Documente Academic

Documente Profesional

Documente Cultură

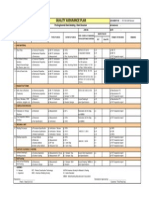

Gmaw Thumb Rule

Încărcat de

0502ravi0 evaluări0% au considerat acest document util (0 voturi)

444 vizualizări68 paginiGMAW is defined as arc welding using a continuously fed consumable electrode and a shielding gas. The basic GMAW process includes three distinctive process techniques. Short Circuit (short arc) Operates at low voltages and welding current.

Descriere originală:

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PPT, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentGMAW is defined as arc welding using a continuously fed consumable electrode and a shielding gas. The basic GMAW process includes three distinctive process techniques. Short Circuit (short arc) Operates at low voltages and welding current.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

444 vizualizări68 paginiGmaw Thumb Rule

Încărcat de

0502raviGMAW is defined as arc welding using a continuously fed consumable electrode and a shielding gas. The basic GMAW process includes three distinctive process techniques. Short Circuit (short arc) Operates at low voltages and welding current.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PPT, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 68

GMAW Fundamentals

Gas Metal Arc Welding

Metal Inert Gas

Safety

Electrocution hazard

Skin burns from flying metal

Skin burns from direct light from arc

Skin burns from indirect light from arc

Cotton clothing and leather gloves

Helmet to protect eyes from light

Safety glasses when chipping slag

Ventilation to remove dangerous fumes

Do not weld near water

Do not weld near combustible materials

Keep welding cables and jobs free grease

Protect bystanders from arc rays

Introduction

GMAW is defined as arc welding using a

continuously fed consumable electrode and

a shielding gas.

GMAW is also known as MIG (Metal Inert

Gas).

Produces high-quality welds

Yields high productivity

Advantages

Large gaps filled or bridged easily

Welding can be done in all positions

No slag removal required

High welding speeds

High weld quality

Less distortion of work piece

Disadvantages

Hard to reach locations are less easily welded

because of bulky torch and cables

Wind or air drafts may compromise gas shielding

Reactive metals (i.e. titanium) may need special

shielding provisions

High heat may be uncomfortable to welders

Correct parameter selection learning needs

dedicated training

Equipment is more complex and expensive than

that of alternative processes

Several tips must be consider in

selecting mode of transfer

Type, intensity and polarity of welding

current

Electrode size

Electrode composition

Electrode extension

Shielding gas mix composition

Types of Metal Transfer

The basic GMAW process includes three

distinctive process techniques:

1. Short Circuit (Short Arc)

2. Globular Transfer

3. Spray Arc Transfer

Modes of GMAW Transfer

Short Circuit (Short Arc)

Operates at low voltages and welding current

Small fast-freezing weld puddle obtained

Useful in joining thin materials in any position, as

well as thick materials in vertical and overhead

positions

Metal transfer occurs when an electrical short

circuit is established

this cycle can repeat itself between 20 and as

much as 250 times per second.

Short Circuit

A - Electrode is short circuited to base metal. No

arc, and current is flowing through electrode wire

and base metal.

B - Resistance increases in electrode wire causing

it to heat, melt and neck down.

C - Electrode wire separates from weld puddle,

creating an arc. Small portion of electrode wire

is deposited which forms a weld puddle.

D - Arc length and load voltage are at maximum.

Heat of arc is flattening the puddle and increasing

the diameter tip of electrode.

E - Wire feed speed overcomes heat of arc and

wire approaches base metal again.

F - Arc is off and the short circuit cycle starts

again.

Advantages

All-position capability, including flat, horizontal,

vertical-up, vertical-down and overhead.

Handles poor fit-up extremely well, and is capable

of root pass work on pipe applications.

Lower heat input reduces weldment distortion.

Higher operator appeal and ease of use.

Higher electrode efficiencies, 93% or more.

Limitations

Restricted to sheet metal thickness range and open

roots of groove joints on heavier sections of base

material.

Poor welding procedure control can result in

incomplete fusion. Cold lap and cold shut are

additional terms that serve to describe incomplete

fusion defects.

Poor procedure control can result in excessive

spatter, and will increase weldment cleanup cost.

To prevent the loss of shielding gas to the wind,

welding outdoors may require the use of a

windscreen(s).

Globular Transfer

Welding current and wire speed are

increased above maximum for short arc

Droplets of metal have a greater diameter

than the wire being used

Spatter present

Welding is most effectively done in the flat

position when using globular transfer

Globular transfer is often a

high voltage, high

amperage, high wire feed

speed transfer, and is the

result of using CO2

shielding gas (or 75% AR-

25% CO2) with parameters

higher than the short-

circuiting range

Advantages

Uses inexpensive CO2 shielding gas, but is

frequently used with argon/CO2 blends.

Is capable of making welds at very high

travel speeds.

Inexpensive solid or metal-cored electrodes.

Welding equipment is inexpensive.

Limitations

Higher spatter levels result in costly cleanup.

Prone to cold lap or cold shut incomplete fusion defects,

which results in costly repairs.

Weld bead shape is convex, and welds exhibit poor wetting

at the toes.

High spatter level reduces electrode efficiency to a range

of 87 93%.

Less desirable weld appearance than spray arc transfer

Welding is limited to flat positions and horizontally fillet

welds

Welding is limited to metal 1/8 inch (3 mm) or thicker

Spray Arc Transfer

Occurs when the current and voltage settings are

increased higher than that used for Globular

Transfer

Used on thick sections of base material, best

suited for flat position due to large weld puddle

Spatter is minimal to none

Uses 5% to 10% co2 mix with argon or oxygen.

>Forms very small droplets of metal

>Very good stability

>Very little spatter

Spray arc transfer sprays a stream

of tiny molten droplets across the

arc, from the electrode wire to the

base metal.

Spray arc transfer uses relatively

high voltage, wire feed speed and

amperage values, compared to short

circuit transfer.

Advantages

High deposition rates.

High electrode efficiency of 98% or more.

Employs a wide range of filler metal types in an

equally wide range of electrode diameters.

Excellent weld bead appearance.

High operator appeal and ease of use.

Requires little post weld cleanup.

Absence of weld spatter.

Excellent weld fusion.

Lends itself to semiautomatic, robotic, and hard

automation applications.

Limitations

Restricted to the flat and horizontal welding

positions.

Welding fume generation is higher.

The higher-radiated heat and the generation of a

very bright arc require extra welder and bystander

protection.

The use of axial spray transfer outdoors requires

the use of a windscreen(s).

The shielding used to support axial spray transfer

costs more than 100% CO2.

Pulse Spray Transfer

GMAW-P was developed for two demanding reasons:

control of weld spatter and the elimination of incomplete

fusion defects common to globular and short-circuiting

transfer.

The welding current alternates between a peak current and

a lower background current.

This faster-freezing weld puddle is what allows the pulsed-

spray transfer to be used fort thinner metals,

better control on out-of-position work.

allows for larger wire sizes to be used on varied metal

thicknesses.

In pulse spray transfer (GMAW-P) the

welding power sources pulse control

pulses the welding output with

high peak currents (amperage) which are

set at levels which will cause the transfer

to go into a spray. The background

current (amperage) is set at a level that

will maintain the arc,

but is too low for any metal transfer to

occur.

Pulsed arc transfer

Advantages

Absent or very low levels of spatter.

More resistant to lack of fusion defects than other modes

of GMAW metal transfer.

Excellent weld bead appearance and offers an engineered

solution for the control of weld fume generation.

Reduced levels of heat induced distortion and tendency for

arc blow

Ability to weld out-of-position and handles poor fit-up.

When compared to FCAW, SMAW, and GMAW-S,

pulsed spray transfer provides a low cost high-electrode

efficiency of 98%.

Lends itself to robotic and hard automation applications.

Is combined for use with Tandem GMAW or other

multiple arc scenarios.

Capable of arc travel speeds greater than 50 inches per

minute (1.2 M/min.).

Limitations

Equipment to support the process is more

expensive than traditional systems.

Blends of argon based shielding gas are

more expensive than carbon dioxide.

Higher arc energy requires the use of

additional safety protection for welders and

bystanders.

Adds complexity to welding.

Requires the use of windscreens outdoors.

Manual GMAW Equipment

Three major elements are :

1.) Welding torch and accessories

2.) Welding control & Wire feed motor

3.) Power Source

GMAW equipment can be used either

manually or automatically

GMAW Schematic Diagram

WIRE CONTROL

&

WIRE FEED MOTOR

POWER SOURCE

Welding Torch & Accessories

The welding torch guides the wire and

shielding gas to the weld zone.

Brings welding power to the wire also

Major components/parts of the torch are the

contact tip, shielding gas nozzle, gas

diffuser, and the wire conduit

Others types of torch

TRIGGER

INSTALLED

COMPONENTS

NOZZLE

CONTACT TIP

GAS DIFFUSER

Welding Control & Wire

Feed Motor

Welding control & Wire feed motor are

combined into one unit

Main function is to pull the wire from the

spool and feed it to the arc

Controls wire feed speed and regulates the

starting and stopping of wire feed

Wire feed speed controls Amperage

Types of Wire Feed Motor

Types of WFM Roller

Types of Wire Feeder

WIRE FEEDER

Power Source

Almost all GMAW is done with reverse

polarity also known as DCEP

Positive (+) lead is connected to the torch

Negative (-) lead is connected to the work

piece

Provides a relatively consistent voltage to

the arc

Arc Voltage is the voltage between the end

of the wire and the work piece

Contact Tip To Work Distance

In constant current, the CTWD (contact tip to

work distance) determines the arc length.

As the CTWD increases the arc length increases, and

as the

CTWD decreases the arc length decreases. This

presented a

problem for semiautomatic welding because it is

difficult to

maintain the same CTWD. To compensate for this

problem an arc voltage controlled wire

Constant voltage power source designs provide a specific

arc voltage for a given pre-selected wire feed speed The

volt-amp curve, or slope, is comparatively flat. As the

CTWD increases with these types of power sources, there

is a decrease in the welding current. As the CTWD

decreases there is an increase in the welding current. The

arc in this case becomes a series circuit, and the CTWD

provides resistance to current. In either scenario, the

voltage remains the same and the arc length remains the

same

POSITIVE

TERMINAL

NEGATIVE

TERMINAL

Shielding Gases

Purpose of shielding gas is the protect the

weld area from the contaminants in the

atmosphere

Gas can be Inert, Reactive, or Mixtures of

both

Gas flow rate is between 25-35 CFH

Argon, Helium, and Carbon Dioxide are the

main three gases used in GMAW

Properties of Gases

Affect the performance of the welding process

include:

1) Thermal properties at elevated temperatures.

2) Chemical reaction of the gas with the various

elements in the base plate and welding wire.

3) Effect of each gas on the mode of metal

transfer.

Types of shielding gases

Inert Gas

1. Argon

2. Helium

3. Ar + He

Active Gas

1. Carbon Dioxide

2. Inert gas + any type of active gas

Argon is an inert gas which is used both

singularly and in combination with other

gases to achieve desired arc characteristics

for the welding of both ferrous and non-

ferrous metals.

Carbon Dioxide Pure carbon dioxide is not an

inert gas, because the heat of the arc breaks down

the CO2 into carbon monoxide and free oxygen.

This oxygen will combine with elements

transferring across the arc to form oxides which are

released from the weld puddle in the form of slag

and scale.

Helium is an inert gas which is used on

weld applications requiring higher heat

input for improved bead wetting, deeper

penetration and higher travel speed. In

GMAW it does not produce as stable an arc

as argon. Compared to argon, helium has a

higher thermal conductivity and voltage

gradient

FLOW METER

CYLCINDER

PRESSURE

GAUGE

CFH PRESSURE

ADJUSTMENT

KNOB

Filler Wire

Wire Chemistries

GMAW Operation techniques

To setting WFS (Wire Feed Speed)

Voltage-bead Change

Electrode Stick-out

ESO Setting

EOS

Gun angles and techniques

Direction of Travel

THANK YOU

S-ar putea să vă placă și

- Estimation of Welding Cost: by K.R.Prasanna Venkatesan WE0663Document41 paginiEstimation of Welding Cost: by K.R.Prasanna Venkatesan WE0663Anonymous 7yN43wjl100% (1)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDe la Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideEvaluare: 3.5 din 5 stele3.5/5 (7)

- Amateur Radio Guide To DMRDocument28 paginiAmateur Radio Guide To DMRIeħor Biss100% (1)

- Welding Process Notes BestDocument152 paginiWelding Process Notes Bestaravindan100% (2)

- Welding Quality ControlDocument7 paginiWelding Quality ControlPRAMOD KUMAR SETHI S100% (1)

- Welder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamDe la EverandWelder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamÎncă nu există evaluări

- Miller RMDDocument4 paginiMiller RMDRony Lesbt100% (1)

- Stainless Steel DefectsDocument30 paginiStainless Steel Defects0502ravi100% (1)

- Determining The Cost of WeldingDocument22 paginiDetermining The Cost of WeldingSanjay J NÎncă nu există evaluări

- QAQC References 2Document138 paginiQAQC References 2Mohd SharainiÎncă nu există evaluări

- Fabrication Cost Estimation Including ManpowerDocument33 paginiFabrication Cost Estimation Including ManpowerVinayak PujariÎncă nu există evaluări

- How To Calculate MIG Welding CostDocument5 paginiHow To Calculate MIG Welding CostTiago FerreiraÎncă nu există evaluări

- Ss Pipe WeldingDocument3 paginiSs Pipe WeldingshridharbshenoyÎncă nu există evaluări

- Welding Defect PhotoDocument14 paginiWelding Defect Photo0502raviÎncă nu există evaluări

- BGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&ADe la EverandBGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&AÎncă nu există evaluări

- The Orbital Welding HandbookDocument56 paginiThe Orbital Welding HandbookMilorad NozinicÎncă nu există evaluări

- Welding Consumable ReconcilationDocument21 paginiWelding Consumable Reconcilationraju100% (2)

- Operating FactorDocument9 paginiOperating Factormekhman mekhtyÎncă nu există evaluări

- 31 Management System For Structrural Steel Products Using Barcodes Between Construction Job Site and Steel Fabrication ShopDocument10 pagini31 Management System For Structrural Steel Products Using Barcodes Between Construction Job Site and Steel Fabrication ShopajaymrÎncă nu există evaluări

- Overview of Advanced Welding ProcessesDocument55 paginiOverview of Advanced Welding ProcessesSaravanan RajendranÎncă nu există evaluări

- Introduction To Cost EstimatingDocument22 paginiIntroduction To Cost EstimatingArwa HusseinÎncă nu există evaluări

- Cost Calculation Program For Productivity in WeldingDocument20 paginiCost Calculation Program For Productivity in WeldingiyigunÎncă nu există evaluări

- FabricationDocument50 paginiFabricationashishghadiya75% (16)

- Determining The Cost of WeldingDocument7 paginiDetermining The Cost of WeldingSriram VjÎncă nu există evaluări

- Handbook - Calculations0Document10 paginiHandbook - Calculations0paimpillyÎncă nu există evaluări

- Din 6700 2 enDocument27 paginiDin 6700 2 en0502ravi100% (1)

- 4.2. Consumable Consumption and Welding Time 4.2.1 Calculation of Electrode ConsumptionDocument9 pagini4.2. Consumable Consumption and Welding Time 4.2.1 Calculation of Electrode ConsumptionNejat Ababay50% (2)

- Productivity and EcononyDocument69 paginiProductivity and EcononyVijayan MunuswamyÎncă nu există evaluări

- Weld Acceptance CriteriaDocument14 paginiWeld Acceptance Criteria0502raviÎncă nu există evaluări

- Welding Cost, Economics - GMAW & MMAW Process & QualityDocument6 paginiWelding Cost, Economics - GMAW & MMAW Process & Qualityratneshkumar2004Încă nu există evaluări

- WELDABILITY of SteelDocument41 paginiWELDABILITY of Steel0502ravi100% (1)

- Welding and Fabrication NoteDocument54 paginiWelding and Fabrication NoteluminiousÎncă nu există evaluări

- Demo Weld Cost Calc XL-UnprotectedDocument10 paginiDemo Weld Cost Calc XL-UnprotectedA R0% (1)

- Determining The Cost of WeldingDocument7 paginiDetermining The Cost of WeldingGilbertoUGO0% (1)

- Group 8, Welding AssignmentDocument11 paginiGroup 8, Welding AssignmentKavish ChandraÎncă nu există evaluări

- Weld CostsDocument2 paginiWeld CostsJina Chandran100% (1)

- En 15085 ClassDocument63 paginiEn 15085 Class0502ravi100% (3)

- CWI ResponsibilitiesDocument9 paginiCWI ResponsibilitiesahmedÎncă nu există evaluări

- Estimating & Comparing Weld Metal CostDocument21 paginiEstimating & Comparing Weld Metal CostKyaw Kyaw AungÎncă nu există evaluări

- Welding DefectsDocument47 paginiWelding Defects0502raviÎncă nu există evaluări

- Ss WeldingDocument12 paginiSs Welding0502ravi100% (1)

- 09 Welding Procedures and Qualifcations As Per ASME SEC IXDocument7 pagini09 Welding Procedures and Qualifcations As Per ASME SEC IXvilukÎncă nu există evaluări

- Welder Level C Program OutlineDocument185 paginiWelder Level C Program OutlineRon Carlo DiosoÎncă nu există evaluări

- Determining The Cost of Welding Part 1 by Duane K. Miller 2004 7pDocument7 paginiDetermining The Cost of Welding Part 1 by Duane K. Miller 2004 7pjosea_pena100% (1)

- RTL Verilog Navabi PDFDocument294 paginiRTL Verilog Navabi PDFSiva chowdaryÎncă nu există evaluări

- Commercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsDe la EverandCommercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsÎncă nu există evaluări

- BS EN 1011-3-2000 - Recommendations For Arc Welding of Stainless Steels PDFDocument25 paginiBS EN 1011-3-2000 - Recommendations For Arc Welding of Stainless Steels PDF0502ravi100% (1)

- Defects On Weld BEADDocument47 paginiDefects On Weld BEADarash59_4uÎncă nu există evaluări

- Fabrication Division QMDDocument11 paginiFabrication Division QMDRakesh RanjanÎncă nu există evaluări

- Smaw Welding Electrode ClassificationDocument2 paginiSmaw Welding Electrode ClassificationsamyÎncă nu există evaluări

- Cswip 3 1 Welding Inspector Multiple Choice Question Dec 7 2007Document43 paginiCswip 3 1 Welding Inspector Multiple Choice Question Dec 7 2007sri.majji8937100% (1)

- Weld Plan D00651285Document14 paginiWeld Plan D00651285sandeepÎncă nu există evaluări

- Weld Cost Calc XL1.3.2mmDocument3 paginiWeld Cost Calc XL1.3.2mmVipin JoseÎncă nu există evaluări

- A Guide To Estimating The Consumption of Welding Consumables-NADocument1 paginăA Guide To Estimating The Consumption of Welding Consumables-NAManuel Antonio Santos VargasÎncă nu există evaluări

- Asme Sec Ix - Short NotesDocument20 paginiAsme Sec Ix - Short NotesParvee K NakwalÎncă nu există evaluări

- E1648-01 Aluminum Fusion WeldsDocument3 paginiE1648-01 Aluminum Fusion Welds0502raviÎncă nu există evaluări

- Welding Prcesses Estimation RecordDocument5 paginiWelding Prcesses Estimation RecorddineshshankarÎncă nu există evaluări

- Terms in Welding Standard en 15085Document6 paginiTerms in Welding Standard en 150850502raviÎncă nu există evaluări

- Welding Processes & InspectionDocument52 paginiWelding Processes & InspectionKaung Htet Cho100% (1)

- Railway Vehicle Welding inspectionEN 15085-5Document16 paginiRailway Vehicle Welding inspectionEN 15085-50502raviÎncă nu există evaluări

- Gmaw & Fcaw-MsmeDocument73 paginiGmaw & Fcaw-MsmemilindÎncă nu există evaluări

- Elance Service Manaual - Rev H PDFDocument94 paginiElance Service Manaual - Rev H PDFJuanAguileraOlivo50% (2)

- GMAWDocument53 paginiGMAWarvidkumar87060Încă nu există evaluări

- FCAWDocument6 paginiFCAWshravan.office11Încă nu există evaluări

- En 15085 - 1 & 2Document34 paginiEn 15085 - 1 & 20502ravi100% (4)

- Advanced Welding ProcesssDocument11 paginiAdvanced Welding Processs0502ravi100% (1)

- GMAWDocument53 paginiGMAWJithuJohn100% (1)

- Fit-Up Inspection Report: Location: Weld Type Equipment Description: Date: Report No.: SystemDocument1 paginăFit-Up Inspection Report: Location: Weld Type Equipment Description: Date: Report No.: SystemAnonymous 0rt9KWmNÎncă nu există evaluări

- Welding Electrode-Wire SpecificationDocument3 paginiWelding Electrode-Wire SpecificationRajan SteeveÎncă nu există evaluări

- AWS N-9 Stud Welding Procedure Specification (WPS) FormDocument1 paginăAWS N-9 Stud Welding Procedure Specification (WPS) FormNatalia StarkÎncă nu există evaluări

- How To Calculate Filler MetalDocument3 paginiHow To Calculate Filler MetalEdgar Coavas PérezÎncă nu există evaluări

- Approved Welding Procedures List RegioDocument2 paginiApproved Welding Procedures List Regiogabriel__regio100% (1)

- M2010051in-Mcb - Rolling Suggestions PDFDocument42 paginiM2010051in-Mcb - Rolling Suggestions PDFthaivinhtuyÎncă nu există evaluări

- QAP GeneralDocument1 paginăQAP GeneralVenkatRaghavendar100% (2)

- PreheatDocument2 paginiPreheatScott TrainorÎncă nu există evaluări

- Painting Inspector: Passbooks Study GuideDe la EverandPainting Inspector: Passbooks Study GuideÎncă nu există evaluări

- Welding Procedure & Welder Qualification: Pak-Arab Refinery LimitedDocument70 paginiWelding Procedure & Welder Qualification: Pak-Arab Refinery LimitedRizwan BangashÎncă nu există evaluări

- Weld DefectsDocument6 paginiWeld Defects0502raviÎncă nu există evaluări

- Wps 15614 TemplateDocument2 paginiWps 15614 Template0502raviÎncă nu există evaluări

- CANFAN Airzon BLDC Super Efficient Fans - ICF PeramburDocument13 paginiCANFAN Airzon BLDC Super Efficient Fans - ICF Perambur0502raviÎncă nu există evaluări

- Icf-Pioneering in A Changing Economic EnvironmentDocument18 paginiIcf-Pioneering in A Changing Economic Environment0502raviÎncă nu există evaluări

- To CNC Machines & RobotsDocument29 paginiTo CNC Machines & Robots0502raviÎncă nu există evaluări

- WPSPQRDocument11 paginiWPSPQR0502raviÎncă nu există evaluări

- Plasma Cutting Process: Plasma Arc Associated With Arc Constriction Resulting in Higher Ionisation Level in ArcDocument27 paginiPlasma Cutting Process: Plasma Arc Associated With Arc Constriction Resulting in Higher Ionisation Level in Arc0502raviÎncă nu există evaluări

- Weld ImperfectionsDocument11 paginiWeld Imperfections0502raviÎncă nu există evaluări

- GMDocument57 paginiGMTuhina bhuiyaÎncă nu există evaluări

- Datasheet LCDDocument8 paginiDatasheet LCDSebasXR100% (1)

- EC6303 - Linear Integrated Circuits and Applications NotesDocument132 paginiEC6303 - Linear Integrated Circuits and Applications NotesbrsreddyÎncă nu există evaluări

- Implementation of Modified P&o-Mppt AlgorithmDocument8 paginiImplementation of Modified P&o-Mppt AlgorithmVaralakshmi SeerapuÎncă nu există evaluări

- DataSheet M-Duino 21 +LoRaDocument4 paginiDataSheet M-Duino 21 +LoRaDr. Bashir M SaadÎncă nu există evaluări

- Moscap5mar 2020Document2 paginiMoscap5mar 2020Omkar KatkarÎncă nu există evaluări

- VS Phontech Maritime Catalog 2020Document96 paginiVS Phontech Maritime Catalog 2020Ehsan RohaniÎncă nu există evaluări

- Module 1 - Advanced Computer ArchitectureDocument15 paginiModule 1 - Advanced Computer ArchitectureDream CatcherÎncă nu există evaluări

- Marechal DX2 Decontactor Range enDocument2 paginiMarechal DX2 Decontactor Range enramana.kumarÎncă nu există evaluări

- AVT - Air Velocity TransmitterDocument4 paginiAVT - Air Velocity Transmitternik amirulÎncă nu există evaluări

- Aspire 8930qDocument124 paginiAspire 8930qSg TopolinoÎncă nu există evaluări

- WEG Guia de Instalacao pws5610 Quick Guide English PDFDocument1 paginăWEG Guia de Instalacao pws5610 Quick Guide English PDFÁgó AttilaÎncă nu există evaluări

- Error Code For Omron Card ReaderDocument3 paginiError Code For Omron Card ReaderDendy PratamaÎncă nu există evaluări

- SPICE Macro Model For IC ResistorDocument10 paginiSPICE Macro Model For IC ResistorSharath_Patil_7623Încă nu există evaluări

- MD1D Evalmanual A1en - EvalBoardDocument8 paginiMD1D Evalmanual A1en - EvalBoardS Puneeth Kumar100% (1)

- Otn Framing v1.0 PDFDocument17 paginiOtn Framing v1.0 PDFDerrick Senyo100% (1)

- SENG 440 Slides Lesson 01Document21 paginiSENG 440 Slides Lesson 01mrgoboomÎncă nu există evaluări

- Automatic Distance Measurement& Braking-UltrasonicDocument24 paginiAutomatic Distance Measurement& Braking-Ultrasonicjyothisaravind100% (8)

- DX DiagDocument28 paginiDX DiagAri NurdiansyahÎncă nu există evaluări

- Resimold Resiglas CRT DryType CommercialBrochure enDocument12 paginiResimold Resiglas CRT DryType CommercialBrochure engreyllom9791Încă nu există evaluări

- DQ Blisteadora PDFDocument15 paginiDQ Blisteadora PDFsami2210Încă nu există evaluări

- Fingerprint-Authentication Using BiometricDocument59 paginiFingerprint-Authentication Using BiometricDebashishParidaÎncă nu există evaluări

- EdExcel A Level Chemistry Unit 1 Mark Scheme Results Paper 1 Jun 2005Document10 paginiEdExcel A Level Chemistry Unit 1 Mark Scheme Results Paper 1 Jun 2005ProdhanÎncă nu există evaluări

- Automated Comparator: Radian Research, IncDocument97 paginiAutomated Comparator: Radian Research, IncManuel Lavado SilvaÎncă nu există evaluări

- A Novel High-Gain DC-DC Converter Applied in Fuel Cell VehiclesDocument13 paginiA Novel High-Gain DC-DC Converter Applied in Fuel Cell Vehiclesrock starÎncă nu există evaluări

- Spaj 140 CDocument8 paginiSpaj 140 CaktifiantoÎncă nu există evaluări

- Smart HelmetDocument5 paginiSmart HelmetIJARSCT JournalÎncă nu există evaluări