Documente Academic

Documente Profesional

Documente Cultură

May Progress Meeting

Încărcat de

Gohar AliDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

May Progress Meeting

Încărcat de

Gohar AliDrepturi de autor:

Formate disponibile

CONTENTS OF MEETING

1. General Discussion

2. Review of Previous Meeting Points

3. New Points

4. Talk of The Day

5. Comments and Suggestions

GENERAL DISCUSSION

GENERAL DISCUSSION

Surveillance audit EMS 14001-2004 LPG Plant

Meyal was conducted on 24-03-2014.

By the grace of Allah Almighty the surveillance

audit was conducted successfully without any

Major or Minor Non Conformance.

Congratulation and thanks to all the

departments for their TEAM effort and

mutual interest to achieve this milestone for

POL MEYAL.

H2S Drill AT MGC PLANT

March 18, 2014 at MGC Plant

To ascertain the efficiency of the

H

2

S emergency response procedure.

To create awareness regarding H2S

leakage scenarios.

To refresh and highlight the role of

emergency response team.

To minimize losses and in time

recovery of resources.

Observation:

All the staff reported in time at

assembly point .

Environmental Walk for Awareness

of EMS 14001:2004

Objective:

Environmental walk for

awareness of EMS 14001:2004

was held on 24 April, 2014 at

09:40 AM for

Introduction to EMS

14001:2004

Types of Waste and proper

disposal at designated areas

at LPG Plant.

Importance of Good

housekeeping

ALIVE FIRE PRACTICE

April 16, 2014 at Fire Station.

To create awareness regarding

different types of fire and methods.

To create awareness regarding

different methods to extinguish fire.

To familiarize and train employees

about the fire detection and fire

fighting equipments.

To deal with any emergency situation

efficiently without creating panic in a

planned manner.

EMERGENCY SIREN SHEDS

Emergency siren sheds have been

fabricated and installed at Power

house and MGC plant.

Replacement Leaky Fire Water Lines

Two leaky Fire water lines replaced at MGC and LPG plant.

NEW WIND SOCK

Fabrication and installation of new wind sock at Tank farm.

INCIDENT / ACCIDENT

( Fire Incident)

On April 18, 2014 at 0550hrs, main

breaker of SS and JMS colony tripped

at Power house. During visual inspection

by power house Shift In-charge

(Muhammad Younas ), small fire was

Observed at HT cable.

The fire was extinguished by using DCP-6Kg.

Losses:

No human injury/loss reported.

DCP 6 kg Fire extinguisher was used

INCIDENT / ACCIDENT

Short circuiting at main Store

On 19 April, 2014 at 09:35hrs, short circuiting

was observed in main store office. The store

JMS (Mr. Sarfraz) immediately switched off the

breaker and informed Electrical & HSE

department. The electrical department

inspected and short circuiting found at LT

cable at roof of main store.

INCIDENT / ACCIDENT

On 24-04-2014 at 15:45 Hrs, Contractor Mr. Fazal

Karim with his one Helper was lifting the newly

fabricated main gate of ERS with overhead crane.

The overhead Crane block hit the shaft support

due to over tightening of crane block. After

hitting of Crane block, Shaft support cracked due

to impact and fell down on ground and slightly

touched on his left eyebrow of Mr. Waseem

(Contractor Helper).

Immediately he was sent to Meyal hospital and

minor cut was observed on his left eyebrow .

STATUS OF PREVIOUS

OBSERVATIONS

PREVIOUS POINTS

1. Loose connections, cable joints, broken sockets.

Hazard:

Fire/explosion/electric shock hazard

Areas:

ERS, machine shop, MGC, Maintenance workshops,

Laboratory, Old POLGAS etc.

Responsibility:

Concerned Area I/Cs and E&I Engr.

Status: Work In progress

PICTORIAL VIEW

PICTORIAL VIEW

PREVIOUS POINTS

2(a) Improper handling and storage of filled gas cylinders

2(b) The improper storage of the chemicals/lubricants

drums in store

Hazard: Can lead to severe incident/accident, explosion

and spillage in case of chemicals and lubricants.

Areas: Chemical lab, Main store

Responsibility: Exec. Stores and Exec. Lab.

Status: In progress

PICTORIAL VIEW

PREVIOUS POINTS

3(a). Gas Leakage (LEL & H2S)

LEL and H2S Gas Detected at following points;

LEL detected on Fuel Gas Line at Sour Compressor

Gasoline Pump at LPG Plant (out of range)

Level (Rota) Gauge of LPG Tank #18 at LPG Plant ( Out of

range)

LEL detected at F-101 (A/B) inlet and outlet valves at LPG

Plant (out of range)

LEL detected at Solvent Pump near Gasoline Tanks.

Hazard:

Fire / Explosion

Areas:

Tank Farm/ LPG Plant

Responsibility:

S.P.E/Sr. Executive ERS

Status : Completed

PREVIOUSPOINTS

3 (b). Gas Leakage (LEL & H2S)

H2S Gas Detected at following points;

Leakage from B-Unit (Stage-2) at Sour Gas

Compressor.

Gas detected from LP Knock out Vessel Drain

channels at Tank Farm Plant area.(+ 50 ppm)

Hazard:

Continuous exposure leading to Health effects.

Unconsciousness

Areas:

Tank Farm

Responsibility:

S.P.E

Status: Completed

PREVIOUS POINTS

4. Oxygen & Acetylene Cylinders

Oxygen & acetylene cylinders are scattered at ground

without proper racks.

Hazard:

Fire/explosion

Areas:

Fabrication Shed

Responsibility:

F.E

Status: Completed

PREVIOUS POINTS

5. MGC Lab Room

MGC Lab building is in very bad condition

specially roof loose falling material on walk

ways.

Hazard:

Building collapse, Serious Injury

Areas:

MGC Lab Building.

Responsibility:

F.E/P.E

Status: Estimate forwarded for approval

PREVIOUS POINTS

6. Missing gratings

There are gaps on SRU-II platform due to missing grating and

without handrails.

Hazard:

Fall from Height, Object Falling

Areas:

SRU-II (MGC)

Responsibility:

F.E/PME

Status:

Completed

PREVIOUS POINTS

PREVIOUS POINTS

7. Short Circuit of HT Links

Lube oil drums and oily rags are placed under the HT Links

Poles near Residual Compressor area where short-circuiting

is observed many times.

Hazard:

Fire / Explosion, Electric Hazard

Areas:

Residual Compressor

Responsibility:

E & I Executive/ Executive Engineering

Status:

Still no action.

NEW POINTS

NEW POINTS

(1) Gas Leakage (LEL & H2S)

LEL and H2S Gas Detected at following points;

(a)LEL detected on E-109 at LPG Plant.(Out of range)

Hazard:

Fire / Explosion

Areas: LPG Plant

Responsibility:

S.P.E

NEW POINTS

1.Gas Leakage (LEL & H2S)

H2S Gas Detected at following point;

(b)H2S gas detected at inlet valve at SRU# 2 inlet valve MGC

plant.(up to 100ppm)

Hazard:

Continuous exposure leading to Health effects.

Unconsciousness

Areas:

Tank Farm

Responsibility:

S.P.E

NEW POINTS

NEW POINTS

2.NRV Replacement at Solvent Oil Tanks

solvent oil leakage observed from solvent tank# B foam

system line due to malfunctioning of NRV.

Hazard:

FIRE ,

Areas:

Solvent tanks

Responsibility:

MPE

NEW POINTS

NEW POINTS

3. DRAIN CHANNEL FOR CUMULATIVE EFFLUENTS OF

LPG PLANT AND POWER HOUSE

Oil spillage near fence due to no proper drain channel for

cumulative effluents of LPG plant and power house.

Hazard:

Fire/explosion/ soil contamination.

Areas:

New Power House

Responsibility:

F.E

NEW POINTS

NEW POINTS

3.Condensate Drain Channel at LPG plant

The condensate channel at LPG plant is damage

Hazard:

Fire/explosion/ soil contamination

Areas:

Solvent tanks

Responsibility:

F.E

NEW POINTS

NEW POINTS

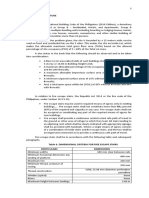

4.POOR LIGHTING CONDITION AT PLANT AREA

Poor lighting condition observed at plant areas due to

missing bulbs.(Combined lighting survey conducted by PE,

Engr E& I& HSE Engineer)

Hazard:

Slip/Trip/evacuation/snake bite

Areas:

Main store, Tank farm, MGC plant ,LPG Plant, Power house,

New POL gas

Responsibility:

Engr E&I

Sr. No. Remarks

Illumination

(Lux)

1 Lights installed Bulbs not working 0

2 Lights installed Bulbs not working 0

3 Lights installed Bulbs not working 0-1

4

Lights installed Bulbs not working

0-1

5 Lights installed Bulbs not working 0-23

6 Lights installed Bulbs not working 1--4

7 Lights installed Bulbs not working 0, 3

8 Lights installed Bulbs not working 5--21

9 Lights installed Bulbs not working 2--3

Sr. No. Remarks

10 Lights installed Bulbs not working 0

11 Lights installed Bulbs not working 1

12 Lights installed Bulbs not working 0

Sr. No. Remarks

13 Lights installed Bulbs not working 0--1

14 Lights installed Bulbs not working 3--9

15 Lights installed Bulbs not working 1--21

16 Lights installed Bulbs not working 1--5

17 Lights installed Bulbs not working 1--24

18 Lights installed Bulbs not working 0--5

Sr. No. Remarks

19 Lights installed, tubes not working 1--13

20 Lights installed, tubes not working 1--8

21 Lights installed, tubes not working 5--21

22 Lights installed, tubes not working 0--5

23 Lights not installed 1--5

24 Lights installed Bulbs not working 0-1

25 Lights installed Bulbs not working 0-1

26 Lights installed Bulbs not working 0-3

27 Lights installed Bulbs not working 0-9

28 Lights installed Bulbs not working 0

29 Lights installed Bulbs not working 1--10

30 Lights installed Bulbs not working 0

31 Lights installed Bulbs not working

32 Lights installed Bulbs not working 0

33 Lights installed Bulbs not working 0-1

34 Lights installed Bulbs not working 1--3

35 Lights installed Bulbs not working 0

36 Lights installed Bulbs not working 0-4

37 Lights installed Bulbs not working 0--1

38 Lights installed Bulbs not working 2--11

39 Lights not installed on way 0-1

Sr. No. Remarks

40 Lights installed Bulbs not working 2--4

41 Lights installed Bulbs not working 0

42 Lights installed Bulbs not working 0-1

43 Lights installed Bulbs not working 1--2

Old Power House house

Enterance gate of New Power House

Crude oil Tank 2

Location

New and Old Power House Area

Mechanical work shop near Old

power house

Distillation columns (aerial view)

Rear Side of ERS and Machine Shop

HP vessel area

V-05

Expander panel and V-106

P-101 A/B, P-103 A/B

P-106, NGL Pump

Turbine (West side)

Plant inlet valves area

ESD valves Pit

Location

Location

GPP-2

Location

K-unit area

Tank Farm Area

Bulky Knock out Well 12

Main Store & Lab

Sour Gas compressor "B"

Engine Repair Shop

Domial and Well 8 Bulky Knock out

Lab outside

Tank Farm Enterance

Location

Crude Tank Lorry Filling point

Near Mosque and water cooler

Pumping shed (When pumps

started the lights get off as per

operator statement)

API sumps Area+ Pond pump

Chemical Store Area

MGC

SRU-1

GPP-1

SRU-2

Light Gasoline Tanks

LPG Mosque

LPG Plant

LPG Tanks (1-10)Front side

LPG Tanks (1-10)Rear side

LPG Tanks (11-18)Front side

LPG Tanks (11-18)Rear side

LPG Cotrol room Front side

Hot oil furnace area

Chemical storage shed

SNGPL header

V-101, 102 area

Solvent oil tank area

Solvent oil Tank Lorry Filling point

LPG Plant enterance to Control

room area

NEW POINTS

5.Clamped Gas Lines at Plant Area .

Clamped discharge line of MEA from sulzer pump to GPP1 at

MGC.

Clamped suction line of D-unit compressor at Tank Farm

Area.

Hazard:

H2S leakage, fire.

Areas:

Tank farm, MGC Plant

Responsibility:

SPE/PME

NEW POINTS

NEW POINTS

NEW POINTS

6.Mainteanace of Fire Tender

Fire tender maintenance required at

Rusty body from rear side, Revolving Emergency light, Hand brake not

working, Door Handles and lock not working properly, Pump floor rear

side damage, the suspension (one Kamani patta) broken, Gauges not

working properly. (Diesel and Temperature),Cabin lights

Hazard:

Emergency equipment

Areas:

HSE Office

Responsibility: Exec. Motor shed/HSE /admin

NEW POINTS

NEW POINTS

TALK OF THE DAY

COMMENTS AND SUGGESTIONS

THANKS TO ALL

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Separation Equipments Mod5Document34 paginiSeparation Equipments Mod5msn1981Încă nu există evaluări

- Line Sizing1Document20 paginiLine Sizing1Srihari KodimelaÎncă nu există evaluări

- Pressure Drop Calculation Equations For PIPING and PIPELINEDocument3 paginiPressure Drop Calculation Equations For PIPING and PIPELINETiano BaLajadia100% (4)

- Pakistan Investment GuideDocument270 paginiPakistan Investment GuideGohar AliÎncă nu există evaluări

- Force Force: Bourdon TubeDocument10 paginiForce Force: Bourdon TubeGohar AliÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- A.O: Against Order: Desktop Hard Disk Laptop Hard Disk Scsi Hard Disk Adaptec Cards External Hard DiskDocument28 paginiA.O: Against Order: Desktop Hard Disk Laptop Hard Disk Scsi Hard Disk Adaptec Cards External Hard DiskArul brittoÎncă nu există evaluări

- (Dust of Snow) & 2 (Fire and Ice) - NotesDocument3 pagini(Dust of Snow) & 2 (Fire and Ice) - NotesdakshÎncă nu există evaluări

- Prestressed Concrete ProblemDocument9 paginiPrestressed Concrete ProblemPrantik Adhar SamantaÎncă nu există evaluări

- Intro To Geometric Design and Vertical AlignmentDocument25 paginiIntro To Geometric Design and Vertical AlignmentAhsan ArfanÎncă nu există evaluări

- Sony DVD Player Power Circuit DiagramDocument40 paginiSony DVD Player Power Circuit DiagramHariyadiÎncă nu există evaluări

- Heat ExchangerDocument5 paginiHeat Exchangersara smithÎncă nu există evaluări

- Inspection List For Electrical PortableDocument25 paginiInspection List For Electrical PortableArif FuadiantoÎncă nu există evaluări

- Lock Maiolo Savonarola MachiavelliDocument22 paginiLock Maiolo Savonarola MachiavelliHeliogabolusÎncă nu există evaluări

- Loading and Hauling Dump Truck: DumperDocument2 paginiLoading and Hauling Dump Truck: DumperRJÎncă nu există evaluări

- SkepticismDocument5 paginiSkepticismstevenspillkumarÎncă nu există evaluări

- Nteq Lesson PlanDocument4 paginiNteq Lesson Planeva.bensonÎncă nu există evaluări

- Science 8: Learning Activity SheetDocument9 paginiScience 8: Learning Activity SheetVan Amiel CovitaÎncă nu există evaluări

- 01 Gyramatic-Operator Manual V2-4-1Document30 pagini01 Gyramatic-Operator Manual V2-4-1gytoman100% (2)

- ECON 304 Course ContentDocument2 paginiECON 304 Course ContentAanand JhaÎncă nu există evaluări

- s145 Series HMM 201902 PDFDocument73 paginis145 Series HMM 201902 PDFEuÎncă nu există evaluări

- Imarest 2021 Warship Development 1997Document43 paginiImarest 2021 Warship Development 1997nugrohoÎncă nu există evaluări

- Low Invasion CoringDocument4 paginiLow Invasion CoringKHALEDFEKAIRÎncă nu există evaluări

- A Research Paper On DormitoriesDocument5 paginiA Research Paper On DormitoriesNicholas Ivy EscaloÎncă nu există evaluări

- Theoretical Grammar of EnglishDocument132 paginiTheoretical Grammar of EnglishMisarabbit NguyenÎncă nu există evaluări

- AKIM Mühendislik - Primavera Türkiye - Earned Value Analysis - v2Document1 paginăAKIM Mühendislik - Primavera Türkiye - Earned Value Analysis - v2Ece GürtekinÎncă nu există evaluări

- Absolute Containers Brochure 2019 2 27 PDFDocument19 paginiAbsolute Containers Brochure 2019 2 27 PDFEduardo SolanoÎncă nu există evaluări

- Literature Review Is The Backbone of ResearchDocument7 paginiLiterature Review Is The Backbone of Researchafmzweybsyajeq100% (1)

- MoveInSync Native Android Mobile AppDocument12 paginiMoveInSync Native Android Mobile AppRismaÎncă nu există evaluări

- Piramal Revanta - Tower 3Document13 paginiPiramal Revanta - Tower 3bennymahaloÎncă nu există evaluări

- Oracle Pac 2nd KeyDocument48 paginiOracle Pac 2nd KeyKrishna Kumar GuptaÎncă nu există evaluări

- IUK Routemap - GovernanceDocument27 paginiIUK Routemap - GovernanceTom RedwayÎncă nu există evaluări

- Mahmoud Darwish TMADocument15 paginiMahmoud Darwish TMABassant Ayman Ahmed Abdil Alim100% (1)

- Catalog ITEM - Pdf4a3667894b315Document552 paginiCatalog ITEM - Pdf4a3667894b315Domokos LeventeÎncă nu există evaluări

- Brochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Document2 paginiBrochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Fernanda RizaldoÎncă nu există evaluări

- Risk LogDocument1 paginăRisk LogOzu HedwigÎncă nu există evaluări