Documente Academic

Documente Profesional

Documente Cultură

Omc Occupationalhealthinlargeopencastmines Good MDC

Încărcat de

ihateu10 evaluări0% au considerat acest document util (0 voturi)

29 vizualizări26 paginijfjfgnfgjtj

Titlu original

Omc Occupationalhealthinlargeopencastmines Good Mdc (1)

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentjfjfgnfgjtj

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

29 vizualizări26 paginiOmc Occupationalhealthinlargeopencastmines Good MDC

Încărcat de

ihateu1jfjfgnfgjtj

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 26

Occupational Health in large

Opencast mines &

Preventive Measures

By Sri GS Khuntia

Former Director, NMDC

Executive Director (Operation) SAIL

Former Mining Advisor,ESSAR /MSL

Currently Director, OMC Ltd & VP,MDC on SHE

Presence of high concentration of

dust in the work place, exposure to

noxious gases, fumes and hot humid

work environment in underground

mines, noise and vibration, poor

illumination, ergonomically different

abnormal positions during work, working

in confined space etc. are the causes of

various short-term and long -term health

hazards in mines. What is

Occupational Health Hazard?

The factors that affect the health of

the miners while working in the

underground mines, surface mines and

quarries are called health hazards.

Occupational Health in large

Opencast mines-provisions as

per 10

th

safety conferences

-Noise & Vibrations provisions

-Audimetry provisions

- G. S. Khuntia

Occupational health sevices

1.1 In respect of small mechanized mines, which

are operating in the non-coal sector, it may not be

possible for small organization to create a special

department on Occupational Health Services. For

such small mines, it is suggested that an

Association of small mine operators creates

common facilities and infrastructure for

Occupational Heath Services. Creation of such

facilities is specially needed for asbestos,

manganese and mica mines.

Noise and vibration

1.1 The recommendations of DGMS(Tech)

circular No 18 of 1975 shall be

implemented forth with(protection of

workers against Noise and Vibration in

Working Environment.

Audiometry

Audiometry should be introduced as a part

of mandatory medical examination of

persons seeking employment in mines and

for persons engaged in endangered

operations / areas where noise level exceed

90 dB(A)

Common Occupational Hazards in Mines

Dust

Dust is the major hazard in any type of mining operation. Fine

dust particles of size range 0.5 micron to 5 micron are injurious to the

health of the miners. These dust particles are inhaled through the nose,

pass through the respiratory tract (breathing passage) and get deposited

in the lungs in the chest cavity.

An occupational disease, Pneumoconiosis is caused due to

coal dust. Depending on the nature and composition of dust, the

pneumoconiosis may be named as Silicosis (silica), Siderosis (iron)

Asbestosis (asbestos fibber), Anthracosis (coal), Anthraco-silicosis (silica-

mixed coal), Baritosis (barium), Stanosis (tin) etc.

Monitoring the dust at the work environment and maintaining a

health record of all miners working in dusty areas is useful.

Noise and Vibration

Hearing defects may be causes due to exposure to excess noise

(above 90dB) during work in the long run.

The disease is called Noise Induced Hearing Loss (NIHL) which

does not affect the normal speech range initially. It affects the high

frequency (above 4000 Hertz) at first and shifts to the speech frequency

gradually.

The person gradually becomes deaf; irritable, talks in a loud

voice, develop sleeplessness and high blood pressure.

The hearing impairment can be detected early by audiometric

test.

Hearing conservation program should be adopted in every mine

in noisy areas to reduce noise hazard.

This program consists of noise measurement at the work place,

control of noise level in the source, on the pathway and at the miners ear

level, use of ear protection (ear plugs and ear muff), periodic ear

examination and audiometer, educating employees about noise hazard

and job rotation to minimise exposure.

A record should be maintained in for every miner for future health

assessment.

Poor Illumination

Poor illumination produces eyestrain and abnormal movement of the

eyeball (nystagmus) among the mines, sometimes poor illumination causes

accidents.

Therefore, it is necessary to keep the work area well lighted without

shadows or glare. The miners should also wear goggles to protect their eyes.

Lighting standards at various work places are specified by DGMS,

Dhanbad.

Ergonomic Hazards(Equation of Man & Machine-due to pose,posture while

working )

Hot humid work environment and mechanical problems during work

lead to health impairment.

Most of the mines in our country uses various equipment, which are not

designed for Indian workers. As a result, most of the miners, who have poor

health condition, suffer from fatigue, back pain, and joint pain and work stress.

In addition to this, poor illumination, lack of ventilation. Hot and humid

work environment and mechanical problems during work lead to health

impairment.

To prevent this, proper workstation design, selection of health workers

to operate heavy equipment, rest pause and periodic medical examination to

assess fitness for the job are some of the important steps to reduce this hazard.

Problems due to Air Pollution

Both in underground and surface mines, dust nuisance is a

problem for the community residing nearby.

To reduce the environmental degradation and to maintain the

ecological balance, reducing dust generation and proper disposal of the

overburden should control air pollution.

Tree plantation at the mining area is another step to reduce air

pollution.

Suspended particulate matter (SPM), smoke, fumes and other

chemical pollutants should not be discharged to the atmosphere

mercilessly.

Air pollution causes irritation to the respiratory systems of the

people staying nearby. Many people, particularly the children suffer from

allergy, asthma, respiratory infection and bronchitis.

Preventive Measures

Engineering Control

Medical Control

Statutory Control

Engineering control measures should be adopted at the work place

and environment to reduce generation of dust, suppression of dust, proper

maintenance of equipment and adopting environmental hygiene measures.

Medical control measures are directed towards the miners with a

view to protect their health. The medical center (OHS) should undertake the

following need based functions.

Pre-employment health examination of all miners.

Emergency medical cares.

Health Education & Training.

Health Counseling

Computerised health information system.

Medical and occupation health facilities are meager in most of the

mines and even nonexistent in a few.

Occupational Health Service of SAIL (Policy) - example

SAIL had established Occupational Health Service centers in all its

manufacturing units including captive mines to promote and maintain the

physical, mental and social well being of all the employees.

Occupational Health Service at the unit level is functioning under

Medical Department.

Occupational Health Service in all units had been equipped to detect

and prevent occupational/work-related diseases and to offer effective emergency

and injury care at work.

Occupational Health Service at unit level has employed any of or all the

specialties of occupational medicine, occupational hygiene, occupational

physiology and ergonomics, occupational psychology, occupational health

nursing, health education, biochemistry and toxicology, health information

system, epidemiology and research depending on the needs of the unit in which

they are housed, as approved by the management.

The Occupational Health Service is headed by the Occupational

Physician who is totally responsible for organising various functions and

comprehensive occupational health programmes as decided from time to time.

Occupational Health Service Centers have sufficient and adequate

facilities (by way of qualified specialists, equipment, reference books and

journals, etc.) to perform there above functions effectively.

OHS had arranged to provide adequate number of First Aid Boxes

with approved contents on the shop floor and in the captive mines. These

boxes shall be maintained and kept under the charge of trained and

competent first-aiders. OHS staff regularly from time to time shall carry out

inspection of such boxes.

Occupational Health Service has developed health education

training packages including use of personal protective equipment for all

employees and impact training accordingly.

OHS Centers had played a vital role in suitably redeploying or

rehabilitating an employee, if it is found that he she is incapacitated due to an

accidental injury, occupational disease or otherwise.

OHS Center had taken special care of women employees working in

hazardous areas or handling toxic substance, which may cause danger or

interfere with pregnancy/childbearing/reproductive system.

The Occupational Physician advises on suitability of the various

personal Protective equipment. While recommending, he considers all

factors relating to health, anthropometric measurements, comfort and other

ergonomic aspects of relevance.

All OHS units of SAIL also caters to the emergency medical care as

outlined in the disaster management plan. It is well equipped with

medicines, dressings, injections and such other medical equipments to

meet the emergency.

Key personnel with assigned specific functions are identified and a

chart indicating this to be displayed prominently. The OHS staff also

participates in mock-drills organised for the purpose.

The Occupational Physician is a member of Medical Board and

Safety & Health oriented Committees.

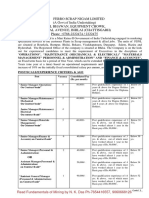

Status of Occupational Health Services at Mines (OHS)

5 OHS centers established with industrial doctors and staffs at an

investment of Rs. 1.50 crore each in 1992 at Iron ore Mines at Barsua,

Kiriburu, Chasnalla, Kuteshwar & Rajhara iron ore mines.

Employee welfare programme, periodic health check-up of

employees beyond 45 years age level at plants & mines are done.

a) In a year about 20% of employees are medically examined b)

Computer records maintained for health records and analysis C) Health

education & Counselling adequate no of employees done. D) BHP Kinhill

joint venture training in Australia, 8 doctors trained in 1994 E) Occupational

Physicians & professionals participated in various programmes.

OHS center in iron ore mines are operating satisfactorily with

provisions of staffs and equipments with following functions.

a) Assessment of risk from health hazards at work place and

surveillance of factors affecting workers health.

b) Workers education of sanitation, hygiene including training &

retraining on first aid;

c) Diagnosis & treatment of occupational injuries including

rehabilitation;

d) Compilation & Maintenance of health records & survey

reports related to dust, noise, temperature etc. e) Identification of

the need of protective equipments & evaluation of their

effectiveness.

Noise survey was conducted once a year in all Iron Ore

Mines of SAIL for initiating corrective measures & each time draws

up plan for job rotation, machine upkeep, employee rehabilitation,

and the details are furnished in Annexure - 1

The international noise level standards are shown below :

Annexure - 1

Status of Noise Pollution in SAIL Mines

A. Details showing Noise level in dBC (A) At different Machine Locations

Operation Mine A

Spl Leq

Dumpers

Empty run 94-99 96.3

Loaded run 97-100 99.8

SHOVELS

Near Operator -- --

3m away -- --

Drills

Near Operator 108-112 108.3

3m away 87-94 92.4

Crushers

Primary 76-83 82.5

Secondary 86-88 87.3

Screens

Primary 95-97 96.2

Secondary 86-99 87.7

Spl - Mean Range, Leq- Level Equivalent

B. Degree of Hearing Loss

Studied at 0-25 db/25-40 db/40-55 dB/above

55 dB

C. Hearing Loss of Employees (Age -Wise)

Studied in age group basis (say-<30age/30-

39/40-49/50-60age)

D. Hearing Loss of Employee (Service-Wise)

Done for years of service say-<10 years/10-

19 years/20-29 years/>30 years

International Noise Level standards - A comparison

Country Maximum Permissible Remarks

exposure level for

8 hours/day

USA 85 dB(A) Exposure to impact noise < 140 dB (A)

Australia 95 dB (A) Number of exposure to 115 dB (A) at any time

Canada 87-90 dB (A) For different noise level exposure time

specified 115 db (A) max. for

U.K 90 dB(A)

USSR 50 dB (A) Office

85 dB (A) Factories / Mines

India 90 dB () DGMS circular

No. 18 of 1975

A 3 years & 5 years OHS activities plan has been

prepared Upto 2005/6 A.D

Examination conducted in SAIL mines OHS :

Periodic medical Examination

Audiometry ( sound measurement)-ear testing

Spirometry-lung testing

Immunisation

Health Education

First Aid

Activities of OHS centres of SAIL mines-

Kiriburu/Meghatuburu mines

Periodical medical examination(PME) of employees working

in mines of KIOM/MIOM

Immunisation against T .T Toxoid to all the workers.At the

end of PME, each employee is given an immunisation cum

health card where immunisation schedule, blood group

name,ST No, Designation & any other personal significant

disease record is maintained

Sound survey & dust survey are carried out

Health examination programme is carried

(2 ).Equipments provided-

Spidometer

Audiometer

Noise Dosimeter

Employees covered under OHS Tests-(HYPOTHETICAL)

Types of Examination 2005 2006 2007

medical examination 294 290 411

Audiometry 304 269 383

Spirometry 114 124 142

Immunisation 54 65 20

Health Education------ 57 65 67

First Aid 33 35 28

Author: Sri G S Khuntia

Formerly Executive Director, SAIL and Director in NMDC,

Hyderabad, currently Director,OMC Ltd & IIMCS,

born in Bhubaneswar.

Graduated in 'Mining Engineering' from 'Indian School of

Mines, Dhanbad' in 1962 and obtained 'First Class

Mines Manager Certificate.

Worked for 33 years in 'Managerial Capacities' in Mining

Industry of India, (mines of OMC, NMDC, SAIL units

at Rourkela,Bokaro,Bhilai,Durgapur SAIL corporate

office )

Received a large number of National awards like

NATIONAL MINERAL AWARDS from Ministry of

Mines, Govt of India, National Design Award-2001 from

Institution of Engineers (India), John Dunn Medal,

Jawaharlal Award, Rungta Awards

Presented over 100 Technical Papers in various National and

International Conferences including 'World Mining

Congress' in DELHI (84) I, SWEDEN (87), CHINA (90),

MARDID (92), AUSTRALIA (96) and DELHI (2003).

Visited widely mines in foreign countries (Sweden, Norway,

Poland, England, France, Switzerland, Germany, Spain,

Hongkong, Dubai, Bangkok, Singapore & Australia). He

has been Chairman of a large number of Professional

bodies-Institution of Engineer, (India), Orissa State (2008-

12)/ Current Council Member ,Past Council member of

I EI /,Kolkatta Vice-President of Multi-disciplinary center

for Presently committee member (Mining) of Institution

of safety, health & environment, Bhubaneswar (a state

govt. sponsored organisation), Editor in Chief of Indian

Mining & Engineering Journal, Consultant (mines &

steel)

Former Mining Advisor to ESSAR /Maharastra Seamless Ltd

/ Currently Director ,IIMCS /Director, OMC Ltd,

Bhubaneswar.

E-mail---gskhuntia@gmail.com

THANKS

S-ar putea să vă placă și

- IS 13517 - Rock Bolts - Resin Type - Bureau of Indian Standards - Free Download, Borrow, and Streaming - Internet ArchiveDocument2 paginiIS 13517 - Rock Bolts - Resin Type - Bureau of Indian Standards - Free Download, Borrow, and Streaming - Internet Archiveihateu1Încă nu există evaluări

- Number of Questions 23 Number of Questions To Answer 20Document4 paginiNumber of Questions 23 Number of Questions To Answer 20Engr. Zahid Ur RehmanÎncă nu există evaluări

- IS 14778 - Portable Methanometer (Interferometer Type) - Bureau of Indian Standards - F - Internet Archive22Document2 paginiIS 14778 - Portable Methanometer (Interferometer Type) - Bureau of Indian Standards - F - Internet Archive22ihateu1Încă nu există evaluări

- Advt Ferro Scrap 2021 E (N)Document5 paginiAdvt Ferro Scrap 2021 E (N)ihateu1Încă nu există evaluări

- Advt Ferro Scrap 2021 E (N)Document5 paginiAdvt Ferro Scrap 2021 E (N)ihateu1Încă nu există evaluări

- GT Question Papers Answers Important Questions Green Technologies R13 JNTUKDocument1 paginăGT Question Papers Answers Important Questions Green Technologies R13 JNTUKihateu1Încă nu există evaluări

- Calculate Postage: Sign in RegisterDocument3 paginiCalculate Postage: Sign in Registerihateu1Încă nu există evaluări

- Leadership Quiz Questions Answers - Quiz 1Document3 paginiLeadership Quiz Questions Answers - Quiz 1ihateu1Încă nu există evaluări

- DGMS-2020 - Exam Scheme and InstructionDocument6 paginiDGMS-2020 - Exam Scheme and Instructionihateu1Încă nu există evaluări

- GT Questions - 4Document1 paginăGT Questions - 4ihateu1Încă nu există evaluări

- Answer Data 1608607135Document1 paginăAnswer Data 1608607135ihateu1Încă nu există evaluări

- gAS - Google SearchDocument1 paginăgAS - Google Searchihateu1Încă nu există evaluări

- Mining Technology - Engineering Notes IndiaDocument4 paginiMining Technology - Engineering Notes Indiaihateu1Încă nu există evaluări

- GT R13 Green Technologies QuestionsDocument1 paginăGT R13 Green Technologies Questionsihateu1Încă nu există evaluări

- GT Questions - 3Document1 paginăGT Questions - 3ihateu1Încă nu există evaluări

- Stability Analysis of A Mine Waste Dump Over An Existing DumpDocument10 paginiStability Analysis of A Mine Waste Dump Over An Existing Dumpihateu1Încă nu există evaluări

- GT Questions - 5 PDFDocument1 paginăGT Questions - 5 PDFihateu1Încă nu există evaluări

- MiningDocument1 paginăMiningihateu1Încă nu există evaluări

- GT Questions - 2Document1 paginăGT Questions - 2ihateu1Încă nu există evaluări

- Gas Testing Exam Questions for Mining StudentsDocument1 paginăGas Testing Exam Questions for Mining Studentsihateu1Încă nu există evaluări

- Stability Analysis of A Mine Waste Dump Over An Existing DumpDocument10 paginiStability Analysis of A Mine Waste Dump Over An Existing Dumpihateu1Încă nu există evaluări

- GoglebDocument1 paginăGoglebihateu1Încă nu există evaluări

- Mining 1Document4 paginiMining 1ihateu1100% (1)

- 03202018145834coal and Lig - AR - 2017Document29 pagini03202018145834coal and Lig - AR - 2017ihateu1Încă nu există evaluări

- Upload A DocumentDocument2 paginiUpload A Documentihateu1Încă nu există evaluări

- Document For ScribdDocument2 paginiDocument For Scribdihateu1Încă nu există evaluări

- Para 4 PDFDocument1 paginăPara 4 PDFihateu1Încă nu există evaluări

- Noticemt2019advt17122019 PDFDocument1 paginăNoticemt2019advt17122019 PDFChandan KumarÎncă nu există evaluări

- Slide 2Document1 paginăSlide 2ihateu1Încă nu există evaluări

- 181639Document7 pagini181639ihateu1Încă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Malaysia Technical Programme ScreenDocument36 paginiMalaysia Technical Programme ScreenMohd Zainee ZainalÎncă nu există evaluări

- Ga F2a55m S1Document31 paginiGa F2a55m S1Kleber CostaÎncă nu există evaluări

- Model Operator'S Manual: Non Contact TonometerDocument100 paginiModel Operator'S Manual: Non Contact TonometerRitesh GuptaÎncă nu există evaluări

- 2019 - 2020 Skills Gap Report FINAL PDFDocument12 pagini2019 - 2020 Skills Gap Report FINAL PDFPradyumna DangewarÎncă nu există evaluări

- AWS CWI Training Program PDFDocument22 paginiAWS CWI Training Program PDFDjamelÎncă nu există evaluări

- Tamil Nadu Fire Licence ApplicationDocument4 paginiTamil Nadu Fire Licence ApplicationPRASANTH PRASANTHÎncă nu există evaluări

- Chineseburned AWADocument7 paginiChineseburned AWAsureshk143100% (1)

- Strategic Housing For Older People PDFDocument130 paginiStrategic Housing For Older People PDFLuz VargasÎncă nu există evaluări

- Accounting For Corporations IDocument13 paginiAccounting For Corporations Iibrahim mohamedÎncă nu există evaluări

- CTA RulingDocument12 paginiCTA RulingGhia TalidongÎncă nu există evaluări

- Fluxes For MetallurgyDocument15 paginiFluxes For Metallurgyramau619Încă nu există evaluări

- Comparison of ROBOT and MIDAS GENDocument2 paginiComparison of ROBOT and MIDAS GENAshish LoyaÎncă nu există evaluări

- SPE-176481-MS Deep Water Reservoir Characterization and Its Challenges in Field Development Drilling Campaign, Kutei Basin, Indonesia-A Case StudyDocument16 paginiSPE-176481-MS Deep Water Reservoir Characterization and Its Challenges in Field Development Drilling Campaign, Kutei Basin, Indonesia-A Case StudyDian KurniawanÎncă nu există evaluări

- COMLAWREV Catindig 2009 ReviewerDocument196 paginiCOMLAWREV Catindig 2009 ReviewerShara LynÎncă nu există evaluări

- Kaessbohrer - MetagoPro - APT - EN - 0616 PDF Web PDFDocument2 paginiKaessbohrer - MetagoPro - APT - EN - 0616 PDF Web PDFnikÎncă nu există evaluări

- Operand Storage in The CPUDocument3 paginiOperand Storage in The CPUisaac setabiÎncă nu există evaluări

- GMP-Inspection Report 2391Document5 paginiGMP-Inspection Report 2391ajitjoshi950Încă nu există evaluări

- Schema Instrument Air-01Document1 paginăSchema Instrument Air-01OudadLeO-marÎncă nu există evaluări

- What Type of Connection Is Used at Transformers Used at Generation Side and Distribution Side PDFDocument1 paginăWhat Type of Connection Is Used at Transformers Used at Generation Side and Distribution Side PDFcharanÎncă nu există evaluări

- Kuwait University Dept. of Chemical Engineering Spring 2017/2018Document8 paginiKuwait University Dept. of Chemical Engineering Spring 2017/2018material manÎncă nu există evaluări

- Riskope The Factor of Safety and Probability of Failure Relationship 1Document12 paginiRiskope The Factor of Safety and Probability of Failure Relationship 1jaguilarn1960Încă nu există evaluări

- HRD Plan. AigDocument25 paginiHRD Plan. Aigminhhr2000Încă nu există evaluări

- BP48100 SpecDocument4 paginiBP48100 SpecP&P IngenieriaÎncă nu există evaluări

- Secretary's Certificate in Re Board ResolutionsDocument2 paginiSecretary's Certificate in Re Board Resolutionslucky joy domingoÎncă nu există evaluări

- Vlan Irtual: V LANDocument35 paginiVlan Irtual: V LANHansa JhaÎncă nu există evaluări

- Tek Radius ManualDocument42 paginiTek Radius ManualjesusvpctÎncă nu există evaluări

- 4 Reference Book (Leszek A. Maciaszek) Requirements Analysis and System DesignDocument651 pagini4 Reference Book (Leszek A. Maciaszek) Requirements Analysis and System DesignPedro LoveipowaÎncă nu există evaluări

- CT ES 072 RFID and GPS Combination Approach Implementation in Fisher Boat TrackingDocument2 paginiCT ES 072 RFID and GPS Combination Approach Implementation in Fisher Boat TrackingkbsmalliÎncă nu există evaluări

- Tumkur University Pre PHD Course Work Syllabus ManagementDocument6 paginiTumkur University Pre PHD Course Work Syllabus Managementafjwftijfbwmen100% (1)