Documente Academic

Documente Profesional

Documente Cultură

Iq, Oq, PQ, DQ

Încărcat de

siruslara649167%(3)67% au considerat acest document util (3 voturi)

3K vizualizări17 paginif

Titlu original

IQ,OQ,PQ,DQ

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentf

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

67%(3)67% au considerat acest document util (3 voturi)

3K vizualizări17 paginiIq, Oq, PQ, DQ

Încărcat de

siruslara6491f

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 17

EQUIPMENT

DESIGN & QUALIFICATIONS

Equipment Qualification

Equipment Qualification (EQ) is the overall

process of ensuring that an instrument is

appropriate for its intended use.

Qualification Stages

Design Qualification

Installation Qualification

Operational Qualification

Performance Qualification

Qualification Purposes

Design qualification (DQ) for setting

functional and performance

specifications (operational

specifications).

Installation qualification (IQ) for

performing and documenting the

installation in the selected user

environment.

Qualification Purposes

Operational qualification (OQ) for testing

the equipment in the selected user

environment to ensure that it meets the

previously defined functional and

operational specifications.

Performance qualification (PQ) for

testing that the system consistently

performs as intended for the selected

application.

Design Qualification

Description of the process

Selection of the process technique

Description of the intended use of the equipment

Description of the intended environment

Preliminary selection of the functional and performance

specifications

(technical, environmental, safety)

Preliminary selection of the supplier

Instrument tests (if the technique is new)

Final selection of the equipment

Final selection of the supplier and equipment

Development and documentation of final functional and

operational specifications

Equipment Design

Appropriate design & specifications

Should be based on process

requirement

Adequate size

Suitably located

To facilitate operations

To facilitate proper cleaning

Equipment Design

Constructed material should be

Non- reactive

Non- additive

Non-absorptive

To prevent product contact with

equipment

lubricants and coolants

Maintenance

Installation Qualification

The process of checking/verifying the

installation to ensure that the critical

components meet the approved specifications

and that they are installed correctly in

accordance with design documentation

To establish that the critical components are

installed correctly and in accordance with

design documentation requirements (ie

purchase orders, contracts etc), that

supporting documentation is in place and of

suitable quality.

IQ Methodology

Verification of utilities and building services

Compare equipment, as received, with

purchase order (including software,

accessories, spare parts)

Check documentation for completeness

(operating manuals, maintenance

instructions, standard operating procedures

for testing, safety and validation certificates)

Check equipment for any damage

IQ Methodology

Install hardware (computer, equipment,

fittings and tubing for fluid connections, power

cables, data flow and instrument control

cables)

Materials in product contact verification

Switch on the instruments and ensure that all

modules power up and perform an electronic

self-test

Verify correct software installation, e.g., are

all files loaded. Utilities to do this should be

included in the software itself.

IQ Methodology

Identify and make a list with a description of

all hardware, include drawings where

appropriate.

Instrumentation (Critical /Non-critical)

List equipment manuals and SOPs

Instrument features (Model no.,Capacity,

Identification no.,)

Prepare an installation report

OQ Methodology

Application SOPs

Utilization list

Process description

Test instruments utilized and calibration

Critical functional parameters

Test reports functions (Challenge tests)

Traceable standards establishment

Training

PQ Methodology

"Performance Qualification (PQ) is the

process of demonstrating that an equipment

consistently performs according to a

specification appropriate for its routine use "

Important here is the word consistently. The

test frequency is much higher than for OQ.

Another difference is that PQ should always

be performed under conditions that are

similar to routine process requirements.

PQ Methodology

Placebo trails (If applicable)

Define the performance criteria and

operating conditions.

Select critical parameters with some

allowance to drift out of predefined

specifications.

Define corrective actions on what to do if

the system does not meet the criteria, in

other words if the system is out of

specification

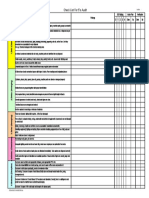

Basic IQ,OQ & PQ

Commissioning and Qualification

Project Phases Qualification Phases

Technology Transfer Collecting data

Conceptual Design

Basic Design Preliminary VMP

Detailed Design Detailed VMP

Procurement Detailed planning,DQ

Construction IQ

Pre commissioning

Commissioning OQ

S-ar putea să vă placă și

- Good Documentation Practices (GDP)Document34 paginiGood Documentation Practices (GDP)siruslara6491100% (6)

- Good Documentation Practices (GDP)Document34 paginiGood Documentation Practices (GDP)siruslara6491100% (6)

- SOP Equipment ValidationDocument15 paginiSOP Equipment Validationfarjana100% (6)

- IQ-OQ-PQ - Excel PDFDocument3 paginiIQ-OQ-PQ - Excel PDFshri_palaniÎncă nu există evaluări

- IQOQPQ TemplateDocument25 paginiIQOQPQ TemplateValidator201192% (52)

- Validation Summary Report Template PDFDocument12 paginiValidation Summary Report Template PDFAnonymous OreX6RrRP100% (1)

- Cooper Perspective Stage GateDocument26 paginiCooper Perspective Stage GateRubi Flaviano67% (3)

- Critical Spare ListDocument38 paginiCritical Spare Listsiruslara6491Încă nu există evaluări

- Tim Fields Master Validation PlanDocument7 paginiTim Fields Master Validation Planmanoj262400/2100% (1)

- Validation Master PlanDocument5 paginiValidation Master Planazamyn83% (6)

- SOP For Equipment Qualification - Pharmaceutical GuidelinesDocument4 paginiSOP For Equipment Qualification - Pharmaceutical GuidelinesMuthuraman M100% (2)

- An Approach To Process ValidationDocument17 paginiAn Approach To Process ValidationBibek Singh Mahat100% (4)

- Purified Water System IQ/OQ ReportDocument11 paginiPurified Water System IQ/OQ ReportVemulapalli SaibabuÎncă nu există evaluări

- Installation QualificationDocument17 paginiInstallation Qualificationtrinath16198067% (6)

- SOP - 0400 - 10 - Design Qualification SOPDocument13 paginiSOP - 0400 - 10 - Design Qualification SOPsandipkumardshahÎncă nu există evaluări

- Installation Qualification Template IQDocument25 paginiInstallation Qualification Template IQSheila Bersamin TabuconÎncă nu există evaluări

- Tool & Die Design Lecture Jan2011 13mar12Document100 paginiTool & Die Design Lecture Jan2011 13mar12azizmaarof100% (8)

- Validation Master PlanDocument27 paginiValidation Master PlanPrashansa Shrestha85% (13)

- Basics of Equipment Qualification - Pharma Pathway PDFDocument6 paginiBasics of Equipment Qualification - Pharma Pathway PDFJ VENKATESHÎncă nu există evaluări

- Validation ProtocolDocument63 paginiValidation ProtocolIndústria Petys64% (22)

- Validation Master Plan Annex 15Document29 paginiValidation Master Plan Annex 15spark80988100% (6)

- UL Traceability RequirementsDocument5 paginiUL Traceability RequirementsvintecomÎncă nu există evaluări

- Installation Qualification For Informatic System ExampleDocument7 paginiInstallation Qualification For Informatic System ExampleCarlos SanchezÎncă nu există evaluări

- Diffference Between Temperature Mapping Study and ValidationDocument20 paginiDiffference Between Temperature Mapping Study and ValidationVacker Group UAE100% (1)

- Validation of EquipmentDocument31 paginiValidation of Equipmentjyothisahadevan100% (3)

- Iq OqDocument20 paginiIq OqDaniela Cotoman100% (1)

- IQ, OQ, PQ For FBDDocument31 paginiIQ, OQ, PQ For FBDBayyapureddy Rakesh89% (45)

- Site Validation Master Plan OverviewDocument34 paginiSite Validation Master Plan OverviewJonatan Dominguez PerezÎncă nu există evaluări

- Operational Qualification TemplateDocument7 paginiOperational Qualification TemplateFrilya Andarni Saragih SumbayakÎncă nu există evaluări

- Calibration Master Plan LMDocument45 paginiCalibration Master Plan LMJAGADISH PHARMACEUTICALS50% (2)

- VALIDATION MASTER PLAN (Repaired)Document56 paginiVALIDATION MASTER PLAN (Repaired)aman pathania100% (3)

- Process Validation ProtocolDocument10 paginiProcess Validation ProtocolDivya SekarÎncă nu există evaluări

- 6.E Installation Qualification (IQ) : Here You Will Find Answers To The Following QuestionsDocument10 pagini6.E Installation Qualification (IQ) : Here You Will Find Answers To The Following QuestionsFilipÎncă nu există evaluări

- Iqoqpq RMGDocument11 paginiIqoqpq RMGjpmaurya7750% (4)

- HVAC OQ ProtocolDocument12 paginiHVAC OQ ProtocolamrinÎncă nu există evaluări

- 2015 VMP TemplateDocument10 pagini2015 VMP Templatekulbhushan singh100% (2)

- Validation Protocall For AutoclaveDocument7 paginiValidation Protocall For AutoclaveBalakrishnan S NadarÎncă nu există evaluări

- Introduction To Manufacturing SystemDocument13 paginiIntroduction To Manufacturing SystemmltgÎncă nu există evaluări

- Master Validation PlanDocument23 paginiMaster Validation Planchennamareddysriniva88% (8)

- Design QualificationDocument9 paginiDesign Qualificationtrinath16198050% (2)

- Installation QualificationDocument14 paginiInstallation QualificationTuan Nguyen100% (1)

- Just in Time (JIT) StrategyDocument38 paginiJust in Time (JIT) StrategyMuhammad Mubeen Iqbal Puri100% (1)

- Validation Master Plan A Complete Guide - 2020 EditionDe la EverandValidation Master Plan A Complete Guide - 2020 EditionÎncă nu există evaluări

- PQ FBDDocument6 paginiPQ FBDScott Adkins100% (1)

- Cleanroom Technology: Fundamentals of Design, Testing and OperationDe la EverandCleanroom Technology: Fundamentals of Design, Testing and OperationÎncă nu există evaluări

- The Preparation of Validation Master Plan: Manual: 035Document6 paginiThe Preparation of Validation Master Plan: Manual: 035Rambabu komati - QA71% (7)

- PRINCE2 Training Foundation & PractitionerDocument107 paginiPRINCE2 Training Foundation & PractitionerMonir Bhuiyan67% (6)

- Iq Oq PQ ChamberDocument17 paginiIq Oq PQ Chamberelias_7760% (5)

- Taylor-Wharton Cryogenic Freezer DQ IQ OQ PQ ProtocolDocument31 paginiTaylor-Wharton Cryogenic Freezer DQ IQ OQ PQ ProtocolManolo Moreno100% (3)

- Validation master plan Complete Self-Assessment GuideDe la EverandValidation master plan Complete Self-Assessment GuideÎncă nu există evaluări

- 50 Activities For Developing Management Skills PDFDocument332 pagini50 Activities For Developing Management Skills PDFDanish ButtÎncă nu există evaluări

- IQ Purified WaterDocument127 paginiIQ Purified Wateranon-204001100% (11)

- Sap QMDocument93 paginiSap QMgrv0009100% (3)

- Validation Document For FLP-1.5Document19 paginiValidation Document For FLP-1.5Reza Jafari100% (1)

- CommMill IQOQPQDocument16 paginiCommMill IQOQPQAtul Sharma100% (2)

- IQDocument12 paginiIQManish Shah100% (3)

- 1-5 Equipment QualificationDocument47 pagini1-5 Equipment QualificationSandip NajanÎncă nu există evaluări

- Variable and Absorption Costing Income StatementsDocument5 paginiVariable and Absorption Costing Income StatementsMonica GarciaÎncă nu există evaluări

- Cantier Profile With MES - Industry 4.0 (Partners)Document28 paginiCantier Profile With MES - Industry 4.0 (Partners)lampfievÎncă nu există evaluări

- 10072-02 RQ Protocol Line-1 Tunnel-001Document34 pagini10072-02 RQ Protocol Line-1 Tunnel-001deepanmb00750% (2)

- Design Qualification Document-SAMPLEDocument25 paginiDesign Qualification Document-SAMPLEVikram Chhabra67% (6)

- Introduction To Reliability Centered SparesDocument10 paginiIntroduction To Reliability Centered SparescajascÎncă nu există evaluări

- Company Detail - G. NoidaDocument11 paginiCompany Detail - G. Noidasaurabh2986Încă nu există evaluări

- SCADA Process Control System User RequirementsDocument65 paginiSCADA Process Control System User Requirementskapernikov50% (2)

- Performance Qualification Protocol For Alu Alu Blister Packing MachineDocument15 paginiPerformance Qualification Protocol For Alu Alu Blister Packing Machinemehrdarou.qaÎncă nu există evaluări

- Equipment QualificationDocument23 paginiEquipment QualificationDrSyeda Rima100% (4)

- Installation Qualification (Iq) Protocol FOR Mechanical SifterDocument22 paginiInstallation Qualification (Iq) Protocol FOR Mechanical SiftercorneliusÎncă nu există evaluări

- VDA Standards - Why They Are Important & Overview of New Standards in 2020Document47 paginiVDA Standards - Why They Are Important & Overview of New Standards in 2020Daffa HanifÎncă nu există evaluări

- PhEn602 Spring09 Notes1Document66 paginiPhEn602 Spring09 Notes1Abd Al-Rahmman Al-qatanani100% (1)

- Design Qualification TemplateDocument4 paginiDesign Qualification Templateltrevino10017% (6)

- WCM Methods & ToolsDocument45 paginiWCM Methods & ToolsUlises Gutierrez Aviles100% (1)

- IQ For Strip Packing Machine SE - 140Document15 paginiIQ For Strip Packing Machine SE - 140Fernanda GarantiaÎncă nu există evaluări

- IQOQ ProtocolDocument4 paginiIQOQ ProtocolVijay RajaindranÎncă nu există evaluări

- PR 1400 Iq, Oq, PQDocument28 paginiPR 1400 Iq, Oq, PQvizay237_430788222Încă nu există evaluări

- IGBC Green Guidelines For Fast Track & Emergency COVID FacilitiesDocument69 paginiIGBC Green Guidelines For Fast Track & Emergency COVID Facilitiessiruslara6491Încă nu există evaluări

- Critical Spares ListDocument19 paginiCritical Spares Listsiruslara6491Încă nu există evaluări

- Pending Jobs UpdatedDocument4 paginiPending Jobs Updatedsiruslara6491Încă nu există evaluări

- Annexure - 3 - Scheme 3Document2 paginiAnnexure - 3 - Scheme 3siruslara6491Încă nu există evaluări

- Critical Spare List For Thermax Oil Fired BoilerDocument1 paginăCritical Spare List For Thermax Oil Fired Boilersiruslara6491100% (2)

- Pump Spares 20.03.2010Document4 paginiPump Spares 20.03.2010siruslara6491Încă nu există evaluări

- Utility Online Log For Apr-09Document29 paginiUtility Online Log For Apr-09siruslara6491Încă nu există evaluări

- FFT Check ListDocument1 paginăFFT Check Listsiruslara6491Încă nu există evaluări

- Technochem Labs Report Analyzes Steam Purity for Tanfac IndustriesDocument5 paginiTechnochem Labs Report Analyzes Steam Purity for Tanfac Industriessiruslara6491Încă nu există evaluări

- Utility Report 07032009Document1 paginăUtility Report 07032009siruslara6491Încă nu există evaluări

- ScrubberDocument1 paginăScrubbersiruslara6491Încă nu există evaluări

- FAG Bearings India MRP ListDocument13 paginiFAG Bearings India MRP Listsiruslara6491Încă nu există evaluări

- Asme Standards For BoilersDocument4 paginiAsme Standards For Boilerssiruslara6491Încă nu există evaluări

- Pump Power Calculation NoteDocument2 paginiPump Power Calculation NoteAsad KhanÎncă nu există evaluări

- AhuDocument1 paginăAhusiruslara6491Încă nu există evaluări

- Atmospheric PressureDocument1 paginăAtmospheric Pressurerampw14581Încă nu există evaluări

- Emergency LightsDocument3 paginiEmergency Lightssiruslara6491Încă nu există evaluări

- Cleanroom Certification and Acceptance ReportDocument7 paginiCleanroom Certification and Acceptance ReportJovanny MarquezÎncă nu există evaluări

- ChillerDocument2 paginiChillersiruslara6491Încă nu există evaluări

- Check List For 5s Audit For UtyDocument1 paginăCheck List For 5s Audit For Utysiruslara6491Încă nu există evaluări

- Motors PDFDocument79 paginiMotors PDFsiruslara6491Încă nu există evaluări

- Battery Charger ChecklistDocument1 paginăBattery Charger Checklistsiruslara6491Încă nu există evaluări

- Storage Battery M&PDocument84 paginiStorage Battery M&Psiruslara6491Încă nu există evaluări

- Motors PDFDocument79 paginiMotors PDFsiruslara6491Încă nu există evaluări

- Motors PDFDocument79 paginiMotors PDFsiruslara6491Încă nu există evaluări

- Good PracticesDocument32 paginiGood Practicessiruslara6491Încă nu există evaluări

- Guide to recycling waste plastics for local authoritiesDocument2 paginiGuide to recycling waste plastics for local authoritiesMBA103003Încă nu există evaluări

- 5PLs of LogsitcsDocument3 pagini5PLs of Logsitcsaqeelkhan7942Încă nu există evaluări

- Cost Accounting RefresherDocument15 paginiCost Accounting Refresherfat31udm100% (1)

- Process Strategy PPT at BEC DOMSDocument68 paginiProcess Strategy PPT at BEC DOMSBabasab Patil (Karrisatte)100% (1)

- 4/3/2014 1 Hareesha N G, Dept of Aero Engg, DSCE, BloreDocument57 pagini4/3/2014 1 Hareesha N G, Dept of Aero Engg, DSCE, BloreramptechÎncă nu există evaluări

- 1 Introduction To Statistical Quality Control, 7th Edition by Douglas C. MontgomeryDocument78 pagini1 Introduction To Statistical Quality Control, 7th Edition by Douglas C. MontgomeryNejra Trle0% (1)

- Forging Parts Catalog EngDocument22 paginiForging Parts Catalog EngCeausu Razvan DanutÎncă nu există evaluări

- Medical Device and Pharmaceutical: Value Stream Mapping: The Map of Your Journey To Becoming "Lean"Document4 paginiMedical Device and Pharmaceutical: Value Stream Mapping: The Map of Your Journey To Becoming "Lean"Brendan CrowleyÎncă nu există evaluări

- Case 1Document3 paginiCase 1SHILPA GOPINATHANÎncă nu există evaluări

- TACO Hardware E-CatalogueDocument15 paginiTACO Hardware E-Catalogueiqbal abdul azizÎncă nu există evaluări

- Modern Rapid 3D Printer - A Design ReviewDocument9 paginiModern Rapid 3D Printer - A Design ReviewIAEME PublicationÎncă nu există evaluări

- Road ResurfacingDocument16 paginiRoad ResurfacingLovish SinghalÎncă nu există evaluări

- Unit V Inventory Theory: Improve Customer ServiceDocument20 paginiUnit V Inventory Theory: Improve Customer ServiceyvigkÎncă nu există evaluări

- PHD Thesis - A Hierarchical Model For SC OptimizationDocument264 paginiPHD Thesis - A Hierarchical Model For SC OptimizationjohnconnorÎncă nu există evaluări

- BM1805 Marginal Costing and Absorption CostingDocument4 paginiBM1805 Marginal Costing and Absorption CostingMaria Anndrea MendozaÎncă nu există evaluări