and philosophy laid down by its founder, Jamshedji

Nusserwanji Tata. The first private sector steel plant which started with a

production capacity of 1,00,000 tonnes has transformed into a global

giant.

Tata Steel plan to grow and globalise through organic and inorganic

routes. Its 6.8 million tonnes per annum (MTPA) Jamshedpur Works

plan to achieve 10MT capacity by 2010. The Company also has

three Greenfield steel projects in the states of Jharkhand, Orissa

and Chhattisgarh proposed steel making facilities in Vietnam.

Tata Steel is a global player with a balanced presence in developed

European and fast growing Asian market and with a strong position

in the construction, automotive and packaging markets. Its

Jamshedpur steel works produce hot and cold rolled coils and

sheets, galvanized sheets, tubes, wire rods, construction rebars,

rings and bearings. In an attempt to decommodities steel, the

Company has introduced several branded steel products, including

Tata Steelium (the worlds first branded Clod Rolled Steel), Tata

Shaktee (Galvanised Corrugated Sheets), Tata Tiscon (rebars), Tata

Pipes, Tata Bearings, Tata Structura, Tata Agrico (hand tools and

implements) and Tata Wiron (galvanized wire products).

In the financial year 2006-07 revenue from the sale of these

branded steel products was 26% of the companys sales

revenues.

Tata Steels vision is to be the global steel industry benchmark

for Value Creation and Corporate Citizenship.

Tata Steel is one of the few steel companies in the world that

is Economic Value Added (EVA) positive. It was ranked the

"World's Best Steel Maker", for the third time by World Steel

Dynamics in its annual listing in February, 2006. Tata Steel

has been conferred the Prime Minister of India's Trophy for

the Best Integrated Steel Plant five times.

INTRODUCTION TO COKE PLANT

Coke plant converts naturally found coal into coke, which is

suitable for use in the Blast Furnaces. There are six batteries

in operation with a total of 284 nos. Stamp Charged ovens

And 54 nos. of top charged ovens.

KEY ACTIVITIES OF COKE PLANT

BLENDING

COAL PREPARATION

STAMPING OF COAL & CAKE MAKING

CARBONISATION OF COKE (BATTERY # OPERATION)

WHARF MANAGEMENT

SIZING OF COKE

DESPATCHING OF COKE TO BLAST FURNACE

BLENDING

COAL PREPARATION

STAMPING & CHARGING PUSHING

HANDLING OF COKE QUENCHING SYSTEM

WHARF MANAGEMENT SCREENING & SIZING

COKE DESPATCH TO CUSTOMER

COKE PLANT

Coke plant is an essential part of an integrated steel plant. Coking process consist of

heating of coal (pyrolysis) in absence of air at temperature ranging 950

0

C to 1200

0

C in

oven made up of refractory materials for 20 Hrs. The coal undergoes physical and

chemical changes producing volatile chemicals in the form of complex mixture of vapour

and gases. At the end of the process a hard porous mass remains, which is coke.

Quenching with water-cools the lump coke. The coke is further crushed and screened.

During carbonization about 23-25% (by weight) of the initial charges of the coal spews

out as mixed gases and vapours, which pass from oven to collecting mains. Byproducts

are recovered from these gases and vapours.

COAL CARBONIZATION OR COKING

When coking coal heated in the absence of air they become plastic and soft over

a temperature range of 310

0

C to 500

0

C. The coal particle agglomerate into a

coherent mass, which swells and resolidifies to form a porous structure known as

coke.

When coal is charged in the hot oven, the temperature of oven refractory wall

being at about 1100

0

C to 1500

0

C, the portion of the coal in immediate contact

with hot wall is heated very rapidly to a high temperature, a thin layer softens,

becomes plastic and melts. This layer of plastic material travels towards the

centre of the oven and some of the gaseous product force their way out of the

plastic materials, as the temperature of the charge is raised. On the wall side, the

plastic layer hardens into a cellar residue and the volatile matter left in the coke is

driven of gradually as the temperature rises during remainder of the coke period.

Thus in an oven, during initial stage of coking, the coal exists side by side in

several phases, e.g. coke, semicoke, a plastic mass and granular coal.

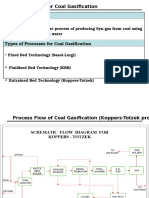

Schematic Diagram of COKE Plant

Oven:

Length 13760 mm

Height 4570 mm

Average Width 460 mm

(Ram side 450 mm, Middle 460 mm, Coke side 470 mm)

Oven Taper 20 mm

(From Ram side to Oven side)

Oven to Oven Centre Distance 1200 mm

Heating chamber:

Length 13760 mm

Height 4570 mm

Average Width 740 mm

(Ram side 750 mm, Middle 740 mm, Coke side 730 mm)

Thickness of Stretcher Wall 95 mm

(5 mm more that old Batteries)

IMPORTANT DIMENSIONS AND

PARAMETERS

The Battery 8 and 9 of the TATA STEEL is the state of

the art battery with worlds best technology achieving

the quality parameters of the world class coke as well

as meeting 100% of the environmental norms. These

are OTTO DESIGN, Stamp Charge battery with 70

ovens in each battery. Its heating system is twin flue,

under jet firing type, double stage air, and compound

ovens. It can be operated in B.F. (Blast Furnace) Gas or

C.O. (Coke Oven) Gas according to requirement. So it is

called compound ovens. The capacity of both the

batteries combined is one million tons per annum.

BATTERY 8 AND 9

17

POWER DISTRIBUTION IN SCP M/C

Main

Transformer

6.6 KV/ 433 V

General

MCC-1

General

MCC-2

Stamping

MCC

Master

Drive-1

Master

Drive-2

F

r

o

m

H

T

b

r

e

a

k

e

r

* SEPARATE BREAKER FOR MASTER DRIVES IN GNL. MCC-1

18

MAIN TRANSFORMER (SPEC.)

1OOO KVA, Dry Type Resin cast Transformer.

6.6Kv/433, 433v, Dyn5, yn5

Secondary current 666.7, 666.7Amps.

HT side Amps= 87.5

Make: Kirloskar

1U

1V

1W

2U

H T Side

L T Side

3U

3W

3V

To Drives

2V

2W

To General

MCCs

TITLE OF THE PROJECT

TO STUDY DRIVE FAILURE AND

INTERRUPTION IN SCP MACHINES OF

BATTERY 567,COKE PLANT AND SUGGEST

PRACTICES TO REDUCE INTERRUPTION.

INTRODUCTION TO DRIVE

Drives are employed for systems that require motion control e.g. transportation

system, fans,robots, pumps, machine tools, etc. Prime movers are required in drive

systems to provide themovement or motion and energy that is used to provide the

motion can come from varioussources: diesel engines, petrol engines, hydraulic

motors, electric motors etc.

Drives that use electric motors as the prime movers are known as electrical drives

There are several advantages of electrical drives:

a. Flexible control characteristic This is particularly true when power electronic

converters are employed where the dynamic and steady state characteristics of the

motorcan be controlled by controlling the applied voltage or current.

b. Available in wide range of speed, torque and power

c. High efficiency, lower noise, low maintenance requirements and cleaner operation

d. Electric energy is easy to be transported.

DRIVE

AC drives, inverters, and adjustable frequency drives are all terms that are used to

refer to equipment designed to control the speed of an AC motor. The term SIMOVERT

is used by Siemens to identify a SIemens MOtor inVERTer (AC drive).

AC drives receive AC power and convert it to an adjustable frequency, adjustable

voltage output for controlling motor operation. A typical inverter receives 480 VAC,

three-phase, 50 Hz input power and in turn provides the proper voltage and frequency

for a given speed to the motor. The three common inverter types are the variable

voltage inverter (VVI), current source inverter (CSI), and pulse width modulation

(PWM).

Another type of AC drive is a cycloconverter. These are commonly used for very large

motors and will not be described in this course. All AC drives convert AC to DC, and

then through various switching techniques invert the DC into a variable voltage,

variable frequency output.

Variable Voltage Inverter (VVI):

The variable voltage inverter (VVI) uses an SCR converter bridge to convert the

incoming AC voltage into DC. The SCRs provide a means of controlling the value of the

rectified DC voltage from 0 to approximately 600 VDC. The L1 choke and C1

capacitor(s) make up the DC link section and smooth the converted DC voltage. The

inverter section consists of six switching devices. Various devices can be used such as

thyristors, bipolar transistors, MOSFETS, and IGBTs. The following schematic shows an

inverter that utilizes bipolar transistors. Control logic (not shown) uses a

microprocessor to switch the transistors on and off providing a variable voltage and

frequency to the motor.

This type of switching is often referred to as six-step because it takes six 60 steps to

complete one 360 cycle. Although the motor prefers a smooth sine wave, a six-step

output can be satisfactorily used. The main disadvantage is torque pulsation which

occurs each time a switching device, such as a bipolar transistor, is switched. The

pulsations can be noticeable at low speeds as speed variations in the motor. These

speed variations are sometimes referred to as cogging. The non-sinusoidal current

waveform causes extra heating in the motor requiring a motor derating.

Current Source Inverter:

The current source inverter (CSI) uses an SCR input to produce a variable voltage DC

link. The inverter section also uses SCRs for switching the output to the motor. The

current source inverter controls the current in the motor. The motor must be carefully

matched to the drive.

Current spikes, caused by switching, can be seen in the output. At low speeds current

pulses can causes the motor to cog.

Pulse Width Modulation:

Pulse width modulation (PWM) drives, like the Siemens MICROMASTER and

MASTERDRIVE VC, provide a more sinusoidal current output to control frequency

and voltage supplied to an AC motor. PWM drives are more efficient and typically

provide higher levels of performance. A basic PWM drive consists of a converter,

DC link, control logic, and an inverter.

Converter and DC Link:

The converter section consists of a fixed diode bridge rectifier which converts the

three-phase power supply to a DC voltage. The L1 choke and C1 capacitor(s) smooth

the converted DC voltage. The rectified DC value is approximately 1.35 times the line-

to-line value of the supply voltage. The rectified DC value is approximately 650 VDC for

a 480 VAC supply.

Control Logic and Inverter:

Output voltage and frequency to the motor are controlled by the control logic and

inverter section. The inverter section consists of six switching devices. Various devices

can be used such as thyristors, bipolar transistors, MOSFETS and IGBTs. The following

schematic shows an inverter that utilizes IGBTs. The control logic uses a

microprocessor to switch the IGBTs on and off providing a variable voltage and

frequency to the motor.

IGBTs(Insulated Gate Bipolar Transistor):

IGBTs provide a high switching speed necessary for PWM inverter operation. IGBTs are

capable of switching on and off several thousand times a second. An IGBT can turn on

in less than 400 nanoseconds and off in approximately 500 nanoseconds. An IGBT

consists of a gate, collector and an emitter. When a positive voltage (typically +15

VDC) is applied to the gate the IGBT will turn on. This is similar to closing a switch.

Current will flow between the collector and emitter. An IGBT is turned off by removing

the positive voltage from the gate. During the off state the IGBT gate voltage is

normally held at a small negative voltage (-15 VDC) to prevent the device from turning

on.

Using Switching Devices to Develop AC Output:

In the following example, one phase of a three-phase output is used to show how an

AC voltage can be developed. Switches replace the IGBTs. A voltage that alternates

between positive and negative is developed by opening and closing switches in a

specific sequence. For example, during steps one and two A+ and B- are closed. The

output voltage between A and B is positive. During step three A+ and B+ are closed.

The difference of potential from A to B is zero. The output voltage is zero. During step

four A- and B+ are closed. The output voltage from A to B is negative. The voltage is

dependent on the value of the DC voltage and the frequency is dependent on the

speed of the switching. An AC sine wave has been added to the output (A-B) to show

how AC is simulated.

PWM (Pulse Width Modulation) Output:

There are several PWM modulation techniques. It is beyond the scope of this book to

describe them all in detail. The following text and illustrations describe a typical pulse

width modulation method. An IGBT (or other type switching device) can be switched

on connecting the motor to the positive value of DC voltage (650 VDC from the

converter). Current flows in the motor. The IGBT is switched on for a short period of

time, allowing only a small amount of current to build up in the motor and then

switched off. The IGBT is switched on and left on for progressively longer periods of

time, allowing current to build up to higher levels until current in the motor reaches a

peak. The IGBT is then switched on for progressively shorter periods of time,

decreasing current build up in the motor. The negative half of the sine wave is

generated by switching an IGBT connected to the negative value of the converted DC

voltage.

PWM Voltage and Current:

The voltage and frequency is controlled electronically by circuitry within the AC drive.

The fixed DC voltage (650 VDC) is modulated or clipped with this method to provide a

variable voltage and frequency. At low output frequencies a low output voltage is

required. The switching devices are turned on for shorter periods of time. Voltage and

current build up in the motor is low. At high output frequencies a high voltage is

required. The switching devices are turned on for longer periods of time, allowing

voltage and current to build up to higher levels in the motor.

COMPONENT OF DRIVE

The main components of a modern electrical drive are the motors, power

processor, control unitand electrical source. These are briefly discussed below.

a) Motors:

Motors obtain power from electrical sources. They convert energy from

electrical tomechanical - therefore can be regarded as energy converters. In

braking mode, the flow of power is reversed. Depending upon the type of power

converters used, it is also possible for the power to be fed back to the sources rather

than dissipated as heat.

There are several types of motors used in electric drives choice of type used

depends onapplications, cost, environmental factors and also the type of sources

available.. Broadly, they can be classified as either DC or AC motors:

DC motors (wound or permanent magnet).

AC motors:

Induction motors squirrel cage, wound rotor.

Synchronous motors wound field, permanent magnet.

Brushless DC motor require power electronic converters.

Stepper motors require power electronic converters.

Synchronous reluctance motors or switched reluctance motor.

b) Power Processor or Power Modulator:

Since the electrical sources are normally uncontrollable, it is therefore necessary to be

able to control the flow of power to the motor this is achieved using power

processor or power modulator. With controllable sources, the motor can be reversed,

brake or can be operated with variable speed. Conventional methods used, for

example, variable impedance or relays, to shape the voltage or current that is supplied

to the motor these methods however are inflexible and inefficient.

Modern electric drives normally used power electronic converters to shape the

desired voltage or current suppof the motors can be changed at will. Power electronic

converters have several advantages over classical methods of power conversion, such

as:

More efficient since ideally no losses occur in power electronic converters.

Flexible voltage and current can be shaped by simply controlling switching

functions of the power converter.

Compact smaller, compact and higher ratings solidstate power electronic devices

are continuously being developed the prices are getting cheaper.

Converters are used to convert and possibly regulate (i.e. using closed-loop control)

the available sources to suit the load i.e. motors. These converters are efficient

because the switches operate in either cut-off or saturation modes.

Several conversion are possible:

AC to DC

DC to AC

DC to DC

AC to AC

c) Control Unit

The complexity of the control unit depends on the desired drive performance and the

type of motors used. A controller can be as simple as few op-amps and/or a few digital

ICs, or it can be as complex as the combinations of several ASICs and digital signal

processors (DSPs).

The types of the main controllers can be:

Analog - which is noisy, inflexible. However analog circuit ideally has infinite

bandwidth.

Digital immune to noise, configurable. The bandwidth is obviously smaller than the

analog controllers depends on sampling frequency.

DSP/microprocessor flexible, lower bandwidth compared to above. DSPs perform

faster operation than microprocessors (multiplication in single cycle). With

DSP/microp. complex estimations and observers can be easily implemented.

d) Source

Electrical sources or power supplies provide the energy to the electrical motors. For

high efficiency operation, the power obtained from the electrical sources need to be

regulated using power electronic converters.

Power sources can be of AC or DC in nature and normally are uncontrollable, i.e. their

magnitudes or frequencies are fixed or depend on the sources of energy such as solar

or wind. AC source can be either three-phase or single-phase; 3-phase sources are

normally for high power applications.

There can be several factors that affect the selection of different configuration of

electrical drive system such as:

a) Torque and speed profile - determine the ratings of converters and the quadrant of

operation required.

b) Capital and running cost Drive systems will vary in terms of start-up cost and

running cost, e.g. maintenance.

c) Space and weight restrictions.

d) Environment and location.

Comparison Between DC and AC Drives

Motors :

DC require maintenance, heavy, expensive, speed limited by mechanical

construction.

AC less maintenance, light, cheaper, robust, high speed (esp. squirrelcage type).

Control unit:

DC drives: Simple control decoupling torque and flux by mechanical commutator

the controller can be implemented using simple analog circuit even for high

performance torque control cheaper.

AC drives, the types of controllers to be used depend on the required drive

performance obviously, cost increases with performance. Scalar control drives

technique does not require fast processor/DSP whereas in FOC or DTC drives, DSPs or

fast processors are normally employed.

Siemens MASTERDRIVES

The Siemens MASTERDRIVES can be used for variable-speed control on motors rated from 1

to 5000 HP. MASTERDRIVES are available for all major worldwide 3-phase supply voltages:

208-230, 380-460, 500-575, 660-690 volts. The Siemens MASTERDRIVES can also be referred

to by a model series number, 6SE70.

AC - AC (AC - to - AC):

A single inverter can be used with single motor, single motor with a tach, and multimotor

applications. This is referred to as the AC-AC version. Various options allow for analog and

encoder tachometer types.

DC - AC (DC - to - AC):

The Siemens MASTERDRIVES can also be configured so that acommon DC bus supplies

power to several AC inverters. Common DC bus systems also allow single and multimotor

combinations. This is referred to as the DC-AC version.

Braking unit:

In the speed-torque chart there are four quadrants accordingto direction of rotation

and direction of torque. Quadrant I is forward motoring or driving (CW). Quadrant III is

reverse motoring or driving (CCW). Reverse motoring is achieved by reversing the

direction of the rotating magnetic field. The dynamics of certain loads may require

four-quadrant operation. When equipped with an optional braking unit Siemens

MASTERDRIVES are capable of four-quadrant operation. Braking occurs in quadrants II

and IV. Several regenerative rectifier products are also available which return braking

energy to the power source instead of dissipating (wasting) it in resistors.

Compact units:

Compact units require the smallest mounting space. Units canbe DIN-G rail mounted

side-by-side without spacing. There are four sizes: A, B, C, and D. Compact units are

available with ratings from 3 to 50 HP (5.6 to 72 Amps) at 460 VAC.

Chassis Units:

Chassis units can also be mounted side-by-side without spacing. They are easily

mounted on the wall when supplied in an IP20 enclosure. There are four sizes: E, F, G,

and K. Chassis units are available with ratings from 60 to 500 HP (83.7 to 590 Amps) at

460 VAC.

Cabinet Units:

Cabinet units are ready-wired complete units for single and multimotor applications.

All components are accessible from the front of the cabinet. Cabinet units are

available with ratings from 50 to 5000 HP (45 to 4500 KW).

Programming and operating sources:

The MASTERDRIVES can be programmed and operated from the following sources:

Operator Control Panel (OP1S)

Parameterization Unit (PMU)

Terminal strips on the CU board

Serial interface (various)

Digital tachometers:

Digital tachometers (encoders) can be used to measure the actual speed of the motor.

The Digital Tachometer Interface (DTI) is designed to be used with digital tachometers

(encoders) that operate at a voltage other than 11-30 VDC. The DTI is also required if

the following encoders are used:

HTL encoder with inverted channel.

Floating HTL encoder.

TTL encoder.

Encoder with cables greater than 495 feet.

Analog tachometers:

Analog tachometers can also be used to measure the actual motor speed. Analog

tachometers generate a DC voltage which is proportional to the speed. The voltage at

maximum speed is a function of the actual tachometer, and generally lies between 10

V and 300 V. Closed loop speed control with an analog tach can be applied to a speed

range from 1 RPM to 6000 RPM. An analog tach interface (ATI) board is used to

connect an analog tach to the CUVC board.

Applications

When applying an AC drive and motor to an application it is necessary to know the

horsepower, torque, and speed characteristics of the load. The following chart shows

characteristics of various loads.

Loads generally fall into one of three categories:

Constant torque - The load is essentially the same throughout the speed range.

Hoisting gear and belt conveyors are examples.

Variable torque - The load increases as speed increases. Pumps and fans are

examples.

Constant horsepower - The load decreases as speed increases. Winders and rotary

cutting machines are examples.

S-ar putea să vă placă și

- Collection and Preparation of Coke Samples For Laboratory AnalysisDocument4 paginiCollection and Preparation of Coke Samples For Laboratory Analysisharrison_sÎncă nu există evaluări

- Stamped Charging Review: How Coke Quality Improves with Dense Coal BlendsDocument31 paginiStamped Charging Review: How Coke Quality Improves with Dense Coal BlendsJorge MadiasÎncă nu există evaluări

- Vocational Training Report at Bokaro Steel PlantDocument34 paginiVocational Training Report at Bokaro Steel PlantRavi kumarÎncă nu există evaluări

- Waste Water - Coke PlantDocument13 paginiWaste Water - Coke PlantSejla Becirovic Cehajic100% (1)

- Coke Oven Life Prolongation - A Multidisciplinary ApproachDocument31 paginiCoke Oven Life Prolongation - A Multidisciplinary ApproachJorge MadiasÎncă nu există evaluări

- Waste Management at JSW Steel - An Innovative Approach: DR Amit Ranjan ChakrabortyDocument25 paginiWaste Management at JSW Steel - An Innovative Approach: DR Amit Ranjan ChakrabortyAnindya RoyÎncă nu există evaluări

- AmiimDocument9 paginiAmiimRanjan SahooÎncă nu există evaluări

- Sesa GoaDocument8 paginiSesa Goamek00sÎncă nu există evaluări

- Analyses of The Coal Densification Behaviour and The Coal Cake Stability Within The Stamped Charge Coke Making OperationDocument16 paginiAnalyses of The Coal Densification Behaviour and The Coal Cake Stability Within The Stamped Charge Coke Making OperationBhadra1964100% (2)

- Numerical Analysis Blast Furnace PDFDocument9 paginiNumerical Analysis Blast Furnace PDFLTE002Încă nu există evaluări

- Proposal For Coal GasificationDocument7 paginiProposal For Coal GasificationDeepakGawasÎncă nu există evaluări

- Ecomak - 2019 DeSOx PresentationDocument37 paginiEcomak - 2019 DeSOx PresentationHsein WangÎncă nu există evaluări

- Enquiry Specification For BOD PlantDocument94 paginiEnquiry Specification For BOD PlantBanerjee SuvranilÎncă nu există evaluări

- Bhilai Steel Plant: An OverviewDocument9 paginiBhilai Steel Plant: An OverviewAKANKSHA LAKRA100% (1)

- TSML Report - ShazDocument21 paginiTSML Report - ShazUmer AleemÎncă nu există evaluări

- Coal Based Sponge Iron Industry Drives Indian Steel MakingDocument4 paginiCoal Based Sponge Iron Industry Drives Indian Steel MakingchaitanyabhansaliÎncă nu există evaluări

- Introduction CO & CCDDocument14 paginiIntroduction CO & CCDAaditya Sharma100% (1)

- Coke CVDocument4 paginiCoke CVAshutosh MishraÎncă nu există evaluări

- Nippon Steel & Sumikin Engineering's Blast FurnaceDocument4 paginiNippon Steel & Sumikin Engineering's Blast Furnacekalai100% (1)

- List of FiguresDocument22 paginiList of FiguresvishalÎncă nu există evaluări

- Critical Analysis of Tap Hole Length and its Impact on Blast Furnace LifeDocument24 paginiCritical Analysis of Tap Hole Length and its Impact on Blast Furnace Liferavish8888Încă nu există evaluări

- EU Coke Production Perspectives and Environmental RegulationsDocument27 paginiEU Coke Production Perspectives and Environmental RegulationsFilipe Mansur100% (1)

- DSP Overview 10-07-2017Document46 paginiDSP Overview 10-07-2017Binod Kumar Padhi0% (1)

- Steel Titans - Inventory Optimization - Steel - A - Thon Presentation FileDocument10 paginiSteel Titans - Inventory Optimization - Steel - A - Thon Presentation FileKumar GauravÎncă nu există evaluări

- Steel: The Indian Steel IndustryDocument43 paginiSteel: The Indian Steel IndustrySylvia GraceÎncă nu există evaluări

- Benchmarking of Integrated Steel PlantsDocument38 paginiBenchmarking of Integrated Steel PlantsAnaruzzaman Sheikh100% (1)

- Durgapur Steel Plant's State-of-the-Art Facilities and ProductsDocument11 paginiDurgapur Steel Plant's State-of-the-Art Facilities and ProductsSharmistha MitraÎncă nu există evaluări

- Dri PDFDocument4 paginiDri PDFhablimasyahidÎncă nu există evaluări

- Tecnored Process - High Potential in Using Different Kinds of Solid FuelsDocument5 paginiTecnored Process - High Potential in Using Different Kinds of Solid FuelsRogerio CannoniÎncă nu există evaluări

- Sinter Plant JSPL, RaigarhDocument14 paginiSinter Plant JSPL, RaigarhJatin BangaliÎncă nu există evaluări

- Mill ScaleDocument6 paginiMill ScaleJhovanny RendónÎncă nu există evaluări

- Blast FurnaceDocument28 paginiBlast Furnaceavanisharma_1991Încă nu există evaluări

- Design, Manufacturing and Testing of Induction Furnace: Submitted byDocument65 paginiDesign, Manufacturing and Testing of Induction Furnace: Submitted byGuru ChaudhariÎncă nu există evaluări

- KeithwrightDocument37 paginiKeithwrightSumit GuptaÎncă nu există evaluări

- New-Project Tata SteelDocument24 paginiNew-Project Tata Steelsomnath banerjeeÎncă nu există evaluări

- Augmenting Use of Non-Coking Coal in Steel Industry:: 4 Coal Summit 19-20 November Hotel The Ashok, New DelhiDocument31 paginiAugmenting Use of Non-Coking Coal in Steel Industry:: 4 Coal Summit 19-20 November Hotel The Ashok, New DelhiakshukÎncă nu există evaluări

- Utilization of Fly Ash and Rice Husk Ash As A Supplement To Concrete Materials - A Critical ReviewDocument9 paginiUtilization of Fly Ash and Rice Husk Ash As A Supplement To Concrete Materials - A Critical Reviewijetrm journalÎncă nu există evaluări

- Unit Operations of Bokaro Steel Plant and Their Environmental AspectsDocument52 paginiUnit Operations of Bokaro Steel Plant and Their Environmental AspectsGopalSingh100% (2)

- CSR PredictionDocument10 paginiCSR PredictionROWHEITÎncă nu există evaluări

- Byproduct Operations and ProcessDocument8 paginiByproduct Operations and ProcessAbhaySnghÎncă nu există evaluări

- Optimization of Tap Hole Concept in JSPL BFDocument9 paginiOptimization of Tap Hole Concept in JSPL BFSaumit PalÎncă nu există evaluări

- Electric Arc Furnace Injection System For OxygenDocument7 paginiElectric Arc Furnace Injection System For OxygenIcilma LiraÎncă nu există evaluări

- Coke Oven PDFDocument22 paginiCoke Oven PDFPrabhanjan BeheraÎncă nu există evaluări

- Treatment of Coke Oven & Coal EffluentsDocument77 paginiTreatment of Coke Oven & Coal EffluentsCHELLA BOBYÎncă nu există evaluări

- Steel Processing in Energy Optimizing Furnace: 4.1 Preparation of EofDocument8 paginiSteel Processing in Energy Optimizing Furnace: 4.1 Preparation of EofRitesh KumarÎncă nu există evaluări

- 09 Ironmaking MM BF Burden CalculationDocument1 pagină09 Ironmaking MM BF Burden CalculationSunil Kumar Dwivedi100% (1)

- Iron Making Unit 2Document72 paginiIron Making Unit 2Prashant NÎncă nu există evaluări

- Gujarat NRE Coke Strategy AnalysisDocument20 paginiGujarat NRE Coke Strategy AnalysisMangesh GulkotwarÎncă nu există evaluări

- Coke Oven New1Document6 paginiCoke Oven New1abhishekgarg98Încă nu există evaluări

- Coke Oven PlantDocument45 paginiCoke Oven PlantSameer Shekhar100% (1)

- JSW Steels LimitedDocument18 paginiJSW Steels Limitedrinkal_143Încă nu există evaluări

- CMR Jan 13Document7 paginiCMR Jan 13James WarrenÎncă nu există evaluări

- What Is SteelDocument10 paginiWhat Is SteelKristo Ver TamposÎncă nu există evaluări

- Sci 401pptDocument107 paginiSci 401pptNiña Viaña BinayÎncă nu există evaluări

- Steel Industries Problem by Amitab - MudgalDocument22 paginiSteel Industries Problem by Amitab - MudgalRavinder Singh PadamÎncă nu există evaluări

- Blast Furnace HydraulicsDocument36 paginiBlast Furnace Hydraulicssghane5674Încă nu există evaluări

- Continuous casting The Ultimate Step-By-Step GuideDe la EverandContinuous casting The Ultimate Step-By-Step GuideÎncă nu există evaluări

- Chlorine: International Thermodynamic Tables of the Fluid StateDe la EverandChlorine: International Thermodynamic Tables of the Fluid StateÎncă nu există evaluări

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasDe la EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasÎncă nu există evaluări

- DC Motor Control Techniques and Speed Control MethodsDocument39 paginiDC Motor Control Techniques and Speed Control Methodsnarendramaharana39Încă nu există evaluări

- To Study Feasibility and Implement Thruster Brakes in LT Motor of SCP-1 at Battery 5,6,7 Coke Plant.Document31 paginiTo Study Feasibility and Implement Thruster Brakes in LT Motor of SCP-1 at Battery 5,6,7 Coke Plant.narendramaharana39Încă nu există evaluări

- AntennaDocument88 paginiAntennanarendramaharana39100% (1)

- Multiplexing and Multiple AcessDocument122 paginiMultiplexing and Multiple Acessnarendramaharana39Încă nu există evaluări

- ArmDocument43 paginiArmnarendramaharana39Încă nu există evaluări

- 8038Document22 pagini8038narendramaharana39Încă nu există evaluări

- Nagel PLC Upgradtion ProjectDocument35 paginiNagel PLC Upgradtion Projectnarendramaharana39Încă nu există evaluări

- Pic 16F877Document115 paginiPic 16F877narendramaharana39100% (1)

- AntennaDocument88 paginiAntennanarendramaharana39100% (1)

- Gate Ec 2011Document33 paginiGate Ec 2011narendramaharana39Încă nu există evaluări

- 07 EDCTransistors Oiho Univ Lesson 07Document84 pagini07 EDCTransistors Oiho Univ Lesson 07bhaavan22Încă nu există evaluări

- PIC16 Architecture, Instruction Set and Assembly Language ProgrammingDocument96 paginiPIC16 Architecture, Instruction Set and Assembly Language Programmingnarendramaharana39100% (1)

- Mentoring for Transformation, Growth and HealthDocument103 paginiMentoring for Transformation, Growth and Healthnarendramaharana39Încă nu există evaluări

- ModemDocument21 paginiModemnarendramaharana39Încă nu există evaluări

- Electrical Drives LecturesDocument231 paginiElectrical Drives Lecturesdivinelight100% (16)

- TransistorDocument42 paginiTransistornarendramaharana39Încă nu există evaluări

- Electrical Drives LecturesDocument231 paginiElectrical Drives Lecturesdivinelight100% (16)

- EC-GATE-2011 (1) .PDF SolutionDocument28 paginiEC-GATE-2011 (1) .PDF SolutionMudit MittalÎncă nu există evaluări

- E175 Electrical SystemDocument22 paginiE175 Electrical Systemygor81Încă nu există evaluări

- Multi V 5 OMTDocument80 paginiMulti V 5 OMTShofchatin MardiyahÎncă nu există evaluări

- BeneView T8 Service ManualDocument192 paginiBeneView T8 Service ManualbmjuberÎncă nu există evaluări

- PVS-175-TL - Product Manual en-RevA (M0000045AG)Document186 paginiPVS-175-TL - Product Manual en-RevA (M0000045AG)Anibal Vargas100% (1)

- Field Inspection Checklist For Rooftop Photovoltaic PV SystemsDocument2 paginiField Inspection Checklist For Rooftop Photovoltaic PV Systemsnino causapinÎncă nu există evaluări

- A Brief Review On Multi Level Inverter Methodology Topologies and TechniquesDocument5 paginiA Brief Review On Multi Level Inverter Methodology Topologies and TechniquesMurtaza KaziÎncă nu există evaluări

- DC-Motor Speed ControllerDocument3 paginiDC-Motor Speed ControllerchakralabsÎncă nu există evaluări

- Operational Manual: DGYF-S500 Type Electromagnet Induction Sealing MachineDocument8 paginiOperational Manual: DGYF-S500 Type Electromagnet Induction Sealing MachineHaroldÎncă nu există evaluări

- AC Solar Installation and Commissioning Checklist ChecklistDocument5 paginiAC Solar Installation and Commissioning Checklist ChecklistJames K. BitokÎncă nu există evaluări

- PRO LCD C Series InverterDocument4 paginiPRO LCD C Series InverterJuan SanchezÎncă nu există evaluări

- Grundfos RSI: Renewable Solar Inverter For Pump Control 1.5 - 250 KWDocument20 paginiGrundfos RSI: Renewable Solar Inverter For Pump Control 1.5 - 250 KWJa AcostaÎncă nu există evaluări

- ET4119 2007-12-07 Ten Met BundelDocument23 paginiET4119 2007-12-07 Ten Met BundelmeteÎncă nu există evaluări

- 2017.04.17 Bidding Documents For Dist - HanguDocument40 pagini2017.04.17 Bidding Documents For Dist - HanguYasir ShahzadÎncă nu există evaluări

- SOLAREDGE P Series Commercial Add On Frame Mounted Power Optimizer DatasheetDocument2 paginiSOLAREDGE P Series Commercial Add On Frame Mounted Power Optimizer DatasheetMaisa LuanaÎncă nu există evaluări

- Inverter Comparison Report for 30MW PV Plant in Durango, MexicoDocument41 paginiInverter Comparison Report for 30MW PV Plant in Durango, MexicoHernan ArrigoneÎncă nu există evaluări

- HVDC Transmission CalculationsDocument1 paginăHVDC Transmission CalculationsJagannathWijekoonÎncă nu există evaluări

- Automation & Speed Control of Transfer Car by Interfacing An Induction Motor Drive With Programmable Logic ControllerDocument11 paginiAutomation & Speed Control of Transfer Car by Interfacing An Induction Motor Drive With Programmable Logic ControllerYusuf MochtarÎncă nu există evaluări

- Best Books Power Electronics Reference GuideDocument1 paginăBest Books Power Electronics Reference GuideShakir AhmadÎncă nu există evaluări

- Sample Documentation For Technical SeminarDocument21 paginiSample Documentation For Technical Seminar18-208 LingaÎncă nu există evaluări

- Installation Guide JAT710E 26Document136 paginiInstallation Guide JAT710E 26prasad kandavarapuÎncă nu există evaluări

- Project Documentation For Multilevel InvertersDocument89 paginiProject Documentation For Multilevel InvertersAnonymous hm7nSy1ebÎncă nu există evaluări

- AEG Inverter 8000012364 01 Bal enDocument42 paginiAEG Inverter 8000012364 01 Bal ennewionÎncă nu există evaluări

- Design and Implementation of a Domestic Solar-Wind Hybrid Energy SystemDocument5 paginiDesign and Implementation of a Domestic Solar-Wind Hybrid Energy SystemVijayant VJÎncă nu există evaluări

- Manual de Instrucciones FroniusDocument186 paginiManual de Instrucciones Froniussaunders260Încă nu există evaluări

- Hybrid Solar Wind Trainer Generates Renewable EnergyDocument3 paginiHybrid Solar Wind Trainer Generates Renewable EnergySasa VrtunicÎncă nu există evaluări

- Optimal Grid Connected InverterDocument83 paginiOptimal Grid Connected Inverterashraf-84Încă nu există evaluări

- INTRODUCTION TO CONTRO SYSTEM Book PDFDocument395 paginiINTRODUCTION TO CONTRO SYSTEM Book PDFahmadÎncă nu există evaluări

- MosfetDocument90 paginiMosfetseahateÎncă nu există evaluări

- Archimod HE Tender Threephase 20kW enDocument14 paginiArchimod HE Tender Threephase 20kW enMuhammad Qumar NazeerÎncă nu există evaluări

- Simulation and Comparison of SPWM and SVPWM Techniques for InvertersDocument6 paginiSimulation and Comparison of SPWM and SVPWM Techniques for InvertersIkram RidhoÎncă nu există evaluări