Documente Academic

Documente Profesional

Documente Cultură

Foundations in Building Constuction

Încărcat de

Divya TadepalliDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Foundations in Building Constuction

Încărcat de

Divya TadepalliDrepturi de autor:

Formate disponibile

Prepared by :

Othman Hassan

Senior Lecturer / Registered Interior Designer with Lembaga Arkitek Malaysia (Reg. No: ID/O 6)

Department of Interior Architecture

UiTM Perak

c

FOUNDATIONS

INA105/151

Building Construction & Materials 1

FOUNDATIONS

INA105/151

The construction of foundation starts after all the tasks below completed.

1. Site Investigation

2. Clearing the site

3. Establishing level

4. Setting out the building line

1. FOUNDATION AND ITS FUNCTIONS

1. As the base on which a building rests and its purpose is to safely transfer

the load of a building to a suitable subsoil.

2. Prevent possible movement of structure due to settlement (ground movement)

3 Allow building over water or water-logged ground

4. Resist uplifting or overturning forces due to wind

5. Resist lateral forces due to soil movement

6. Underpin (support) existing or unstable structures

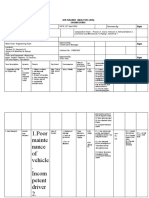

2. FACTORS THAT INFLUENCE THE CHOICE OF FOUNDATION TYPE

The choice and design of foundations for many types of building depend mainly on

factors below:

1. The total loads of the building

2. The nature and bearing capacity of the soil.

3. Materials used for the foundation

4. Economical consideration of using a right kinds of foundation

5. Layout of the structures (building/floor plan, positioning loads)

6. Conditional of the site (location and sufficient work space)

FOUNDATIONS

INA105/151

3. SUBSOIL AND BEARING CAPACITY

Subsoils are soils below the topsoil ; the topsoil being about 300mm deep from the

ground level surface. Bearing capacity is safe load per unit area which the ground can

carry.

Typical bearing capacities of subsoils are as follows:

Rock, granite 600 -10,000 kN/m

2

(60,000-1,000,000kg)

Non-cohesive soils, compact sand 600 kN/m

2

Cohesive soils, hard clay <600 kN/m

2

Having ascertained the nature and bearing capacity of the subsoil the foundation can

be determined by calculating the total (dead + imposed) load per meter run of

foundation and relating this to the analyzed safe bearing capacity of the subsoil

Total load of building per meter = min. foundation width

Safe bearing capacity of subsoil

The average total loading for a two-storey house is 30-50 kN/m

2

FOUNDATIONS

INA105/151

3. SUBSOIL AND BEARING CAPACITY

Example: If the total load of a house is 40 kN/m

2

and the subsoil safe bearing capacity

is 80 kN/m

2

, then the foundation width is:

40 = 0.5 m or 500mm (strip foundation)

80

FOUNDATIONS

INA105/151

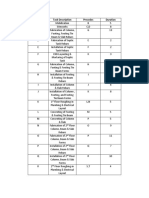

SUBSOIL TYPE kN/m2

Hardpan overlaying rock 1290

Very compact sandy gravel 1075

Loose gravel and sandy gravel, compact sand and 645

gravelly sand, very compact sand-inorganic silt soils

Hard, dry, consolidated clay 537

Loose coarse to medium sand, medium compact fine sand 430

Compact sand clay 322

Loose, fine sand, medium compact sand-inorganic silt soils 215

Firm or stiff clay 161

Loose, saturated sand-clay soils, medium soft clay 107

FOUNDATIONS

INA105/151

3. SUBSOIL AND BEARING CAPACITY

High

Bearing Capacity

Medium

Bearing Capacity

Low

Bearing Capacity

Under pure vertical

downward loads

Wind

4. FORCES ACTING ONTO BUILDING

Under lateral

wind loads

Combined effect

Downward load

Uplifting

action

Tendency to

turn under

wind

Building Building Building

FOUNDATIONS

INA105/151

5. TYPES OF BUILDING FOUNDATION:

1. Shallow Foundation

a. Pad Foundation or Isolated Foundation

b. Raft Foundations - Solid Slab Raft Foundation

- Beam and Slab Raft Foundation

- Cellular Raft Foundation

c. Strip Foundation

d. Trench-Fill Foundation

2. Deep Foundation

a. Pile Foundation

FOUNDATIONS

INA105/151

1. Shallow Foundation

Shallow foundation or sometimes called spread footing usually refers to those being

rested on stratum with adequate bearing capacity and laid less than 3 meters below

ground level. Examples included pad or isolated, raft, strip and trench-fill foundations.

The selection of the right type of shallow foundation normally depend on the the

magnitude and disposition of the structural loads and the bearing capacity of subsoil.

A combination of two or three type of shallow foundation in one single structure is not

uncommon

a. Pad Foundation or Isolated Foundation

Pad foundations or isolated foundations are used to support an individual point load such

as that due to a structural column. They may be circular,square or rectangular. They

usually consists of a block or slab of uniform thickness to spread the load from a column.

Pad foundations or isolated foundations are usually shallow. This type of foundation is

suitable on high bearing capacity subsoils.

FOUNDATIONS

INA105/151

Stages of work in preparing Pad Foundation

Stage 1: Excavation works

Stage 2: Formwork preparation

Stage 3: Reinforcement bar preparation

Stage 4: Installation of reinforcement and starter bars

Stage 5: Concreting works

Stage 6: Installation of stumps

FOUNDATIONS

INA105/151

Stages of work in preparing Pad Foundation

Stage 1: Excavation works

FOUNDATIONS

INA105/151

The first stage of works in preparing

Pad Foundation is excavation works.

Ground will be dug between 1m to 3m

deep to make a trench.

FOUNDATIONS

INA105/151

Stages of work in preparing Pad Foundation

Stage 2: Formwork preparation

The second stage of works in

preparing Pad Foundation is

formworks preparation.

Formwork

Reinforcement bar

FOUNDATIONS

INA105/151

Stages of work in preparing Pad Foundation

Stage 3: Reinforcement bar preparation

The third stage of works in preparing

Pad Foundation is reinforcement bar

preparation.

Stages of work in preparing Pad Foundation

Stage 4: Installation of reinforcement and starter bars

FOUNDATIONS

INA105/151

The fourth stage of works in preparing

Pad Foundation is installing

reinforcement and starter bars in

formworks.

Starter bar

Reinforcement bar

Stages of work in preparing Pad Foundation

Stage 5: Concreting works

FOUNDATIONS

INA105/151

The fifth stage of works in preparing

Pad Foundation is concreting works.

Concrete Grade M30 is used for this

foundation.

Concrete Grade

Concrete mixes (cement, fine aggregate, coarse aggregate) can be expressed as volume grade and

ratios:

Grade M5 (5N/mm) - 1:5:10 = 1 part of cement, 5 parts of fine aggregate, 10 parts of coarse

aggregate.(ordinary concrete)

Grade M10 (10N/mm) - 1:3:6 = 1 part of cement, 3 parts of fine aggregate, 6 parts of coarse

aggregate.(ordinary concrete)

Grade M15 (15N/mm) - 1:2:4 = 1 part of cement, 2 part of fine aggregate, 4 parts of coarse

aggregate. (ordinary concrete) - for solid ground floor

Grade M20 (20N/mm) - 1:1.5:2 = 1 part of cement, 1.5 parts of fine aggregate, 2 parts of coarse

aggregate. (standard concrete)

Grade M25 (25N/mm) - 1:1:2 = 1 part of cement, 1 parts of fine aggregate, 2 parts of coarse

aggregate. (standard concrete)

Grade M30 (30N/mm) - 1:1.5:3 = 1 part of cement, 1.5 parts of fine aggregate, 3 parts of coarse

aggregate. (standard concrete) - for structures and upper floor

Grade M35 (35N/mm) - 1:1.6:2.9 = 1 part of cement, 1.9 parts of fine aggregate, 2.9 parts of

coarse aggregate. (standard concrete) - for structures

- Cement (Portland cement) - made from limestone and clay and is generally produced by wet process.

- Fine Aggregate - those which will pass a standard 5mm sieve . (Sand)

- Coarse Aggregate - those are retained on a standard 5mm sieve. (Gravel, crushed stone)

FOUNDATIONS

INA105/151

Stages of work in preparing Pad Foundation

FOUNDATIONS

INA105/151

Coarse

Aggregate

(gravel)

Fine

Aggregate

(sand)

Portland cement

Stages of work in preparing Pad Foundation

Stages of work in preparing Pad Foundation

Stage 6: Installation of stumps

FOUNDATIONS

INA105/151

The final stage of works in preparing

Pad Foundation is installing stumps.

Stump

FOUNDATIONS

INA105/151

Pad Foundation Is Completed

Stages of work in preparing Pad Foundation

Pad Foundation

Note: Graphic symbols illustrated are not to architectural standard symbols. Students

are advised to refer to the building construction books for proper symbols available at

the library.

Column starter bars

FOUNDATIONS

INA105/151

Pad Foundation

FOUNDATIONS

INA105/151

Pad Foundation

(Shallow Foundation)

Pad Foundation

Stump

Pad Foundation

reinforcement bar

Column starter bars

High bearing

capacity subsoil

Note: Graphic symbols illustrated are not to architectural standard symbols. Students

are advised to refer to the building construction books for proper symbols available at

the library.

Soil

Starter bars

Reinforced concrete stump

Cross Sectional View

(Not to scale)

FOUNDATIONS

INA105/151

Pad Foundation (Shallow Foundation)

Note: Graphic symbols illustrated are not to architectural standard

symbols. Students are advised to refer to the building construction

books for proper symbols available at the library.

Reinforced concrete (Grade M30)

Reinforcement bars 12mm diameter

High bearing

capacity subsoil

Reinforced concrete stump

1m to 3m

deep

Ground Level

Sand screed 25mm thk.

Floor finishes (tiles)

Interior skirting

Soil

Interior part of building

Exterior part of building

Column reinforcement bars

Column

Drain

Plaster

Reinforcement bars 12mm

diameter

Skirting

Hardcore

Concrete

Reinforced concrete stump

Concrete (Grade M25)

Floor 150mm thk.

Concrete ground

Beam (Grade M30)

Cement render

Hardcore 150mm thk.

Pad Foundation & Solid Ground Floor

Cross Sectional View

(Not to scale)

FOUNDATIONS

INA105/151

Reinforced concrete (Grade M30)

Starter bars

Note: Graphic symbols illustrated are not to architectural standard symbols. Students are advised

to refer to the building construction books for proper symbols available at the library.

Apron

High bearing

capacity subsoil

Brick wall

Sand blinding 25mm thk.

Damp-proof Membrane

Ground Level

b. Raft Foundations

The principle of any raft foundation is to spread the load over large area, normally the

entire area of the structure. It usually consists of a concrete slab which extends over the

entire loaded area. It may be stiffened by ribs or beams and floor incorporated into the

foundation .This method often needed on soft or loose soils with low bearing capacity

as they can spread the loads over larger area.

Raft foundation has the advantage of reducing differential settlements as the concrete

slab resists differential movements between loading positions.

Three types of raft foundation:

1. Solid Slab Raft Foundation

Solid slabs are constructed of uniform thickness over the whole raft area. This

foundation suitable on soft or loose soils with low bearing capacity as it can spread the

loads over larger area.

FOUNDATIONS

INA105/151

2. Beam and Slab Raft Foundation

Beam and slab rafts are an alternative to solid slab raft and are used where poor soils

encountered. The beams are used to distribute the column loads over the area of the

raft , which usually results in a reduction of the slab thickness. The beams can be

upstand or downstand depending upon the bearing capacity of the soil near the

surface.

3. Cellular Raft Foundation

This foundation can be used where a reasonable bearing capacity subsoil can only be

found at depths where beam and slab techniques become uneconomic. The

construction is similar to reinforced concrete basements except that internal walls are

used to spread the load over raft and divide the void into cells.

FOUNDATIONS

INA105/151

1. Solid Slab Raft Foundation

FOUNDATIONS

INA105/151

2. Beam and Slab Raft Foundation

FOUNDATIONS

INA105/151

3. Cellular Raft Foundation

FOUNDATIONS

INA105/151

FOUNDATIONS

INA105/151

Beam & Slab Raft Foundation & Ground Floor (Shallow Foundation)

FOUNDATIONS

INA105/151

Stages of work in preparing Beam & Slab Raft Foundation

Stage 1: Excavation works

Stage 2: Installation of Formworks

Stage 3: Installation of Reinforcement Bars For Beams

Stage 4: Installation of Damp Proof Membrane (DPM)

Stage 5: Installation of Reinforcement Bars For Slab

Stage 6: Concreting works

Stages of work in preparing Beam & Slab Raft Foundation

Stage 1: Excavation works

FOUNDATIONS

INA105/151

The first stage of works in

preparing Beam & Slab Raft

Foundation is excavation works.

Installing pipes for sewage and

plumbing are done at this stage.

FOUNDATIONS

INA105/151

Stages of work in preparing Beam & Slab Raft Foundation

Stage 2: Formworks preparation

The second stage of works in

preparing Beam & Slab Raft

Foundation is formworks installation.

At this stage valley are formed for

beams and compacting works are

done.

FOUNDATIONS

INA105/151

Stages of work in preparing Beam & Slab Raft Foundation

Stage 3: Installation of Reinforcement Bars For Beams

The third stage of works in

preparing Beam & Slab Raft

Foundation is reinforcement

bar installation.

Reinforcement bars

FOUNDATIONS

INA105/151

Stages of work in preparing Beam & Slab Raft Foundation

Stage 4: Installation of Damp Proof Membrane (DPM)

The fourth stage of works in

preparing Beam & Slab Raft

Foundation is installation of Damp

Proof Membrane(DPM)

DPM sheet

Stages of work in preparing Beam & Slab Raft Foundation

Stage 5: Installation of Reinforcement Bar For Slab and Starter Bar

FOUNDATIONS

INA105/151

The fifth stage of works in

preparing Beam & Slab Raft

Foundation is installation of

reinforcement bars for slab and

starter bar after installation of

DPM

Slab reinforcement bar

Starter bar

FOUNDATIONS

INA105/151

5. Concreting

Stages of work in preparing Beam & Slab Raft Foundation

Stage 6: Concreting works

The sixth stage of works in preparing

Beam & Slab Raft Foundation is concreting

works. The suitable concrete is Grade M25.

FOUNDATIONS

INA105/151

The Raft Foundation

Stages of work in preparing Beam & Slab Raft Foundation

FOUNDATIONS

INA105/151

Beam & Slab Raft Foundation

Compacted

Hardcore

Beam & Slab Raft

Foundation (Grade

M25 concrete)

Column starter bars

Low Bearing

Capacity Subsoil

DPM

Slab Reinforcement bar

Beam Reinforcement bar

Note: Graphic symbols illustrated are not to architectural standard symbols. Students

are advised to refer to the building construction books for proper symbols available at

the library.

A

Hardcore 150mm thk.

Column starter bars

Reinforced concrete

(Grade M25) foundation

forming ground floor slab

150mm thk.

Sand Blinding 25mm thk.

Damp-Proof Membrane

(DPM)

Slab Reinforcement bars

Beam Reinforcement bars

Beam & Slab Raft Foundation (Shallow Foundation)

Cross Sectional View (Detail A)

(Not to scale)

FOUNDATIONS

INA105/151

Formwork

Note: Graphic symbols illustrated are not to architectural standard

symbols. Students are advised to refer to the building construction

books for proper symbols available at the library.

Low bearing capacity subsoil

Downstand beam

Sand screed 25 mm thk

Floor Finishes

Skirting

Cement render

Drain

Low bearing capacity subsoil

Interior part of building

Exterior part of building Column reinforcing bars

Column

Concrete slab

Hardcore

Hardcore 150mm thk

Plaster Reinforced concrete

(Grade M25) forming

ground floor slab

150mm thk.

Sand Blinding 25mm thk

Damp-proof Membrane

(DPM)

Slab Reinforcement bars

Beam Reinforcement bars

Beam & Slab Raft Foundation & Solid Ground Floor

Skirting

Cross Sectional View

(Not to scale)

FOUNDATIONS

INA105/151

Note: Graphic symbols illustrated are not to architectural standard

symbols. Students are advised to refer to the building construction books

for proper symbols available at the library.

Apron

Downstand beam

Damp-proof Course(DPC)

Column starter bars

Brick wall

c. Strip Foundation

Strip foundation is used to support a line of loads, either due to a load-bearing wall, or if

a line of columns need supporting where column positions are so close that individual

pad foundations would be inappropriate. This type of foundation is suitable on high

bearing capacity subsoil.

FOUNDATIONS

INA105/151

Stages of work in preparing Strip Foundation

1. Excavation works

2. Reinforcement bar preparation

3. Concreting

FOUNDATIONS

INA105/151

Strip Foundation

FOUNDATIONS

INA105/151

Note: Graphic symbols illustrated are not to architectural standard symbols. Students

are advised to refer to the building construction books for proper symbols available at

the library.

Strip Foundation

(Grade M30 concrete)

To support a line of

loads, either due to a

load-bearing wall

Soil

FOUNDATIONS

INA105/151

Strip Foundation (Shallow Foundation) with cavity wall

Cross Sectional View

(Not to scale)

Note: Graphic symbols illustrated are not to architectural standard symbols.

Students are advised to refer to the building construction books for proper

symbols available at the library.

High bearing

capacity subsoil

Reinforced concrete (Grade M30)

Longitudinal reinforcement bars

12mm diameter

Weak concrete

filling to base cavity

Damp-proof course (DPC)

Brick Cavity wall

Insulation

Ground Level

1m

FOUNDATION

INA105/151

Strip Foundation with

Cavity Wall

Note: Graphic symbols illustrated are not to architectural standard symbols. Students

are advised to refer to the building construction books for proper symbols available at

the library.

Weak

Concrete

filling

Strip Foundation

Insulation

DPC

Cavity Wall

High bearing

capacity subsoil

Drain

Interior skirting

Floor finishes

Interior part of building Exterior part of building

Plaster

Concrete floor slab 150mmthk

Cement/sand screed 25mm thk

Damp-proof membrane

(DPM)

Concrete slab

Hardcore

Strip Foundation with cavity wall and Solid Ground Floor

Skirting

Hardcore 150mm thk

Sand blinding 25mm thk

Cross Sectional View

(Not to scale)

FOUNDATIONS

INA105/151

Longitudinal reinforcement bars

Note: Graphic symbols illustrated are not to architectural

standard symbols. Students are advised to refer to the building

construction books for proper symbols available at the library.

Apron

High bearing

Capacity subsoil

Weak

concrete

filling

Reinforced concrete (Grade M30)

Damp-poof course (DPC)

Cement render

Ground Level

Insulation

Brick cavity wall

d. Trench-Fill Foundation

Trench -fill foundation is almost similar to strip foundation. Trench-fill foundations can be

dug deeper and bigger than strip, which means they are particularly practical where

the water table is high, where soil is loose and unstable, and in areas with heavy clay

soils. The thickness of any trench -fill foundation should be not less than 500mm and the

foundation concrete should finish about 150mm to 100mm below ground level. The

trench sides may need to be lined with a slip membrane unless the soil is firm. This type

of foundation is suitable on high bearing capacity subsoils.

FOUNDATIONS

INA105/151

Stages of work in preparing Trench-Fill Foundation

1. Excavation works

2. Reinforcement bar preparation

3. Concreting

FOUNDATIONS

INA105/151

Trench-Foundation

FOUNDATIONS

INA105/151

Trench-Foundation

(Grade M25 concrete)

To support a line of

loads, either due to a

load-bearing wall

Soil

FOUNDATIONS

INA105/151

Trench-Fill Foundation (Shallow Foundation)

Cross Sectional View

(Not to scale)

Note: Graphic symbols illustrated are not to architectural standard symbols. Students

are advised to refer to the building construction books for proper symbols available at

the library.

High bearing

Capacity subsoil

Reinforced concrete Grade M30

Longitudinal reinforcement bars

12mm diameter

Weak concrete filling

to base cavity

Brick Cavity wall

Insulation

Ground Level

1-2m

deep

Damp proof course (DPC)

Cavity Wall

FOUNDATION

INA105/151

Trench-Fill Foundation with

Cavity Wall

Note: Graphic symbols illustrated are not to architectural standard symbols. Students

are advised to refer to the building construction books for proper symbols available at

the library.

DPC

Weak

Concrete

filling

Insulation

Trench-Fill Foundation

High bearing

capacity subsoil

2. Deep Foundation

1. Pile Foundation

Pile foundation is a form of foundation using piles to transfer the loads of a structure

down to a firm soil stratum with sufficient load-taking capacity. Suitable for multi storey

building and on low bearing capacity subsoil.

Materials for piles can be of:

1. Precast concrete

2. H section steel piles

3. Metal sheets piles

4. Timber or bakau (mangroves) piles

5. CISS or Cast-In-Steel-Shell/pipes piles

FOUNDATIONS

INA105/151

Precast concrete piles

MATERIALS FOR PILING

FOUNDATIONS

INA105/151

Precast cylindrical concrete piles

1. Pre-Cast Concrete Pile

Pre-cast or pre-stressed concrete piles are one of the most commonly used concrete piles. Pre-cast concrete piles are typically

made with steel reinforcing and pre-stressing tendons to obtain the tensile strength required, to survive handling and driving, and to

provide sufficient bending resistance. Long piles can be difficult to handle and transport. Pile joints can be used to join two or more

short piles to form one long pile. Pile joints can be used with both precast and pre-stressed concrete piles. Pre-cast concrete piles

are driven into the ground and used for deep foundations to support structures in residential houses, commercial construction, such

as buildings and bridges. They are also used for: heavy highway, public works, marine, and industrial applications.

FOUNDATIONS

INA105/151

Pre-Cast Concrete Pile

MATERIALS FOR PILING

FOUNDATIONS

INA105/151

Pre-Cast Concrete Pile

MATERIALS FOR PILING

FOUNDATIONS

INA105/151

MATERIALS FOR PILING

Steel H section piles

FOUNDATIONS

INA105/151

H-Piles are often driven into the ground and used for deep

foundations to support structures in commercial construction,

such as buildings and bridges. They are also used for: heavy

highway, public works, marine, and industrial applications. Due

to their strength, they can be utilized for driving in soil conditions

that other piling would have difficulty penetrating. The durability

of these steel columns work well for applications in areas that

are that are prone to earthquakes or other natural disasters.

2. H-Pile

H- piles are the ideal solution when foundations are required for complex

structures or where the ground conditions are difficult. The properties of steel

mean that they can be used to resist tensile as well as compressive loads and

they can be designed for bending. They are ideally suited to hard driving

through difficult ground conditions eg. silty, fine, water bearing sand containing

cobles and boulders/ dense sands and gravels/ glacial till and are particularly

effective when founded on rock or a similar hard stratum

MATERIALS FOR PILING

FOUNDATIONS

INA105/151

Steel Sheet piles

3. Metal Sheet Pile

A sheet pile wall is a row of interlocking, vertical pile segments installed to form an essentially straight wall with a

plan dimension sufficiently large enough for its behavior to allow for the analysis of a .3048-meter (1 foot) wide

vertical segment of the wall cross-section. Sheet pile walls are typically used as earth retaining structures along

shorelines to allow for higher exposed grades to occur adjacent to lower river bottoms, dredge or mud lines. Sheet

piling can also be used to retain fill around open landside excavations via rectangular trenches or circular

cofferdams.

MATERIALS FOR PILING

FOUNDATIONS

INA105/151

3. Metal Sheet piles

MATERIALS FOR PILING

FOUNDATIONS

INA105/151

Metal Sheet Pile

Steel Sheet piles

MATERIALS FOR PILING

Bakau piles (mangrove)

FOUNDATIONS

INA105/151

4. Timber Pile

The mangrove piles are widely used in peninsular

Malaysia for most building and homes. The use of

mangrove piles is also recognized in other countries,

Malaysia contractors and developers are so confident that

the mangrove piles can actually be used for piling in all

buildings and homes due to the mangrove wood nature

superb density and its woods strength.

The mangrove piles are not only cheap, but it is also easy

to handle in most pilling during construction work. The

buildings which are using mangrove piles as foundation

can at least stand for a decades or more than 10 years.

The use of mangrove wood in piling brings so much of

benefits and advantages. Cheap, Strong Strength, High

Density, Long Lasting

MATERIALS FOR PILING

FOUNDATIONS

INA105/151

CISS or Cast-in-Steel-Shell piles Steel pipes piles

Source: http://www.foundationpiledriving.com/ciss.htm 200px-Metal_tubes_stored_in_a_yard[1]

5. CISS or Cast-in-Steel-Shell piles

MATERIALS FOR PILING

TYPES OF PILE CONSTRUCTION

There are two common types of pile construction:

1. Displacement piles

Displacement piles cause the soil to be displaced radially as well as vertically

as the pile shaft is driven or jacked into the ground.

2. Non-displacement or replacement piles

Non-displacement, soil is removed and the resulting hole filled with concrete

or a precast pile is dropped into the hole and grouted in.

FOUNDATIONS

INA105/151

Pile is driven

into the soil

1. Displacement pile 2. Non-displacement or

Replacement pile

Soil is removed

by using boring

rig and drill

to form a hole

Soil

Ground level

or

Precast pile is

dropped into the

hole

FOUNDATIONS

INA105/151

Bed rock or stratum

soil on firm base

Concrete is

pored into the

steel pipes in the

hole to form pile

TYPES OF PILE CONSTRUCTION

LOADING SUPPORT TO PILE

Load from a superstructure is transmitted to the subsoil either by:

1. Skin friction - load is supported by the frictional resistance so created between

the contact surface of the pile and the embracing soil.

2. End-bearing - load is support by resting onto a firm stratum such as bed-rock or

stratum of subsoil with the required bearing capacity.

FOUNDATIONS

INA105/151

1. Skin friction

support

Piles

Loading Support

to Pile

Bed rock or

stratum soil

on firm

base

2. End-bearing

support

Pile caps

Friction

FOUNDATIONS

INA105/151

Ground level

Soil

Friction

Building

METHODS OF PILING

Piling methods can be done in several way depending on factors mentioned earlier,

they are:

1. Driven piling (Displacement)

Piles are driven into the ground using a pile driver. Driven piles are either wood,

reinforced concrete, or steel.

a. Gravity hammer

b. Diesel hammer

c. Hydraulic hammer

d. Vibratory pile driver

e. Silent pile hammer

f. Air hammer

FOUNDATIONS

INA105/151

2. Drilled piling (Non-displacement)

Piling in which boring is done until the hard rock or soft rock layer is

reached in the case of end bearing piles.

a. Caissons

b. Boring rig and auger drill

c. Bucket barrel

FOUNDATIONS

INA105/151

METHODS OF PILING

1. Driven piling (Gravity (Drop) hammer)

FOUNDATIONS

INA105/151

Gravity pile for bakau

The drop hammer consists of

a heavy ram in between the

leads. The ram is lifted up to a

certain height and released to

drop on the pile. This type is

slow and therefore not in

common use. It is used in the

cases where only a small

number of piles are driven.

METHODS OF PILING

FOUNDATIONS

INA105/151

1. Driven piling (Diesel Hammer)

Diesel hammer piling in action

A modern diesel pile hammer is a

very large two-stroke diesel

engine. The weight is the piston,

and the apparatus which

connects to the top of the pile is

the cylinder. Piled riving is started

by having the weight raised by

auxiliary means usually a cable

from the crane holding the pile

driver which draws air into the

cylinder. The weight is dropped,

using a quick-release. The

weight of the piston compresses

the air, heating it to the ignition

point of diesel fuel. Diesel fuel is

added/injected into the cylinder.

The mixture ignites, transferring

the energy of the falling weight to

the pile head, and driving the

weight back up.

The diesel hammer is a small, light

weight and highly mobile. They use

gasoline for fuel. To start the

operation, the ram is raised, and the

fuel is injected. As the ram is

released, the ram falls and

compresses air and fuel. The air and

fuel becomes hot because of the

compression and the air-fuel mixture

is ignited. The resulting explosion

Advances the pile and

Lifts the ram. If the pile advance is

very great as in soft soils, the ram is

not lifted by the explosion sufficiently

to ignite the air-fuel mixture on the

next cycic, requiring that the ram be

again manually lifted.

METHODS OF PILING

1. Driven piling (Hydraulic Hammer)

Hydraulic hammer piling in action

FOUNDATIONS

INA105/151

A hydraulic hammer is a

modern type of piling hammer

used in place of diesel and air

hammers for driving steel pipe

precast concrete, and timber

piles. Hydraulic hammers are

more environmentally

acceptable than the older, less

efficient hammers as they

generate less noise and

pollutants. However, in many

cases the dominant noise is

caused by the impact of the

hammer on the pile, or the

impacts between components

of the hammer, so that the

resulting noise level can be

very similar to diesel hammers.

METHODS OF PILING

Vibratory pile driver in action

FOUNDATIONS

INA105/151

1. Driven piling (Vibratory Pile Driver)

Vibratory pile hammers

contain a system of counter-

rotating eccentric weights,

powered by hydraulic

motors, and designed in

such a way that horizontal

vibrations cancel out, while

vertical vibrations are

transmitted into the pile.

Vibratory hammers can

either drive in or extract a

pile; extraction is commonly

used to recover steel "H"

piles used in temporary

foundation shoring.

The principle of the vibratory

driver is two counter-rotating

eccentric weights. The driving

unit vibrates at high frequency

and provides two vertical

impulses, one up and one

down. The downward pulse

acts with the pile weight to

increase the apparent gravity

force. These hummers have

reduced driving vibrations,

reduced noise, and great speed

of penetration.

METHODS OF PILING

1. Driven piling (Silent Pile Driver)

Silent pile driver in action

FOUNDATIONS

INA105/151

The Silent Piler is a hydraulic

machine for vibration-free

installation or extraction of

sheet piles. The machine

operates by gripping previously

driven piles to provide reaction

force for pressing in the next

pile. The Silent Piler works on

top of the reaction piles and

self-moves to the next position

as illustrated in the adjacent

picture. This technique allows

pile driving at sites which are

not accessible for conventional

piling techniques. Only a

relatively light-weight service

crane is needed to pitch the

sheet piles.

METHODS OF PILING

FOUNDATIONS

INA105/151

1. Driven piling (Air Hammer)

Air hammer pile in action

Very basic hammer

design, impact based

with a rapid blow action

and air powered . Less

affected by ground

type, typically used to

finish drive to depth, if

not for the full drive.

Can be handled by an

excavator. Will drive

sheets into virtually all

ground conditions.

METHODS OF PILING

FOUNDATIONS

INA105/151

2. Drilled piling (Caissons)

Caissons pile driling in progress

A caisson is a retaining structure

that is normally water tight that

is used to allow construction

work to be undertaken under dry

conditions below the water table

(including below the surface of a

river or lake). Examples of when

a caisson might be used include

on a river bed during the

construction of bridge pillars and

foundations, or during the

construction of a shaft. A pile is

a type of deep foundation which

usually extends to a significant

depth in the ground compared to

it's cross sectional area. Piles

may be either driven or cast in

place.

METHODS OF PILING

2. Drilled piling (Boring Rig and Auger Drill)

Boring rig and auger drilling in progress

FOUNDATIONS

INA105/151

This piling method is ideal

for use in cohesive soils.

The rotating auger screws

into the strata reaming out

the soil. Once the required

depth has been achieved

the steel cage and concrete

is placed. These highly

mobile rigs are economic to

use on large open sites

with cohesive ground, and

on some chalk or sand,

which have good access.

Smaller models are

suitable for internal use. As

a rotary auger causes

minimal vibration it is ideal

for use next to buildings or

underground services

METHODS OF PILING

2. Drilled piling (Bucket Barrel)

Bucket barrel drilling in action

FOUNDATIONS

INA105/151

METHODS OF PILING

Stages of work in preparing Deep Foundation

Stage 1: Piling works

Stage 2: Excavation and pile cutting works

Stage 3: Preparation and fabrication of reinforcement for pile cap

Stage 4: Preparation of pile cap formwork

Stage 5: Installation of pile cap reinforcement bar and starter bar

Stage 6: Concreting works

Stage 7: Installation of stumps

FOUNDATIONS

INA105/151

FOUNDATIONS

INA105/151

Stages of work in preparing Deep Foundation

Stage 1: Piling works

Point for piling

The first stage of works in preparing Deep

Foundation is piling works that involve 1. Points

setting. 2. Piling 3. Piling Jointing (where more

piles are required).

FOUNDATIONS

INA105/151

Jointing the pile coupling end plates

Welding the end plates

Stages of work in preparing Deep Foundation

Stage 1: Piling works

Stages of work in preparing Deep Foundation

Stage 2: Excavation and pile cutting works

FOUNDATIONS

INA105/151

Concrete piles

The second stage of works in preparing Deep

Foundation is excavation and pile cutting works.

Backhoe loader is needed to excavate the soil and

hydraulic pile cutter is required to cut the piles.

Pile cutting in action

FOUNDATIONS

INA105/151

Stages of work in preparing Deep Foundation

Stage 2: Excavation and pile cutting works

Hydraulic pile cutter

Concrete piles

Stages of work in preparing Deep Foundation

Stage 3: Preparation & Fabrication of reinforcement bar for pile cap

FOUNDATIONS

INA105/151

Pile Cap reinforcement bar

The third stage of works in preparing

Deep Foundation is preparing and

fabricating reinforcement bar for pile

cap..

Stages of work in preparing Deep Foundation

Stage 4: Preparation of formworks for pile cap

FOUNDATIONS

INA105/151

Formwork

The fourth stage of works in preparing

Deep Foundation is preparing formworks

for pile cap

Stages of work in preparing Deep Foundation

Stage 5: Installing pile cap reinforcement & starter bars in formworks

FOUNDATIONS

INA105/151

The fifth stage of works in preparing Deep

Foundation is installing pile cap reinforcement

& starter bars in formworks.

Pile Cap

reinforcement bar

Starter bar

Stages of work in preparing Deep Foundation

Stage 6: Concreting works

FOUNDATIONS

INA105/151

The sixth stage of works in preparing

Deep Foundation is concreting. The

suitable concrete is Grade M30.

FOUNDATIONS

INA105/151

Pile Caps

Stages of work in preparing Deep Foundation

Stage 6: Concreting works

FOUNDATIONS

INA105/151

Stages of work in preparing Deep Foundation

Stage 7: Installation of stumps

Stump

Pile Cap Starter bar

The final stage of works in preparing Deep

Foundation is installing the stumps.

FOUNDATIONS

INA105/151

Deep /Pile Foundation

Deep foundation is completed and ready for ground beams works

Deep Foundations Starter bar

Pile Foundation

Note: Graphic symbols illustrated are not to architectural standard symbols. Students

are advised to refer to the building construction books for proper symbols available at

the library.

Piles

Piles Cap

Column starter bar

FOUNDATIONS

INA105/151

FOUNDATIONS

INA105/151

Pile Foundation

(Deep Foundation)

Note: Graphic symbols illustrated are not to architectural standard symbols. Students

are advised to refer to the building construction books for proper symbols available at

the library.

Low bearing

capacity subsoil

Pile Cap

Pile

Stump

Pile Cap

reinforcement bar

Column starter bar

Soil

Cross Sectional View

(Not to scale)

Pile Foundation (Deep Foundation)

FOUNDATIONS

INA105/151

Note: Graphic symbols illustrated are not to architectural standard symbols. Students are advised

to refer to the building construction books for proper symbols available at the library.

Low bearing

capacity

subsoil

Piles

Reinforced concrete stump

Reinforced concrete pile cap

(Grade M30)

Reinforcement bars 12mm diameter

Pile Cap

1m to 3m

deep

Starter bar

Ground Level

Pile Foundation & Suspended Ground Floor

Skirting

Sand screed 25mm

Floor finishes (tiles)

Damp-proof Membrane

Cement render

Drain

Reinforcement bars 12mm diameter

Interior part of building

Hardcore 150mm thk.

Column

Column

reinforcement bars

Sand blinding 25mm

Piles

Floor reinforcement bars

10mm diameter

Reinforced concrete

(Grade M25) ground floor

slab 150mm thk.

Reinforced concrete

stump

Starter bars

Skirting

Concrete Ground Beam

(Grade M30)

Ground beam

reinforcement bars

Cross Sectional View

(Not to scale)

FOUNDATIONS

INA105/151

Note: Graphic symbols illustrated are not to

architectural standard symbols. Students are

advised to refer to the building construction books

for proper symbols available at the library.

Apron

Exterior part of building

Low bearing

capacity

subsoil

Brick wall

Plaster

Concrete

Hardcore

Damp-proof Course

Concrete pile cap (Grade M30 )

Ground Level

References:

1. Ivor H. Seeley (1995):Building Technology. Fifth edition. MacMillan.

2. Roland Ashcroft (1992); ConstructionFor Interior Designers. Second Edition. Longman.

3. Roger Greeno (1998):Advanced Construction Technology.

FOUNDATIONS

INA105/151

THE END

FOUNDATIONS

INA105/151

S-ar putea să vă placă și

- Clearing and GrubbingDocument4 paginiClearing and GrubbingDevrim GürselÎncă nu există evaluări

- BT3 Heavy RCPrestressetcDocument106 paginiBT3 Heavy RCPrestressetcHeather HallÎncă nu există evaluări

- SfgfdsDocument10 paginiSfgfdsMartyn M. EleÎncă nu există evaluări

- Job Hazard Analysis Engineering Site Inspection 2Document5 paginiJob Hazard Analysis Engineering Site Inspection 2Nonsoufo ezeÎncă nu există evaluări

- Waterstop Installation InstructionsDocument1 paginăWaterstop Installation Instructionsapi-431034657Încă nu există evaluări

- Demolition Specifications 1Document1 paginăDemolition Specifications 1JonÎncă nu există evaluări

- Pe Exam For ContractorDocument8 paginiPe Exam For ContractorMELCHOR JR ESPILOYÎncă nu există evaluări

- Earth Dam Rehabilitation BEMEDocument6 paginiEarth Dam Rehabilitation BEMENuruddeen Muhammad100% (1)

- Masonry ConstructionDocument15 paginiMasonry Constructionsaima BatoolÎncă nu există evaluări

- Foundation TypesDocument26 paginiFoundation TypesAnand TatteÎncă nu există evaluări

- Lecture 3 - Soil InvestigationDocument27 paginiLecture 3 - Soil InvestigationLemiÎncă nu există evaluări

- Reporter: Silo, Jeter Gabayan, Lorence Batayo, Jayson Pasco, John Caesar RDocument14 paginiReporter: Silo, Jeter Gabayan, Lorence Batayo, Jayson Pasco, John Caesar RJohn Ceasar PascoÎncă nu există evaluări

- Water Stop EnglishDocument16 paginiWater Stop EnglishNick Ramos ChavezÎncă nu există evaluări

- Site-Specific Steel Erection Plan SummaryDocument3 paginiSite-Specific Steel Erection Plan SummaryQi ZengÎncă nu există evaluări

- Concrete Slab: Engr. Lito I. MauroDocument29 paginiConcrete Slab: Engr. Lito I. MauroJetty CruzÎncă nu există evaluări

- Stair Construction PDFDocument25 paginiStair Construction PDFJOYCE AIMEE DELIMAÎncă nu există evaluări

- BOQ DescriptionsDocument8 paginiBOQ Descriptionsnayanahari100% (1)

- Dito Tower Wall Perimeter EstimateDocument52 paginiDito Tower Wall Perimeter EstimateRex ImperialÎncă nu există evaluări

- Task No. Task Description Precedes DurationDocument3 paginiTask No. Task Description Precedes DurationANDREA MARTINA BAYÎncă nu există evaluări

- Dole 2Document24 paginiDole 2Ramil S. ArtatesÎncă nu există evaluări

- Equipment Types in ConstructionDocument7 paginiEquipment Types in ConstructionJivson BuayaÎncă nu există evaluări

- Types of floors construction methodsDocument2 paginiTypes of floors construction methodsMuhafeez Goolab100% (1)

- Professional PracticeDocument3 paginiProfessional Practiceforbeska100% (1)

- Riprap SpecsDocument2 paginiRiprap SpecsKaren-John Richard NelsonÎncă nu există evaluări

- Mast and Tower PDFDocument14 paginiMast and Tower PDFKwan-Rin RatchaneeyaÎncă nu există evaluări

- Demolition Method for Dublin Shared Living DevelopmentDocument27 paginiDemolition Method for Dublin Shared Living DevelopmentPaul OchiengÎncă nu există evaluări

- Structural analysis of multi-storey steel frames exposed to travelling fires and traditional design firesDocument17 paginiStructural analysis of multi-storey steel frames exposed to travelling fires and traditional design firesAlem LoajnerÎncă nu există evaluări

- Workmanship On Building SitesDocument28 paginiWorkmanship On Building SitesSa Reddi100% (1)

- What Is Pad Foundation? Design Principles, Types and SelectionDocument5 paginiWhat Is Pad Foundation? Design Principles, Types and SelectionNhoek RenÎncă nu există evaluări

- Cep Lecture5 FormworkDocument69 paginiCep Lecture5 FormworkKrm ChariÎncă nu există evaluări

- BOQDocument327 paginiBOQshyamsundar_ce100% (1)

- 01 JSB551 Introduction To Design of Multi Storey BuildingsDocument34 pagini01 JSB551 Introduction To Design of Multi Storey BuildingsBarongan BsgÎncă nu există evaluări

- 1.1 Intended Learning Outcomes: Structural DesignDocument6 pagini1.1 Intended Learning Outcomes: Structural DesignJenevive Tumacder100% (1)

- Site InvestigationDocument68 paginiSite Investigationhansyusof100% (1)

- BidFile 100Document816 paginiBidFile 100Ed SalangaÎncă nu există evaluări

- Guidelines On The Design and Construction of Bamboo ScaffoldsDocument24 paginiGuidelines On The Design and Construction of Bamboo ScaffoldsRizwan MirzaÎncă nu există evaluări

- Formwork For Concrete: University of WashingtonDocument36 paginiFormwork For Concrete: University of Washingtonraahul_nÎncă nu există evaluări

- Fundamentals of Soil StabilizationDocument25 paginiFundamentals of Soil StabilizationFrancheska BeltranÎncă nu există evaluări

- 2.4 Bored Piles PDFDocument28 pagini2.4 Bored Piles PDFAbhijith AjithÎncă nu există evaluări

- Excavations - The OSHA Competent Person Course 7Document37 paginiExcavations - The OSHA Competent Person Course 7Melchezadek0% (1)

- Ultracote Ultracote Ultracote Ultracote: Ultrazinc 2120Document3 paginiUltracote Ultracote Ultracote Ultracote: Ultrazinc 2120Cherbee FerrerÎncă nu există evaluări

- Scaffolding CalculationDocument8 paginiScaffolding CalculationAsmadi Rifa'at100% (1)

- Concrete Slope ProtectionDocument10 paginiConcrete Slope ProtectionTAHER AMMARÎncă nu există evaluări

- Bored Pile Series NG 1600Document30 paginiBored Pile Series NG 1600Avelino De Leon JrÎncă nu există evaluări

- Method Statement: Remedial Measures Against Flooding in Al JoufDocument12 paginiMethod Statement: Remedial Measures Against Flooding in Al Joufamju0% (1)

- Manual On Hazard Resistant ConstructionDocument117 paginiManual On Hazard Resistant ConstructionKUNAL RELAÎncă nu există evaluări

- Construction Stages Building FrameworkDocument4 paginiConstruction Stages Building FrameworkGerald Andrin0% (1)

- Structural Risk Assessment & Method StatementDocument19 paginiStructural Risk Assessment & Method StatementNaresh DharmaÎncă nu există evaluări

- Lesson 5 Excavations and Excavation SupportsDocument15 paginiLesson 5 Excavations and Excavation SupportsRsjBugtong100% (1)

- BCP Lab ManualDocument38 paginiBCP Lab ManualShaik MunnaÎncă nu există evaluări

- Foundation Underpinning and Shoring MethodsDocument43 paginiFoundation Underpinning and Shoring Methodsdan4books100% (1)

- Heavy Duty Shoring Installation MethodDocument1 paginăHeavy Duty Shoring Installation MethodNizam ShafieÎncă nu există evaluări

- Construction ToolsDocument82 paginiConstruction ToolsLouise Andrea OliquianoÎncă nu există evaluări

- Method Statement For Earthwork Cutting and FillingDocument8 paginiMethod Statement For Earthwork Cutting and FillingABDO ALLIAÎncă nu există evaluări

- Risk Assessment Method Statement Documents: April 2007Document11 paginiRisk Assessment Method Statement Documents: April 2007Tamilchelvam MurogayahÎncă nu există evaluări

- Train on plastering and anti-crack application standardsDocument13 paginiTrain on plastering and anti-crack application standardsJOHN CARLO AZORESÎncă nu există evaluări

- Standards for Slope Protection StructuresDocument8 paginiStandards for Slope Protection StructuresNasir ZakiÎncă nu există evaluări

- General NotesDocument4 paginiGeneral Noteszamree BMÎncă nu există evaluări

- 1Document43 pagini1Yachika SharmaÎncă nu există evaluări

- Types of Foundations - Shallow vs Deep Systems ExplainedDocument50 paginiTypes of Foundations - Shallow vs Deep Systems ExplaineddeepakjoghuÎncă nu există evaluări

- 9 Project ManagementDocument15 pagini9 Project ManagementDivya TadepalliÎncă nu există evaluări

- Asian Pacific Heritage MonthDocument12 paginiAsian Pacific Heritage MonthMG CaguladaÎncă nu există evaluări

- 73 2013 PDFDocument8 pagini73 2013 PDFSoundar PachiappanÎncă nu există evaluări

- Watershed ManagementDocument46 paginiWatershed ManagementDivya Tadepalli100% (1)

- Estimation NotesDocument32 paginiEstimation NotesSrinivas P50% (2)

- CIVIL 8.environmental Engineering PDFDocument249 paginiCIVIL 8.environmental Engineering PDFDivya TadepalliÎncă nu există evaluări

- 4-2 CIVIL R13 SyllabusDocument6 pagini4-2 CIVIL R13 SyllabusDivya TadepalliÎncă nu există evaluări

- Unit 9 Selection, Planning and Matching of Construction EquipmentDocument9 paginiUnit 9 Selection, Planning and Matching of Construction EquipmentDivya TadepalliÎncă nu există evaluări

- Chapter-3 Construction Equipment ManagementDocument92 paginiChapter-3 Construction Equipment ManagementDivya TadepalliÎncă nu există evaluări

- 1 s2.0 S1877042813045035 MainDocument10 pagini1 s2.0 S1877042813045035 MainDivya TadepalliÎncă nu există evaluări

- 1.2 Advantages Types of Pre StressingDocument11 pagini1.2 Advantages Types of Pre StressingcatiexpertÎncă nu există evaluări

- Cadd VivaDocument5 paginiCadd VivaDivya TadepalliÎncă nu există evaluări

- AEE Environmental Engineering NOTESDocument10 paginiAEE Environmental Engineering NOTESVaradharajan SÎncă nu există evaluări

- Watershed ManagementDocument46 paginiWatershed ManagementDivya Tadepalli100% (1)

- Replacement of Coarse Aggregate by Scrap Tyre RubberDocument6 paginiReplacement of Coarse Aggregate by Scrap Tyre RubberDivya TadepalliÎncă nu există evaluări

- Replacement of Coarse Aggregate by Scrap Tyre RubberDocument6 paginiReplacement of Coarse Aggregate by Scrap Tyre RubberDivya TadepalliÎncă nu există evaluări

- Soils ConsolidationDocument41 paginiSoils ConsolidationDavid CastañoÎncă nu există evaluări

- Experimental Study On Properties of Cement With RHA As Replacement in ConcreteDocument6 paginiExperimental Study On Properties of Cement With RHA As Replacement in ConcreteDivya TadepalliÎncă nu există evaluări

- Enviromental Lab ManualDocument16 paginiEnviromental Lab ManualDivya TadepalliÎncă nu există evaluări

- Enviromental Lab ManualDocument16 paginiEnviromental Lab ManualDivya TadepalliÎncă nu există evaluări

- Surveying Previous Question PaperDocument2 paginiSurveying Previous Question PaperDivya TadepalliÎncă nu există evaluări

- Specific Gravity and Absorption of Coarse AggregateDocument2 paginiSpecific Gravity and Absorption of Coarse AggregateDivya Tadepalli100% (1)

- M40 Pumpable Concrete Mix DesignDocument29 paginiM40 Pumpable Concrete Mix DesignChirag TanavalaÎncă nu există evaluări

- Project On Partial Replacement of Cement With Marble PowderDocument11 paginiProject On Partial Replacement of Cement With Marble PowderSaurabh Pandey100% (2)

- Notes Theodolite PDFDocument9 paginiNotes Theodolite PDFAshok_sth71% (7)

- Advanced Foundation EngineeringDocument3 paginiAdvanced Foundation EngineeringDivya TadepalliÎncă nu există evaluări

- A Study On Use of Rice HUsk Ash in Concrete - M.B.G Sameer KumarDocument94 paginiA Study On Use of Rice HUsk Ash in Concrete - M.B.G Sameer KumarNarayan Singhania100% (21)

- CTDocument8 paginiCTDivya TadepalliÎncă nu există evaluări

- Enviromental Lab ManualDocument16 paginiEnviromental Lab ManualDivya TadepalliÎncă nu există evaluări

- Structural DynamicsDocument1 paginăStructural DynamicsDivya TadepalliÎncă nu există evaluări

- Proposed TitlesDocument13 paginiProposed Titleskelvinolenasha123Încă nu există evaluări

- Effect of Eccentricity On Analysis and Design of Isolated FootingsDocument18 paginiEffect of Eccentricity On Analysis and Design of Isolated Footingsप्रभु नाथ सिंहÎncă nu există evaluări

- 2152-0.50LL Esr-Str-Cal-01 - R1Document30 pagini2152-0.50LL Esr-Str-Cal-01 - R1sssmitÎncă nu există evaluări

- SpecificationDocument15 paginiSpecificationRichard TagleÎncă nu există evaluări

- Backfill Plan Engineering Fill Plan: Standalone VillaDocument10 paginiBackfill Plan Engineering Fill Plan: Standalone Villaabid hamzaÎncă nu există evaluări

- Foundation and Flooring SystemDocument2 paginiFoundation and Flooring Systemqwert qwertyÎncă nu există evaluări

- Construction Process GuideDocument10 paginiConstruction Process GuideVenkat MÎncă nu există evaluări

- DCT10BE Study Guide 2020 - DESIGN AND CONSTRUCTIONDocument17 paginiDCT10BE Study Guide 2020 - DESIGN AND CONSTRUCTIONWanda VersterÎncă nu există evaluări

- Construction of Residential ApartmentsDocument60 paginiConstruction of Residential ApartmentsAdeelBaigÎncă nu există evaluări

- Design of Raft FoundationDocument11 paginiDesign of Raft FoundationMyo AungÎncă nu există evaluări

- National Certificate in Technology Construction ModuleDocument65 paginiNational Certificate in Technology Construction ModuleImani AsalankiÎncă nu există evaluări

- A Year at A Construction SiteDocument27 paginiA Year at A Construction Sitesmyrna_exodusÎncă nu există evaluări

- AS2870 Footing SystemsDocument7 paginiAS2870 Footing SystemsEver Piñon-Simonsson83% (6)

- Pre-Activity Assessment: Foundations WorksheetDocument2 paginiPre-Activity Assessment: Foundations Worksheetjoel lantongÎncă nu există evaluări

- BT Joe Quiz 2Document1 paginăBT Joe Quiz 2corazon philÎncă nu există evaluări

- Foundation Design NotesDocument95 paginiFoundation Design NotesDelina TedrosÎncă nu există evaluări

- Bridge Design Manual - M23-50.03CompleteDocument1.302 paginiBridge Design Manual - M23-50.03CompleteJavier TalledoÎncă nu există evaluări

- Comparison ParametersDocument84 paginiComparison ParametersNazeerÎncă nu există evaluări

- FoundationsDocument14 paginiFoundationsmufrith 123Încă nu există evaluări

- D21FE Foundation EngineeringDocument204 paginiD21FE Foundation EngineeringKHALED MOHAMMAD50% (2)

- Types of Building Foundations Under 40 CharactersDocument3 paginiTypes of Building Foundations Under 40 CharactersRaju ShresthaÎncă nu există evaluări

- Introduction To Foundation EngineeringDocument2 paginiIntroduction To Foundation EngineeringMelvin EsguerraÎncă nu există evaluări

- 12 M High Retaining Wall Design For Seismic LoadingDocument27 pagini12 M High Retaining Wall Design For Seismic Loadingaminjoles0% (1)

- Improving Bearing Capacity of SoilDocument3 paginiImproving Bearing Capacity of SoilJustin MusopoleÎncă nu există evaluări

- FOOTINGS AND RAFTS DESIGNDocument29 paginiFOOTINGS AND RAFTS DESIGNiploguÎncă nu există evaluări

- PPG Track RecordDocument73 paginiPPG Track RecordFernando Emmanuel Benitez100% (1)

- Investigation of Beam and Raft Slab Using Staad ProDocument13 paginiInvestigation of Beam and Raft Slab Using Staad ProErnesto SuarezÎncă nu există evaluări

- Item Description Unit Quantity 1. Site Clearance and DismantlingDocument7 paginiItem Description Unit Quantity 1. Site Clearance and Dismantlinghemant gaikwadÎncă nu există evaluări

- Design Methodology For PilesDocument12 paginiDesign Methodology For PilesmaizansofiaÎncă nu există evaluări

- Seminar REPORT Final 2Document24 paginiSeminar REPORT Final 2Priyanka Kumari100% (1)