Documente Academic

Documente Profesional

Documente Cultură

Weld Acceptance Criteria

Încărcat de

0502ravi0 evaluări0% au considerat acest document util (0 voturi)

421 vizualizări14 paginiEN ISO 5817-2007 provides quality levels of imperfections in fusion-welded joints all types of steel, nickel, titanium and their alloys. It applies to material thickness above 0,5 mm. It covers fully penetrated butt and all fillet welds. Three quality levels are given in order to permit application to a wide range of welded fabrication, designated by symbols B, C and D. Different quality levels are applied to individual welded joints in the same product or component.

Descriere originală:

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPTX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentEN ISO 5817-2007 provides quality levels of imperfections in fusion-welded joints all types of steel, nickel, titanium and their alloys. It applies to material thickness above 0,5 mm. It covers fully penetrated butt and all fillet welds. Three quality levels are given in order to permit application to a wide range of welded fabrication, designated by symbols B, C and D. Different quality levels are applied to individual welded joints in the same product or component.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

421 vizualizări14 paginiWeld Acceptance Criteria

Încărcat de

0502raviEN ISO 5817-2007 provides quality levels of imperfections in fusion-welded joints all types of steel, nickel, titanium and their alloys. It applies to material thickness above 0,5 mm. It covers fully penetrated butt and all fillet welds. Three quality levels are given in order to permit application to a wide range of welded fabrication, designated by symbols B, C and D. Different quality levels are applied to individual welded joints in the same product or component.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPTX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 14

EN ISO 5817-2007

Quality level for imperfections

This International Standard provides quality levels of

imperfections in fusion-welded joints

all types of steel, nickel, titanium and their alloys.

It applies to material thickness above 0,5 mm.

It covers fully penetrated butt welds and all fillet welds

Three quality levels are given in order to permit

application to a wide range of welded fabrication,

designated by symbols B, C and D.

different quality levels are applied to individual welded

joints in the same product or component.

EN ISO 5817-2007

Quality level for imperfections

The quality level necessary in each case

should be defined by

1. the application standard

2. the responsible designer in conjunction with

the manufacturer,

3. user and/or other parties concerned.

EN ISO 5817-2007

Quality level for imperfections

The choice of quality level for any application should take

account of

design considerations,

subsequent processing (e.g. surfacing),

mode of stressing (e.g. static, dynamic),

service conditions (e.g. temperature, Environment)

consequences of failure. Economic factors are also

important and should include not only

the cost of welding but also of inspection, test and

repair.

EN ISO 5817-2007

Quality level for imperfections

Quality level

Description of the quality of a weld on the basis

of type, size and amount of selected

imperfections

Fitness-for-purpose

Ability of a product, process or service to serve a

defined purpose under specific conditions

EN ISO 5817-2007

Quality level for imperfections

Short imperfections

In cases when the weld is 100 mm long or longer,

imperfections are considered to be short- imperfections if,

in the 100 mm which contains the greatest number of

imperfections, their total length is less than 25 mm in cases

when the weld is less than 100 mm long, imperfections are

considered to be short imperfections if their total length is

less than 25 % of the length of the weld

Systematic imperfection

Imperfections that are repeatedly distributed in the weld

over the weld length to be examined, the size of a single

imperfection being within the specified limits

EN ISO 5817-2007

Quality level for imperfections

Assessment of imperfections

Limits for imperfections are given in Table

If, for the detection of imperfections, micro-

examination is used, only those imperfections shall be

considered which can be detected with a maximum of

tenfold magnification. Excluded from this are micro

lack of fusion.

Systematic imperfections are only permitted in quality

level D, provided other requirements of Table 1 are

fulfilled.

EN ISO 5817-2007

Quality level for imperfections

Assessment of imperfections

A welded joint should usually be assessed separately

for each individual type of imperfection. Different

types of imperfection occurring at any cross-section of

the joint need special consideration. The limits for

multiple imperfections are only applicable for cases

where the requirements for a single imperfection are

not exceeded.

Any two adjacent imperfections separated by a

distance smaller than the major dimension of the

smaller imperfection shall be considered as a single

imperfection

EN ISO 5817-2007

Quality level for imperfections

a - nominal throat thickness of the fillet weld (see also ISO

2553)

b -width of weld reinforcement

d -diameter of gas pore

h -height or width of imperfection

l -length of imperfection in longitudinal direction of the

weld

s -nominal butt weld thickness (see also ISO 2553)

t -wall or plate thickness (nominal size)

z -leg length of a fillet weld (see also ISO 2553)

angle of weld toe

angle of angular misalignment

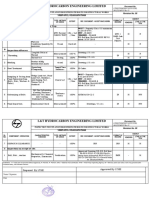

ACCEPTANCE CRITERIA

Imperfect

ion

designati

on

Remarks t

mm

Limits for imperfections for quality levels

D C B

Surface

pore

Maximum

dimension of a

single pore for

butt welds

fillet welds

butt welds

fillet welds

0,5 to 3

0,5 to 3

> 3

> 3

d 0,3 s

d 0,3 a

d 0,3 s,

but max.

3 mm

d 0,3 a,

but max.

3 mm

Not permitted

d 0,2 s, but

max. 2 mm

d 0,2 a, but

max. 2 mm

Not permitted

Not permitted

Not permitted

ACCEPTANCE CRITERIA

Imperfect

ion

designati

on

Remarks t

mm

Limits for imperfections for quality levels

D C B

Incomplet

e root

penetrati

on

Only for single

side butt welds

0,5

Short

imperfectio

ns:

h 0,2 t,

but max. 2

mm

Not permitted

Not permitted

ACCEPTANCE CRITERIA

Imperfection

designation

Remarks t

mm

Limits for imperfections for quality levels

D C B

Continuous

undercut

Intermittent

undercut

Smooth

transition

is required.

This is not

regarded

as a

systematic

imperfecti

on

0,5 to 3

> 3

Short

imperfectio

ns:

h 0,2 t

h 0,2 t,

but max. 1

mm

Short

imperfections:

h 0,1 t

h 0,1 t,

but max. 0,5

mm

Not permitted

h 0,05 t,

but max. 0,5 mm

ACCEPTANCE CRITERIA

Imperfection

designation

Remarks t

mm

Limits for imperfections for quality levels

D C B

Excess weld

metal

(butt weld)

Excessive

convexity

(fillet

weld)

Burn through

Smooth

transition is

required.

0,5

0,5

0,5

h 1 mm +

0,25 b,

but max. 10

mm

h 1 mm +

0,25 b,

but max. 5

mm

Not

permitted

h 1 mm +

0,15 b,

but max. 7 mm

h 1 mm +

0,15 b,

but max. 4 mm

Not permitted

h 1 mm + 0,1 b,

But max. 5 mm

h 1 mm + 0,1 b,

but max. 3 mm

Not permitted

ACCEPTANCE CRITERIA

Imperfection

designation

Remarks t

mm

Limits for imperfections for quality levels

D C B

Excessive

asymmetry

of

fillet weld

(excessive

unequal leg

Length)

In cases

where an

asymmetric

fillet weld

has

not been

prescribed

0,5

h 2 mm +

0,2 a

h 2 mm +

0,15 a

h 1,5 mm + 0,15 a

ACCEPTANCE CRITERIA

Imperfection

designation

Remarks t

mm

Limits for imperfections for quality levels

D C B

Insufficient

throat

thickness

Not

applicable to

processes

with proof of

greater

depth of

penetration

0,5 to 3

> 3

Short

imperfectio

ns:

h 0,2 mm

+ 0,1 a

h 0,3 mm

+ 0,1 a,

but max. 2

mm

Short

imperfections

h0,2 mm

h 0,3 mm +

0,1 a,

but max. 1 mm

Not permitted

Not permitted

S-ar putea să vă placă și

- Quality Level BDocument17 paginiQuality Level BUgonnaÎncă nu există evaluări

- VT Acceptance Criteria PDFDocument10 paginiVT Acceptance Criteria PDFKalaivel ThandavarayanÎncă nu există evaluări

- Weld Imperfection Examination StandardDocument4 paginiWeld Imperfection Examination StandardMohd Akmal ShafieÎncă nu există evaluări

- Is 7310-1Document23 paginiIs 7310-1rajeshÎncă nu există evaluări

- HMC Spec 001 - Welding and Fabrication of Structural SteelDocument29 paginiHMC Spec 001 - Welding and Fabrication of Structural SteelJohnnyÎncă nu există evaluări

- Defectology NDT Final Edit PDFDocument132 paginiDefectology NDT Final Edit PDFIdjzulz Zulkifli100% (1)

- Limits For Imperfections ISO 5817Document2 paginiLimits For Imperfections ISO 5817tudorteuÎncă nu există evaluări

- Visual Examination Procedure: 1 - PurposeDocument4 paginiVisual Examination Procedure: 1 - PurposeElvin MenlibaiÎncă nu există evaluări

- WELDING INSPECTOR AWARENESS TRAINING ENG Rev00 31.12.2019Document65 paginiWELDING INSPECTOR AWARENESS TRAINING ENG Rev00 31.12.2019Ethem Güngör100% (1)

- RT Acceptance Criteria: API-1104 AWS D1.1Document1 paginăRT Acceptance Criteria: API-1104 AWS D1.1Shabbir ali100% (1)

- Job Knowledge 68Document8 paginiJob Knowledge 68Mehmet Soysal100% (1)

- A General Review of The Causes and Acceptance of Shape ImperfectionsDocument7 paginiA General Review of The Causes and Acceptance of Shape ImperfectionsMuhammed SulfeekÎncă nu există evaluări

- Thickness Tolerance of API 5L ASTM A53 EN10219 StandardDocument2 paginiThickness Tolerance of API 5L ASTM A53 EN10219 StandardhungÎncă nu există evaluări

- NDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023Document16 paginiNDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023SANJEEV YADAVÎncă nu există evaluări

- Penetrant Testing (PT)Document11 paginiPenetrant Testing (PT)Maria Cristina DijmarescuÎncă nu există evaluări

- VT Acceptance Criteria WeldsDocument14 paginiVT Acceptance Criteria WeldsCharwin Xiao100% (1)

- Weld Fit Up Inspection Employee TrainingDocument10 paginiWeld Fit Up Inspection Employee TrainingBadiuzzama Azmi100% (1)

- Is 822 Code of Pratice For Inspection of WeldsDocument40 paginiIs 822 Code of Pratice For Inspection of Weldsnarasimhareddy415Încă nu există evaluări

- SNIS UT 578 - Steel PlatesDocument14 paginiSNIS UT 578 - Steel PlatesShailesh DeshmukhÎncă nu există evaluări

- Fcaw 16 THKDocument5 paginiFcaw 16 THKAnonymous Ij6VfaÎncă nu există evaluări

- Procedure: "Straight Beam/Angle Beam Manual Ultrasonic Testing"Document21 paginiProcedure: "Straight Beam/Angle Beam Manual Ultrasonic Testing"mangalraj900Încă nu există evaluări

- Template BUTTDocument1 paginăTemplate BUTTDylan TriggÎncă nu există evaluări

- DR 10.01 Instructions For Non-Destructive Testing of Welds REV 05 2011-07Document13 paginiDR 10.01 Instructions For Non-Destructive Testing of Welds REV 05 2011-07SasaÎncă nu există evaluări

- VT ProcedureDocument5 paginiVT ProcedureFadil WimalaÎncă nu există evaluări

- L&T Hydrocarbon Engineering LimitedDocument2 paginiL&T Hydrocarbon Engineering LimitedAnonymous vchjQ9CQveÎncă nu există evaluări

- Is 7310 RequirementsDocument4 paginiIs 7310 RequirementsRavichandran Tirupattur SubramaniamÎncă nu există evaluări

- As 2205.6.1-2003 Methods For Destructive Testing of Welds in Metal - Weld Joint Hardness TestDocument2 paginiAs 2205.6.1-2003 Methods For Destructive Testing of Welds in Metal - Weld Joint Hardness TestSAI Global - APACÎncă nu există evaluări

- DefectDocument2 paginiDefectanon_90890103100% (1)

- IQIDocument9 paginiIQIalouisÎncă nu există evaluări

- Weldingdefects 150915053459 Lva1 App6892 PDFDocument22 paginiWeldingdefects 150915053459 Lva1 App6892 PDFpaolaÎncă nu există evaluări

- Poster DIN EN 1090-1 ENG Final PDFDocument1 paginăPoster DIN EN 1090-1 ENG Final PDFlth770310Încă nu există evaluări

- Model WopqDocument2 paginiModel WopqAnilkumarGopinathanNairÎncă nu există evaluări

- 22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCDocument1 pagină22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCnwoforÎncă nu există evaluări

- LPT As Per Asme & IsoDocument2 paginiLPT As Per Asme & IsosbmmlaÎncă nu există evaluări

- 4260Document10 pagini4260Lipika GayenÎncă nu există evaluări

- Catalog Fabricante TechnipDocument9 paginiCatalog Fabricante Technipjimy GutiérrezÎncă nu există evaluări

- NEW - ALL Codes For Accptance Criteria For RTDocument4 paginiNEW - ALL Codes For Accptance Criteria For RTBALA CHANDAR M100% (1)

- Procedure A578Document3 paginiProcedure A578debduttamallik50% (2)

- S355 European Standard SteelDocument7 paginiS355 European Standard SteelmaiquelernÎncă nu există evaluări

- Gas Metal Arc Welding (GMAW) : University of Kuala Lumpur - Malaysia France InstituteDocument16 paginiGas Metal Arc Welding (GMAW) : University of Kuala Lumpur - Malaysia France InstituteKamarul Nizam100% (1)

- Bend Test Acceptance CriteriADocument1 paginăBend Test Acceptance CriteriAGowrisanthosh PalikaÎncă nu există evaluări

- P1 To P8Document9 paginiP1 To P8Pat AuffretÎncă nu există evaluări

- AISI 1018 Mild Low Carbon Steel PDFDocument3 paginiAISI 1018 Mild Low Carbon Steel PDFFebrian JhaÎncă nu există evaluări

- MTC Er70s 2Document1 paginăMTC Er70s 2Mirza BaigÎncă nu există evaluări

- Macro Examination StandardDocument4 paginiMacro Examination StandardMohd Akmal ShafieÎncă nu există evaluări

- Weld History Sheet-4Document4 paginiWeld History Sheet-4MITHUNÎncă nu există evaluări

- VT Procedure: 1 - PurposeDocument4 paginiVT Procedure: 1 - PurposeElvin Menlibai100% (1)

- Weld Joint Repaire Procedure - 08.04.14Document6 paginiWeld Joint Repaire Procedure - 08.04.14Raj AryanÎncă nu există evaluări

- 3.3.1-Basics of Weld Joint Design-9th Mar 21Document60 pagini3.3.1-Basics of Weld Joint Design-9th Mar 21Vivek kmÎncă nu există evaluări

- Norma Holiday Detector ASTM D5162-2001 PDFDocument4 paginiNorma Holiday Detector ASTM D5162-2001 PDFDuverlyOrlandoMattaVásquez100% (1)

- Guidance To Prepare Wps PQR For WeldingDocument1 paginăGuidance To Prepare Wps PQR For WeldingHamid MansouriÎncă nu există evaluări

- Asme Sections ListDocument1 paginăAsme Sections ListShreekanthKannathÎncă nu există evaluări

- JIS G3452 PipeDocument0 paginiJIS G3452 PipefaridyeniÎncă nu există evaluări

- Comparison Between API-1104 21st Ed & 22nd EdDocument13 paginiComparison Between API-1104 21st Ed & 22nd EdsadashiwÎncă nu există evaluări

- WIS5 - Appendix 2Document86 paginiWIS5 - Appendix 2Reza Fakhrizal100% (1)

- BS en ISO 5817 2014 Welding. Fusion-Welded Joints (Beam Welding Excluded) - Quality Levels For Imperfections Ref OnlyDocument20 paginiBS en ISO 5817 2014 Welding. Fusion-Welded Joints (Beam Welding Excluded) - Quality Levels For Imperfections Ref Onlyshaggeruk86% (7)

- Iso 5817 Practice: L.Srinivasan Cms/AwtiDocument59 paginiIso 5817 Practice: L.Srinivasan Cms/Awtiaravindan100% (1)

- NDT-Acceptance Various CodesDocument17 paginiNDT-Acceptance Various CodesShanmuga NavaneethanÎncă nu există evaluări

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 paginiAcceptance Criteria of Weld Defects As Per Different CodesdhasdjÎncă nu există evaluări

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 paginiAcceptance Criteria of Weld Defects As Per Different CodesMidhun K Chandrabose96% (24)

- Weld DefectsDocument6 paginiWeld Defects0502raviÎncă nu există evaluări

- CANFAN Airzon BLDC Super Efficient Fans - ICF PeramburDocument13 paginiCANFAN Airzon BLDC Super Efficient Fans - ICF Perambur0502raviÎncă nu există evaluări

- Icf-Pioneering in A Changing Economic EnvironmentDocument18 paginiIcf-Pioneering in A Changing Economic Environment0502raviÎncă nu există evaluări

- Din 6700 2 enDocument27 paginiDin 6700 2 en0502ravi100% (1)

- Wps 15614 TemplateDocument2 paginiWps 15614 Template0502raviÎncă nu există evaluări

- E1648-01 Aluminum Fusion WeldsDocument3 paginiE1648-01 Aluminum Fusion Welds0502raviÎncă nu există evaluări

- To CNC Machines & RobotsDocument29 paginiTo CNC Machines & Robots0502raviÎncă nu există evaluări

- WPSPQRDocument11 paginiWPSPQR0502raviÎncă nu există evaluări

- Stainless Steel DefectsDocument30 paginiStainless Steel Defects0502ravi100% (1)

- WELDABILITY of SteelDocument41 paginiWELDABILITY of Steel0502ravi100% (1)

- BS EN 1011-3-2000 - Recommendations For Arc Welding of Stainless Steels PDFDocument25 paginiBS EN 1011-3-2000 - Recommendations For Arc Welding of Stainless Steels PDF0502ravi100% (1)

- Ss WeldingDocument12 paginiSs Welding0502ravi100% (1)

- Welding Defect PhotoDocument14 paginiWelding Defect Photo0502raviÎncă nu există evaluări

- Terms in Welding Standard en 15085Document6 paginiTerms in Welding Standard en 150850502raviÎncă nu există evaluări

- Railway Vehicle Welding inspectionEN 15085-5Document16 paginiRailway Vehicle Welding inspectionEN 15085-50502raviÎncă nu există evaluări

- En 15085 - 1 & 2Document34 paginiEn 15085 - 1 & 20502ravi100% (4)

- Welding DefectsDocument47 paginiWelding Defects0502raviÎncă nu există evaluări

- Advanced Welding ProcesssDocument11 paginiAdvanced Welding Processs0502ravi100% (1)

- Weld ImperfectionsDocument11 paginiWeld Imperfections0502raviÎncă nu există evaluări

- Gmaw Thumb RuleDocument68 paginiGmaw Thumb Rule0502raviÎncă nu există evaluări

- En 15085 ClassDocument63 paginiEn 15085 Class0502ravi100% (3)

- Plasma Cutting Process: Plasma Arc Associated With Arc Constriction Resulting in Higher Ionisation Level in ArcDocument27 paginiPlasma Cutting Process: Plasma Arc Associated With Arc Constriction Resulting in Higher Ionisation Level in Arc0502raviÎncă nu există evaluări

- Types of Production SystemsDocument15 paginiTypes of Production SystemsAnimesh KumarÎncă nu există evaluări

- Packages Internship ReportDocument75 paginiPackages Internship ReportHamza Hassan0% (2)

- Butt Weld Msi PDFDocument7 paginiButt Weld Msi PDFmohdfaridabubakarÎncă nu există evaluări

- Hot Isostatic PressingDocument31 paginiHot Isostatic PressingmkraijadaÎncă nu există evaluări

- HDPE Material of PipeDocument6 paginiHDPE Material of PipeAnggi Gusti RizaÎncă nu există evaluări

- Balinit LumenaDocument4 paginiBalinit LumenajaumecaroÎncă nu există evaluări

- Concrete RepairDocument7 paginiConcrete RepairjjahaddinÎncă nu există evaluări

- Process Two AssignmentDocument17 paginiProcess Two AssignmentabrhshÎncă nu există evaluări

- Estimation of Total PopulationDocument11 paginiEstimation of Total PopulationHiren PatelÎncă nu există evaluări

- Welding Defects and PreventionDocument2 paginiWelding Defects and PreventionVicky SinghÎncă nu există evaluări

- Inventory Management TechniquesDocument10 paginiInventory Management TechniquesAna Milena ÁbregoÎncă nu există evaluări

- KKC Media 2017 M1Document6 paginiKKC Media 2017 M1Mgn SanÎncă nu există evaluări

- Batching Plant OperationsDocument17 paginiBatching Plant OperationsgarypaulÎncă nu există evaluări

- SMART Case UpdatedDocument13 paginiSMART Case UpdatedPatricia Ordoñez0% (1)

- Cable Tool Drilling MethordDocument5 paginiCable Tool Drilling MethordShehzad khanÎncă nu există evaluări

- Chapter 11 (Foundry Modernization and Mechanization) 2003Document10 paginiChapter 11 (Foundry Modernization and Mechanization) 2003gere33% (3)

- Division9 Wsdot - SpecificationsDocument218 paginiDivision9 Wsdot - SpecificationsrealchicÎncă nu există evaluări

- Effluent Treatment PlantDocument68 paginiEffluent Treatment PlantSegun Olatayo100% (2)

- SAP PP 30 Interview Questions and Answers For 2018Document1 paginăSAP PP 30 Interview Questions and Answers For 2018Hemamber ReddyÎncă nu există evaluări

- BOQ - Bill BageDocument16 paginiBOQ - Bill BageSinthuja DilanÎncă nu există evaluări

- Sulfur Removal and Recovery (1975)Document225 paginiSulfur Removal and Recovery (1975)Ahmed Soliman100% (1)

- Types of CementDocument5 paginiTypes of CementPeniel LuzonÎncă nu există evaluări

- Q.1What Is The Competitive Priorities For Synthite?: Input DataDocument4 paginiQ.1What Is The Competitive Priorities For Synthite?: Input DatarakeshÎncă nu există evaluări

- Benzona 1511Document2 paginiBenzona 1511Dia Putranto HarmayÎncă nu există evaluări

- Gul Ahmed FinalDocument14 paginiGul Ahmed FinalMuhammad Abubakr NaeemÎncă nu există evaluări

- 04-2-TS vOL-II, Sec-IV, FQP R1 PDFDocument20 pagini04-2-TS vOL-II, Sec-IV, FQP R1 PDFsanjeevchhabraÎncă nu există evaluări

- AlterNrg Planta JaponDocument24 paginiAlterNrg Planta JaponCalvin Mitchell100% (1)

- Course Detail 7th Sem Mkm. BBADocument8 paginiCourse Detail 7th Sem Mkm. BBAHari AdhikariÎncă nu există evaluări

- BIOTECH Newsletter-Fall 04Document9 paginiBIOTECH Newsletter-Fall 04Rakshit MathurÎncă nu există evaluări

- Castrol Viscogen® G PDFDocument2 paginiCastrol Viscogen® G PDFAnibal RiosÎncă nu există evaluări