Documente Academic

Documente Profesional

Documente Cultură

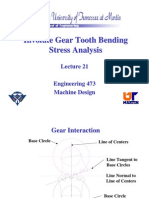

AGMA Method for Calculating Gear Tooth Bending Strength

Încărcat de

Dipak0 evaluări0% au considerat acest document util (0 voturi)

72 vizualizări13 paginiThis document summarizes the AGMA (American Gear Manufacturers Association) method for calculating the bending strength of a gear tooth. It outlines factors to consider like transmitted load, velocity, quality, mounting, geometry, reliability, temperature, and life. It provides formulas that account for these factors to determine the allowable bending stress. The stress calculated should not exceed the allowable stress to avoid failure. It also gives an example problem of calculating the maximum horsepower that can be transmitted using values for pitch, teeth number, face width, and hardness in the AGMA formula.

Descriere originală:

Gear tooth is the description abput the number of gears.

Titlu original

Gear Tooth

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis document summarizes the AGMA (American Gear Manufacturers Association) method for calculating the bending strength of a gear tooth. It outlines factors to consider like transmitted load, velocity, quality, mounting, geometry, reliability, temperature, and life. It provides formulas that account for these factors to determine the allowable bending stress. The stress calculated should not exceed the allowable stress to avoid failure. It also gives an example problem of calculating the maximum horsepower that can be transmitted using values for pitch, teeth number, face width, and hardness in the AGMA formula.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

72 vizualizări13 paginiAGMA Method for Calculating Gear Tooth Bending Strength

Încărcat de

DipakThis document summarizes the AGMA (American Gear Manufacturers Association) method for calculating the bending strength of a gear tooth. It outlines factors to consider like transmitted load, velocity, quality, mounting, geometry, reliability, temperature, and life. It provides formulas that account for these factors to determine the allowable bending stress. The stress calculated should not exceed the allowable stress to avoid failure. It also gives an example problem of calculating the maximum horsepower that can be transmitted using values for pitch, teeth number, face width, and hardness in the AGMA formula.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 13

Design for the Bending Strength of a Gear Tooth:

The AGMA Method

J

K

K

m

b

P

K

K

F

J

K K

bm

K K F

J

K K

b

P

K K F

m

s

v

t

m s

v t

m s

v t

0

0

0

0 . 1

U.S. Customary

SI units

Bending stress at the root of the tooth

Transmitted tangential load

Overload factor

Velocity factor

Diameteral pitch, P

Face width

Metric modue

Size factor

Mounting factor

Geometry factor

Your stress should not exceed

allowable stress

R

T

L

t

all

R T

L t

all

K

K

K

S

K K

K S

Allowable bending stress

Bending Strength

Life factor

Temperature factor

Reliability factor

Overload Factor - K

o

Dynamic Factor - K

v

-Even with steady loads tooth impact can cause shock loading

-Impact strength depends on quality of the gear and the speed of

gear teeth (pitch line velocity)

-Gears are classified with respect to manufacturing tolerances:

-Q

v

3 7, commercial quality

-Q

v

8 12, precision

-Graphs are available which chart K

v

for different quality factors

Load Distribution Factor - K

m

-Failure greatly depends on how load is distributed across face

-Accurate mounting helps ensure even distribution

-For larger face widths even distribution is difficult to attain

-Note formula depends on face width which has to be estimated for initial iteration

-Form goal: b < D

p

; 6 < b*P < 16

Reliability Factor - K

R

-Adjusts for reliability other than 99%

- K

R

= 0.658 0.0759 ln (1-R) 0.5 < R <0.99

- K

R

= 0.50 0.109 ln (1-R) 0.99 < R < 0.9999

AGMA Geometry Factor - J

-Updated Lewis Form Factor includes effect of stress concentration at fillet

-Different charts for different pressure angles

-Available for Precision Gears where we can assume load sharing (upper curves)

-HPSTC highest point of single tooth contact

-Account for meshing gear and load sharing (contact ratio > 1)

-Single tooth contact conservative assumption (bottom curve)

-J = 0.311 ln N + 0.15 (20 degree)

-J = 0.367 ln N + 0.2016 (25 degree)

Bending Strength No. S

t,

Fatigue bending strength

-Tabulated Data similar to fatigue strength

-Range given because value depends on Grade

-Based on life of 10

7

cycles and 99% reliability

S

t

Analytical Estimate

-Through hardened steel gears

-Different charts for different manufacturing methods

-Grade 1 good quality

St = 77.3 H

B

+ 12,800

-Grade 2 premium quality

St = 102 H

B

+ 16,400

Bending Strength Life Factor- K

L

-Adjusts for life goals other

than 10

7

cycles

-Fatigue effects vary with

material properties and surface

finishes

-K

L

= 1.6831 N

-0.0323

N>3E6

Note: @ 2000 rpm reach 3

million cycles in 1 day of

service

Example:

A conveyor drive involving heavy-shock torsional loading is operated by an

electric motor, the speed ratio is 1:2 and the pinion has Diameteral pitch P=10

in

-1

, and number of teeth N=18 and face width of b=1.5 in. The gear has Brinnel

hardness of 300 Bhn. Find the maximum horspower that can be transmitted,

using AGMA formula.

Gear Box Design

S-ar putea să vă placă și

- Refrigerant System - Charge (SENR5664-35)Document8 paginiRefrigerant System - Charge (SENR5664-35)Guido Emanuel SteinbachÎncă nu există evaluări

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- Mooring Design AnalysisDocument41 paginiMooring Design AnalysisRaghu Nath100% (1)

- Gear TrainDocument19 paginiGear TrainGthulasi78Încă nu există evaluări

- Gear TrainDocument19 paginiGear TrainGthulasi78Încă nu există evaluări

- Face WidthDocument24 paginiFace WidthDipak100% (1)

- Planetery GearDocument19 paginiPlanetery GearDipakÎncă nu există evaluări

- Spur Gears: Are Used in Transmitting Torque Between Parallel ShaftsDocument31 paginiSpur Gears: Are Used in Transmitting Torque Between Parallel ShaftsDipakÎncă nu există evaluări

- Machine Design Elements and AssembliesDe la EverandMachine Design Elements and AssembliesEvaluare: 3.5 din 5 stele3.5/5 (2)

- Gears: What We Need To Know About Them. 1. Type of Gears 2. Terminologies or Nomenclatures 3. Forces TransmittedDocument35 paginiGears: What We Need To Know About Them. 1. Type of Gears 2. Terminologies or Nomenclatures 3. Forces TransmittedsyampnaiduÎncă nu există evaluări

- Backlash PDFDocument12 paginiBacklash PDFkorray1100% (1)

- Spur Gear DesignDocument51 paginiSpur Gear Designmshebbal2212100% (1)

- Bearings LifeDocument4 paginiBearings Lifecastingforge4875Încă nu există evaluări

- Chapter 9 Spur Gear DesignDocument31 paginiChapter 9 Spur Gear DesignRamesh Martha100% (1)

- Gearing AgmaDocument17 paginiGearing AgmaDomingos AzevedoÎncă nu există evaluări

- DSE E400 Data Sheet Control US Size PDFDocument2 paginiDSE E400 Data Sheet Control US Size PDFEko SulistyoÎncă nu există evaluări

- Gear Force & StressDocument30 paginiGear Force & StressRanjeethkumar JalalÎncă nu există evaluări

- Worm GearsDocument27 paginiWorm GearsDipakÎncă nu există evaluări

- AC For Mechanical EngineeringDocument77 paginiAC For Mechanical EngineeringHasen Yunne ShemsiÎncă nu există evaluări

- Gear ProfileDocument22 paginiGear ProfileDipak100% (1)

- Gear AnalysisDocument33 paginiGear AnalysisRob Morien100% (1)

- Reinforced Concrete Buildings: Behavior and DesignDe la EverandReinforced Concrete Buildings: Behavior and DesignEvaluare: 5 din 5 stele5/5 (1)

- Transmitted LoadDocument17 paginiTransmitted LoadDipak100% (2)

- Newton's Laws of Motion Summative Test Science 8Document20 paginiNewton's Laws of Motion Summative Test Science 8lie villote100% (1)

- Gear Design and Analysis FundamentalsDocument26 paginiGear Design and Analysis FundamentalsDipakÎncă nu există evaluări

- Solution Manual for 100 Genesys Design Examples: Second EditionDe la EverandSolution Manual for 100 Genesys Design Examples: Second EditionÎncă nu există evaluări

- Load Distribution Factor - KDocument9 paginiLoad Distribution Factor - KDipakÎncă nu există evaluări

- Dynamic Factor KDocument10 paginiDynamic Factor KDipakÎncă nu există evaluări

- UsefulDocument15 paginiUsefulDipakÎncă nu există evaluări

- D In, RPM Rev./min, V In/sec D In, N RPM, V FPM: Sin CosDocument16 paginiD In, RPM Rev./min, V In/sec D In, N RPM, V FPM: Sin CosDipakÎncă nu există evaluări

- AGMADocument7 paginiAGMADipakÎncă nu există evaluări

- Bending Strength No. - S Fatigue Bending StrengthDocument6 paginiBending Strength No. - S Fatigue Bending StrengthDipakÎncă nu există evaluări

- Design For The Bending Strength of A Gear Tooth: The AGMA MethodDocument4 paginiDesign For The Bending Strength of A Gear Tooth: The AGMA MethodGthulasi78Încă nu există evaluări

- Gears Presentation BubuDocument37 paginiGears Presentation BubuAbebaw AyeleÎncă nu există evaluări

- Gears PresentationDocument33 paginiGears PresentationNaveen YadavÎncă nu există evaluări

- What We Need To Know About Them. Type of Gears Terminologies or Nomenclatures Forces Transmitted Design of A Gear BoxDocument33 paginiWhat We Need To Know About Them. Type of Gears Terminologies or Nomenclatures Forces Transmitted Design of A Gear Boxfaith23dbagulÎncă nu există evaluări

- Anly TicalDocument5 paginiAnly TicalDipakÎncă nu există evaluări

- Spur Gear Design GuideDocument13 paginiSpur Gear Design GuideRoshan ShanmughanÎncă nu există evaluări

- MMB411-Tutorial Gears04 SpurGears-Bending&Fatigue PDFDocument26 paginiMMB411-Tutorial Gears04 SpurGears-Bending&Fatigue PDFNdivhuwo NdivhuwoÎncă nu există evaluări

- ch09 3Document155 paginich09 3abdallah ghannamÎncă nu există evaluări

- Machine-Design - Gear Shaft ProblemDocument51 paginiMachine-Design - Gear Shaft ProblemkidseismicÎncă nu există evaluări

- Spur GearsDocument13 paginiSpur GearsVignesh WaranÎncă nu există evaluări

- Technical Information Sheet Radial Ball Bearings Life and Load Ratings ENB 04 0637Document4 paginiTechnical Information Sheet Radial Ball Bearings Life and Load Ratings ENB 04 0637sandeep5Încă nu există evaluări

- Acoplamientos TSK PDFDocument4 paginiAcoplamientos TSK PDFBenicio Joaquín Ferrero BrebesÎncă nu există evaluări

- MD Assignment Punishment B1Document3 paginiMD Assignment Punishment B1Abdul Kadir0% (1)

- Accouplement MecDocument19 paginiAccouplement MecAli Ben Belgacem MahroukÎncă nu există evaluări

- Delhi PPT 11-10-09 PreparedDocument112 paginiDelhi PPT 11-10-09 PreparedOlivia JacksonÎncă nu există evaluări

- Project of Dom 306Document7 paginiProject of Dom 306Somesh KumarÎncă nu există evaluări

- MECH 344 - Final Exam (Winter 2021)Document4 paginiMECH 344 - Final Exam (Winter 2021)Puneet Rudhar100% (1)

- Gear Agma IIDocument49 paginiGear Agma IInathÎncă nu există evaluări

- HES3350 Machine Design, Assignment 2: Gear Specification With Consideration of Bending Fatigue and Surface Durability (Semester 1, 2012)Document21 paginiHES3350 Machine Design, Assignment 2: Gear Specification With Consideration of Bending Fatigue and Surface Durability (Semester 1, 2012)StephenPYBongÎncă nu există evaluări

- Mod-3A. Spur GearDocument7 paginiMod-3A. Spur GearSharthak GhoshÎncă nu există evaluări

- Design of Spur Gear Tutorial No: - DateDocument18 paginiDesign of Spur Gear Tutorial No: - DateAkhilesh NavikÎncă nu există evaluări

- DME-II Gears&RCB VJTI PDFDocument17 paginiDME-II Gears&RCB VJTI PDFASHOK SUTHARÎncă nu există evaluări

- ASSIGNMENTS OF MD II New FormatDocument15 paginiASSIGNMENTS OF MD II New Formatsushant vermaÎncă nu există evaluări

- Design of Special Purpose Hydraulic Press Machine Ijariie8769Document5 paginiDesign of Special Purpose Hydraulic Press Machine Ijariie8769Jack JohnÎncă nu există evaluări

- Assignment 1Document3 paginiAssignment 1Pawan Kumar GoyalÎncă nu există evaluări

- Involute Gear Tooth Bending Stress AnalysisDocument24 paginiInvolute Gear Tooth Bending Stress AnalysisVeerasamy SureshbabuÎncă nu există evaluări

- Design of Spur GearDocument23 paginiDesign of Spur GearNiaz KhanÎncă nu există evaluări

- AVP Catalog 3Document121 paginiAVP Catalog 3Antonio CaballeroÎncă nu există evaluări

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkDe la EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkÎncă nu există evaluări

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsDe la EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsÎncă nu există evaluări

- ISO 9001 2015 DraftDocument37 paginiISO 9001 2015 DraftDipakÎncă nu există evaluări

- 16012016Document1 pagină16012016DipakÎncă nu există evaluări

- 04 05 2015Document1 pagină04 05 2015DipakÎncă nu există evaluări

- 03 10 2016Document1 pagină03 10 2016DipakÎncă nu există evaluări

- FMDocument2 paginiFMDipakÎncă nu există evaluări

- Bending Strength Life Factor-KDocument4 paginiBending Strength Life Factor-KDipakÎncă nu există evaluări

- Seven Quality Control ToolsDocument40 paginiSeven Quality Control Toolsmanojpatel51100% (5)

- Pareto Analysis 2. Flowcharts 3. Check Sheets 4. Histograms 5. Scatter Diagrams 6. Control Charts 7. Fishbone DiagramDocument39 paginiPareto Analysis 2. Flowcharts 3. Check Sheets 4. Histograms 5. Scatter Diagrams 6. Control Charts 7. Fishbone DiagramDipakÎncă nu există evaluări

- Anly TicalDocument5 paginiAnly TicalDipakÎncă nu există evaluări

- 18 04 2015Document1 pagină18 04 2015DipakÎncă nu există evaluări

- ConveyorDocument3 paginiConveyorDipakÎncă nu există evaluări

- Gear Box DesignDocument2 paginiGear Box DesignDipakÎncă nu există evaluări

- Bending Strength No. - S Fatigue Bending StrengthDocument6 paginiBending Strength No. - S Fatigue Bending StrengthDipakÎncă nu există evaluări

- Reliability Factor - K, AGMA Geometry Factor - J, Bending Strength No. - St, Fatigue bending strength, Bending Strength Life Factor- KLDocument8 paginiReliability Factor - K, AGMA Geometry Factor - J, Bending Strength No. - St, Fatigue bending strength, Bending Strength Life Factor- KLDipakÎncă nu există evaluări

- AGMADocument7 paginiAGMADipakÎncă nu există evaluări

- StressDocument12 paginiStressDipakÎncă nu există evaluări

- What To Expect in An AuditDocument19 paginiWhat To Expect in An AuditDipakÎncă nu există evaluări

- Standard Gear TeethDocument21 paginiStandard Gear TeethDipakÎncă nu există evaluări

- Bending Strength Gear Tooth AGMA MethodDocument14 paginiBending Strength Gear Tooth AGMA MethodDipak0% (1)

- D In, RPM Rev./min, V In/sec D In, N RPM, V FPM: Sin CosDocument16 paginiD In, RPM Rev./min, V In/sec D In, N RPM, V FPM: Sin CosDipakÎncă nu există evaluări

- Planetery Gear TrainDocument18 paginiPlanetery Gear TrainDipakÎncă nu există evaluări

- GearDocument23 paginiGearDipakÎncă nu există evaluări

- Noise TDMA Noise and Suppression TechniquesDocument6 paginiNoise TDMA Noise and Suppression TechniquesChansoriya ImÎncă nu există evaluări

- Eep Practical File: IndexDocument17 paginiEep Practical File: IndexAkash GandharÎncă nu există evaluări

- 4 - 254624-400-DS-INT-022 Ball Valve DSDocument8 pagini4 - 254624-400-DS-INT-022 Ball Valve DSNerudaArarÎncă nu există evaluări

- JOSÉ e DANIELA Blow Up of Solutions To Fractional Quasilinear Hyperbolic ProblemDocument6 paginiJOSÉ e DANIELA Blow Up of Solutions To Fractional Quasilinear Hyperbolic ProblemJosé VanterlerÎncă nu există evaluări

- Electromechanical Systems in Building Services EngineeringDocument26 paginiElectromechanical Systems in Building Services EngineeringRendani VeleÎncă nu există evaluări

- ANT-A104518R05v06-3975 DatasheetDocument6 paginiANT-A104518R05v06-3975 DatasheetoimÎncă nu există evaluări

- Aakash Medical Batch Test Schedule 2021-2022Document1 paginăAakash Medical Batch Test Schedule 2021-2022akilan gurumurthyÎncă nu există evaluări

- Soalan Matematik Pertengahan Tahun Ting 5 Smksbu 2019 Kertas 1Document24 paginiSoalan Matematik Pertengahan Tahun Ting 5 Smksbu 2019 Kertas 1ZULKFELI BIN ISMAIL AWANG MoeÎncă nu există evaluări

- H Enthalpy, P Pressure, S Entropy, T V VolumeDocument76 paginiH Enthalpy, P Pressure, S Entropy, T V VolumeFug azÎncă nu există evaluări

- Soil Mechanics Laboratory ReportDocument17 paginiSoil Mechanics Laboratory ReportJordan Marcel100% (1)

- Ficha Tecnica Cat 6a CableDocument3 paginiFicha Tecnica Cat 6a CableVictor Guevara GarciaÎncă nu există evaluări

- Assignment Sheet IDocument2 paginiAssignment Sheet IUtkarsh TripathiÎncă nu există evaluări

- Green University of Bangladesh Man-Made Fiber 00001 YEANDocument12 paginiGreen University of Bangladesh Man-Made Fiber 00001 YEANAbrar RomanÎncă nu există evaluări

- ps-1 Model Paper 2Document3 paginips-1 Model Paper 2Kunal Dev KaushalÎncă nu există evaluări

- Ic-1288-20 Boot Basket A01921Document1 paginăIc-1288-20 Boot Basket A01921ivan dario benavides bonillaÎncă nu există evaluări

- The Capacity of The Noisy Quantum ChannelDocument19 paginiThe Capacity of The Noisy Quantum ChannelElisabeth OrtegaÎncă nu există evaluări

- Coach eDocument14 paginiCoach ealberto diezÎncă nu există evaluări

- Chapter One Talking About The WeatherDocument6 paginiChapter One Talking About The WeatherĐào Nguyễn Duy TùngÎncă nu există evaluări

- Chip Formation: IntroductionDocument5 paginiChip Formation: IntroductionDr.S.Ravi CITÎncă nu există evaluări

- DP1 Practice 2: MarkschemeDocument17 paginiDP1 Practice 2: MarkschemeaurennosÎncă nu există evaluări

- GKH (W - YW) : High-Performance Martensitic Steel For Critical Mechanical ComponentsDocument32 paginiGKH (W - YW) : High-Performance Martensitic Steel For Critical Mechanical ComponentsKimÎncă nu există evaluări

- Flex Cheat SheetDocument1 paginăFlex Cheat SheetjezzieÎncă nu există evaluări

- AsdasdDocument3 paginiAsdasdNero James Sia100% (1)

- Answers of Test On Quantum Physics and Particle PhysicsDocument3 paginiAnswers of Test On Quantum Physics and Particle PhysicsFakin AsholÎncă nu există evaluări

- 08 - Chapter 1Document24 pagini08 - Chapter 1Pothuraju PrudhiviÎncă nu există evaluări